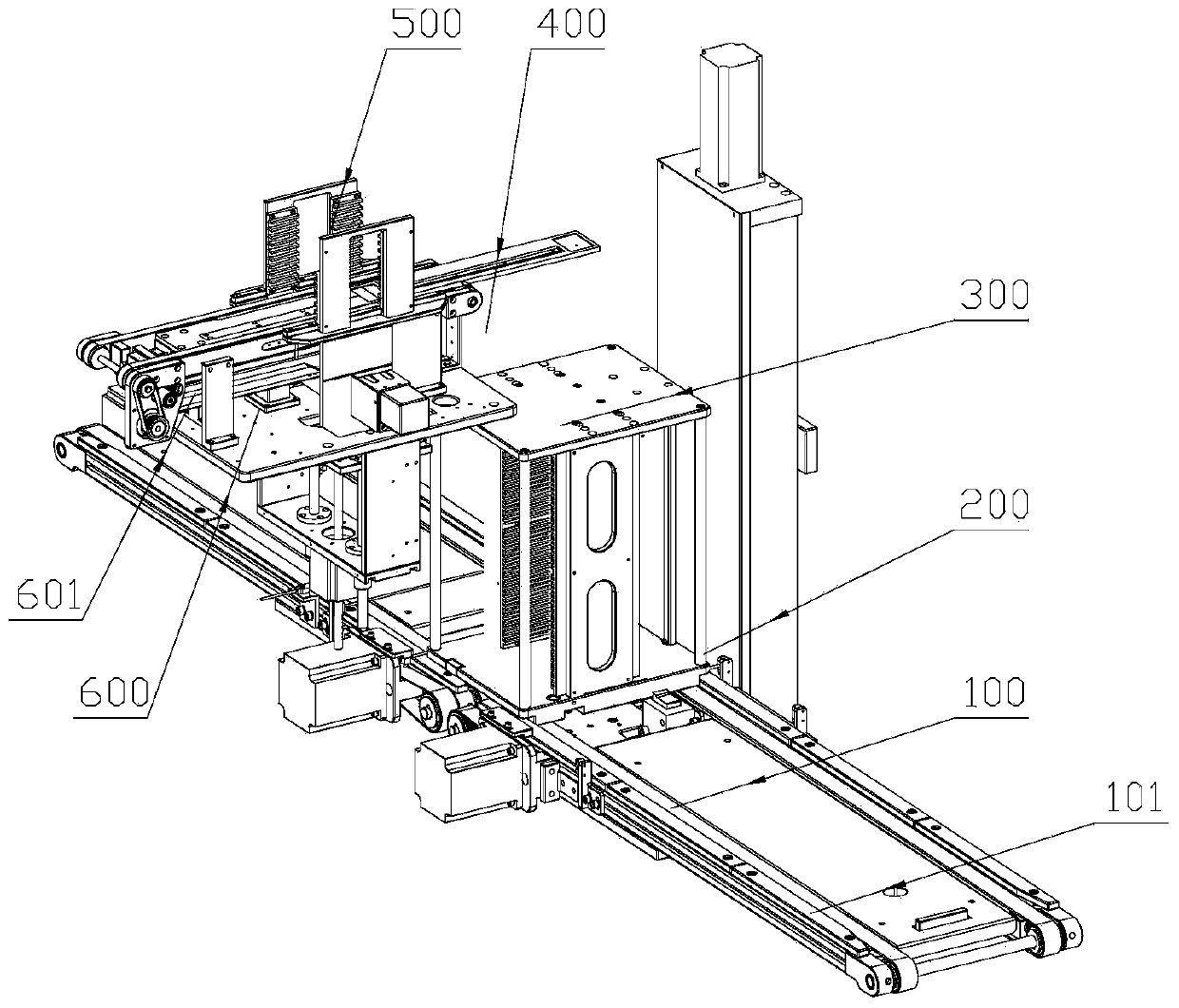

Automatic charge and discharge system for laser cutting of glass

A laser cutting and glass technology, applied in glass production, glass manufacturing equipment, glass cutting devices, etc., can solve the problems of increased instability, low equipment production efficiency, high labor costs, etc., to improve production efficiency and reduce labor costs. Dependence, the effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

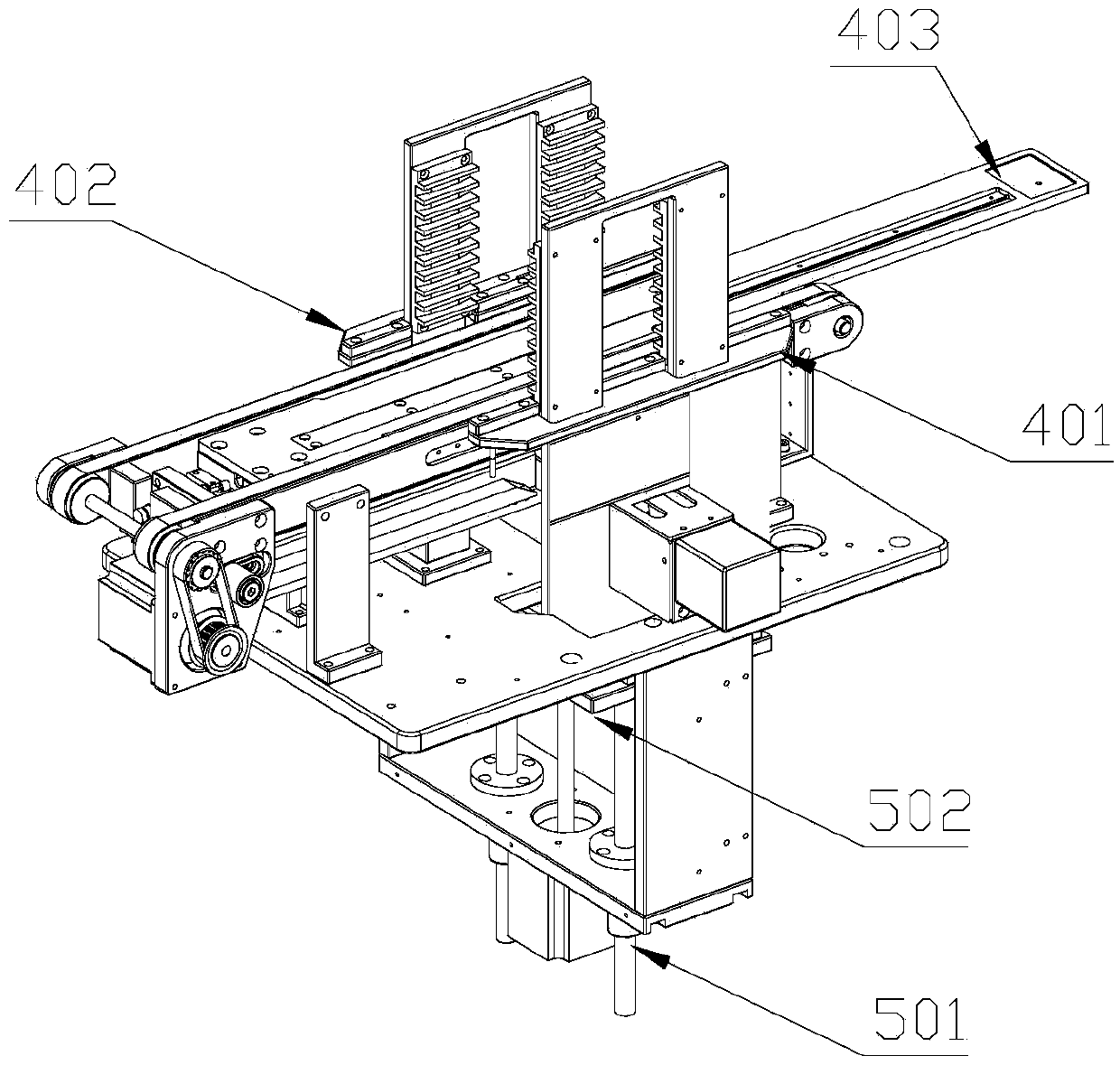

[0025] The feeding buffer unit 500 is in the feeding system. When the laser processing equipment is in a paused state, when the workpiece passes the buffer unit 500, the buffer unit 500 is driven up by the motor, and the workpiece is stored in the buffer unit 500. When the buffer unit 500 reaches the buffer unit When the sensor is at a high level, it means that the buffer unit 500 is fully loaded; during this process, the feeding system works continuously.

[0026] When the feeding buffer system 500 is in the blanking state, if the magazine unit 300 is full to be replaced, when the workpiece passes the buffer unit 500, the buffer unit 500 is driven up by the motor, and the workpiece is stored in the buffer unit 500. When the buffer unit 500 When the high position sensor of the buffer zone is reached, it means that the buffer unit 500 is fully loaded; during this process, the output beat of the laser processing equipment is not affected.

[0027] The invention is applied to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com