Rotary hot roller matching pair mechanism with steam self-positioning spraying function

A self-positioning, hot roller technology, applied in the field of ironing, can solve the problems of bulky and complex structure of the roller ironing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the specific embodiments shown in the accompanying drawings, but these embodiments do not limit the present invention, those of ordinary skill in the art make structural, method, or functional changes based on these embodiments All are included in the scope of protection of the present invention.

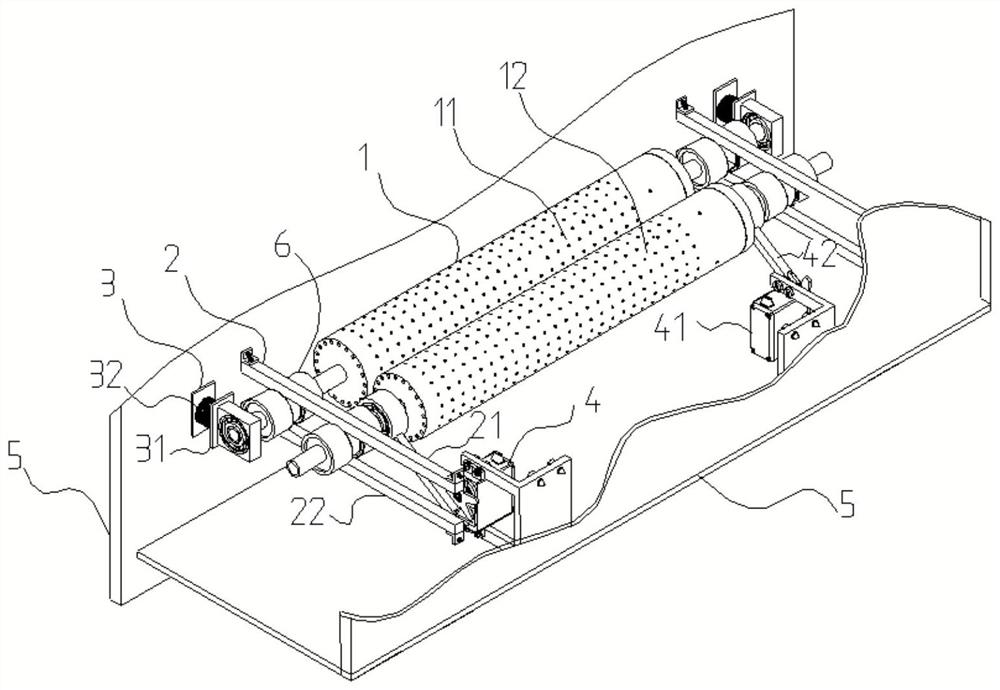

[0042] Such as Figure 1 to Figure 5 As shown, a rotating hot roller matching mechanism with steam self-positioning injection function, which can simultaneously heat iron and steam iron ironing objects; it includes an ironing unit 1, a pair of guide rails 2, and a pair of driving units 4 , support plate 5, a pair of limit units;

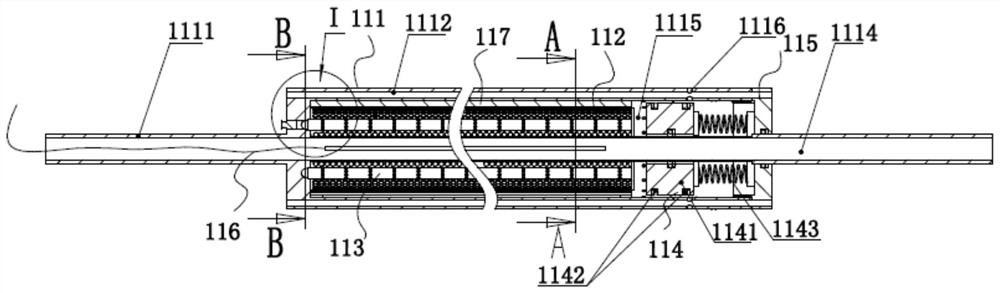

[0043] The ironing unit 1 includes a rotatable first cylinder 11 and a rotatable second cylinder 12; the first cylinder 11 and the second cylinder 12 are installed horizontally and the horizontal distance between the first cylinder 11 and the second cylinder 12 can be adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com