Low-heating laser cutting machine

A technology of laser cutting machine and laser cutting head, which is applied in laser welding equipment, welding/welding/cutting items, applications, etc., can solve the problems of unsightly incision of pipe body, heavy pipe gravity, troublesome cutting, etc., and prevent cutting deviation The effect of moving, cutting size is accurate, and it is easy to unload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

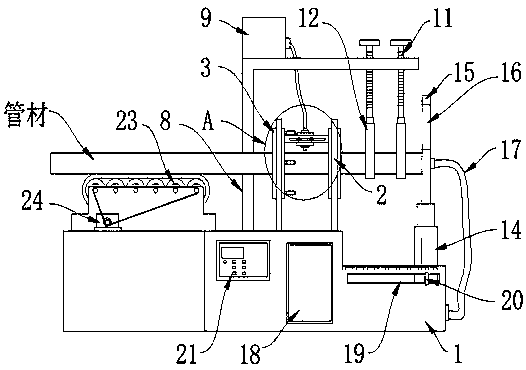

[0025] refer to Figure 1-3 , a low-heat laser cutting machine, including a machine platform 1, the left side of the machine platform 1 is provided with a conveying mechanism, the conveying mechanism includes a conveying platform fixedly connected to the left side of the machine platform 1, and a conveyor belt 23 is installed on the upper surface of the conveying platform , the conveyor belt 23 is driven by a servo drive motor 24, and the servo drive motor 24 is coupled with a PLC controller 21.

[0026] The upper surface of the machine table 1 is fixedly connected with two ring frames 2, and the inner arc surfaces of the rings of the two ring frames 2 are equipped with large-diameter bearings 3, and the inner ring of the large-diameter bearing 3 located on the left side of the laser cutting head 5 A plurality of control handles 22 arranged equidistantly in the circumferential direction are installed on the right side of the motor, and the opposite surfaces of the inner rings ...

Embodiment 2

[0031] refer to Figure 4-5 , and the difference from Embodiment 1 is that the right end front of the machine table 1 is provided with a scale mark, the front of the fixed frame 8 is provided with a sliding groove 25, and the inside of the sliding groove 25 is slidably connected with a slider, and the front of the slider is fixedly connected with an electronic Laser pointer 26; The front of fixed frame 8 is also provided with scale mark, and the material of slide block is magnetic block, and the inwall of sliding groove 25 is embedded with the metal bar that produces magnetic force adsorption with magnetic block.

[0032] In this embodiment, by setting up the sliding groove 25 on the front of the fixed frame 8, and the inside of the sliding groove 25 is embedded with a metal strip, which is magnetically adsorbed with the slider to facilitate the positioning of the electronic laser pointer 26, thereby facilitating the electronic laser pointer. The 26 position adjustment can acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com