Gate cutting device

A technology of cutting equipment and gates, which is applied in the field of gate cutting equipment, can solve problems such as slow batch shearing speed, difficulty in controlling the shearing size, and inability to cut with nozzle pliers, so as to reduce the risk of defective products and improve work efficiency. High, accurate cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

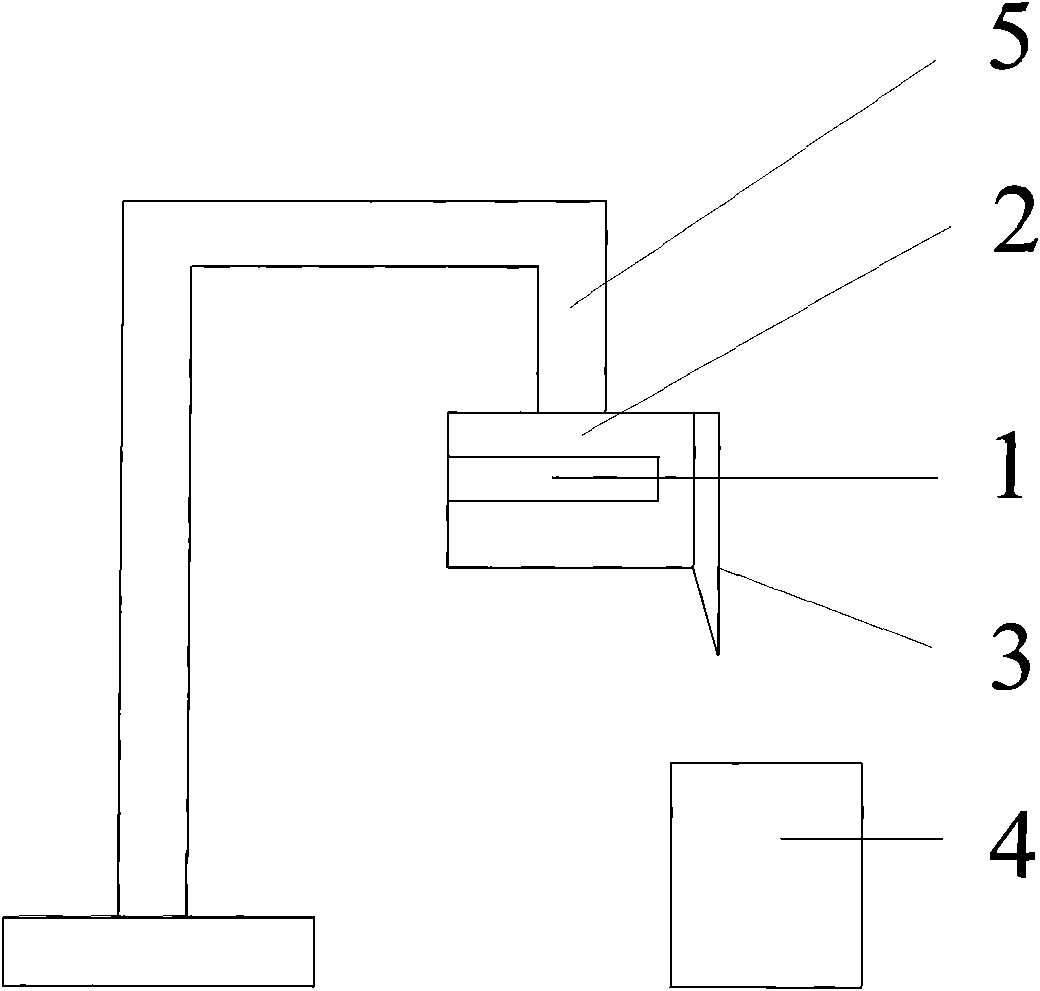

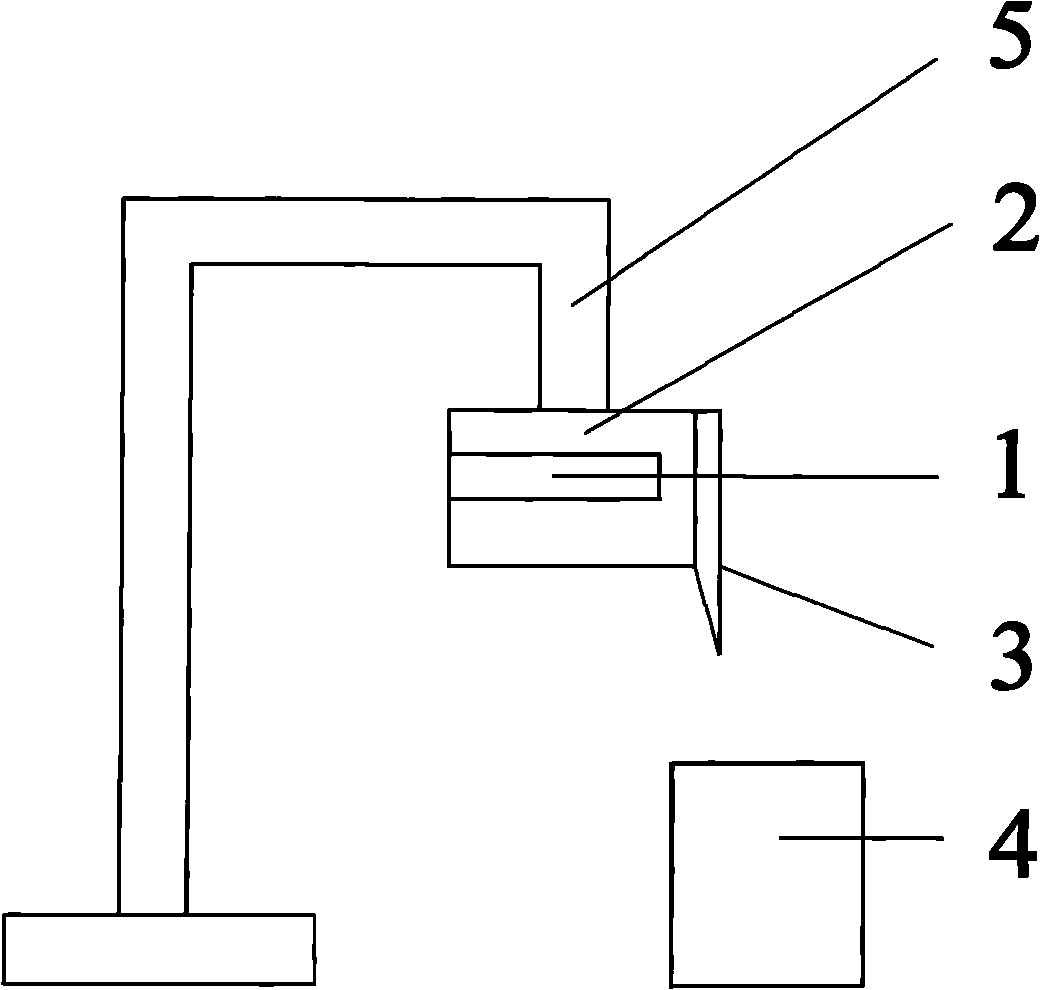

[0021] A gate cutting device, the structure of which is as follows figure 1 As shown, the cutting equipment includes a heater 1, a heat-conducting part 2, a cutting blade 3, a product fixing seat 4 and a punch 5. The heater 1 is connected to the heat-conducting part 2, and the heat-conducting part 2 can be heated by the heater 1, and the heat-conducting part 2 The heat emitted by the heater can be transmitted. The cutting blade 3 is arranged at one end of the heat conducting part 2. The cutting blade 3 can also be heated by the heater 1. The product fixing seat 4 is arranged under the heat conducting part 2. The product fixing seat 4 The cut injection molding product and nozzle are installed and placed on the top, and the punch 5 is connected to the upper part of the heat-conducting part 2, and the punch 5 has a punching effect. When using this device, take the following steps:

[0022] (1) Fix the cutting blade 3 on the heat conducting part 2 with screws;

[0023] (2) Heate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com