Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85results about "Fabric steaming/decatising" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

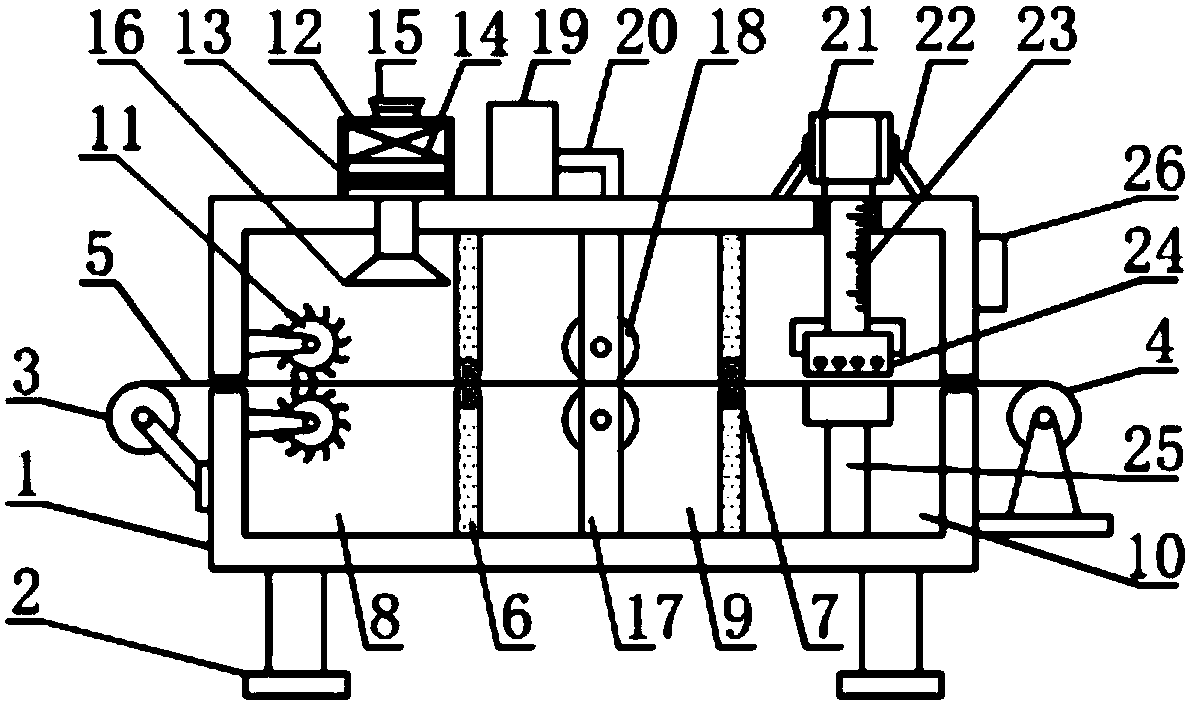

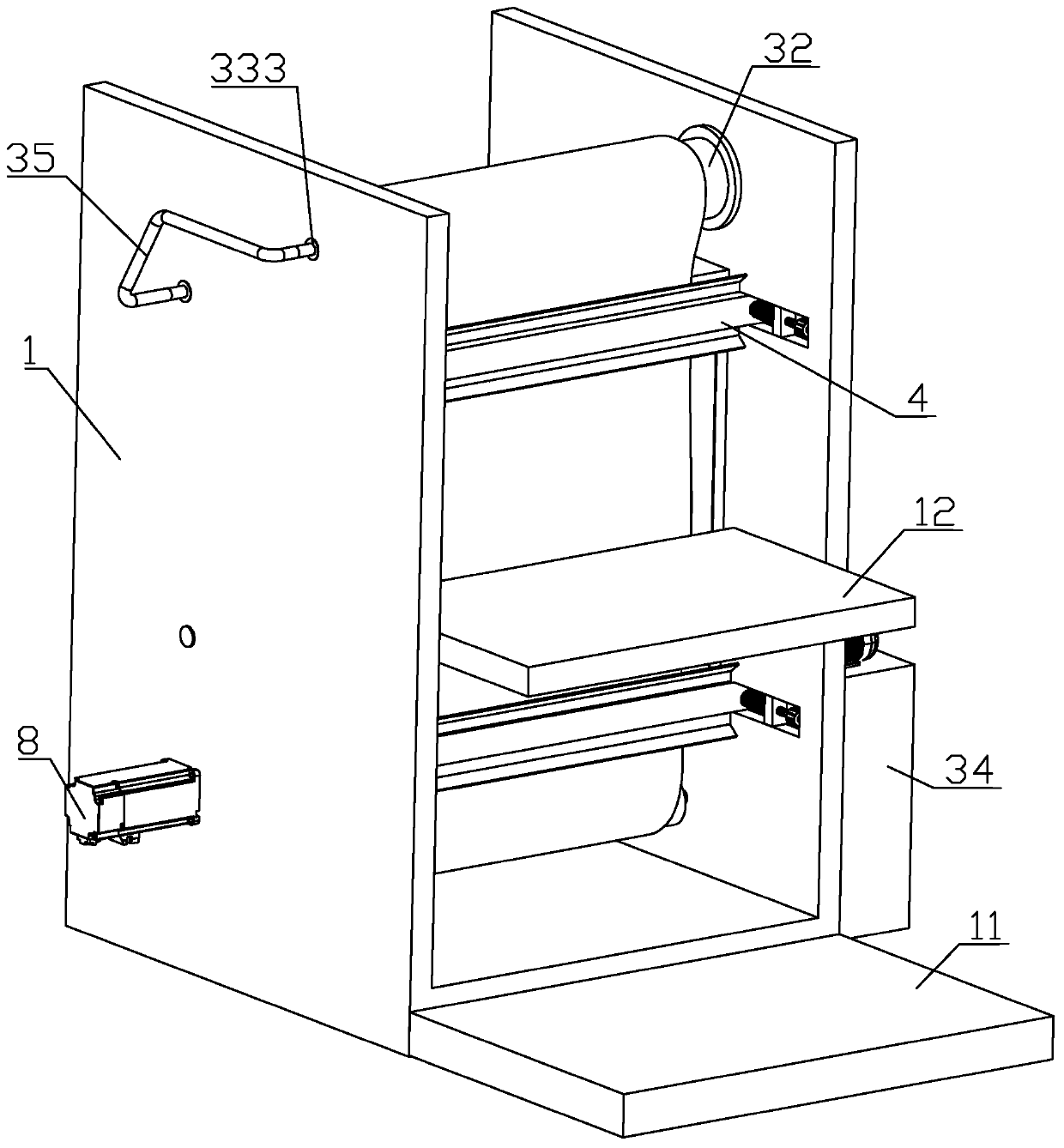

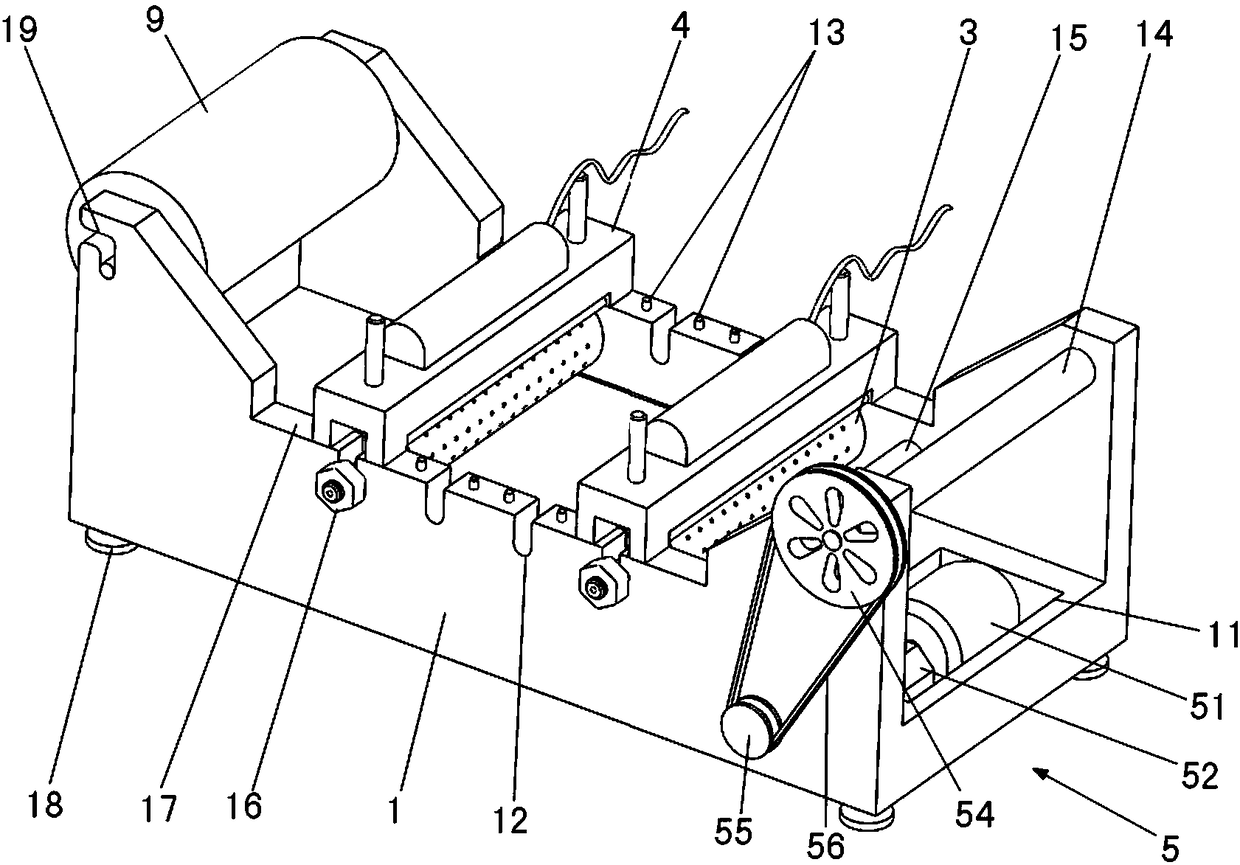

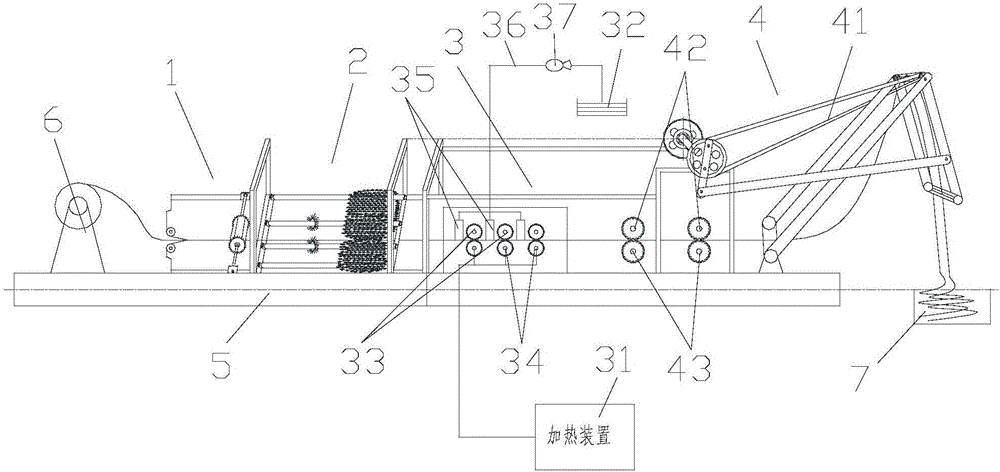

Special automatic dust collecting cloth rolling machine for cloth processing

ActiveCN107938239AEfficient removalEasy to operateCombination devicesMechanical cleaningEngineeringElectric heating

The invention discloses a special automatic dust collecting cloth rolling machine for cloth processing. The special automatic dust collecting cloth rolling machine for cloth processing comprises a rack, wherein an unreeling roller and a reeling roller are separately mounted on the left and right outer walls of the rack; two partition plates successively partition the inner cavity of the rack intoa dust collecting chamber, a steam drying chamber and a wrinkle-removing chamber; a dust collecting box is mounted on the top of the dust collecting chamber; and a steam drier is arranged on the steamdrying chamber. The special automatic dust collecting cloth rolling machine for cloth processing provided by the invention is simple to operate. Arc-shaped rubber brushing hairs are arranged on the outer walls of two dust collecting wheels, and the rotating directions of the two dust collecting wheels are opposite to the cloth forwarding direction, so that dust and cloth chips on the outer wall of the cloth can be eliminated effectively. Steam drying holes are formed in the surface of the steam drying roller, so that the cloth is dried, deodorized, enhanced in aroma, dry-washed and sterilizedconveniently, the storage period of the cloth without dust is improved effectively, the steam dried cloth is ironed by means of an electric heating plate, wrinkles on the surface of the cloth are eliminated conveniently, and the levelness of the cloth is improved effectively.

Owner:RUIAN BOAN STAB RESISTANT MATERIAL TECH

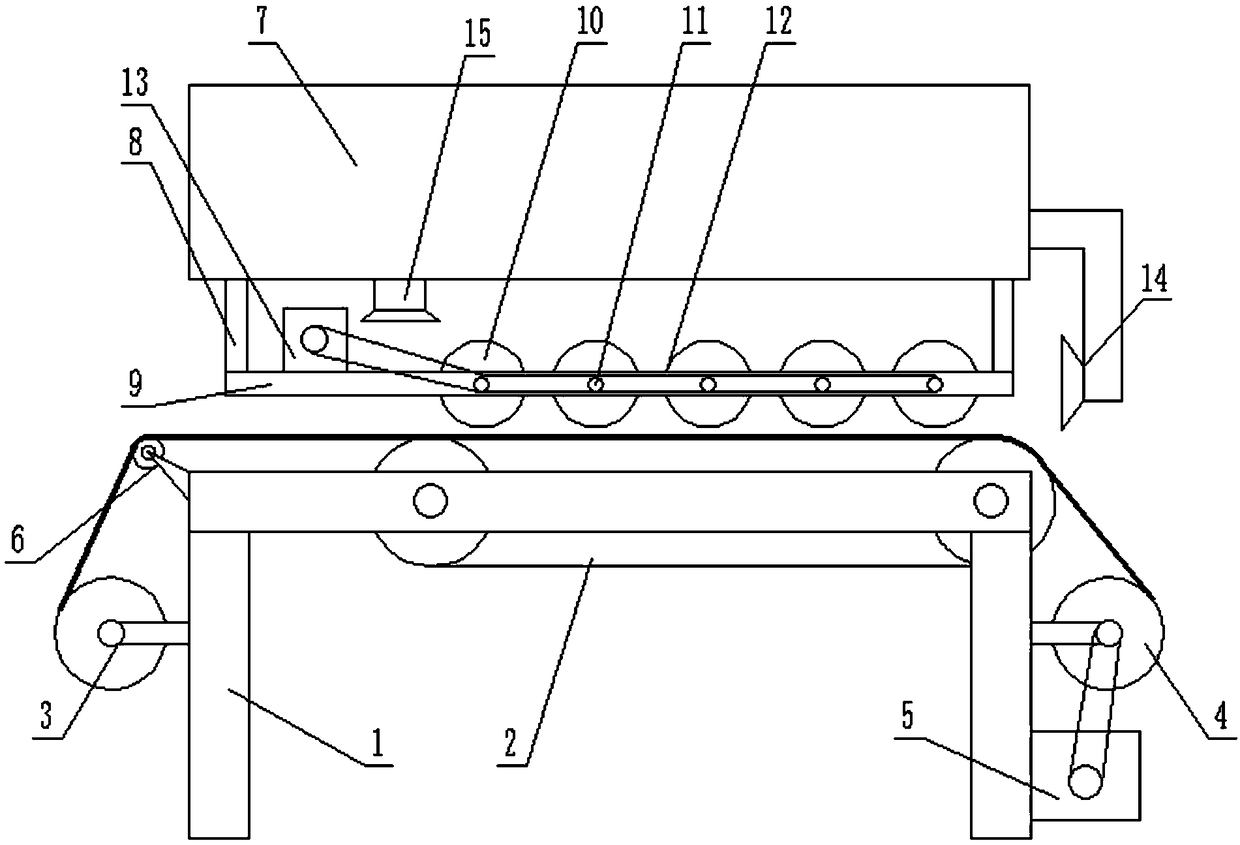

Continuous ironing device for textiles

InactiveCN108914472AImprove processing efficiencyIngenious structureFabric finishing guides/expandersFabric steaming/decatisingElectric machineryEngineering

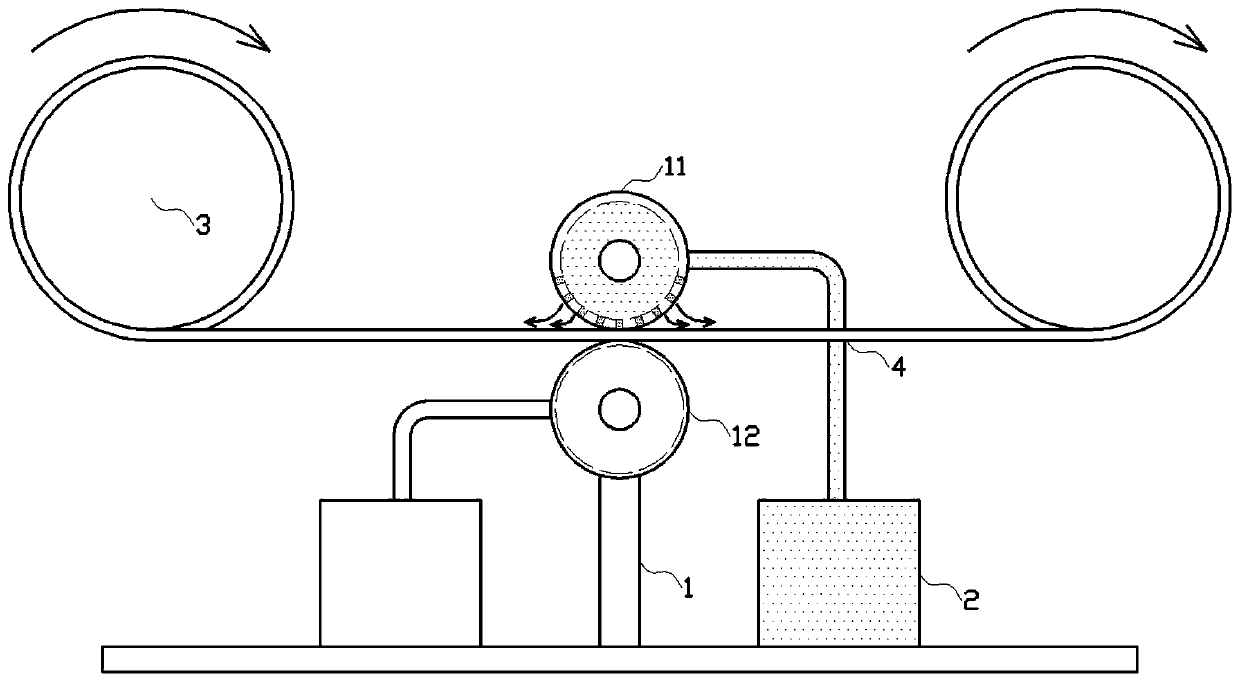

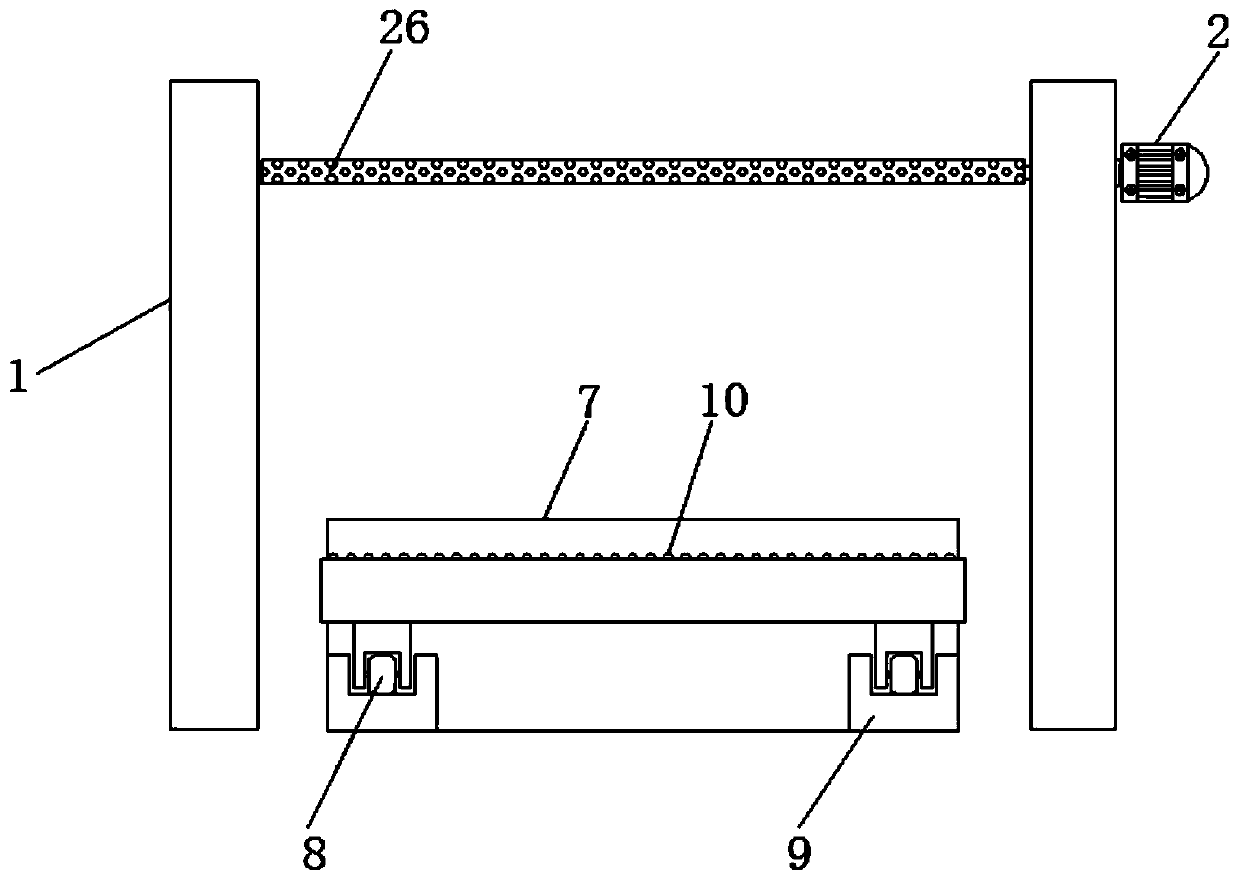

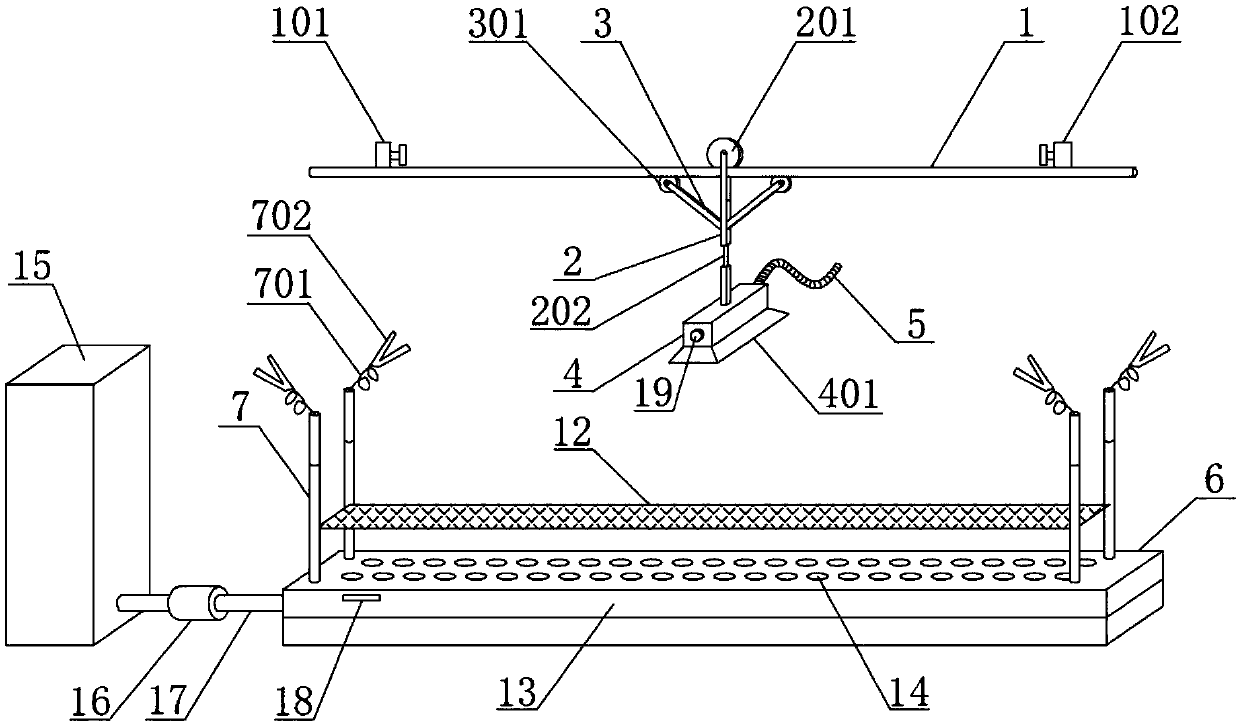

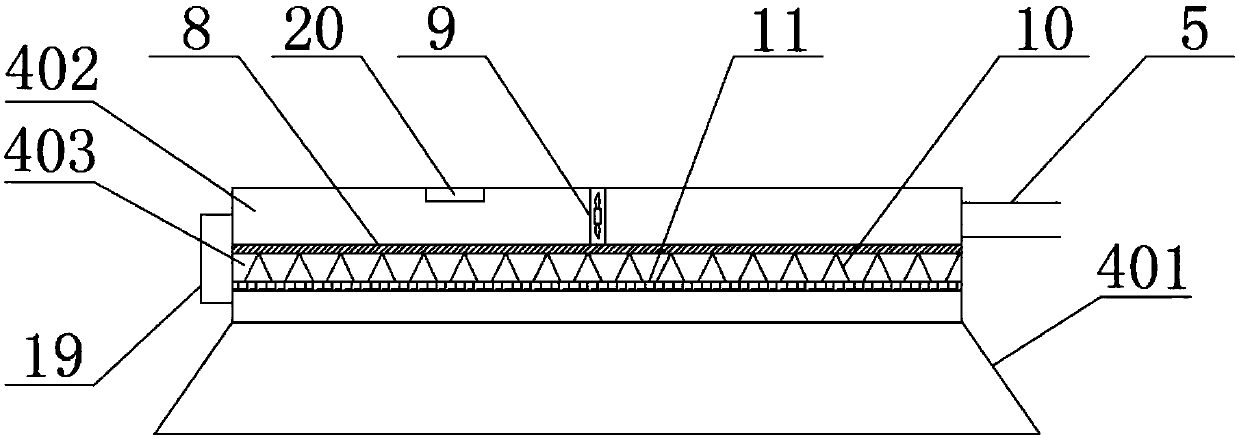

The invention discloses a continuous ironing device for textiles. The continuous ironing device comprises a frame and a device rack, wherein the frame is fixed on the ground; the device rack is suspended above the frame; the upper plane of the frame is provided with a conveyor belt; an unreeling roller and a wind-up roller are respectively arranged at two sides of the frame; a wind-up motor is arranged below the wind-up roller, is in transmission connection with the wind-up roller and controls the rotation of the wind-up roller; and a tension roller is arranged above the wind-up roller and fixed at the edge of the frame. According to the invention, a hollow ironing roller is arranged and inserted into a corrugated pipe used for supplying high-temperature steam, and the high-temperature ironing roller performs continuous ironing on cloth and jets high-temperature steam; compared with a conventional elevating hot-pressing ironing manner, the continuous ironing device of the invention issubstantially improved in processing efficiency; and the continuous ironing device is ingenious in structure and applicable to ironing of cloth of different thicknesses, and has good applicability.

Owner:伍超群

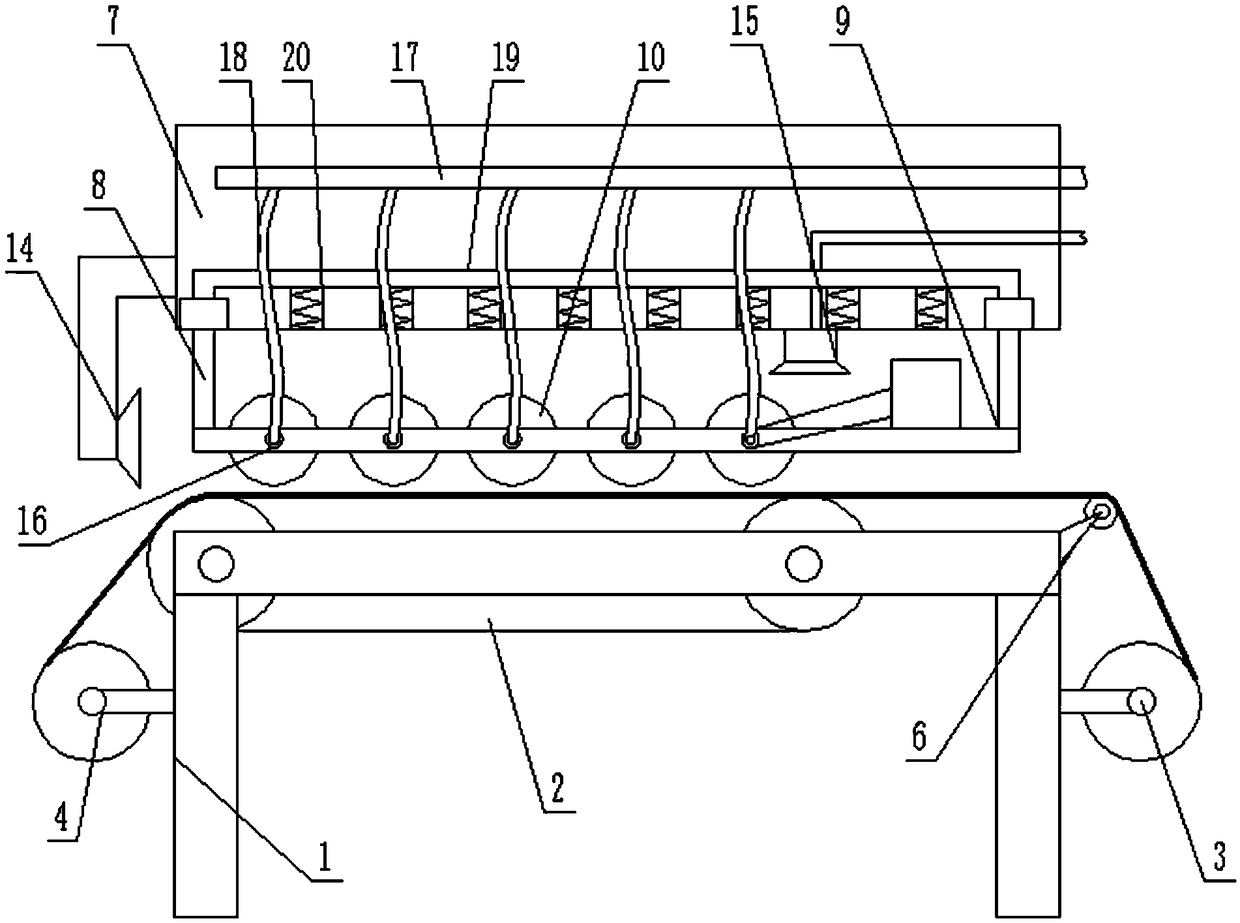

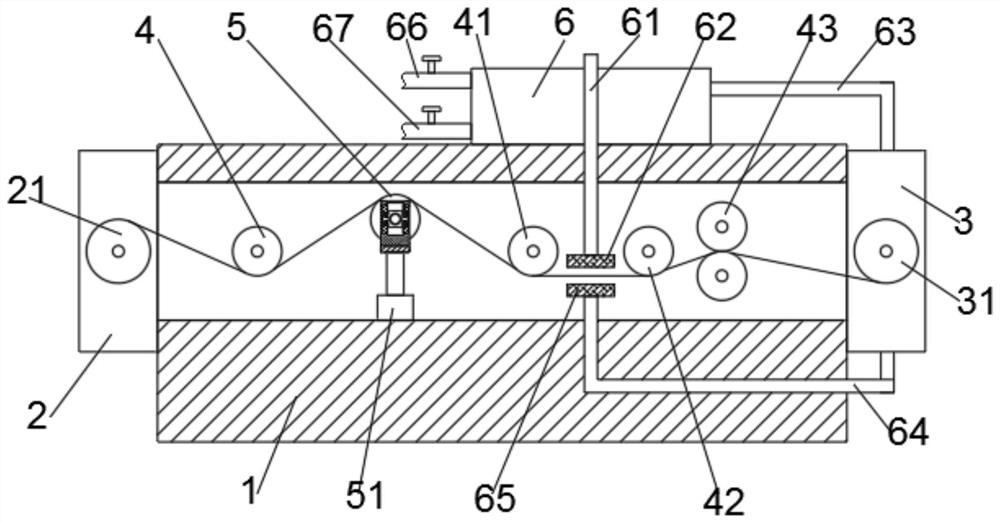

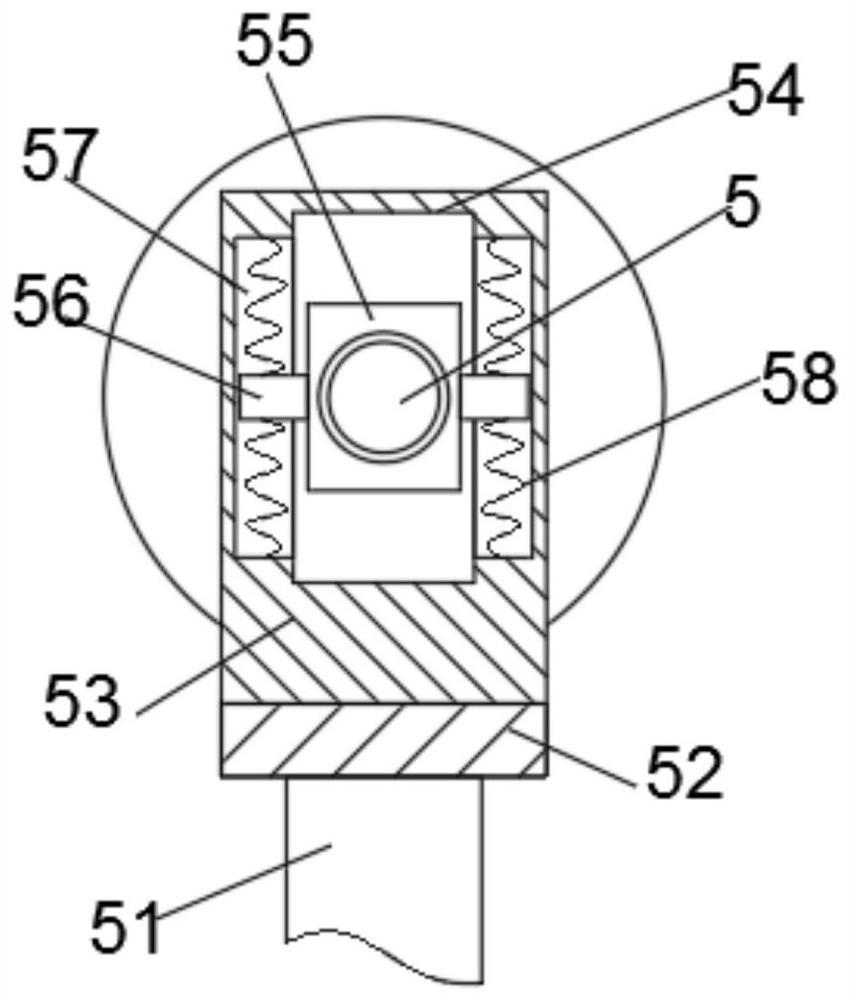

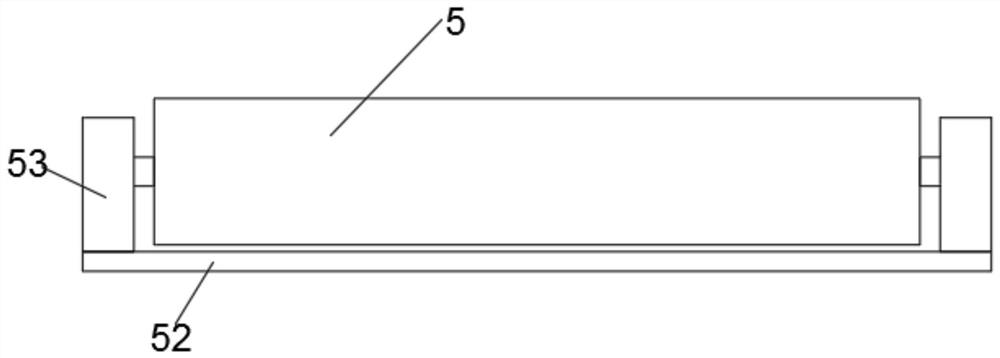

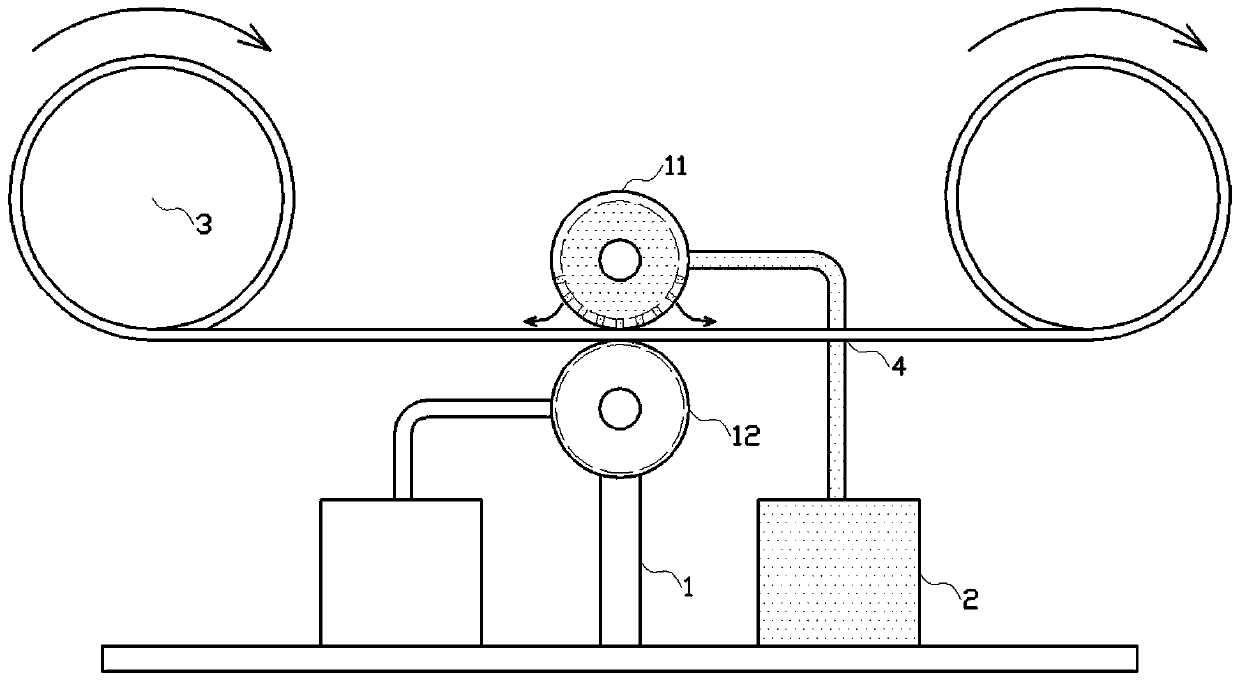

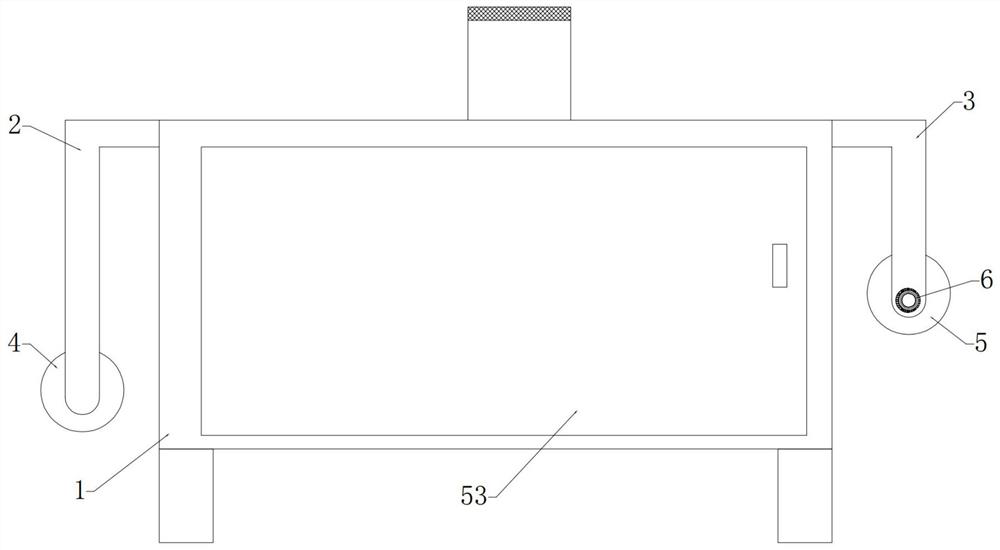

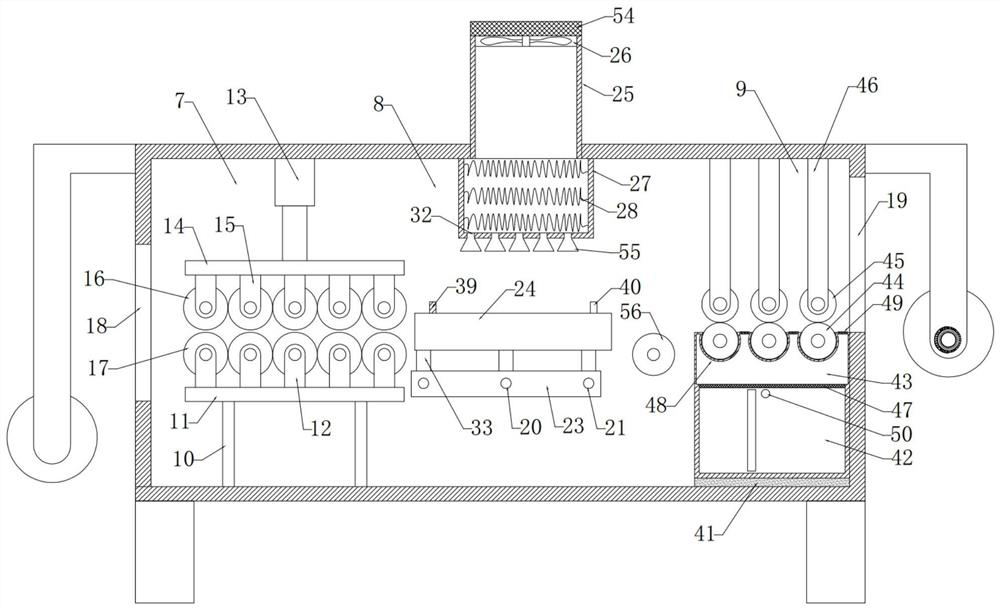

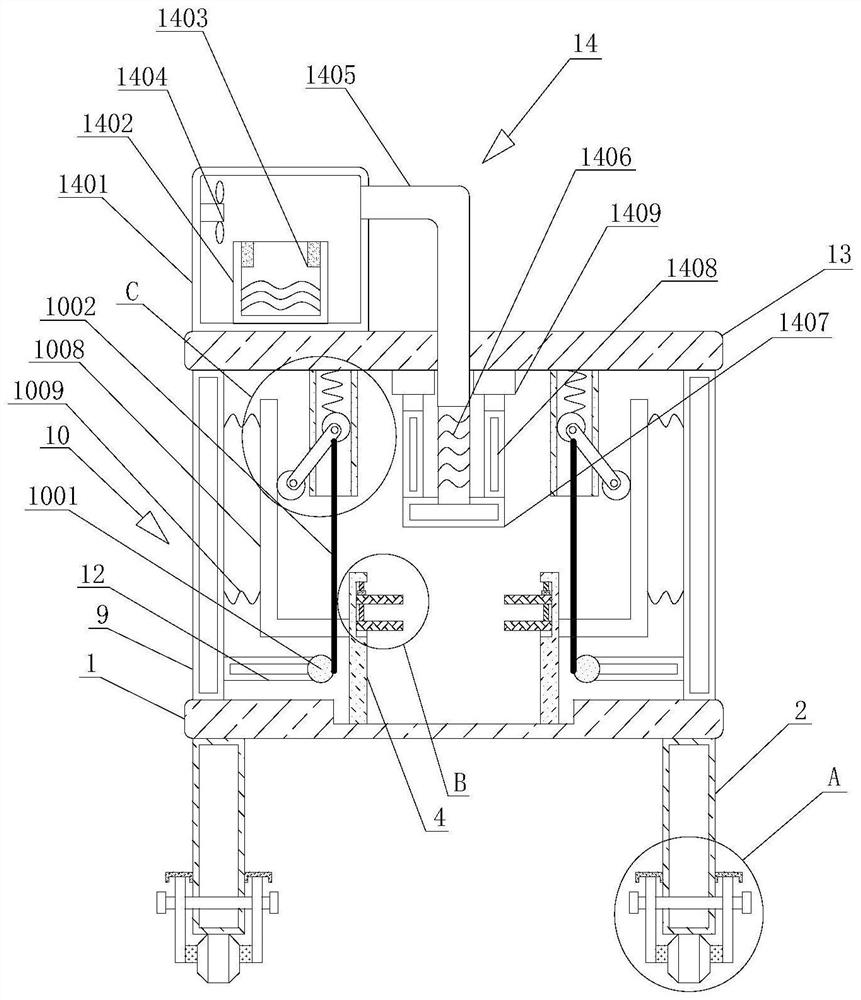

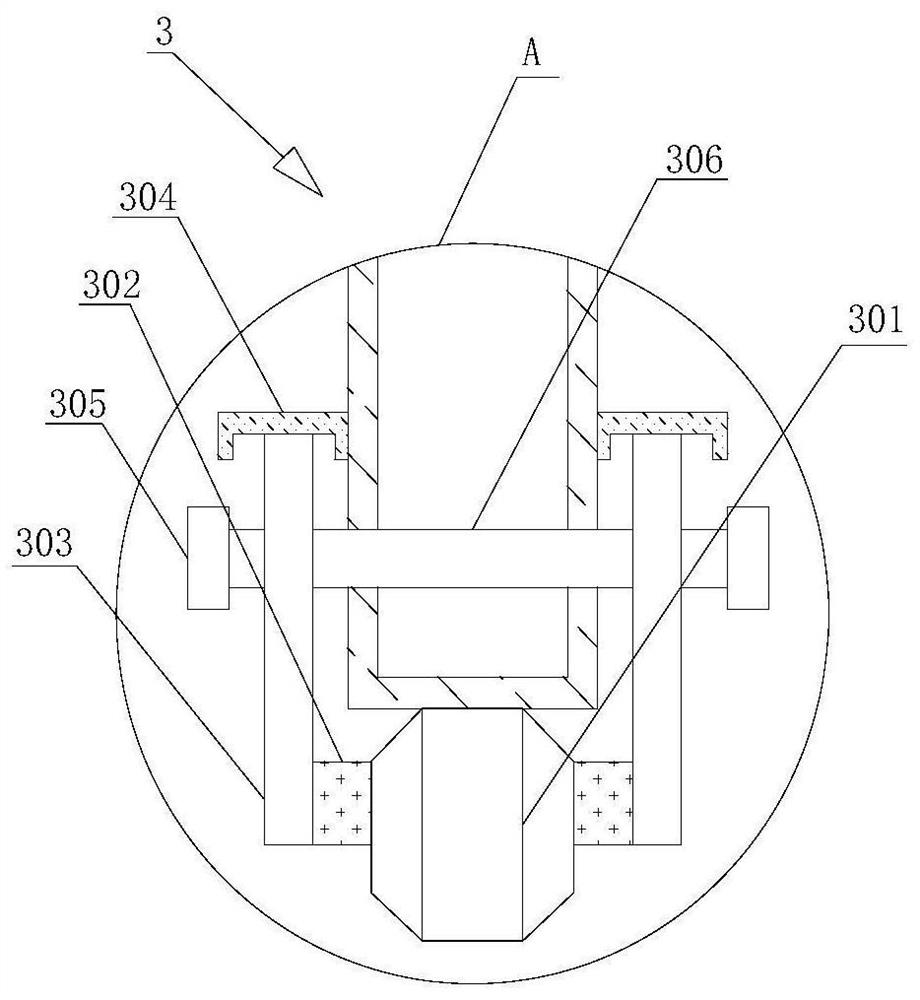

Jet-propelled ironing device with tensioning mechanism for garment processing

InactiveCN112726088AEasy to adjust tensionPlay the role of elastic tensionFabric finishing guides/expandersTextile treatment by spraying/projectingStructural engineeringMechanical engineering

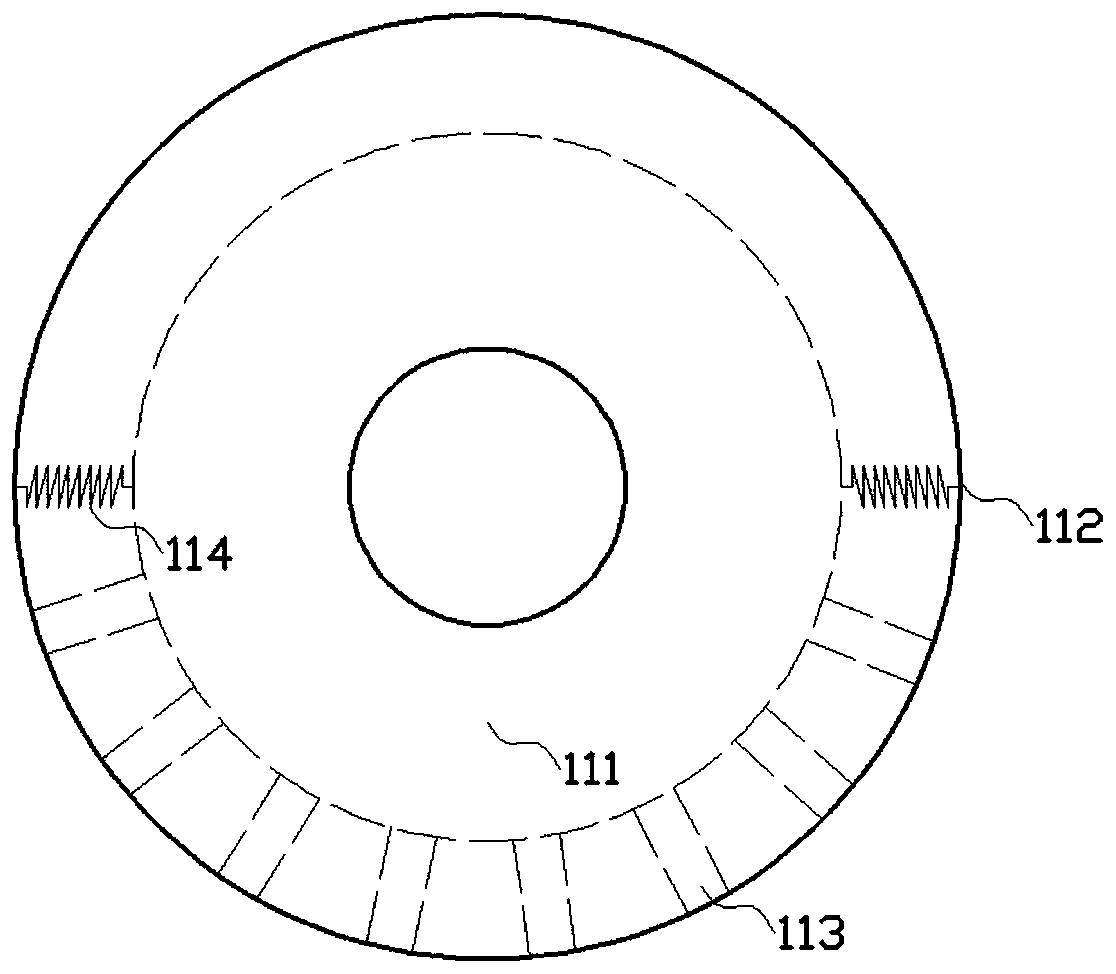

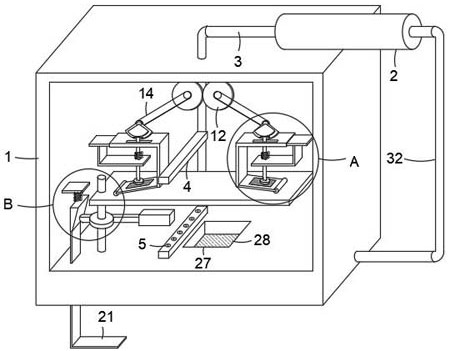

The invention discloses a jet-propelled ironing device with a tensioning mechanism for garment processing in the technical field of garment processing. The jet-propelled ironing device comprises a box body; an unwinding mechanism is arranged on the outer wall of one side of the box body; an unwinding roller is arranged on the unwinding mechanism; a winding mechanism is arranged on the other side of the box body; a winding roller is arranged on the winding mechanism; a first movable roller, a tensioning roller, a second movable roller, a third movable roller and a fourth movable roller are sequentially arranged in the box body from left to right; a tensioning mechanism is arranged outside the tensioning roller, so that double-sided ironing can be conveniently conducted on cloth needed by garment processing, the ironing effect is relatively excellent, and the tension degree of the cloth can be conveniently adjusted; and through arrangement of a spring, a limiting block, a limiting groove and other components, the cloth can be elastically tensioned, the ironing effect of the cloth can be improved through adjustment of the tension degree, the use effect is relatively excellent, and relatively high practicability is achieved.

Owner:SHAANXI INST OF INT TRADE & COMMERCE

Automatic-speed-changing textile fabric ironing device

ActiveCN110629446AAvoid burnsAchieve the function of automatic ironingFabric steaming/decatisingLiquid/gas/vapor textile treatmentRubber materialPulp and paper industry

Owner:杭州兰眼泪服饰有限公司

Clothing production process

ActiveCN110409095AAvoid situations where blemishes are hidden in raised creasesAvoid hiding in crease bumpsLiquid/gas/vapor removalFabric steaming/decatisingPulp and paper industryAnti wrinkle

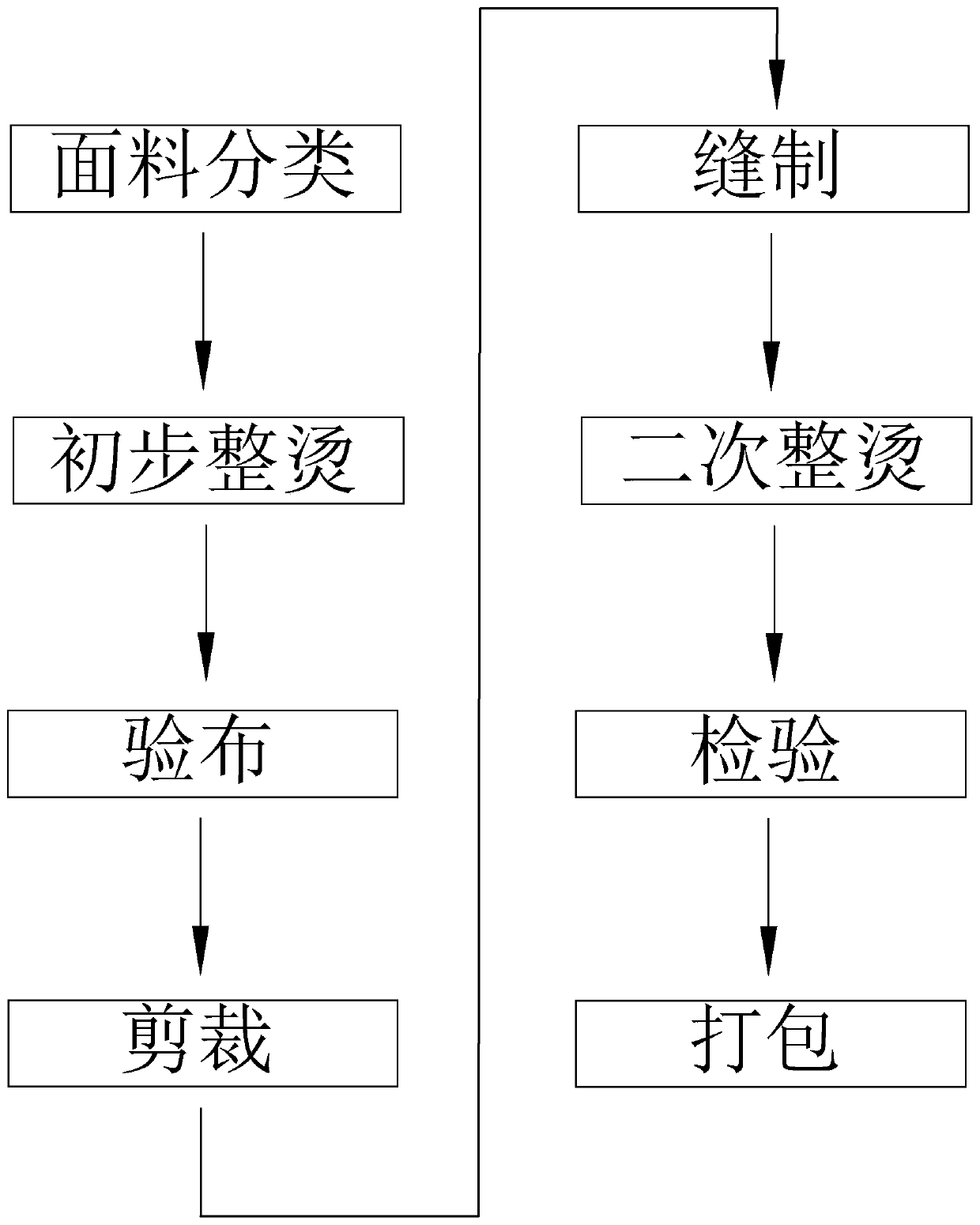

The invention discloses a clothing production process. The clothing production process comprises the following steps of a, fabric classification, wherein fabrics are classified into an easy-to-wrinklefabric and an anti-wrinkle fabric; b, preliminary ironing, wherein the surface of the easy-to-wrinkle fabric is leveled; c, fabric inspection, wherein the leveled cloth is inspected through a fabricinspection machine; d, cutting, wherein the inspected fabric is cut according to a marker; e, sewing, wherein the cut fabric is put into an operation line of machine sewing; f, secondary ironing, wherein the finished product of sewn clothing is ironed to make the surface of the finished product of the clothing leveled; g, inspection; h, packaging. The process has the advantages that the fabric cankeep flat before fabric inspection, thus the success rate of the fabric inspection machine in inspecting defective fabrics is thus improved, the defective fabrics are prevented from involving in theproduction process of the clothing, the size accuracy of the cut fabric is improved, and thus the quality of the finished product of the clothing is improved.

Owner:晋江市霖园塑胶雨具有限公司

Textile fabric ironing flattening device

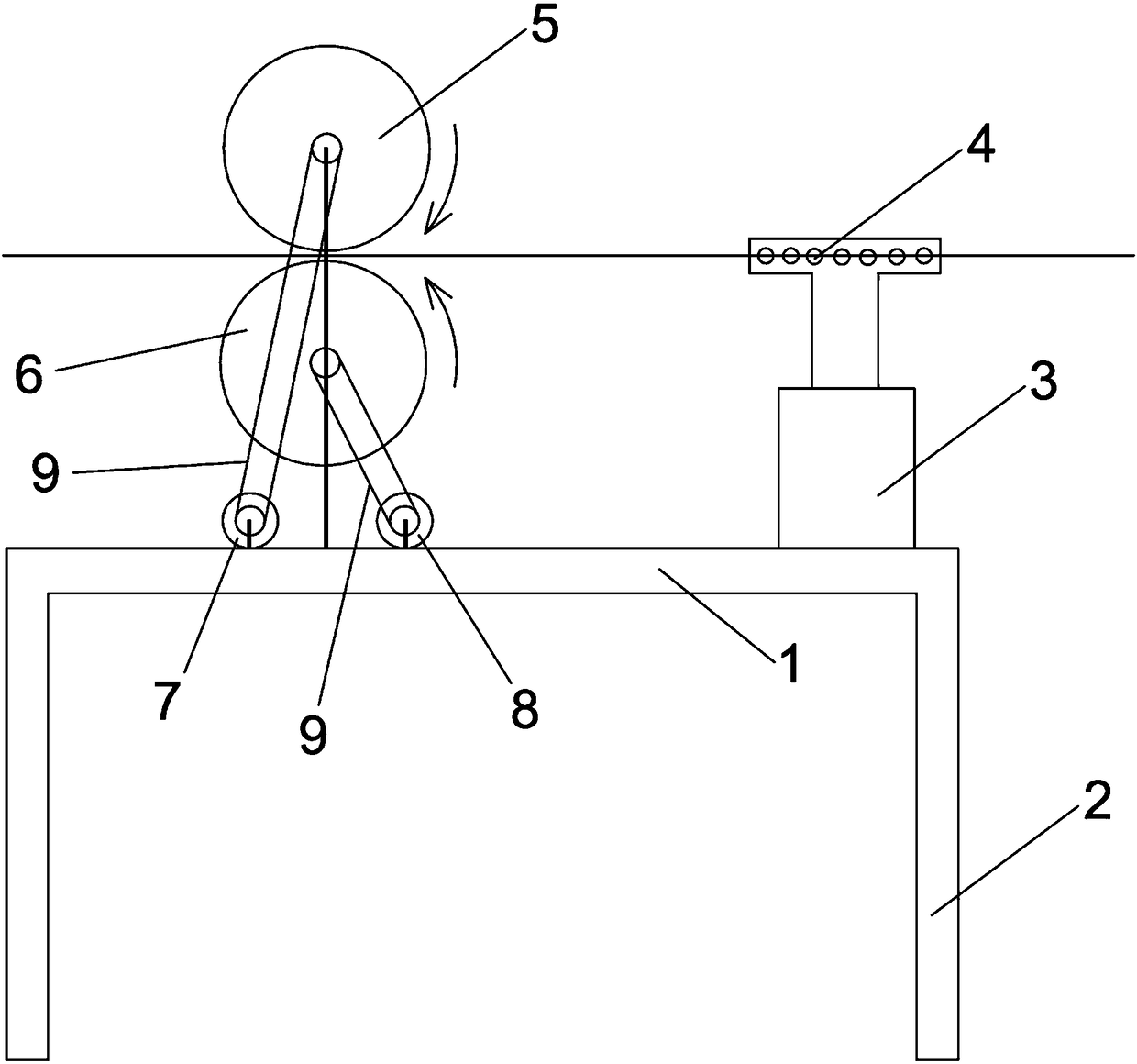

InactiveCN108505268AWith flatteningWith ironing effectFabric steaming/decatisingEngineeringVapor generator

The invention discloses a textile fabric ironing flattening device. A rack comprises a workbench and four machine legs supporting the workbench; an ironing flattening device is fixed on the rack; an ironing part comprises a vapor generator and a steam jet connected with the vapor generator; a whole pressing wheel comprises an upper whole pressing wheel and a lower whole pressing wheel, the upper whole pressing wheel and the lower whole pressing wheel are fixed on the rack through a whole pressing frame, the upper whole pressing wheel, the lower whole pressing wheel and the rack are connected through bearings, the rack is further provided with a transmission motor, the transmission motor is connected with the upper whole pressing wheel and the lower whole pressing wheel through a belt, andthe peripheral walls of the upper whole pressing wheel and lower whole pressing wheel are provided with electric heaters. The textile fabric ironing flattening device has the advantages that the structure is simple, the use is convenient, and through the simple structure, the textile fabric has flattening and ironing effects.

Owner:张素霞

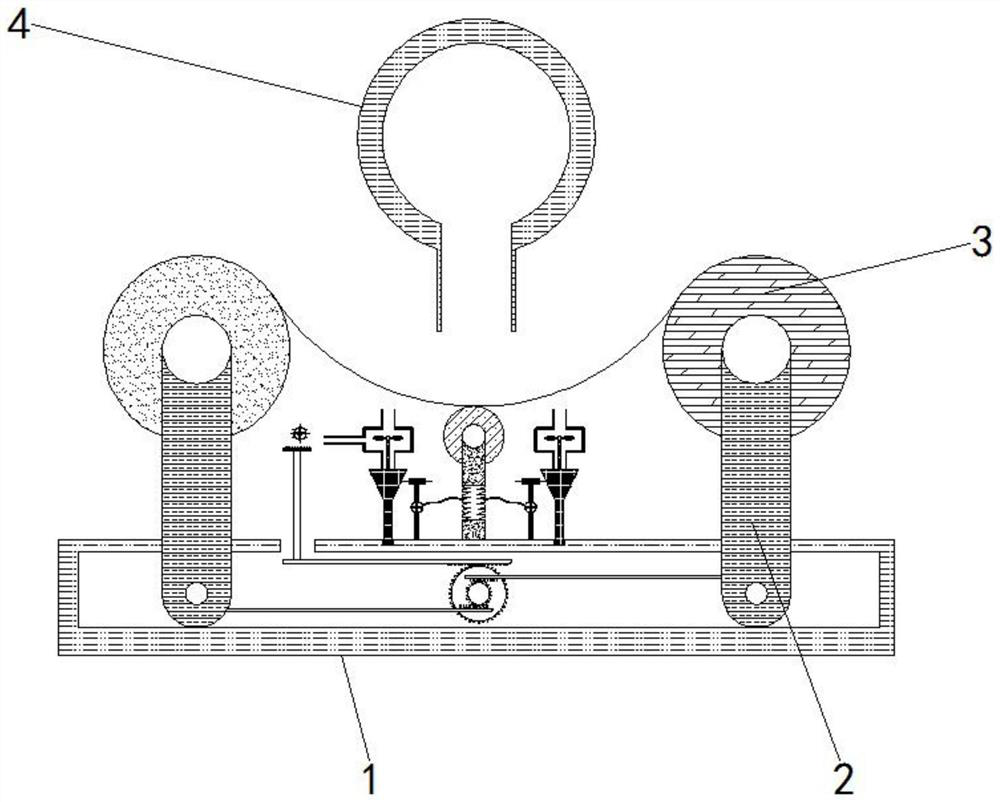

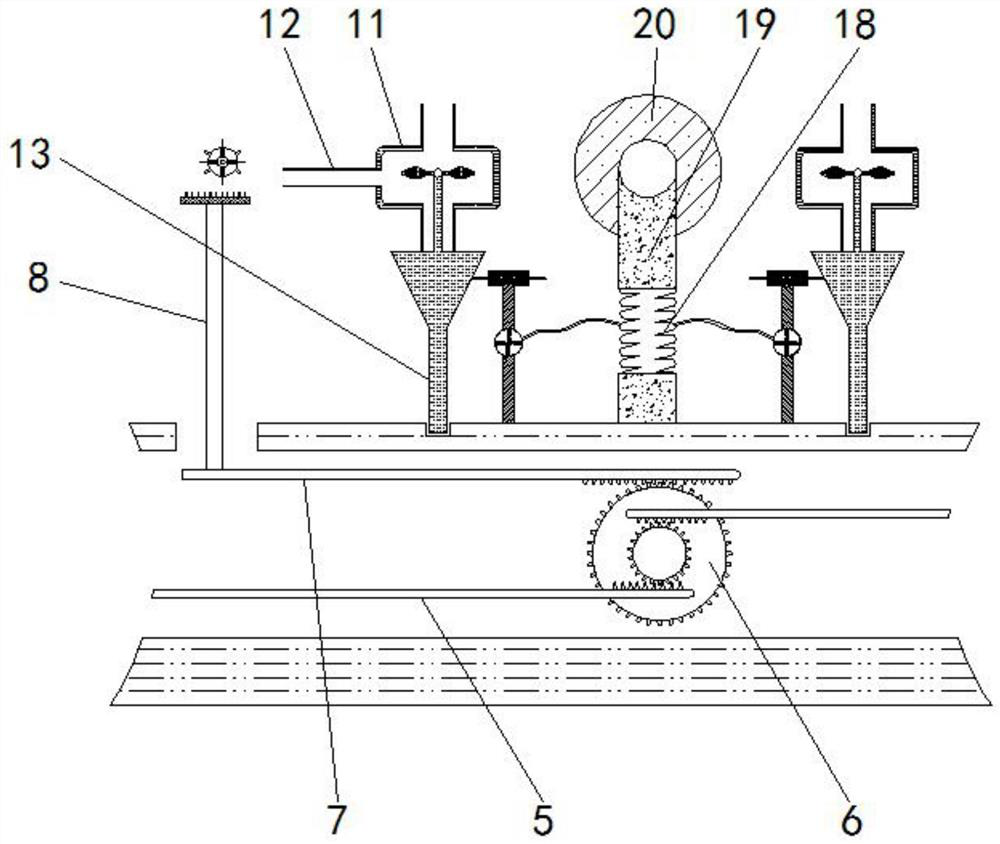

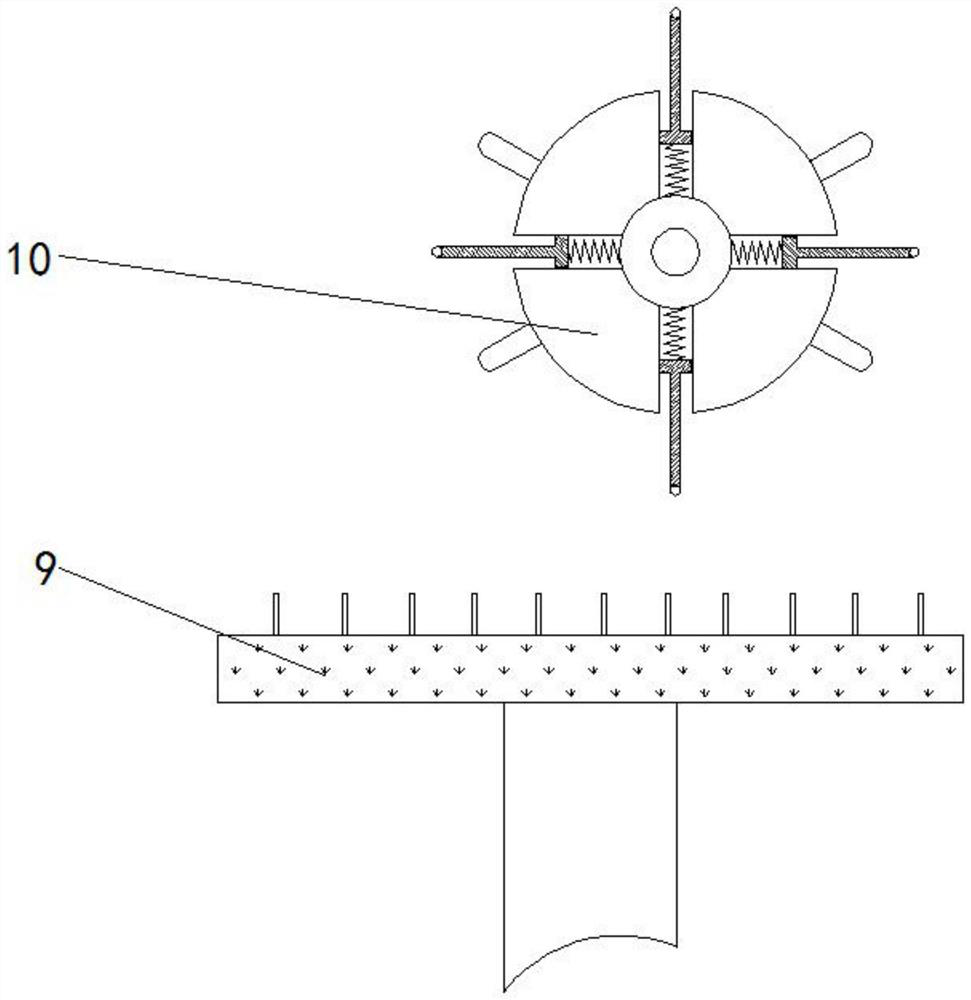

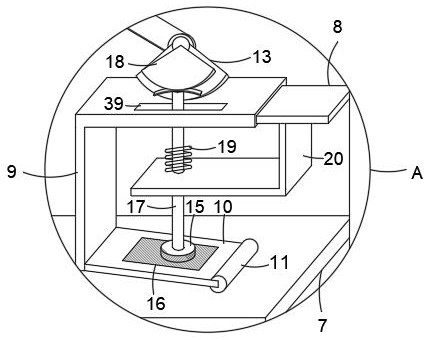

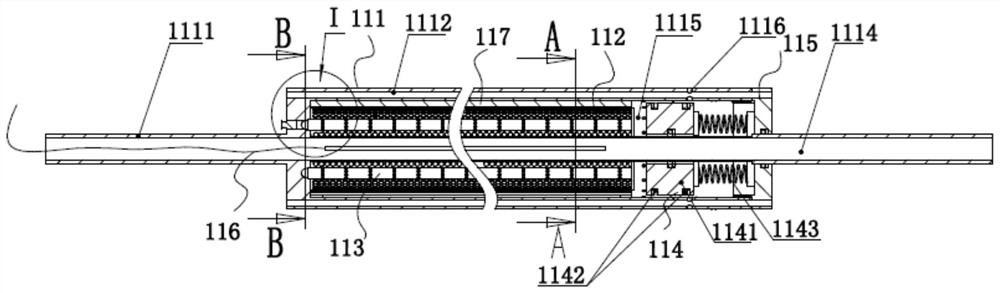

Steam ironing rewinding machine for cloth processing

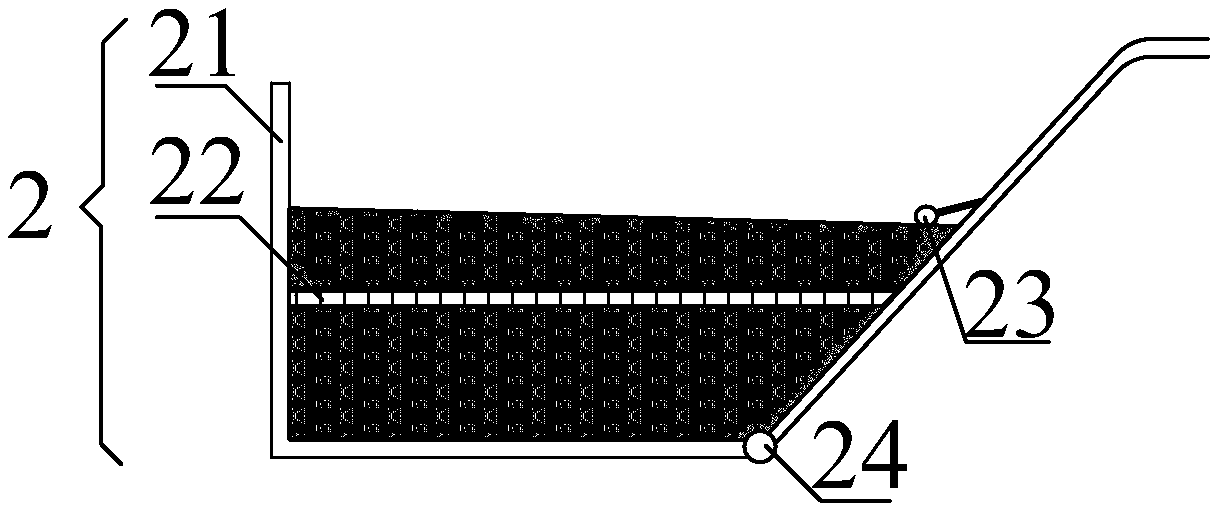

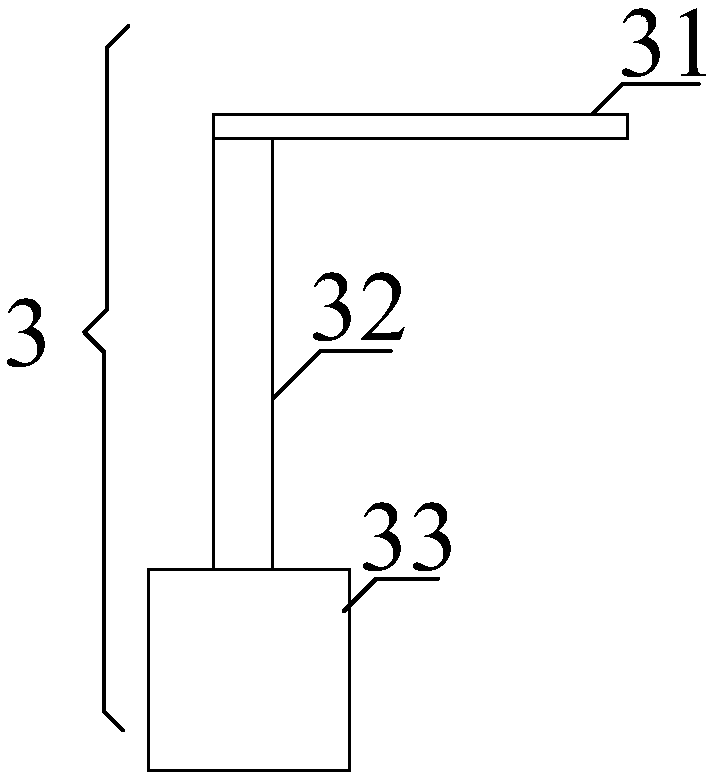

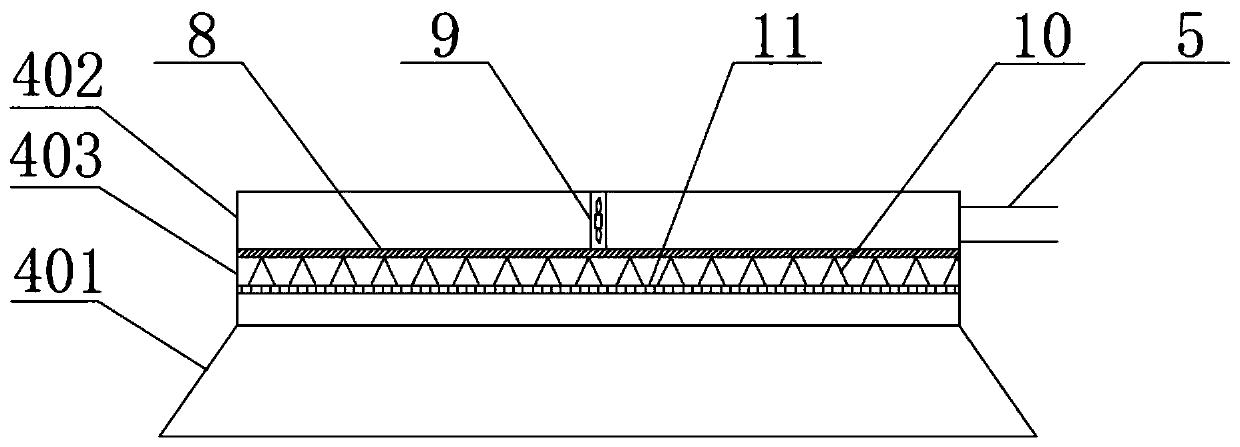

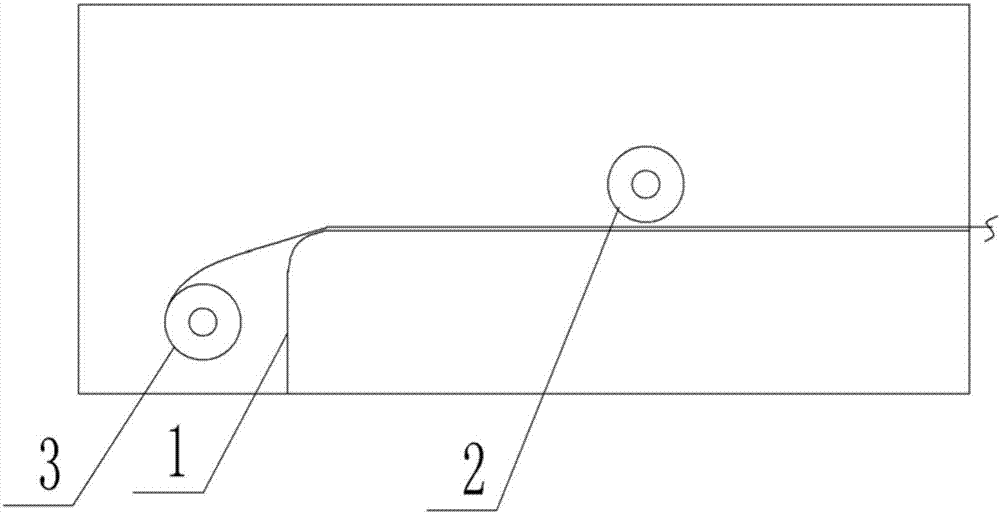

InactiveCN112239099AGuaranteed flatnessLimit movement directionFolding thin materialsFabric steaming/decatisingScrew threadIndustrial engineering

The invention relates to a steam ironing rewinding machine, in particular to a steam ironing rewinding machine for cloth processing. The technical problem to be solved by the invention is to provide the adjustable cloth steam ironing rewinding machine based on the gradual change edgefold, which can automatically flatten cloth, can simultaneously fold two edges of the cloth, automatically irons thecloth after edge folding, and prevents the cloth from being corrugated during cloth collecting. According to the technical scheme, the steam ironing rewinding machine for cloth processing comprises ahorizontal feeding mechanism, an ironing plate, an ironing frame and the like; the horizontal feeding mechanism is used for providing raw materials; rectangular protrusions are arranged on the ironing plate; and two frame plates of the ironing frame are fixedly connected to the ironing plate. According to the steam ironing rewinding machine, a positioning pressing mechanism is additionally arranged, the flatness of the cloth in the moving process is guaranteed through a pressing roller, and two positioning sliding blocks are made to move oppositely or reversely through opposite threads on a first rotating screw rod.

Owner:赵晓鹏

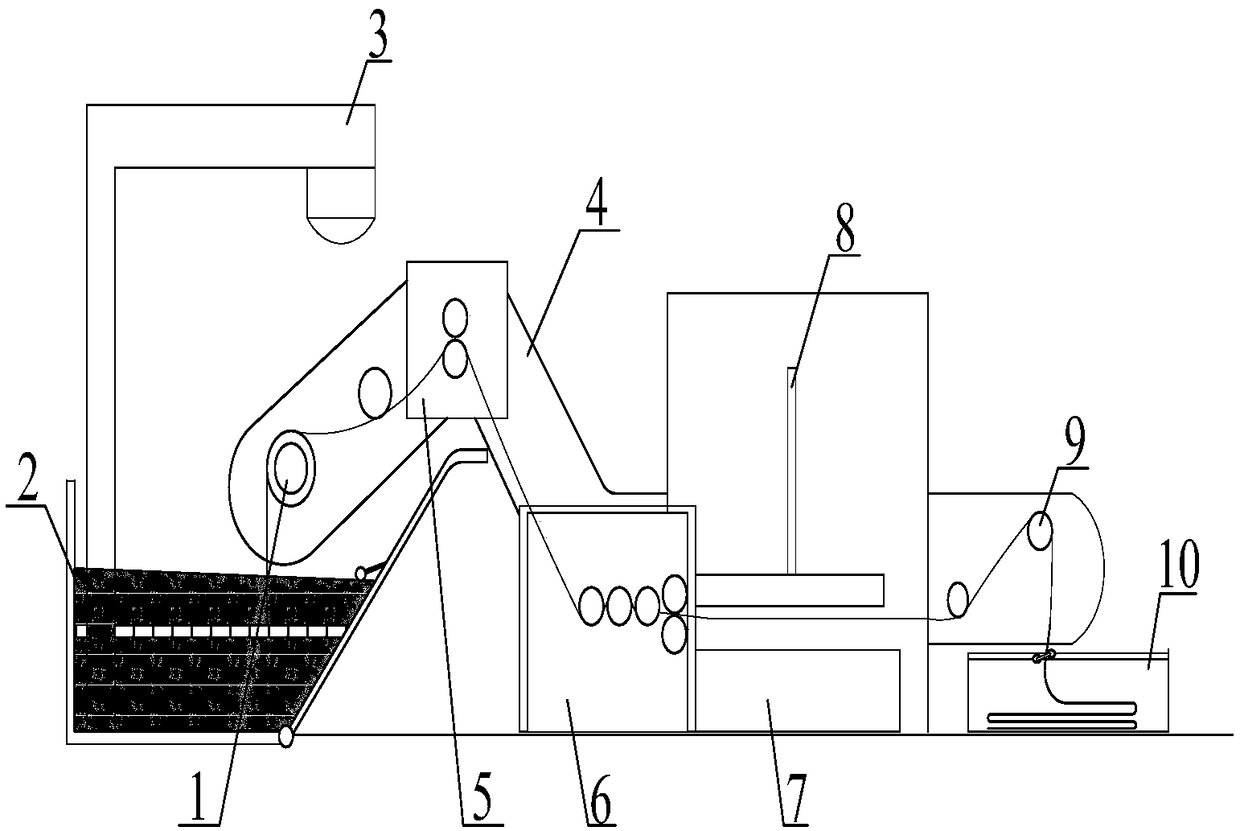

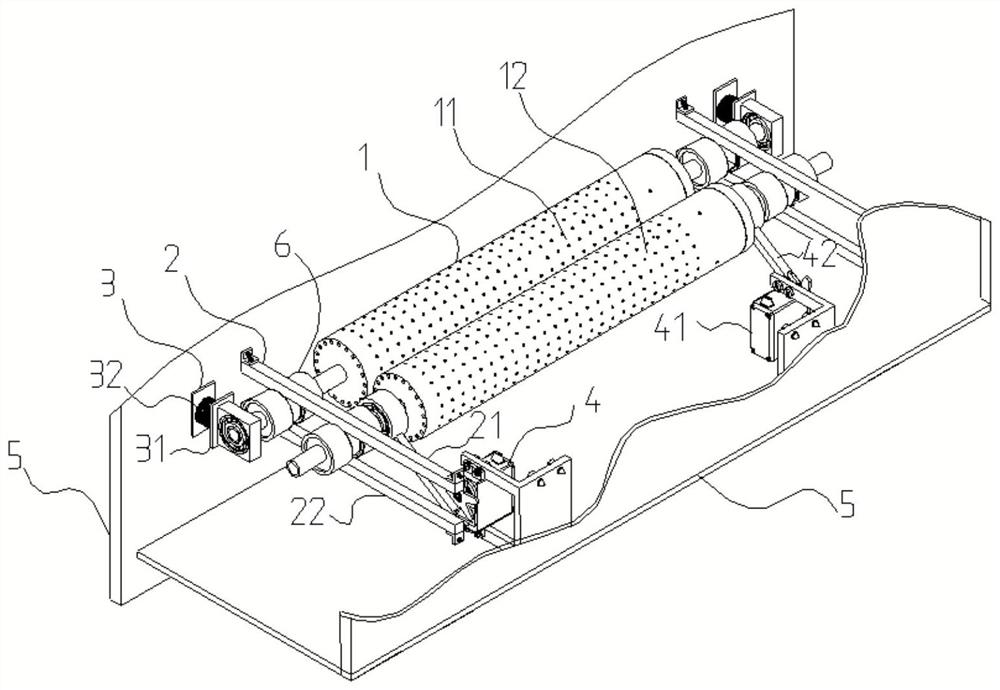

Automatically-rolling fabric drying and dust-removing device

InactiveCN108149431AEasy to dryRemovableMechanical cleaningPressure cleaningEngineeringFront and back ends

The invention discloses an automatically-rolling fabric drying and dust-removing device. The device comprises a base in an elongated concave shape, notches are formed in the middles of the two side walls of the base, a roller and rolled fabric are hinged between the two side walls of the front and back ends of the base respectively, the roller is connected to a drive device installed in an installation groove formed in the upper surface inside the base, multiple drying devices are arranged between the two side walls of the base, first adsorption devices are arranged on the upper surfaces of the two side walls of the base and opposite to the drying devices, and a second adsorption device is arranged on the upper surface inside the base. The automatically-rolling fabric drying and dust-removing device has the advantages that the device can dry the fabric quickly and iron the wrinkled surface of the fabric in the drying process, and has the effect of removing dust and nap; meanwhile, thedevice can automatically roll the dried fabric, which is very convenient.

Owner:HUZHOU LINGHU ZHONGZHAO JINHUI SILK WEAVING FACTORY

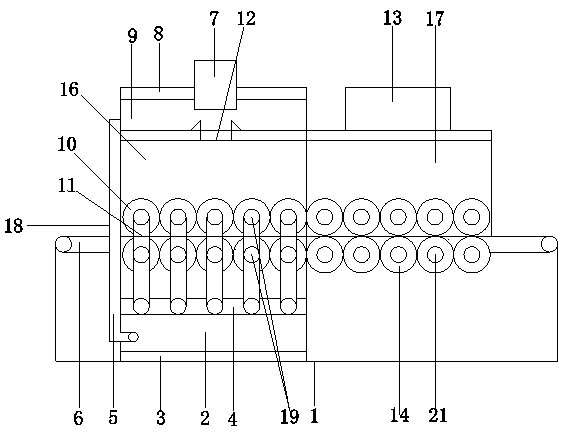

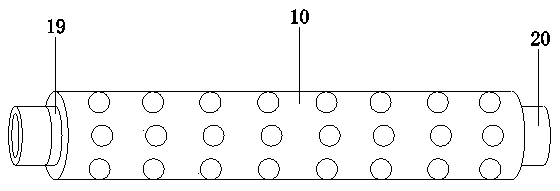

Thin clothes ironing and drying integrated machine

InactiveCN109137353AFast ironing and dryingImprove ironing effectFabric finishing guides/expandersTextiles drying apparatusProcess engineeringWater collection

The invention discloses a thin clothes ironing and drying integrated machine. The thin clothes ironing and drying integrated machine comprises an ironing equipment body, a steam ironing roller and a heating ironing roller; a water tank, a heating pipe, a joint bracket, a backflow pipe, a conveying belt, an exhaust fan, a condenser pipe, a liquefied water collection tank, the steam ironing roller,a steam conveying pipe, a steam outlet, a fan, the heating ironing roller, a heating pipe, a steam ironing box, a dry ironing box, a material inlet, an electromagnetic valve, a joint, a driving motorand a wire through hole are arranged on the ironing equipment body; as the steam ironing box and the dry ironing box are combined on the ironing equipment body, thin clothes are steam-ironed by usingthe steam ironing box first, and then are fed into the dry ironing box to be secondarily ironed; and meanwhile, the steam in the first ironing is removed. The thin clothes ironing and drying integrated machine disclosed by the invention has the advantages of reasonable design, high ironing and drying speed and good ironing effect.

Owner:NANTONG HECHENG TEXTILE CO LTD

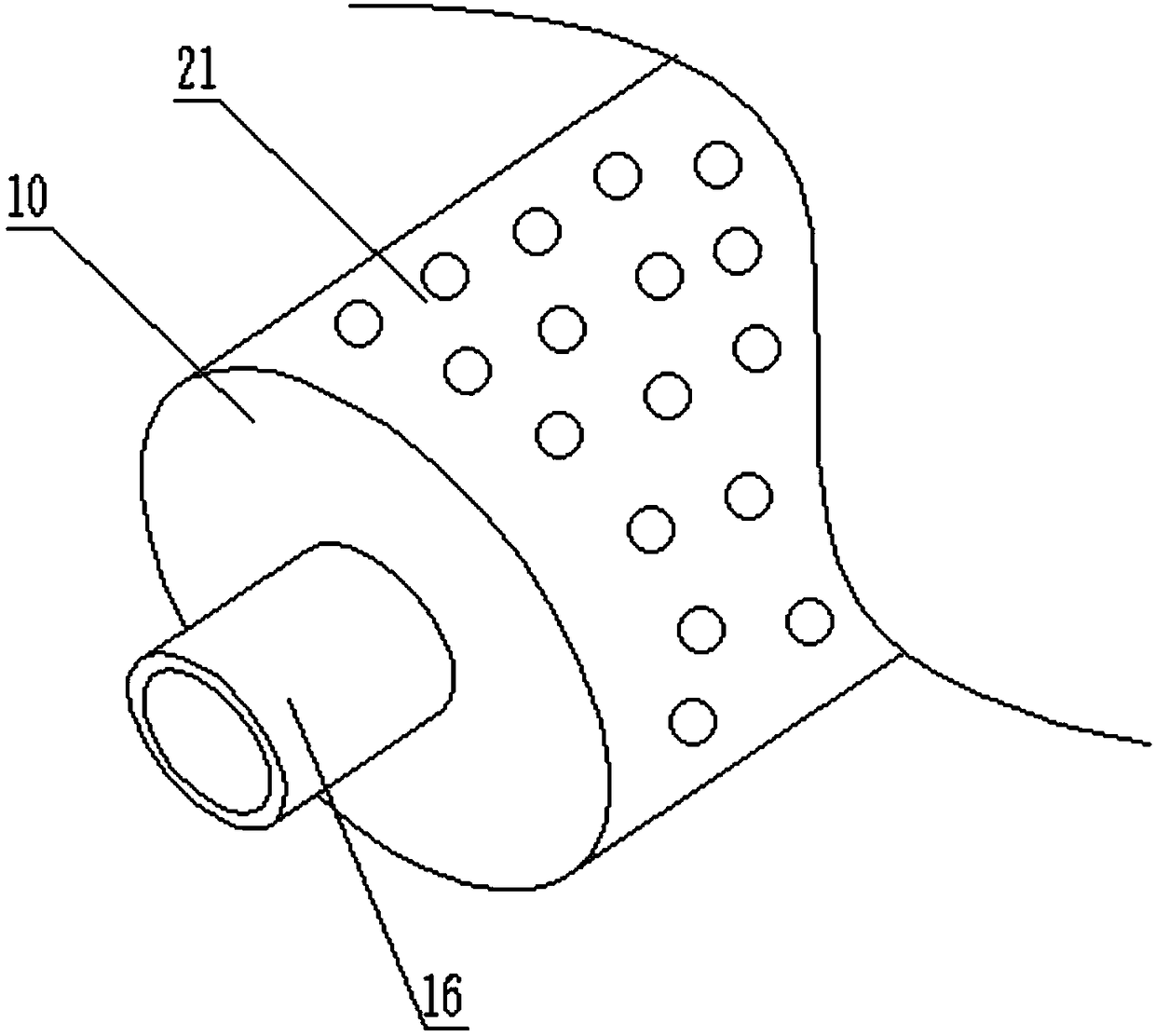

Steam fixing apparatus used for processing socks

InactiveCN108589135AQuality assuranceEvenly dispersedShaping/stretching tubular fabricsFabric steaming/decatisingSOCKSDrive shaft

The invention discloses a steam fixing apparatus used for processing socks. The steam fixing apparatus comprises a fixing bin, injection holes, a steam generator, and a machine body, a placement bin is arranged at the bottom in the machine body, the steam generator is arranged at the bottom in the placement bin, the fixing bin is arranged at the top of the placement bin, injection plates are arranged at two ends in the fixing bin, a fixing rack is arranged at the other side of the fixing bin, a motor is arranged at one side of the fixing rack far from a first sealing door, and rotation rollersare arranged at a driven shaft and a driving shaft in the fixing bin. By arranging the injection plates and the injection hole, the injection hole is in a trumpet shape, so that steam is injected ina peripheral diffusion mode, in addition, the injection holes are uniformly arranged, the injection plates are arranged at two ends in the fixing bin, the steam can be uniformly dispersed, the fixingeffect is increased, in addition, the steam amount is reduced, and the water resource and the production cost are saved.

Owner:海宁市汉达袜业有限责任公司

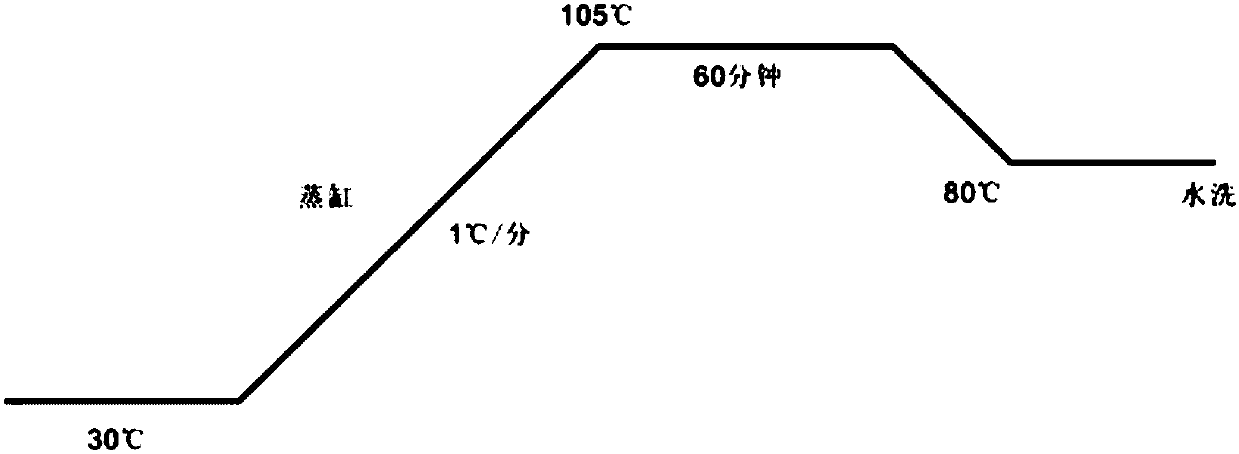

Processing method of permanent crepe fabric

InactiveCN107747158ADoes not cause crepe effectCrepe effect disappearsPattern makingFibre typesEngineeringWeft yarn

The invention relates to a processing method of a permanent crepe fabric. After warp yarn and weft yarn are woven into a fabric weave, original creping, pre-setting, washing, drying, mechanical rope-like creping, steam setting, secondary reduction, dyeing and setting are carried out in sequence, and then the permanent crepe fabric is obtained. Compared with the prior art, the mode of combining original creping with mechanical rope-like creping is utilized to control the creping effect, the process is easier to control precisely, and the reproducibility of fabric production is high; besides, the fabric is good in handfeel, high in dyeing yield and the like.

Owner:劲霸男装(上海)有限公司

Fabric printing and dyeing equipment with negative pressure processing mechanism and printing and dyeing process

InactiveCN111926495AHigh degree of automationImprove printing and dyeing effectMechanical cleaningPressure cleaningProcess engineeringIndustrial engineering

The invention discloses fabric printing and dyeing equipment with a negative pressure processing mechanism and a printing and dyeing process, and relates to the technical field of printing and dyeingequipment. The fabric printing and dyeing equipment with the negative pressure processing mechanism comprises a shell, wherein a sealing cover is movably arranged on the top surface of the shell; an unwinding component and a winding component are respectively and fixedly arranged between the inner surfaces of the shell; a pre-leveling mechanism which is matched with the winding component and the unwinding component is fixedly arranged between the inner surfaces of the shell; a plurality of reversing rollers are fixedly arranged inside the shell; and a pre-cleaning mechanism is fixedly arrangedbetween the inner surfaces of the shell at a position, close to the unwinding component. The fabric printing and dyeing equipment can sequentially complete the pre-leveling, pre-cleaning, negative pressure re-suction, surface ironing, printing and dyeing, press draining and drying of the cloth surface according to an automated procedure through the design of a printing and dyeing mechanism, the pre-cleaning mechanism, an ironing mechanism, the pre-leveling mechanism and a drying mechanism; and the degree of automation of the equipment can be improved through the optimization and realization of the above process flow.

Owner:马鞍山威莎自动化设备科技有限公司

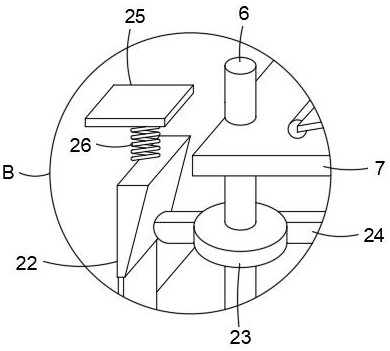

Efficient ironing device for textile cloth

InactiveCN111926516AChange the tensionReduce extrusion pressureTextile treatment by spraying/projectingFabric steaming/decatisingAir springCotton material

The invention discloses an efficient ironing device for textile cloth, comprising a support plate. The efficient ironing device for the textile cloth is characterized in that a support rod is slidablyconnected to the side surface of the support plate; a winding wheel is rotatably connected to the top of the support rod; a bearing tooth rod is fixedly connected to the side surface of the support rod; a bearing wheel is engaged to the side surface of the bearing tooth rod; an air outlet pipe is provided on the left side of an air extracting box; a conical shaft is provided at the bottom of theair extracting box; an engagement rod is engaged to the side surface of the conical shaft; a centrifugal wheel is slidably connected to the side surface of the engagement rod; an adjustment rod is rotatably connected to the bottom of the centrifugal wheel; an extrusion rod is provided on the opposite sides of two airbags; and an extrusion wheel is rotatably connected to the top of the extrusion rod. By means of cooperative use of an air spring and the conical shaft, the efficient ironing device for the textile cloth achieves the effect of preventing the change of the tightening degree of the cloth during ironing the moving cloth.

Owner:何世立

Cleaning and flattening device for tribute silk wadding

ActiveCN108842325AImprove recycling ratesSave resourcesTextile storage in superimposed formLiquid/gas/vapor removalReciprocating motionWater flow

The invention provides a cleaning and flattening device for tribute silk wadding. The cleaning and flattening device comprises a feeding wheel, a sink device, a flushing mechanism, a gear transmissionmechanism, a draining roller, a drying roller set, a steam generator, a flattening mechanism, gathering wheels and a guiding rod, wherein the feeding wheel is connected with the gear transmission mechanism through gear engagement; the sink device is arranged on the left side of the drying roller set; the flushing mechanism is connected to the inner wall of the sink device in a welding mode. According to the arrangement of a lower guide rod mechanism, provided by the invention, a rolling shaft is driven by an electric motor to rotate; a Z-shaped groove on the rolling shaft drives a sliding block and distribution rods to do reciprocating motion; the flattened tribute silk wadding can be neatly stacked in a collection box, so that the cleanliness of the tribute silk wadding is ensured and labor force is reduced; due to the arrangement of the sink, the right oblique wall adopts a ladder shape with 45-degree tilt angle, so that flushed water favorably flows back into a sink; water is supplied by a water supply pipe through a self-priming pump, so that the cycle utilization rate of the water is improved, resources are saved and cost is reduced.

Owner:杭州金利丝业有限公司

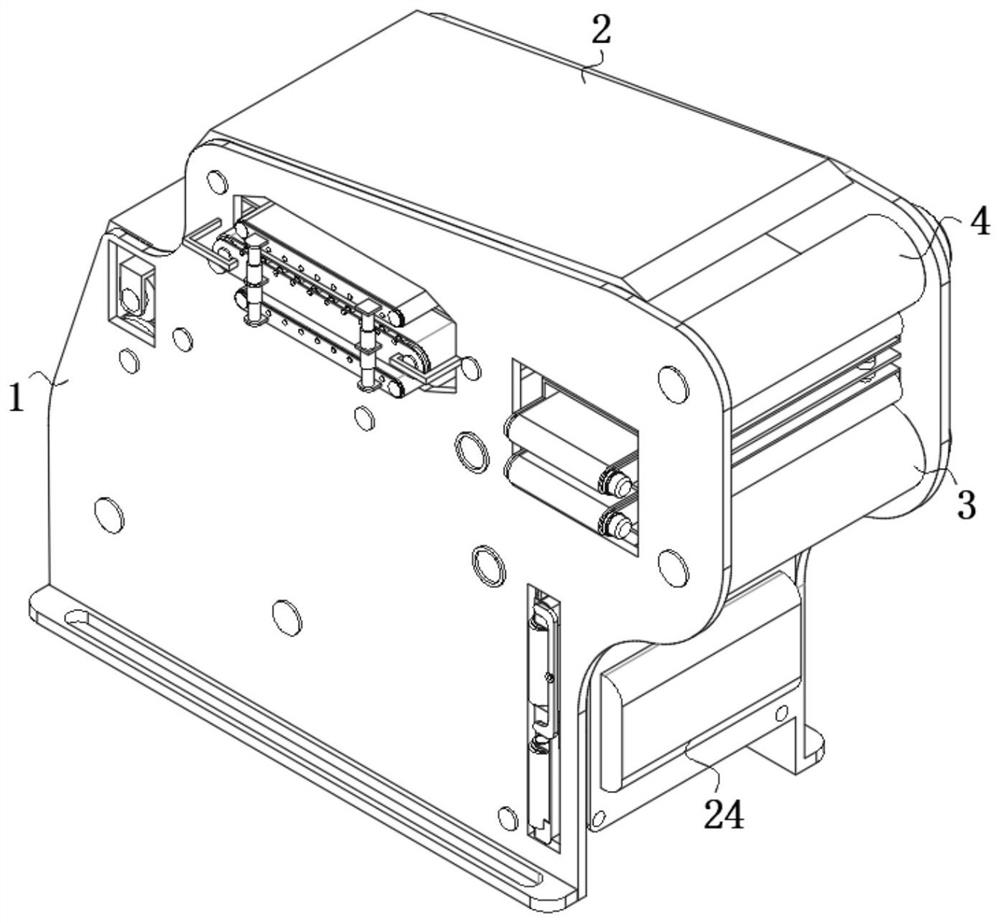

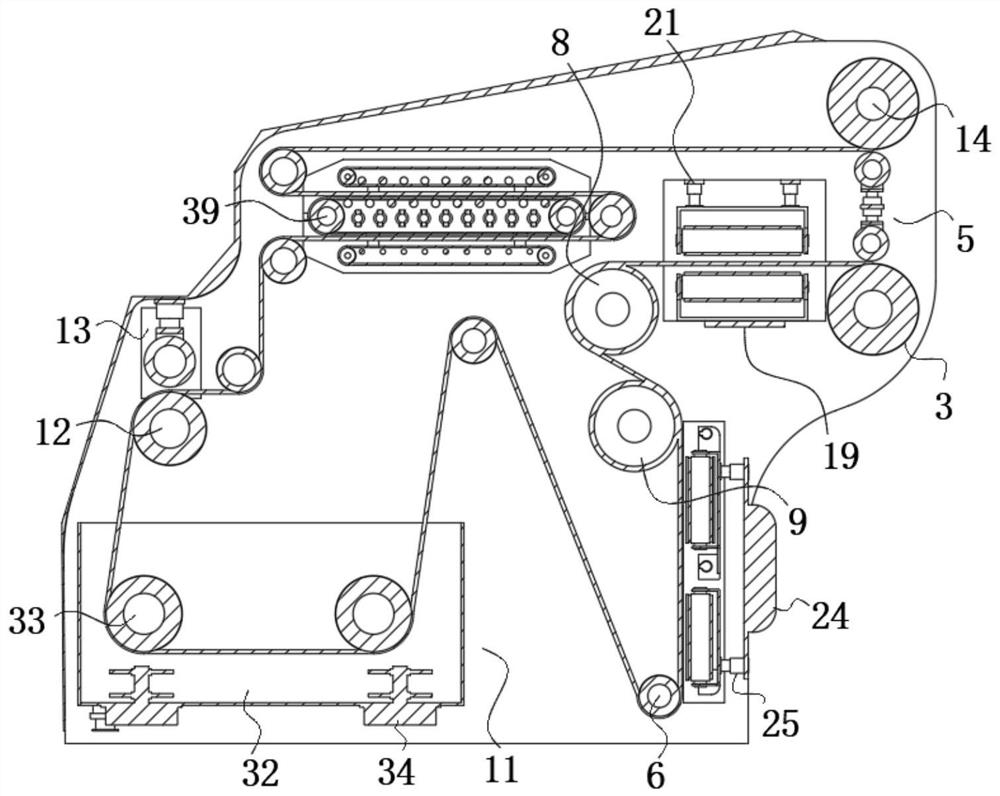

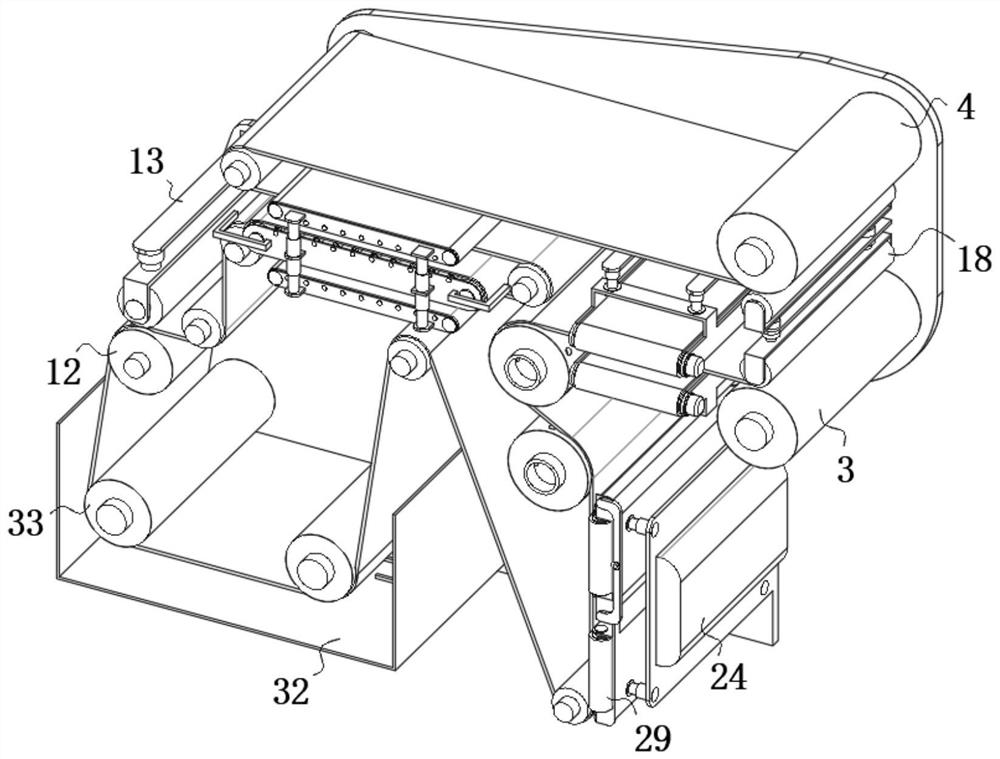

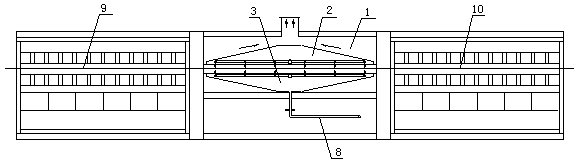

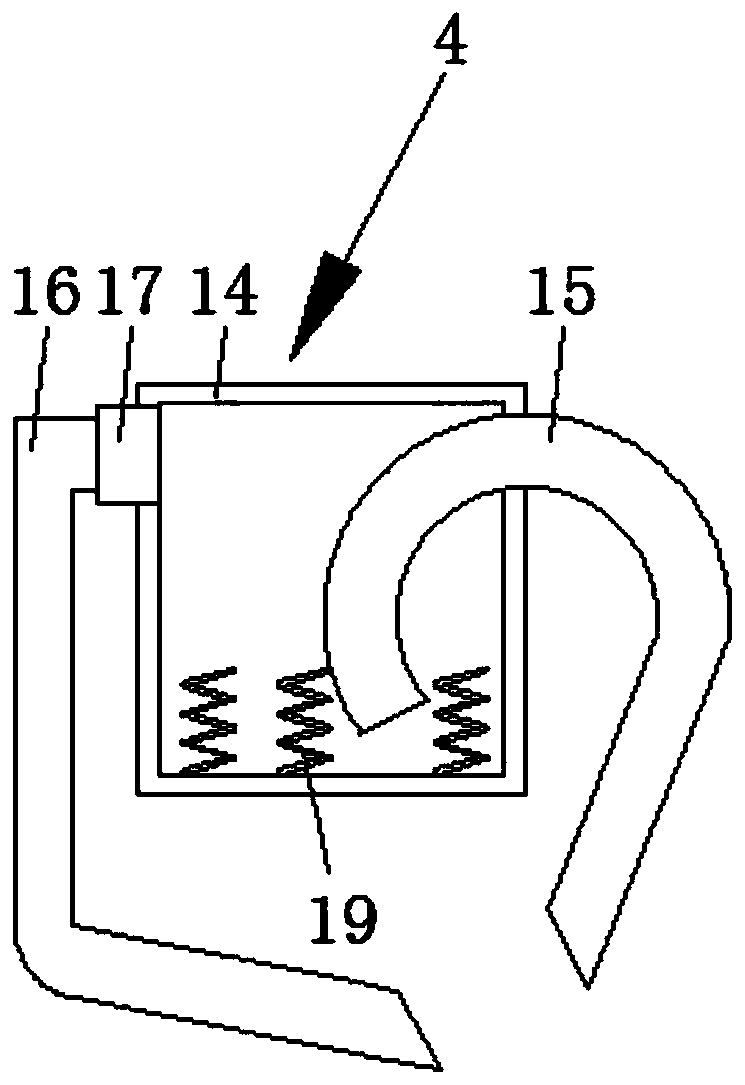

Apparatus for continuous decatizing in autoclave

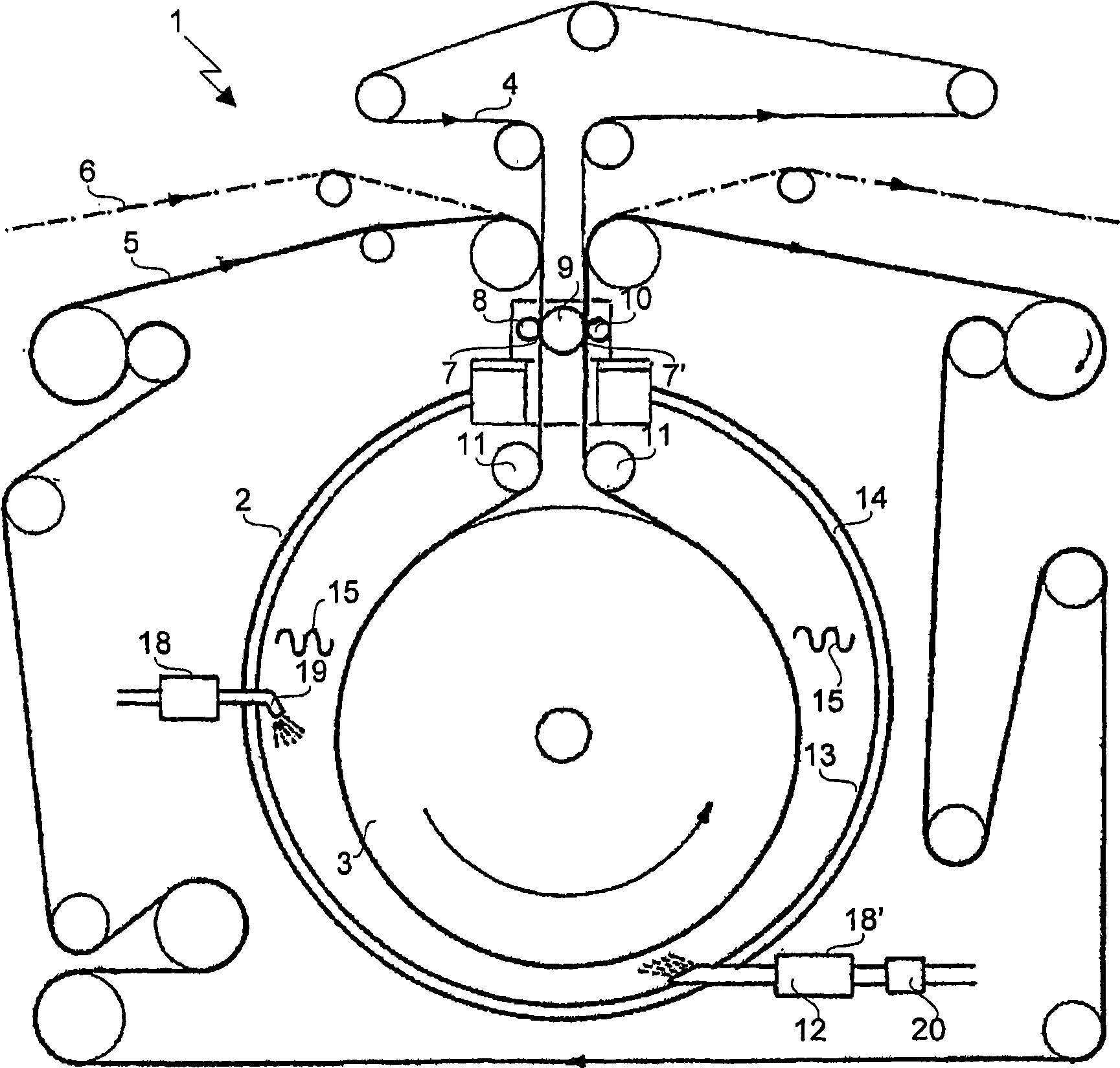

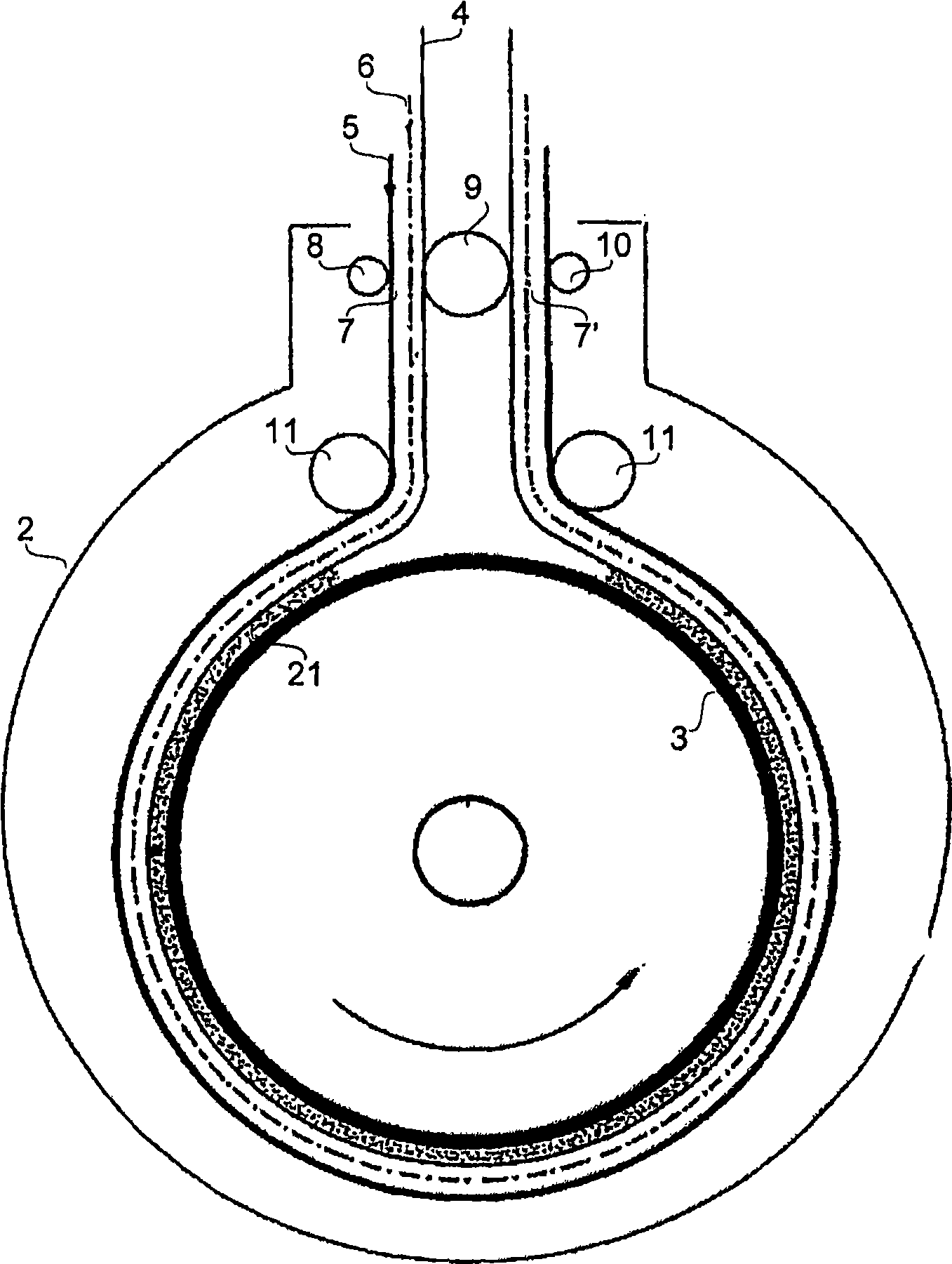

InactiveCN101522977AGood steaming effectImprove steaming effectHeating/cooling textile fabricsFabric steaming/decatisingEngineeringMechanical engineering

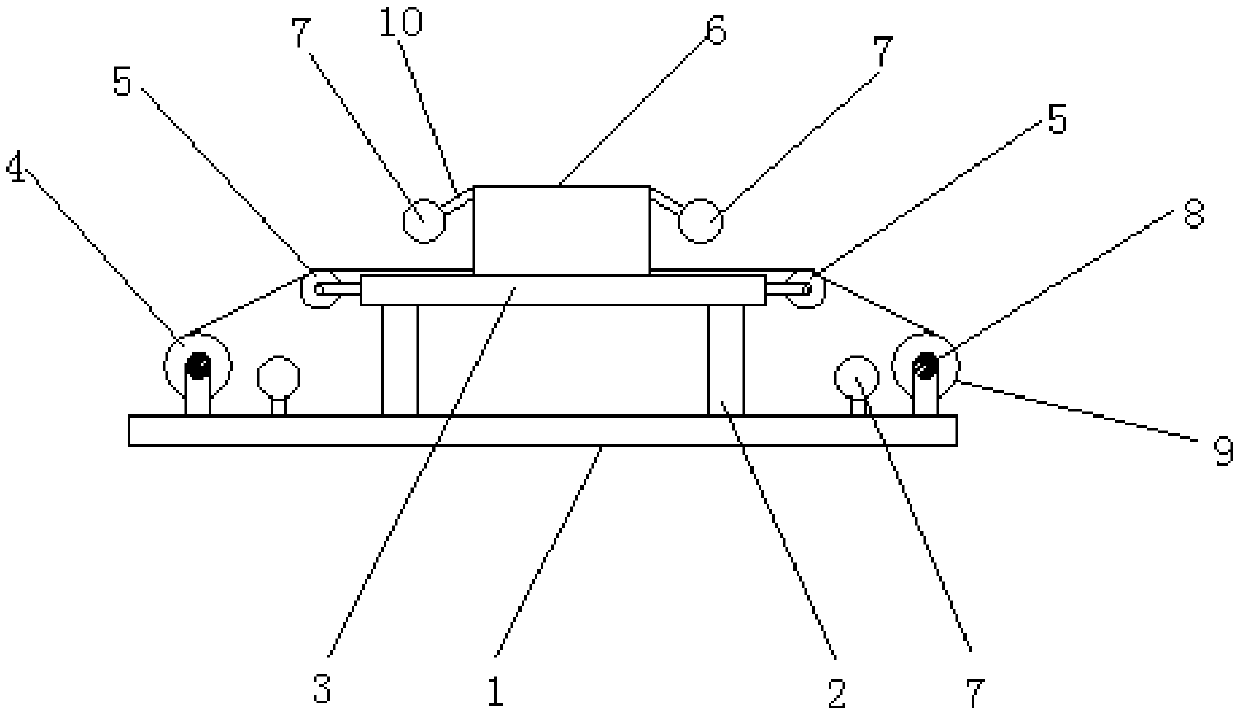

An apparatus (1) for continuous autoclave decatizing which comprises an autoclave (2) containing a cylinder (3) being heated and rotatable around its axis. Said apparatus (1) further comprises a firstconveyor belt (4) and a second conveyor belt (5) which are supported by rolls and suitable to sandwich between themselves a fabric to be treated (6) and to carry said fabric (6) into the autoclave (2) through an inlet sealing slot (7) and out of the autoclave (2) through an outlet sealing slot (7'). The conveyor belts (4, 5) are arranged so as to surround the cylinder (3) and adhere to the cylindrical lateral surface thereof. Further, said apparatus (1) is provided with an internal jacket (13) which can be heated by heating means (14) and is coaxial to the autoclave (2). Said internal jacket(13) and said heated cylinder (3) are suitable to be heated up to temperatures ranging from 160 DEG C to 200 DEG C in order to overheat in a combined way the interior of the autoclave (2) up to a temperature higher than 14O DEG C and the apparatus is provided with means (12) for injecting steam into the autoclave (2). The apparatus (1) is also provided with water injecting means (12, 18, 18', 19)suitable to inject water into the autoclave (2).

Owner:BIELLA SHRUNK PROCESS S A S DI PIETRO ALBERTO & C

Multifunctional cloth loosening machine

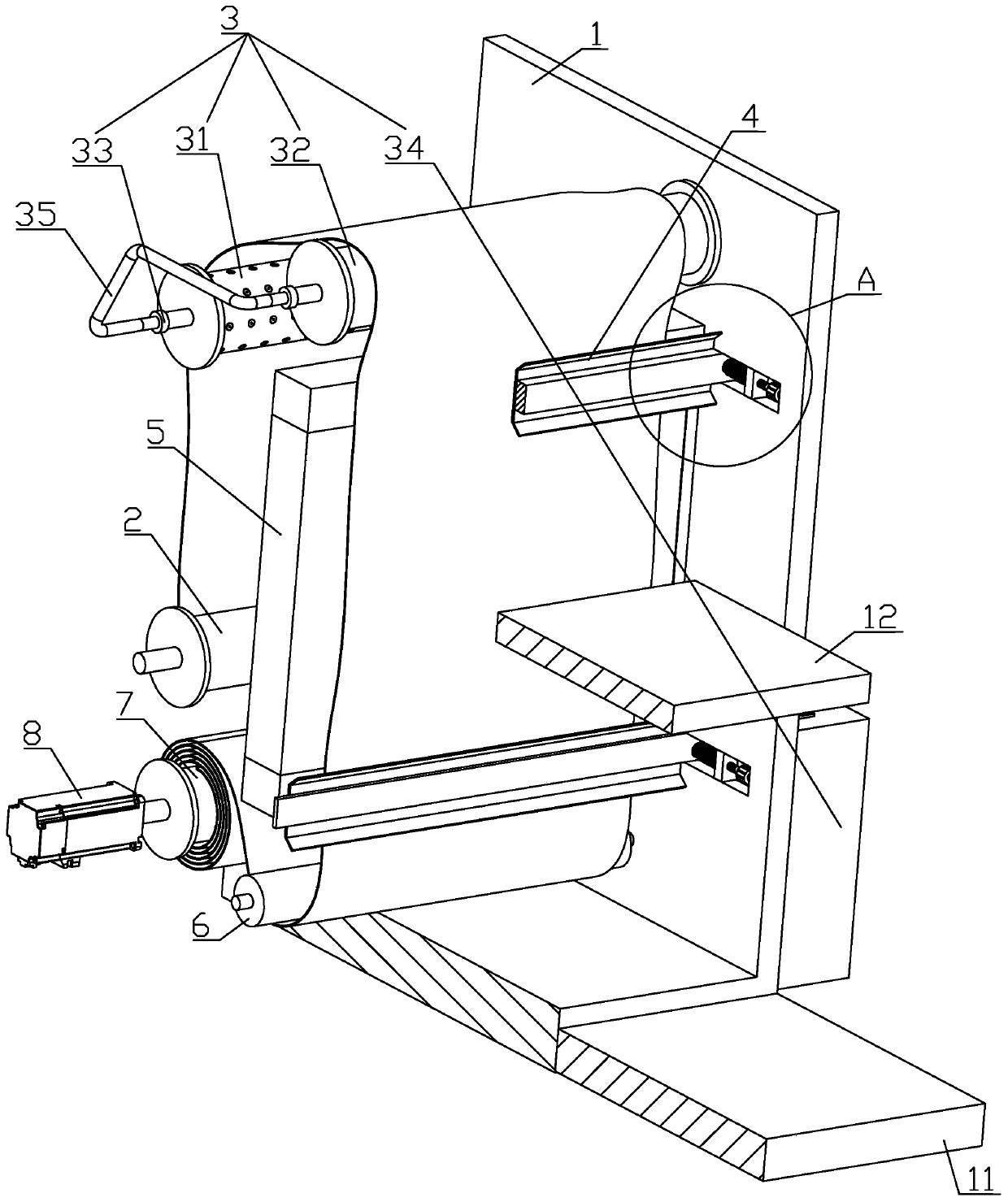

InactiveCN110938983AGuaranteed smoothImprove work efficiencyInspecting textilesTextile treatment with treating outlet contectElectric machineryEngineering

The invention discloses a multifunctional cloth loosening machine. The multifunctional cloth loosening machine comprises a support and a platform plate, wherein the platform plate is fixedly mounted on the top surface of the surface of one side of the support, a cloth loosening roller and an extrusion roller are arranged in the support, and the connecting end of the cloth loosening roller penetrates through the surface of one side of the support and is connected with the output end of a cloth loosening roller motor fixedly connected with the surface of one side of the support. According to themultifunctional cloth loosening machine, firstly, a compression roller, an illuminating lamp, transparent glass, the cloth loosening roller and the extrusion roller are adopted, so that the device can perform cloth inspection and cloth loosening work simultaneously, and the working efficiency is greatly improved; meanwhile, a worker only needs to wind cloth around the surface of a guide roller and place the cloth below the compression roller, then the installation can be completed, and the installation is extremely convenient; secondly, an ironing box is adopted, the cloth penetrates throughthe ironing box to be ironed, and the surface of the cloth is guaranteed to be flat; and the device integrates the ironing function, the cloth is ironed during cloth inspection and cloth loosening, the later process is reduced, and the production efficiency is greatly improved.

Owner:义乌市尼美机械加工厂

Efficient and stable shaping treatment system for fluff on surface of Shu velveteen fabric

ActiveCN112481894AStable stateImprove the three-dimensional effectSucessive textile treatmentsHeating/cooling textile fabricsTextile printerProcess engineering

The invention discloses an efficient and stable shaping treatment system for fluff on the surface of a Shu velveteen fabric, and relates to the technical field of textile fabrics. The efficient and stable shaping treatment system comprises a printing and dyeing device, a washing and drying device, a carding device, a lustring device, a polar fleece treatment device, a shaping device, a plurality of rolling machines and a plurality of unreeling machines, the shaping device comprises two sets of shaping heating rollers and a shaping box; the shaping heating rollers are arranged on the two sidesof the shaping box respectively; a channel for allowing the fabric to pass through is formed in the shaping box; two parallel steam heating plates are arranged at the input end of the fabric channel of the shaping box; and steam nozzles are arranged on the opposite faces of the two steam heating plates. Through multiple high-temperature steam treatment, the fabric has higher adaptability in a hot-pressing high-temperature environment, after subsequent hot-pressing printing, fluff on the surface of the fabric can keep a better standing effect, and the fluff falling resistance of the fabric canbe improved.

Owner:绍兴蓝之印家纺有限公司

Fast ironing machine

ActiveCN107938238AEfficient ironingFast ironingFabric steaming/decatisingTenters/driers accessoriesTemperature senseEngineering

The invention discloses a fast ironing machine. One end of a vertical bar can reciprocally slide along the length direction of a hanging rail, and the other end of the vertical bar is fixedly connected with the middle portion of an ironing head. The ironing head is connected with an ironing machine body through a gas pipe. The outside of the ironing head is provided with a temperature control switch, the temperature control switch is connected with a temperature sensing probe, the temperature sensing probe is fixedly connected with inner wall of the ironing head, a boiling water tank is connected with a water replenishment mechanism, and the boiling water tank is provided with a water level sensor. One end of the water level sensor extends into the boiling water tank, and the other end ofthe water level sensor is connected with a water replenishment mechanism to control the opening and closing of the water replenishment mechanism. A tank cover is provided with a plurality of steam holes. The tank cover is provided with a plurality of supporting columns along the circumferential direction of the tank cover. A spring and a clamp are fixedly connected with the end part, away from a base, of one end of each supporting column in order to fix cloth to be ironed; the periphery of a heating net is fixedly connected with the plurality of supporting columns. The ironing machine is capable of efficiently ironing sheet-like or tileable large pieces of cloth to be ironed.

Owner:芜湖衣码通信息科技有限公司

Fabric ironing machine with drying function

InactiveCN108677447AImprove ironing effectTextiles drying apparatusFabric steaming/decatisingWrinkle skinPulp and paper industry

The invention discloses a fabric ironing machine with a drying function. The fabric ironing machine comprises a base, supporting columns, a first roller body, a second roller body, a worktable, an ironing mechanism and fan mechanisms, wherein the worktable is arranged on the base through the supporting columns; the first roller body and the second roller body are arranged at parts, positioned on the two sides of the worktable, of the upper surface of the base; guide pulleys are arranged on two sides of the worktable; the ironing mechanism is arranged on the upper surface of the worktable; thefan mechanisms are respectively arranged on the two sides of the ironing mechanism; and the wind direction of the fan mechanisms faces downwards. The fabric ironing mechanism solves the problems thatin the prior art, fabric is subjected to wrinkle removal operation by means of steam generally, however, the temperature of the wrinkle-removed fabric is too high, the wrinkle-removed fabric is proneto getting damped, and the fabric is likely to go mouldy after collection.

Owner:WUHU PINDU ELECTRONICS TECH

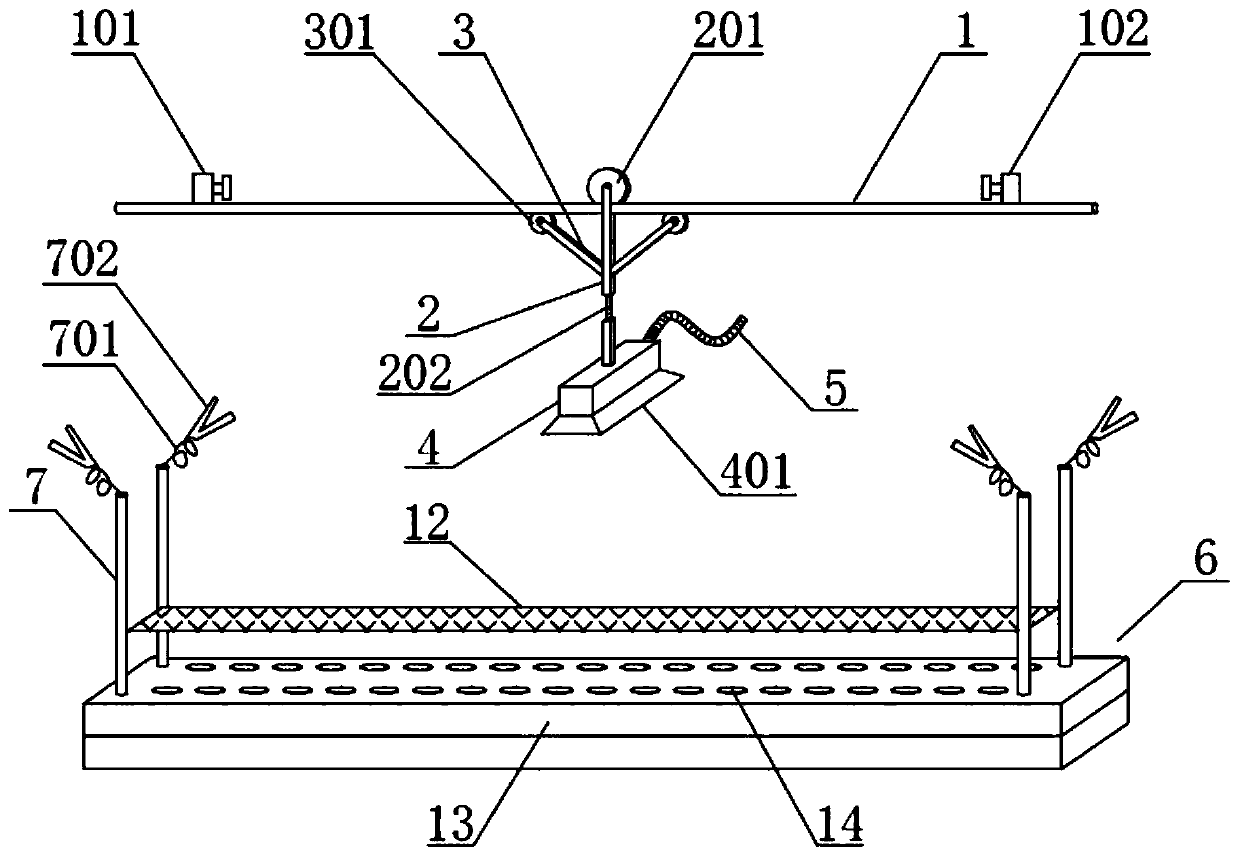

Rapid wall cloth leveling device

ActiveCN113062073AEasy clampingPrevent shrinkageTextiles drying apparatusTextile treatment by spraying/projectingElectric machineElectrical and Electronics engineering

The invention discloses a rapid wall cloth leveling device. The leveling device comprises a leveling cabinet body, an unwinding support frame, a winding support frame, an unwinding shaft, a winding shaft, a winding motor, a primary extrusion device, a secondary anti-shrinkage drying device and a tertiary steam ironing and leveling device, wherein the unwinding support frame and the winding support frame are symmetrically arranged on the two sides of the leveling cabinet body; the unwinding shaft is rotationally arranged on the unwinding support frame; the winding shaft is rotationally arranged on the winding support frame; the winding motor is fixedly connected to the winding support frame; an output shaft of the winding motor penetrates through the winding support frame and is coaxially connected with the winding shaft; the leveling cabinet body is a hollow cavity; and the primary extrusion device, the secondary anti-shrinkage drying device and the tertiary steam ironing and leveling device are sequentially arranged in the leveling cabinet body. The invention belongs to the technical field of wall cloth leveling, and particularly provides the wall cloth leveling device which is convenient to adjust according to the thickness of wall cloth, convenient for rapidly leveling the wall cloth, capable of avoiding shrinkage of the wall cloth and good in leveling effect.

Owner:浙江国富纺织科技有限公司

Cloth ironing device for textile use

InactiveCN112359542AAvoid wrinklesImprove ironing effectBraking element arrangementsFabric steaming/decatisingTextile technologyEngineering

The invention relates to the technical field of textile, and discloses a cloth ironing device for textile use, which comprises a bottom plate, a moving mechanism, a tensioning mechanism and an ironingmechanism. The bottom of the right end of the bottom plate is fixedly connected with the tops of supporting legs; the top of the left end of the bottom plate is fixedly connected with the bottom of asupporting plate; a top plate is arranged above the bottom plate; the bottom of the left end of the top plate is fixedly connected with the top of the supporting plate; a pressing plate I is arrangedabove the bottom plate; and the left end of the pressing plate I is fixedly connected with the inner wall of a groove formed in the right side of the top end of a movable plate. According to the cloth ironing device for textile use, a winding roller can be rotated by starting a driving motor to wind a steel wire rope, so that a circular plate I can move downwards, and a movable rod can deflect; and a circular plate II can extrude an L-shaped plate leftwards through deflection of the movable rod, the L-shaped plate can move leftwards, finally, the movable plate can move leftwards, and broken cloth is tensioned, so that an ironing effect is better.

Owner:绍兴市柯桥再晨纺织品有限公司

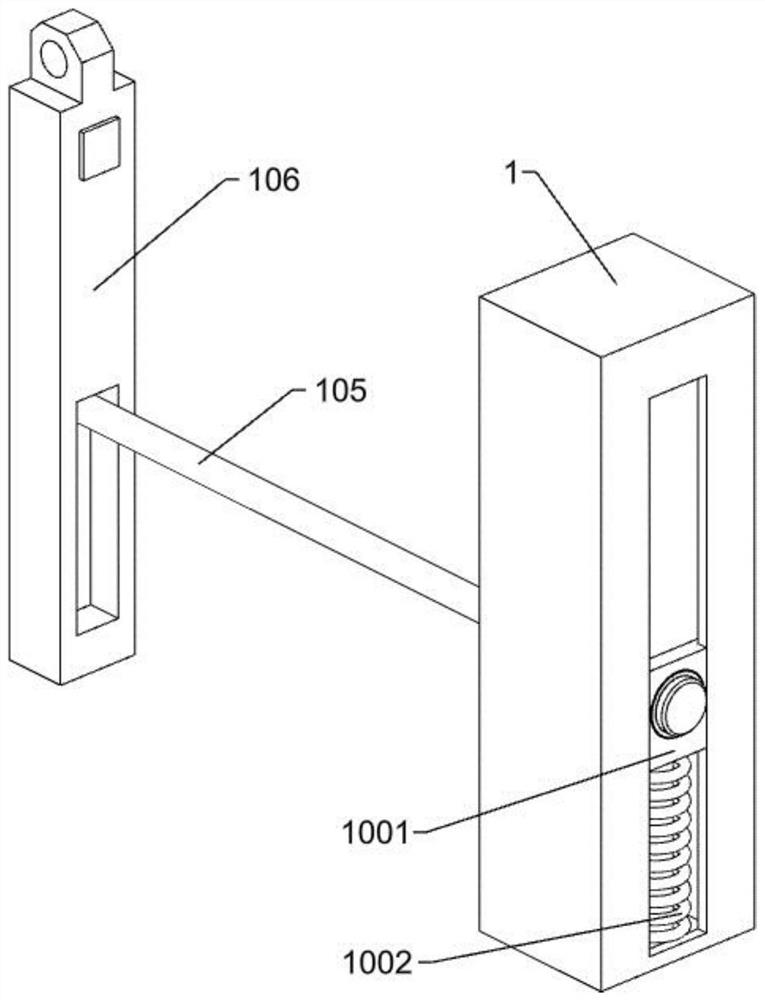

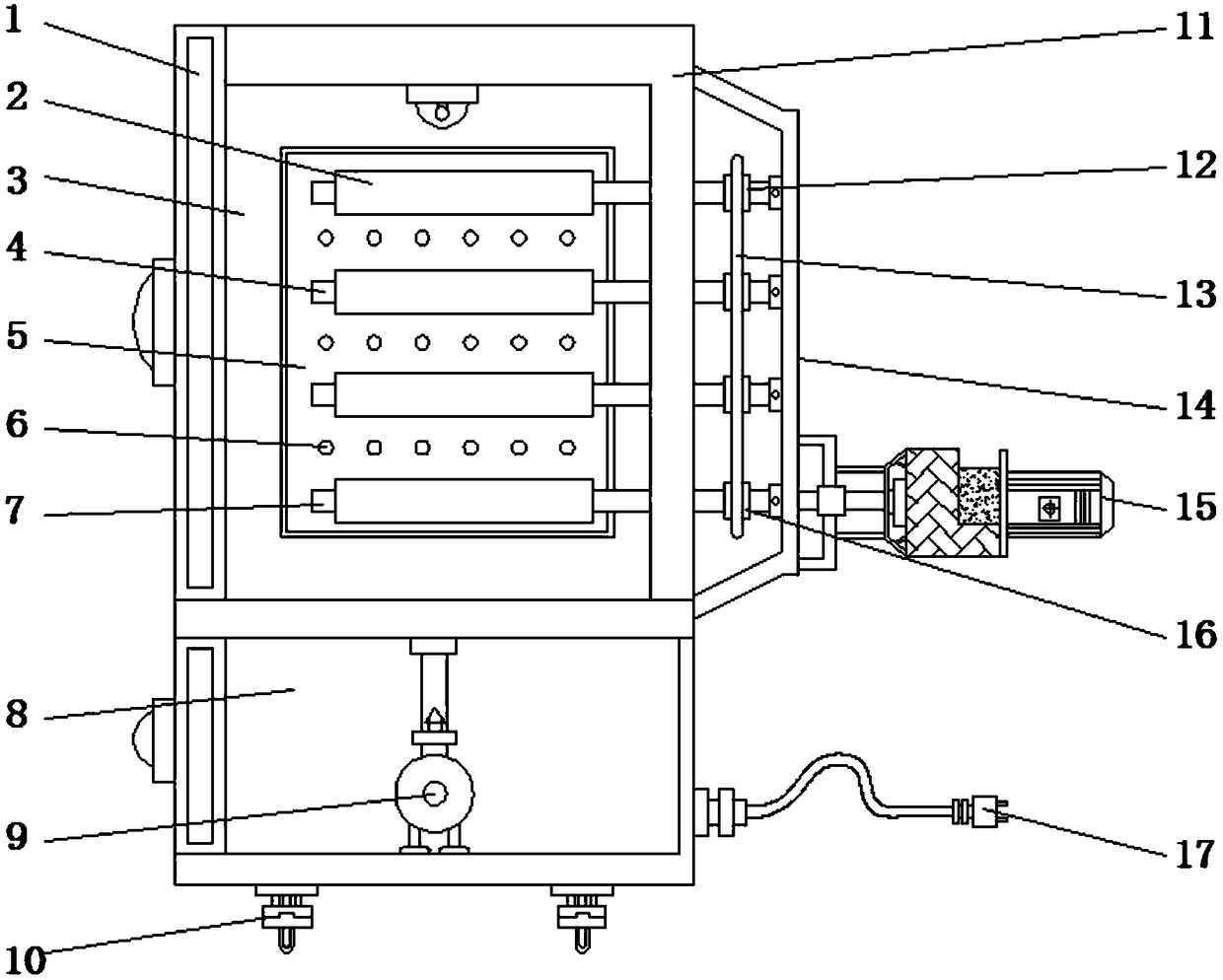

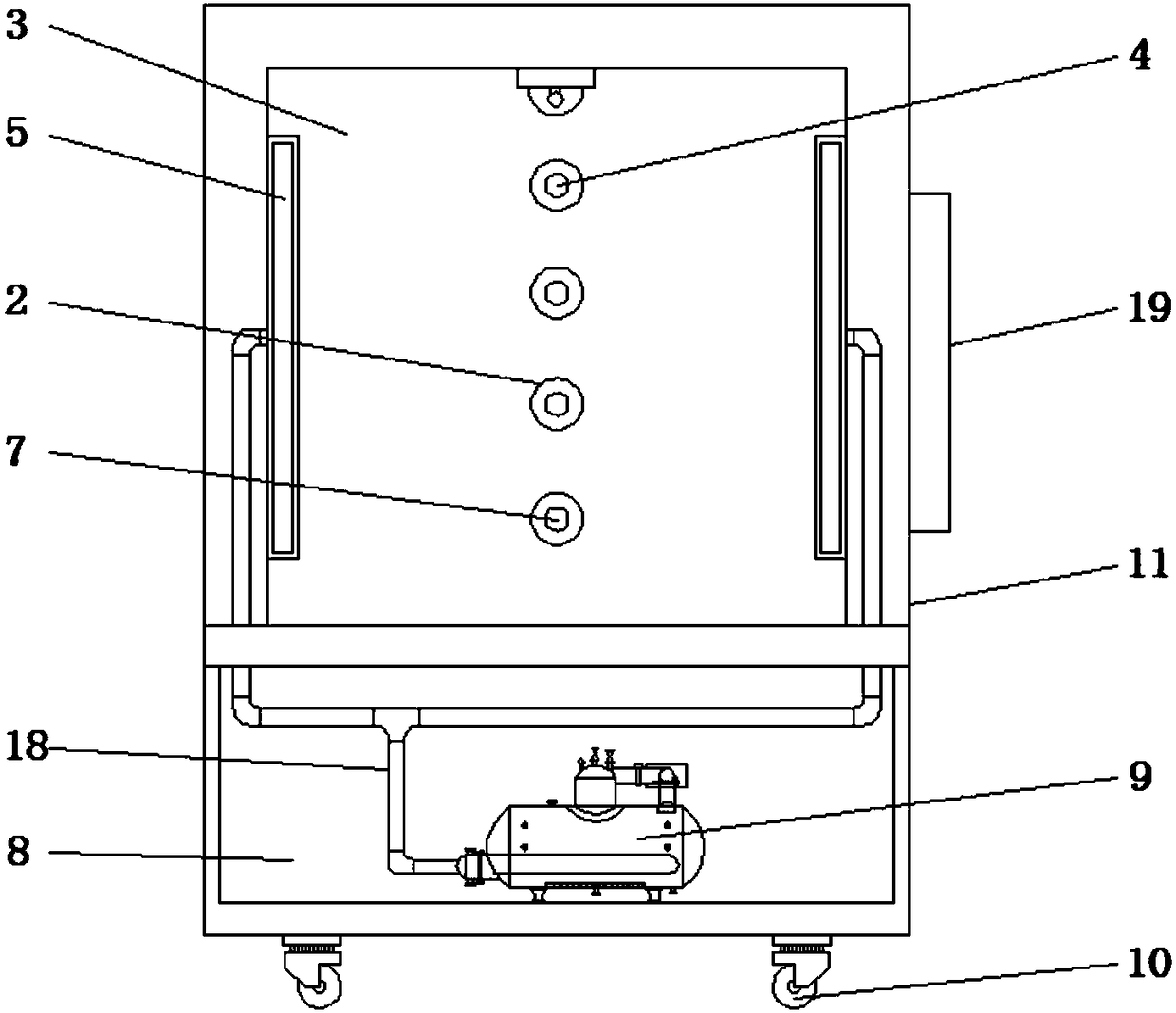

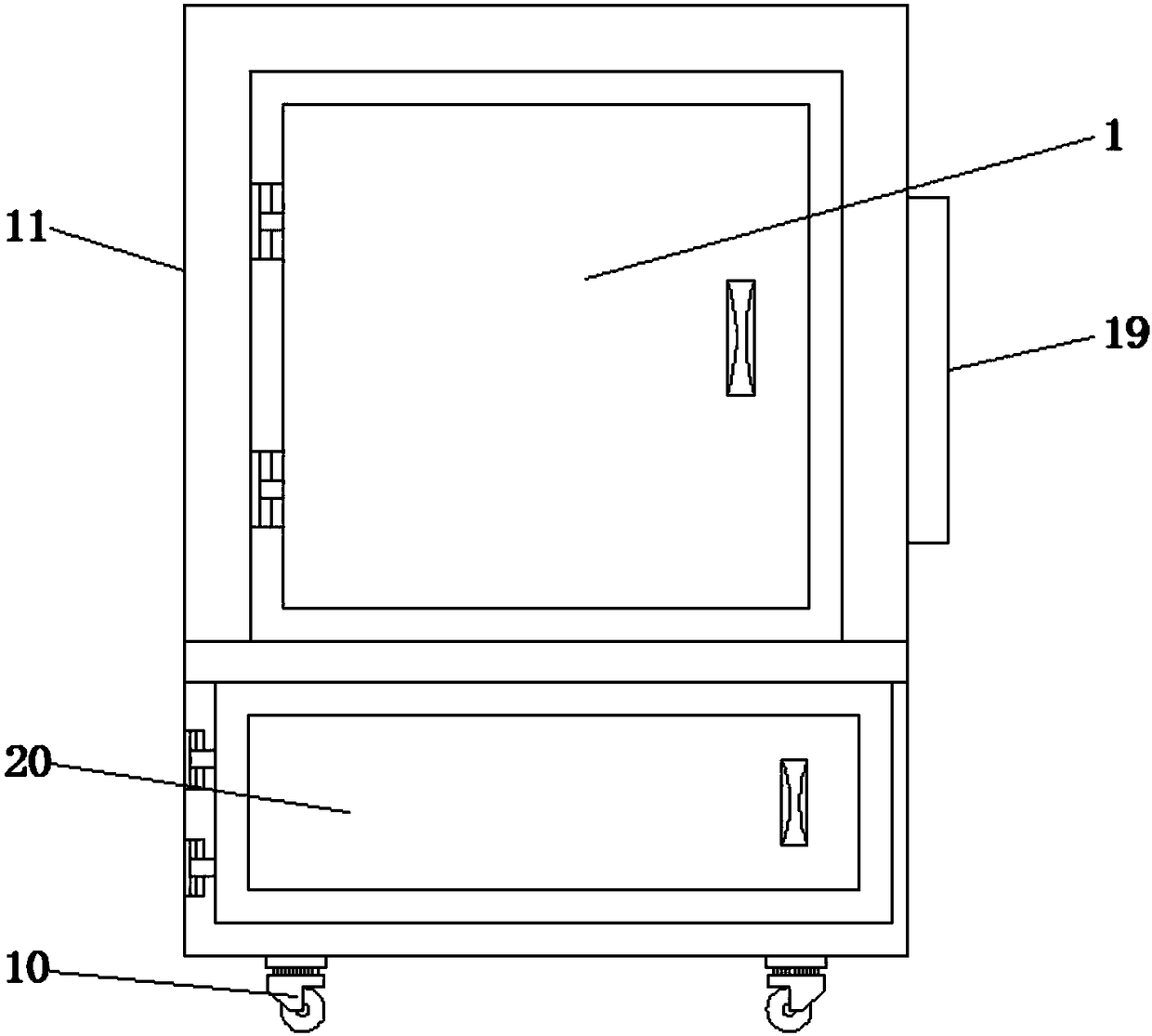

Steam shaping device for stab-resistant garment production

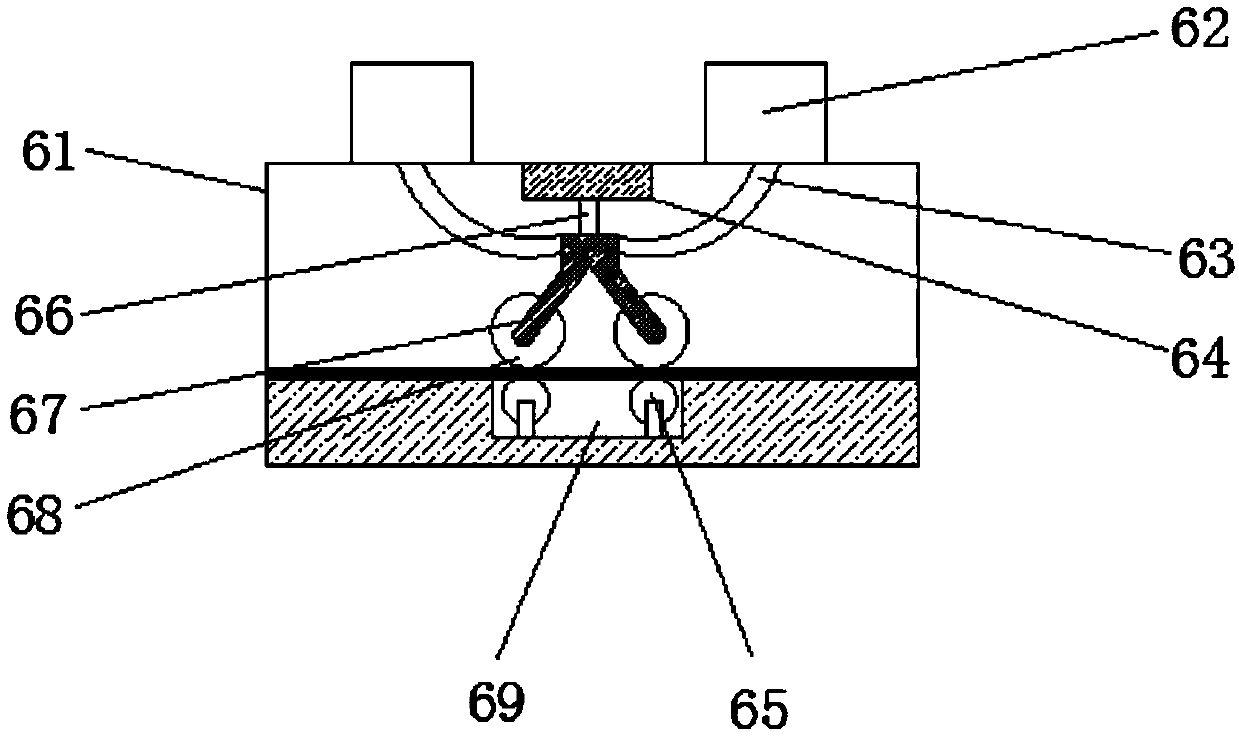

ActiveCN113403792AImprove styling efficiencyLeveling achievedFabric finishing guides/expandersFabric steaming/decatisingMechanical engineeringPleat

The invention discloses a steam shaping device for stab-resistant garment production. The steam shaping device for stab-resistant garment production comprises a box body, wherein a steam generator is fixedly installed on the side wall of the box body; the output end of the steam generator is connected with a gas conveying pipe; two connecting plates are connected onto the outer wall of the gas conveying pipe; nozzles communicated with the interior of the gas conveying pipe are arranged on the opposite sides of the two connecting plates; a rotating rod is installed in the box body and is fixedly sleeved with a sleeve plate; and the two connecting plates are distributed on the upper side and the lower side of the sleeve plate. According to the steam shaping device for stab-resistant garment production provided by the invention, cloth sleeving the sleeve plate is pushed and pulled to be quickly leveled, so that the situation that the setting quality is affected due to wrinkles of the cloth is avoided; and cloth setting is accelerated by spraying steam up and down, and the cloth can be directly taken down from the sleeve plate after setting, so that discharging is convenient.

Owner:南通市通州区顺行纺织有限公司

steam ironing machine

ActiveCN107904848BEfficient ironingFast ironingFabric steaming/decatisingEngineeringMechanical engineering

Owner:芜湖衣码通信息科技有限公司

After-finishing process for textile fabric

The invention discloses an after-finishing process for a textile fabric. The dyeing and finishing process of the textile fabric is characterized by comprising the following steps: (1) fabric refining;(2) singeing; (3) desizing; (4) water processing; (5) steam treatment; (6) soft baking; (7) tentering; (8) reeling; (9) packaging of end product. No chemical additive is adopted by the after-finishing process for the textile fabric disclosed by the invention, so that the environmental pollution is reduced while the weaving process is simplified and the function of protecting human health is achieved; the color and luster of the fabric can be improved and the variegating phenomenon can be avoided through the water processing and the steam treatment; the elasticity of the fabric is promoted through the treatment of soft baking, tentering and high-temperature setting; the product has ultrahigh market competitiveness.

Owner:南通茂业针织服饰有限公司

Device used for weaving

ActiveCN107956028ARemove creasesRealize intermittent transmissionLoomsAuxillary apparatusPulp and paper industry

The invention relates to the technical field of weaving, and especially relates to a device used for weaving. The device comprises a transmission table, a transmission roller used to transmit a clothon the transmission table, and a wind-up roller used to wind up the cloth. The wind-up roller is on a discharge end of the transmission table. The transmission roller comprises a roller body, a pressing column, and a smoothing platform. The roller body is internally provided with a steam channel. The roller body is provided with an air outlet hole and a sliding hole. The sliding hole is internallyslidably connected with a sliding rod. The sliding rod is fixedly connected with the smoothing platform. A spring is arranged between the smoothing platform and the roller body. The pressing column is used to insert into the steam channel and control sliding of the sliding rod. The pressing column is provided with a blocking column used to block the air outlet hole. An end of the transmission roller is rotatably connected with a steam pipe. One end of the pressing column, close to the steam pipe, can contact with an orifice of the steam pipe. The transmission roller is also provided with a positioning portion used to fix the pressing column in the steam channel. The pressing column, the sliding rod, and the smoothing platform are made of a heat conduction material. The scheme can eliminate folds on a surface of the cloth.

Owner:NINGBO HIGH TECH ZONE SHENGWENTU TEXTILE CO LTD

Special decatizing oven

InactiveCN103741413AUniform and comprehensive humidification and shrinkage processLabor savingTextile treatment machine partsHeating/cooling textile fabricsEngineering

The invention discloses a special decatizing oven comprising a drying oven, a decatizing oven body and a shaping oven. The drying oven is arranged at the front end of the decatizing oven body, the shaping oven is arranged at the rear end of the decatizing oven body, two steam intake pipes are arranged inside the decatizing oven body, and the decatizing intake pipes are respectively connected with six down-spraying steam pipes in an upper humidifying steam cover and six up-spraying steam pipes in a lower humidifying steam cover. By the arrangement, drying, humidifying and shaping effects of the special decatizing oven are achieved; fabric before garment manufacturing can be evenly and fully subjected to humidifying and shrinking processes prior to being transferred into an ordinary oven for the shaping process, so that the drying, humidifying and shaping processes can be scheduled and specialized, manual work is reduced, production efficiency is greatly improved, and energy-saving and environment-protection effect is achieved.

Owner:无锡市信文机械制造有限公司

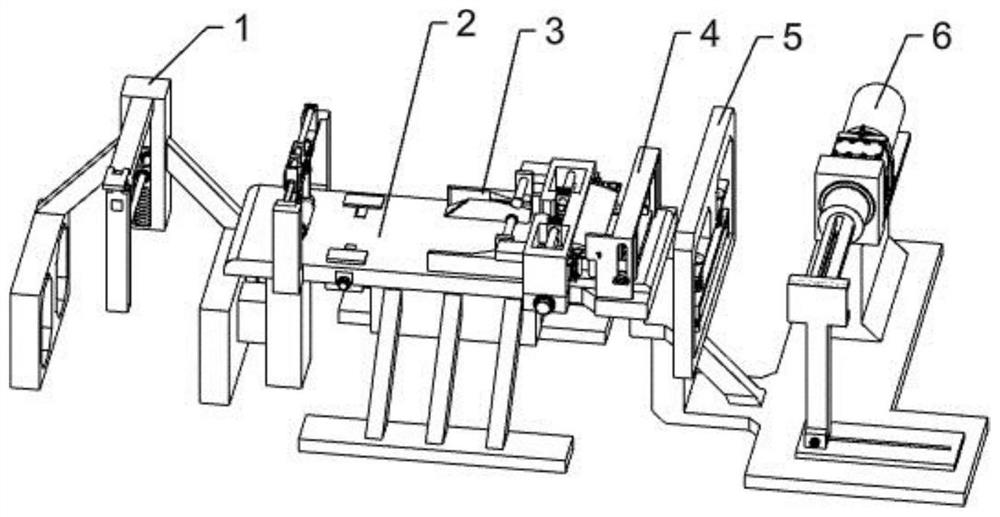

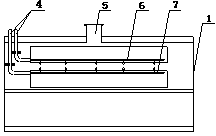

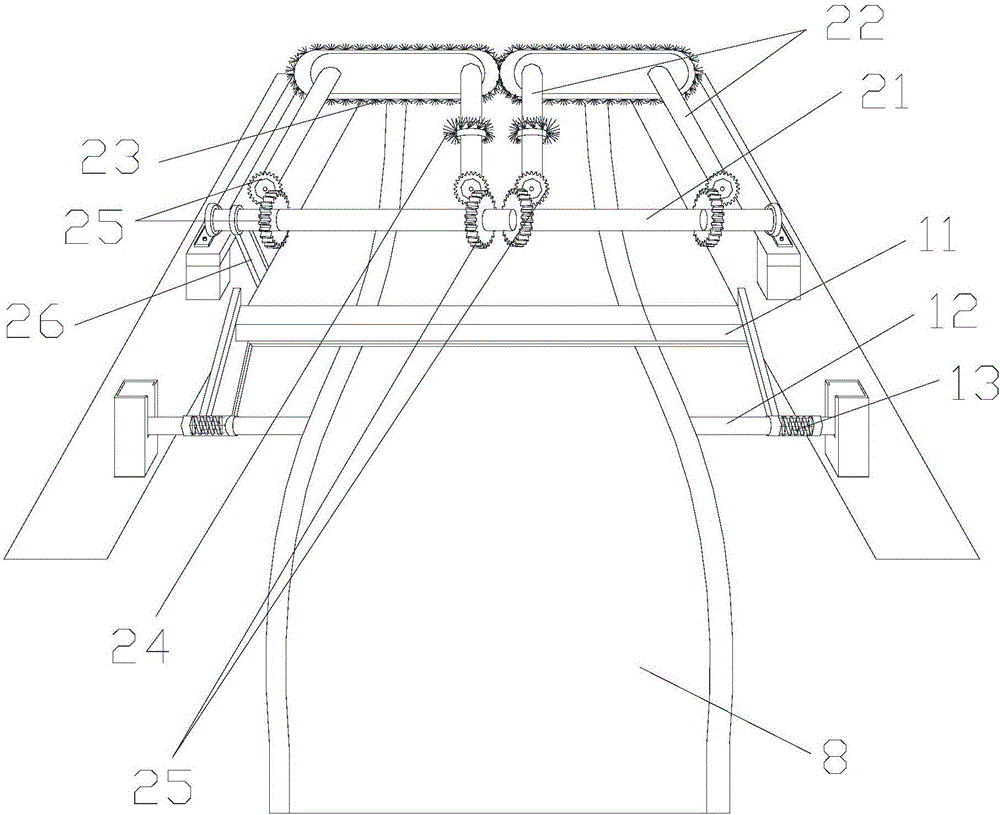

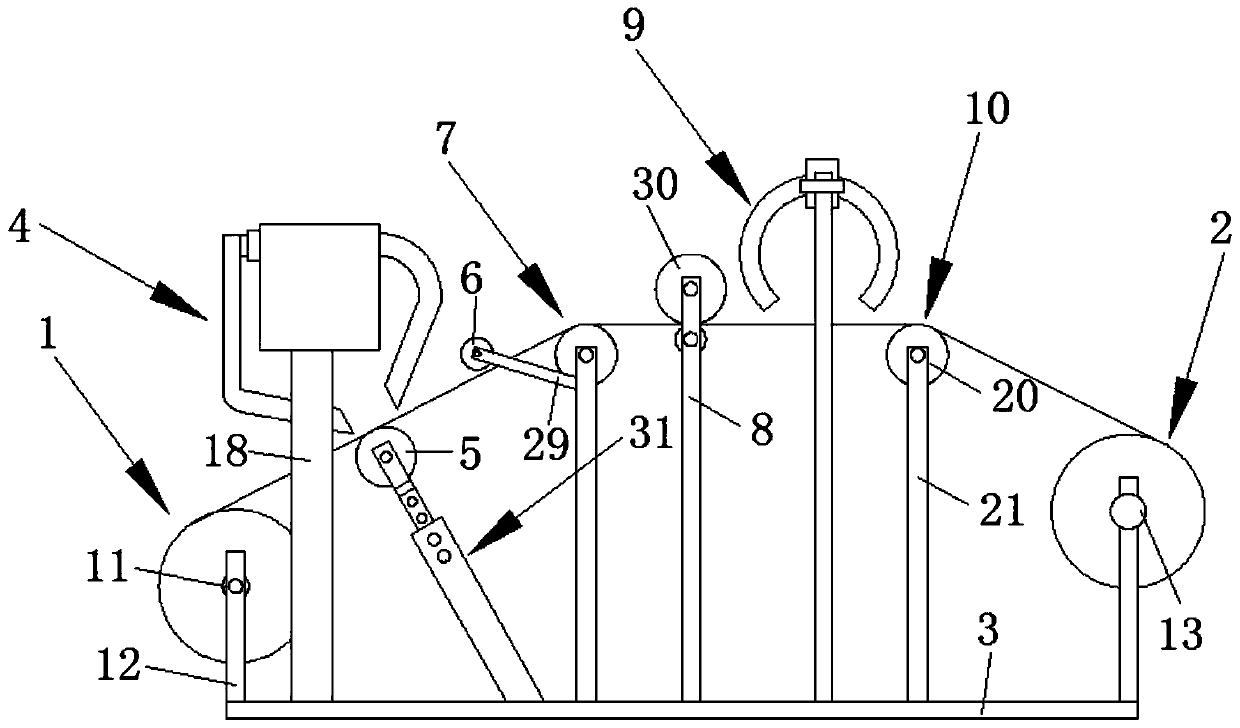

Turned edge removing, ironing and setting machine for large scarf

ActiveCN105755725AGood for curlingImprove processing efficiencyTextile selvedgesFabric steaming/decatisingSpray nozzleINTRODUCTION device

The invention relates to a turned edge removing, ironing and setting machine for a large scarf.The turned edge removing, ironing and setting machine comprises an introduction device, a turned edge removing device, an ironing device and an output device which are sequentially mounted on a rack, a workblank frame is placed in front of the introduction device, and a feeding box is placed behind the output device; a feeding roller in the introduction device is provided with a scarf pressing frame through an elastic device; a drive rotating shaft in the turned edge removing device and driven rotating shafts are in transmission connection through bevel gears, caterpillar brushes and rolling brushes are mounted on the driven rotating shafts, and the drive rotating shaft is connected with a motor through a belt; water vapor spray nozzles are formed among upper ironing shaft rollers in the ironing device and are connected with a steam device through a steam pipe, and lower ironing shaft rollers are connected with a heating device; a tension frame in the output device is located behind an output shaft roller.The turned edge removing, ironing and setting machine has the advantages of being good in turned edge removing rate, high in machining efficiency and convenient to use.

Owner:桐庐手套总厂

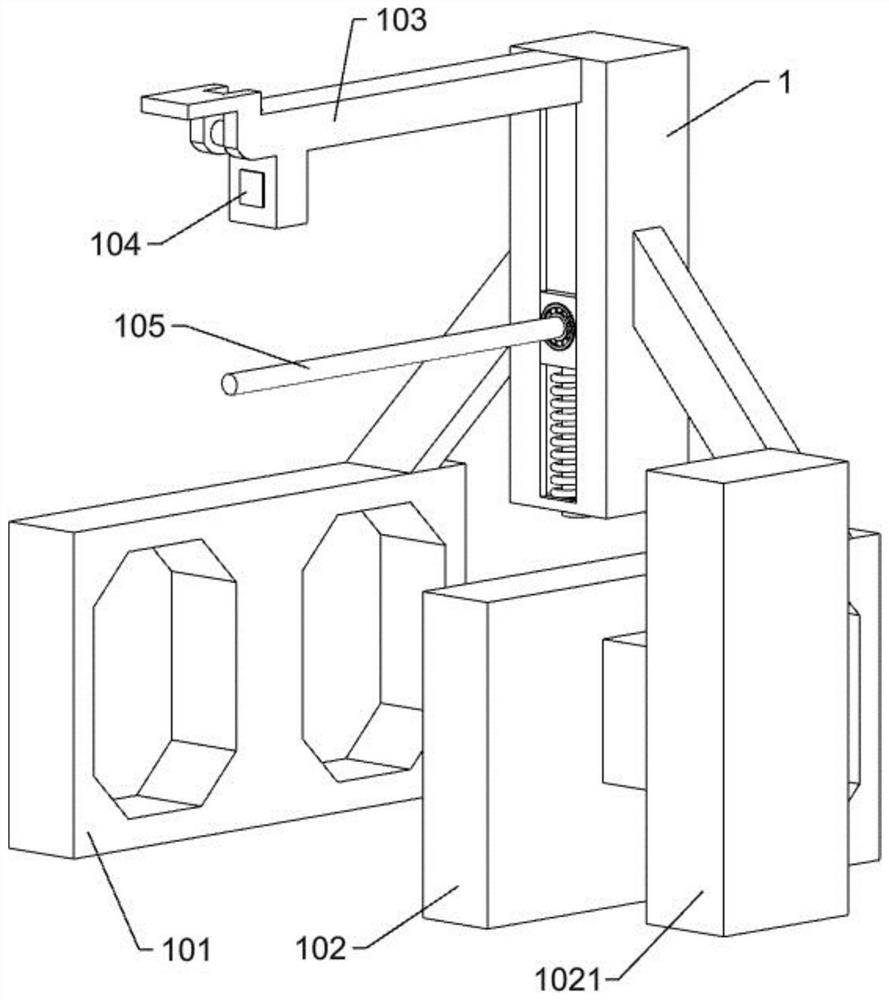

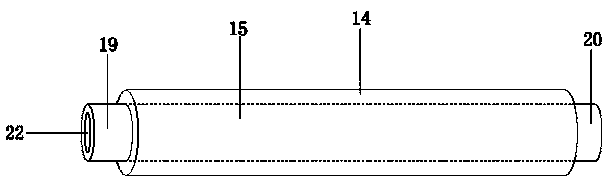

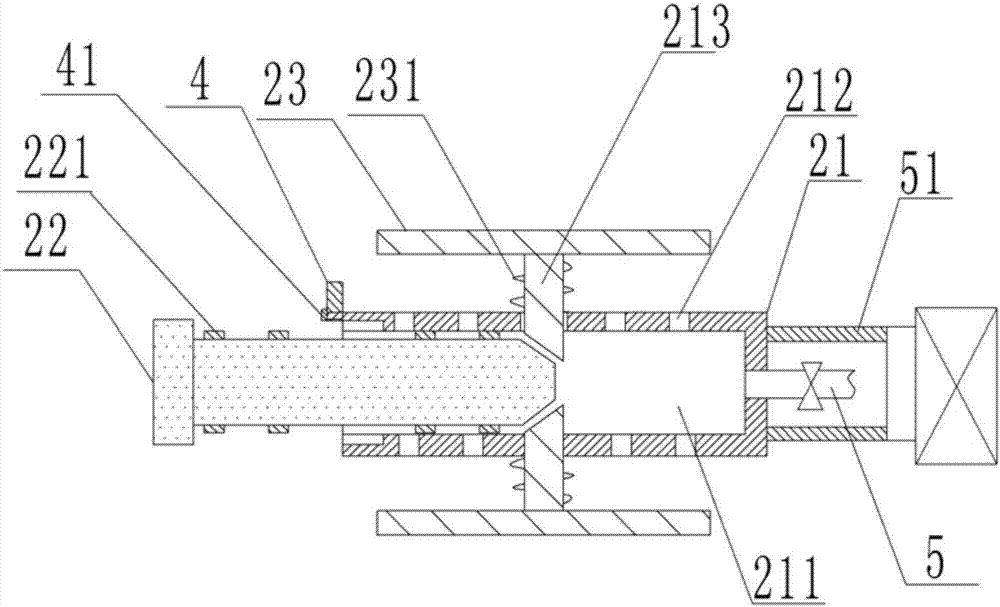

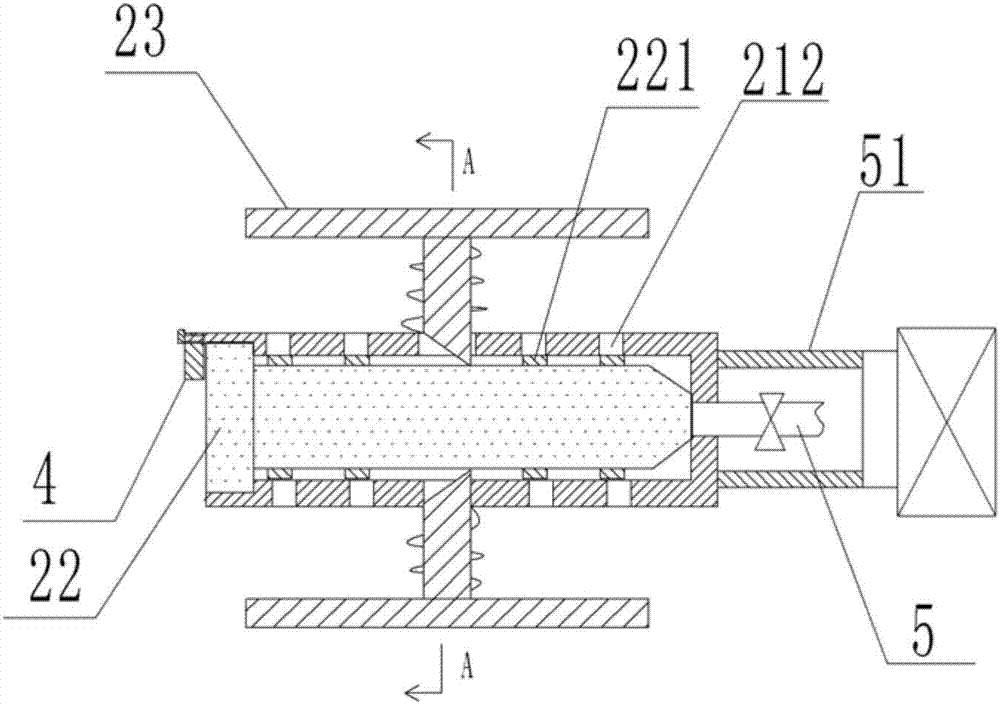

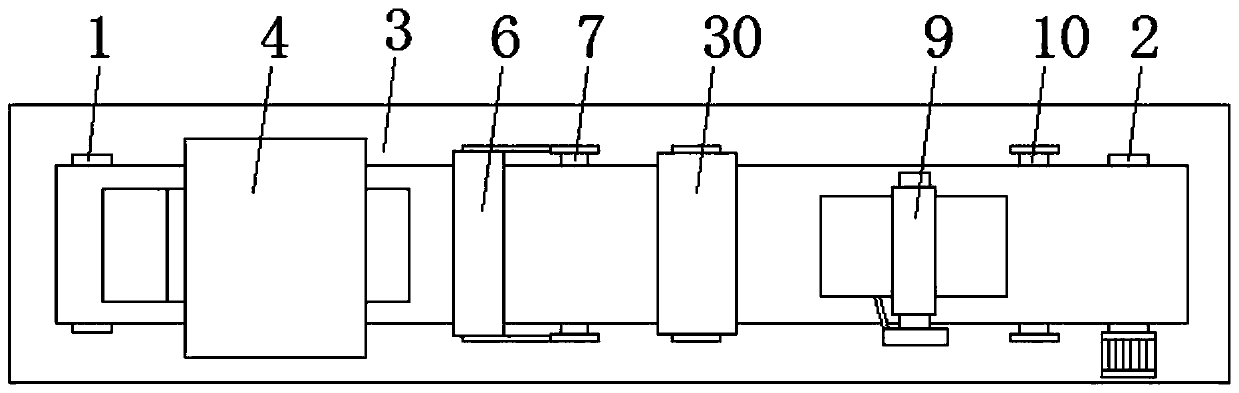

Rotary hot roller matching pair mechanism with steam self-positioning spraying function

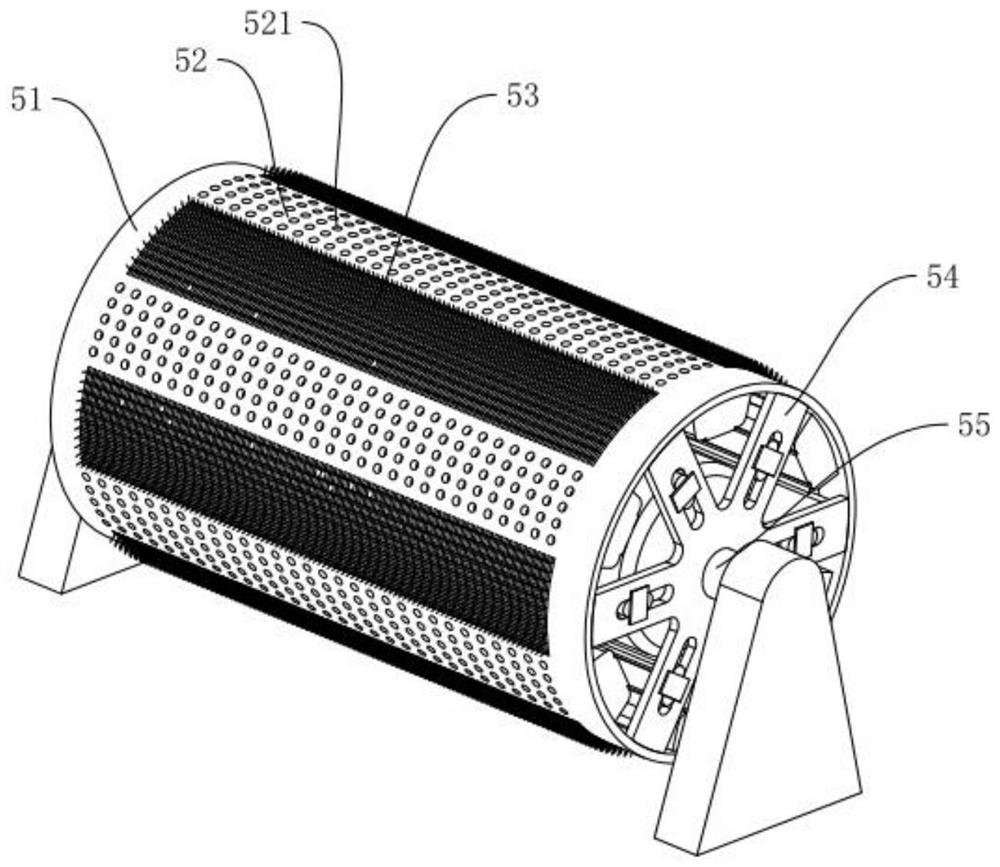

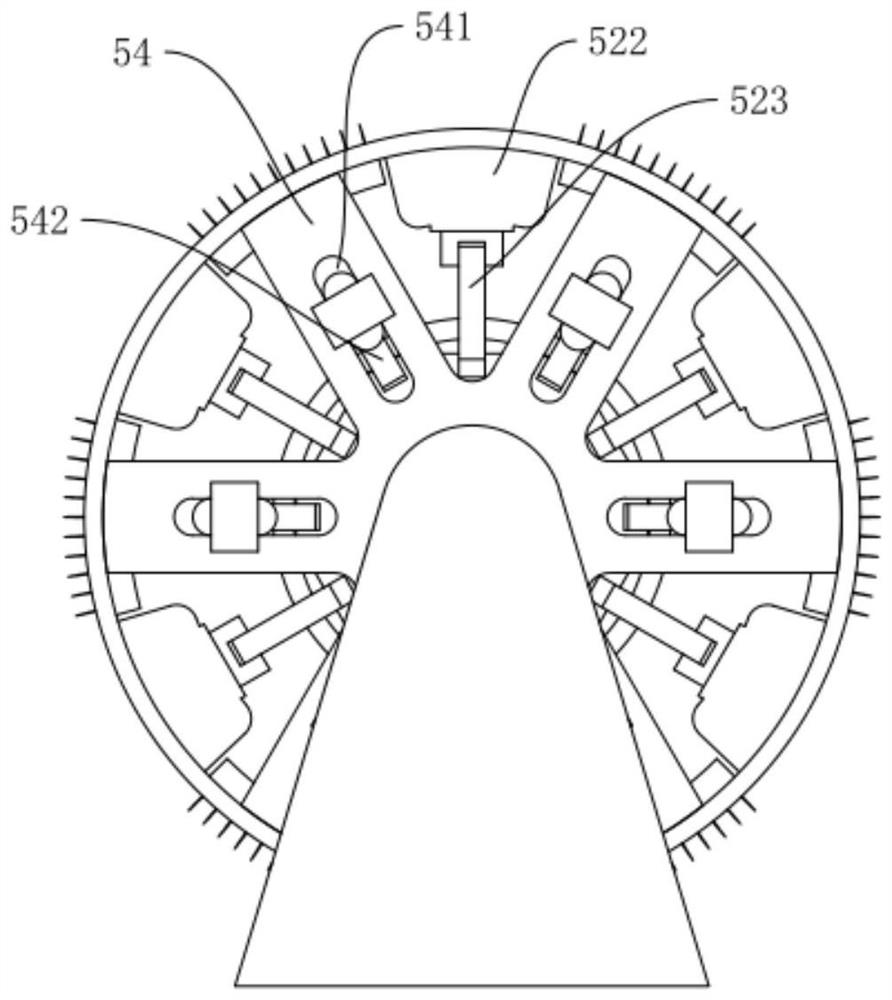

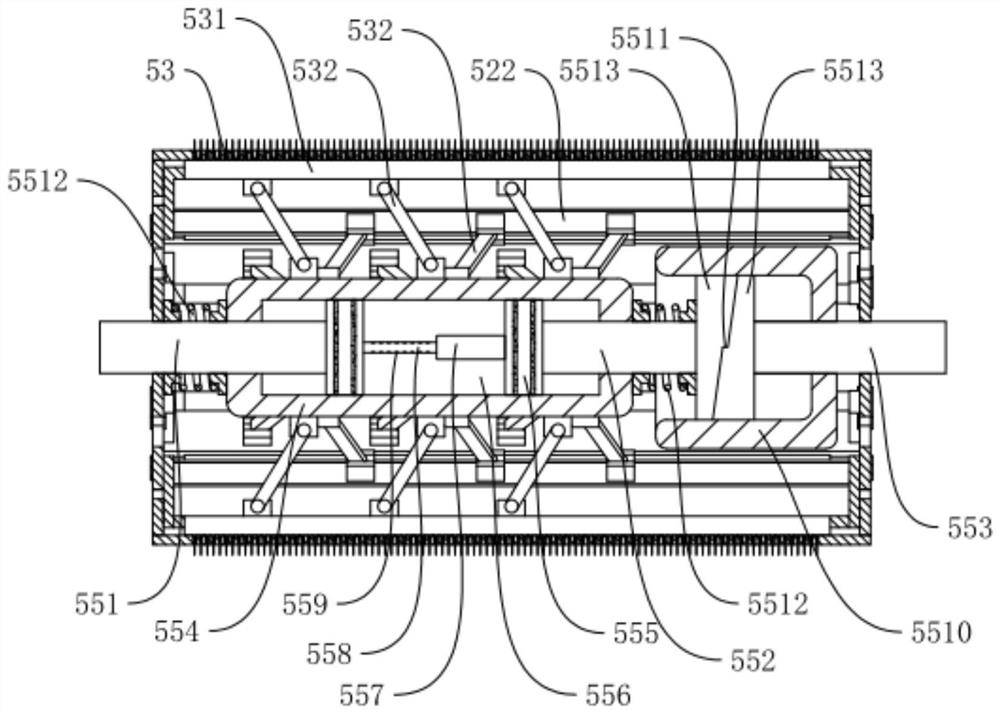

PendingCN112709036AReduce volumeCompact structureFabric steaming/decatisingLiquid/gas/vapor textile treatmentEngineeringMechanical engineering

The invention discloses a rotary hot roller matching pair mechanism with a steam self-positioning spraying function. The rotary hot roller matching pair mechanism comprises an ironing unit, a pair of guide rails, a pair of driving units, a supporting plate and a pair of limiting units; the ironing unit comprises a rotatable first roller and a rotatable second roller, heating and steam structures are arranged in the first roller and the second roller correspondingly, and heating ironing and steam ironing can be conducted on an ironed object at the same time; the first roller and the second roller are mounted on the guide rails and can move on the guide rails; the driving unit is used for controlling the horizontal distance between the first roller and the second roller; the limiting units are mounted at the two ends of the first roller and used for limiting the position of the first roller on the guide rails. The heating and the steam structures are arranged in the rollers, the heating ironing function and the steam ironing function can be achieved at the same time, the size of a roller ironing mechanism is smaller, the structure is more compact, miniaturization and automation of a roller ironing device can be achieved more easily, and the rotary hot roller matching pair mechanism can be better popularized and popularized in the market.

Owner:中国计量大学上虞高等研究院有限公司 +1

Fabric embossing technology for windproof outdoor jacket production

ActiveCN110080005AImprove qualityReduce the possibility of circulationPattern makingFabric steaming/decatisingElectricityCoupling

The invention discloses a fabric embossing technology for windproof outdoor jacket production. The device comprises a fabric feeding piece, a heating dust removal device, a pressure regulating deviceand a fabric retracting piece, wherein the fabric feeding piece and the fabric retracting piece are respectively connected with the two ends of fabric; both the fabric feeding piece and the fabric retracting piece are fixedly welded with the top end of a supporting plate; the heating dust removal device, the pressure regulating device, an ion stick, a first steering piece, a supporting piece a cooling device and a second steering are arranged from the left part to the right part in sequence between the fabric feeding piece and the fabric retracting piece; an embossing roller is further mountedon a supporting plate of the supporting piece; the fabric is arranged between the supporting piece and the embossing roller; each of the e fabric feeding piece and the fabric retracting piece comprises a fabric winding roll and a vertical plate; rotating shafts are fixedly welded with the two ends of the fabric winding roll; one group of rotating shafts of the fabric retracting piece is connectedwith an output shaft of a rotating motor through a coupling. The device can not only perform heating, humidification, impurity removal and electricity removal in the early stage, but also perform aircooling in the late stage.

Owner:刘卫进

Electrochemical bleaching and setting process for ultrasonic-plasma pretreatment of black horsetail hair

InactiveCN109487531AReduce tanglingImprove preprocessing effectHeating/cooling textile fabricsUltrasonic/sonic fibre treatmentPlasma technologyFatty alcohol

The invention discloses an electrochemical bleaching and setting process for ultrasonic-plasma pretreatment of black horsetail hair. The process includes washing the black horsetail hair with a detergent, adding medium water, and preforming ultrasonic treatment; then adopting a plasma technology to preform pretreatment; dissolving penetrants of fatty alcohol polyoxyethylene ether and sodium silicate in water, adjusting the pH value, adding hydrogen peroxide, heating the solution, fixing the obtained pretreated black horsetail hair on an anode of a graphite electrode, setting electric field power, preforming electrochemical bleaching treatment, washing with water, and drying; soaking the bleached and decolorized horsetail hair in distilled water, controlling the water content, setting the setting temperature, and setting in wet heat; and stretching and thinning the wet heat-set horsetail hair, pre-steaming and then stretching, steaming, washing with water, treating the hair with a setting agent, steaming and setting, washing with water, treating with boiling water, and air drying.

Owner:太和县兴阳鬃尾有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com