Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

190results about How to "Improve ironing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

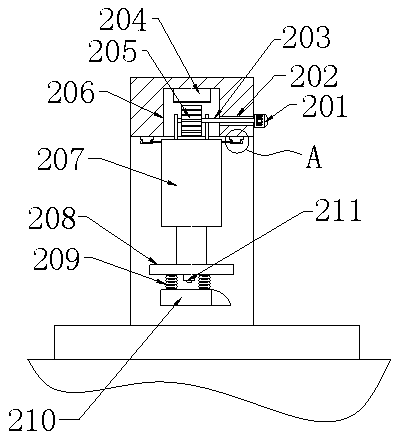

Hand-hold steam brush with steam jet intensity adjustable

ActiveCN104831510AImprove ironing efficiencyGood removal effectIroning apparatusTextiles and paperHand heldEngineering

The invention discloses a hand-hold steam brush with steam jet intensity adjustable, and belongs to clothing ironing equipment. For an existing hand-hold steam brush, the steam jet intensity cannot be adjusted, and the removal effect of the steam jet intensity on stubborn folds is poorer. According to the hand-hold steam brush with the steam jet intensity adjustable, a steam output adjusting mechanism is assembled in a machine body and connected with a switching part which is located on the exterior of the machine body and is capable of switching working positions; when the switching part is located on one working position, the steam output adjusting mechanism jets steam produced by a steam generator from a steam outlet under a lower pressure, that is to say, ordinary steam is jetted; when the switching part is located on the other working position, the steam output adjusting mechanism jets the steam produced by the steam generator from the steam outlet under a higher pressure, that is to say, powerful steam is jetted, therefore, the ironing efficiency of a user is effectively promoted, and a better removal effect on the stubborn folds can be achieved by utilizing the powerful steam.

Owner:NINGBO KAIBO GROUP

Clothing Steam Ironing Apparatus

ActiveUS20130086954A1Good effectImprove ironing efficiencyTextile treatment machine partsOther washing machinesEngineering

Owner:ZHANG YUNFENG

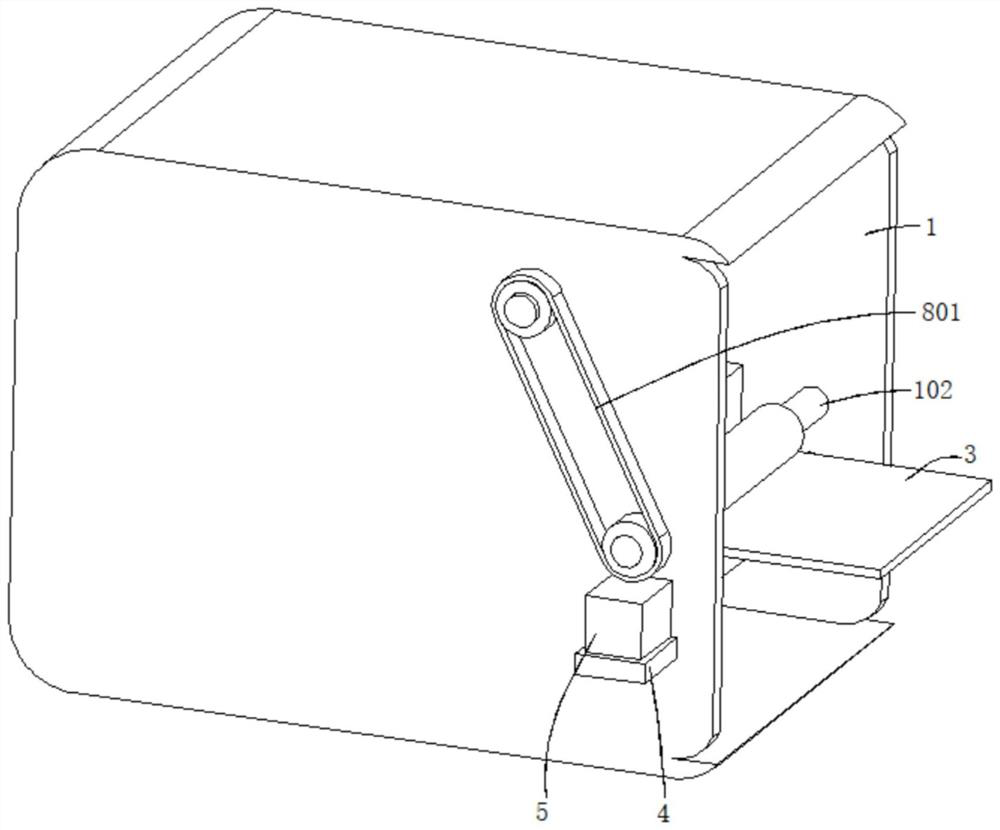

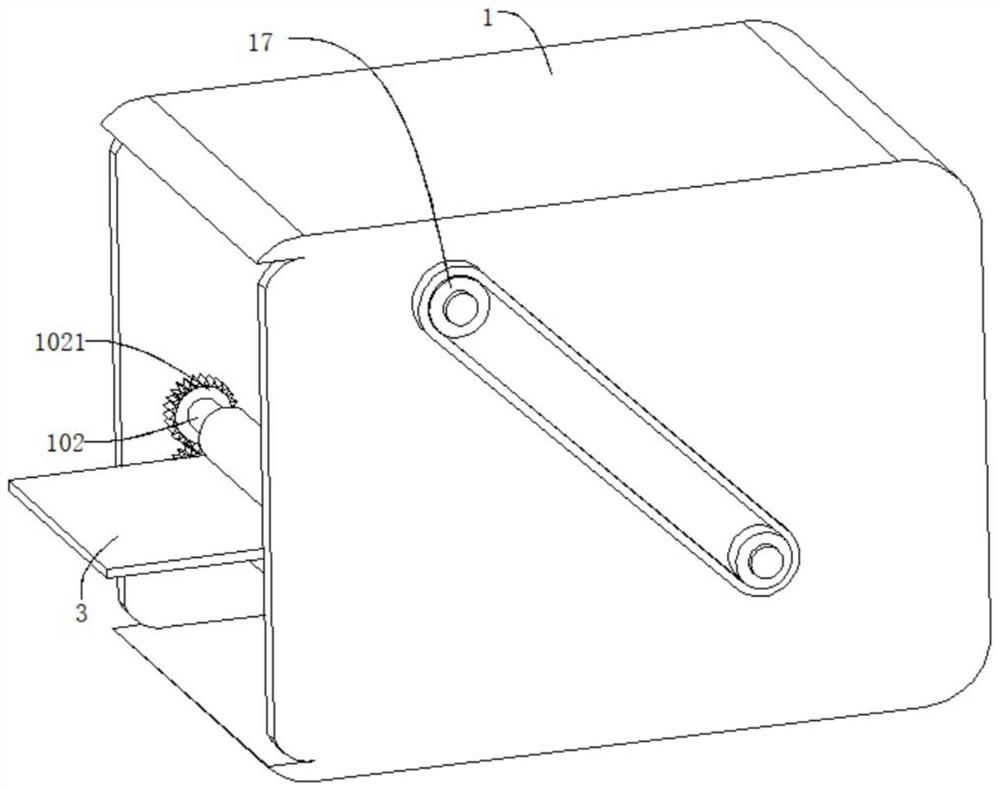

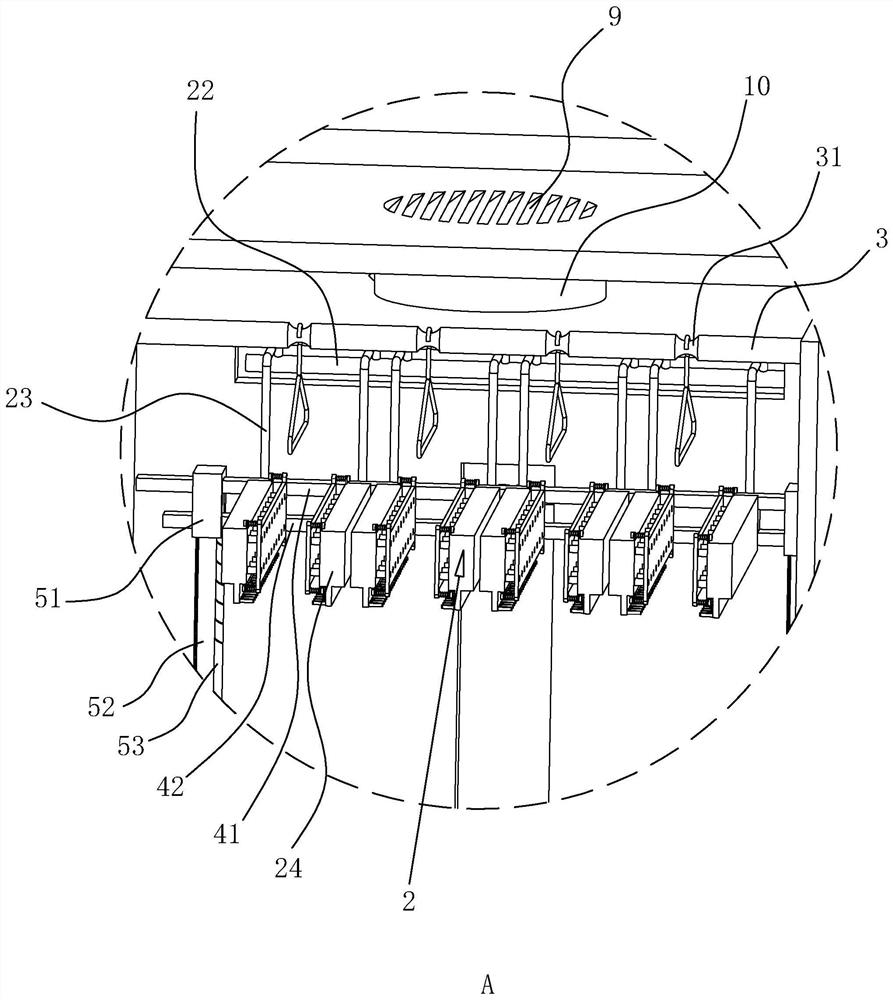

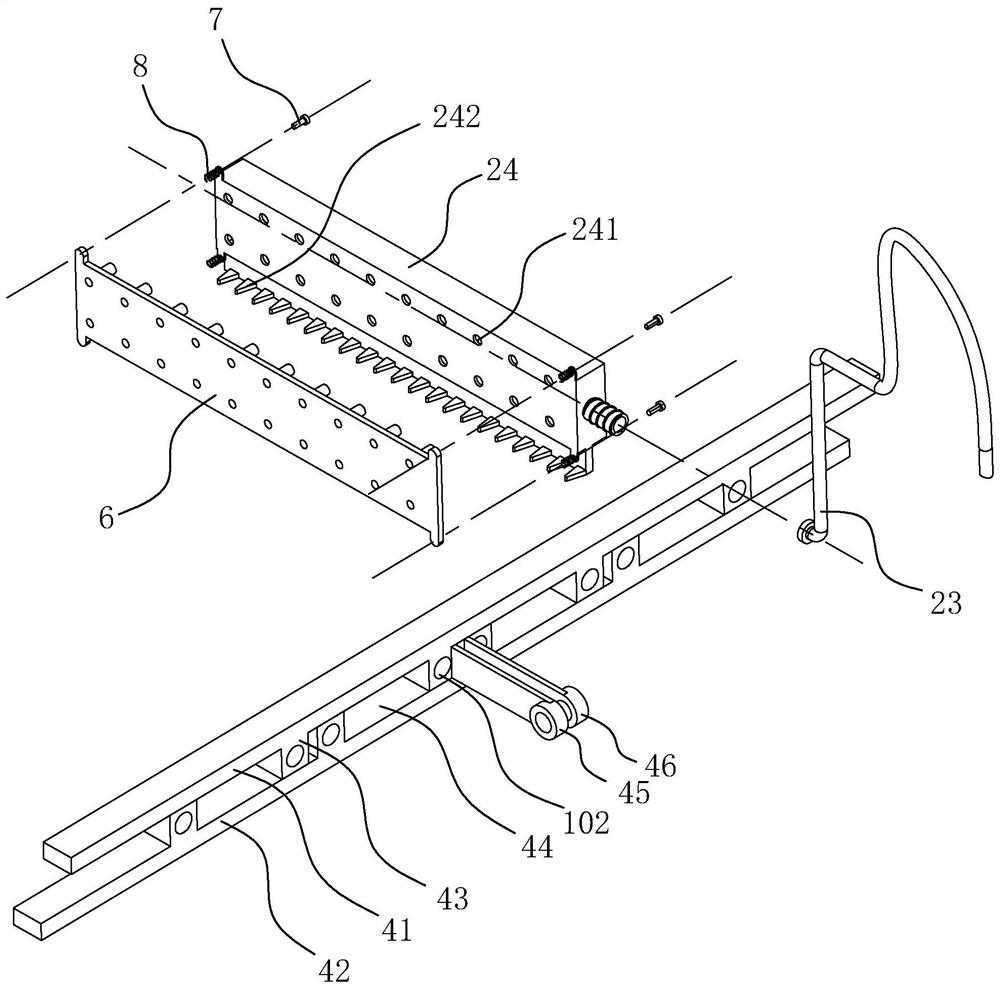

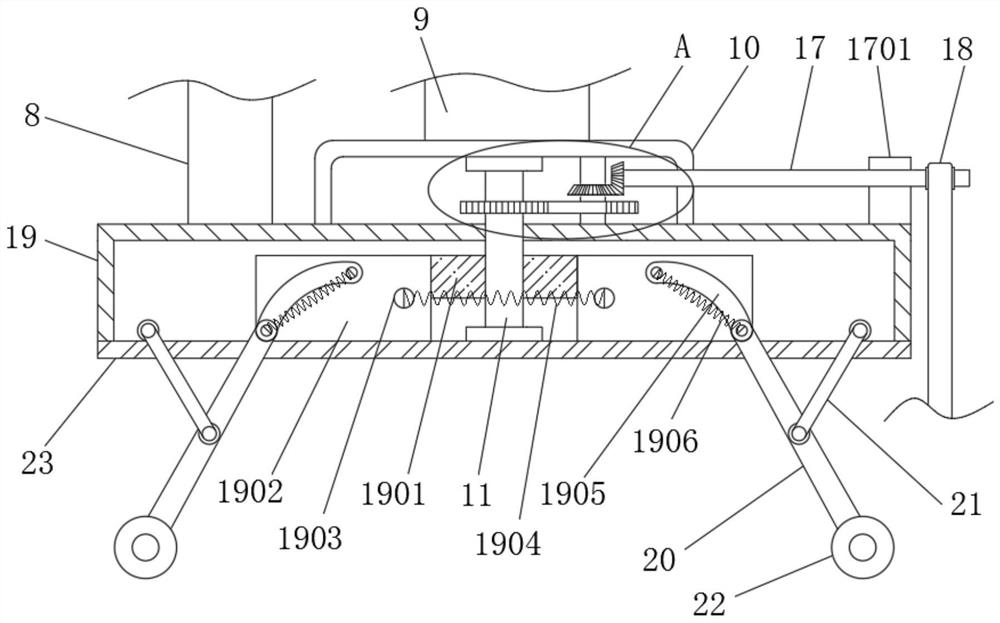

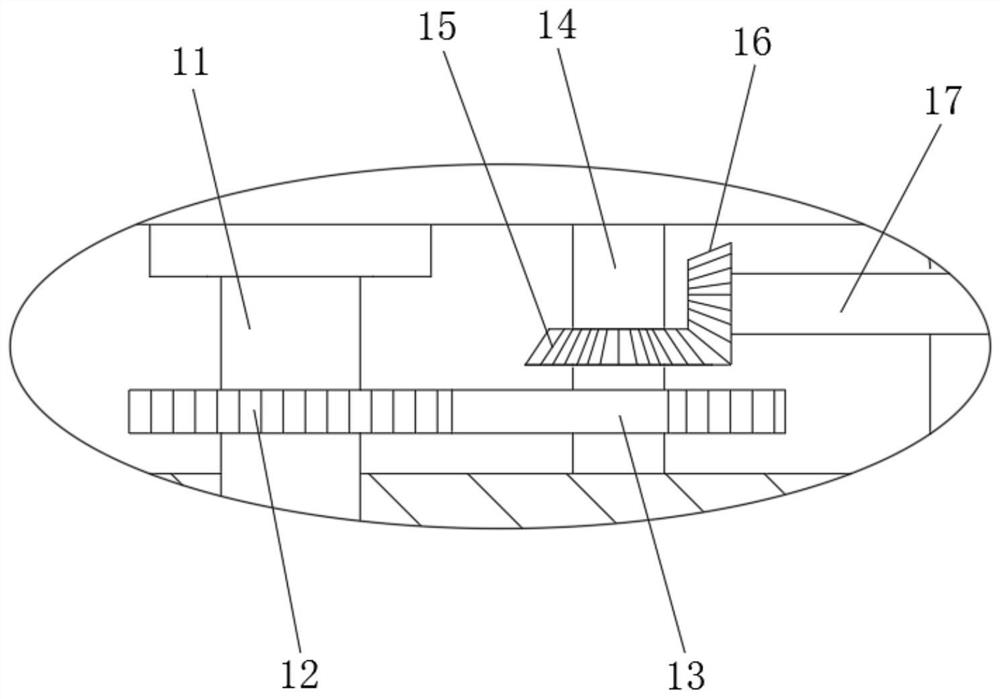

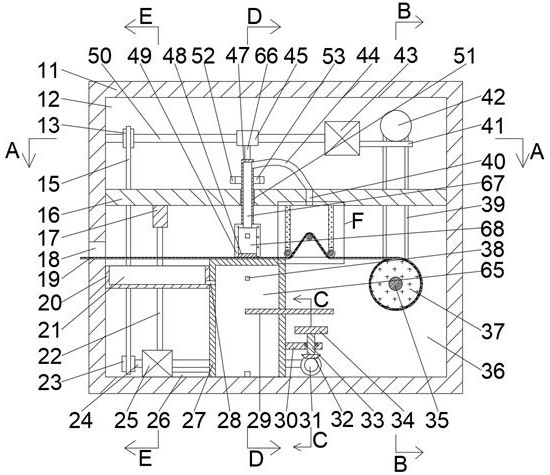

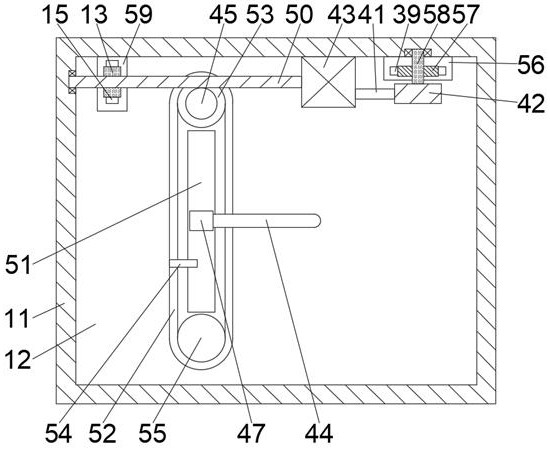

Hair sticking and ironing all-in-one machine

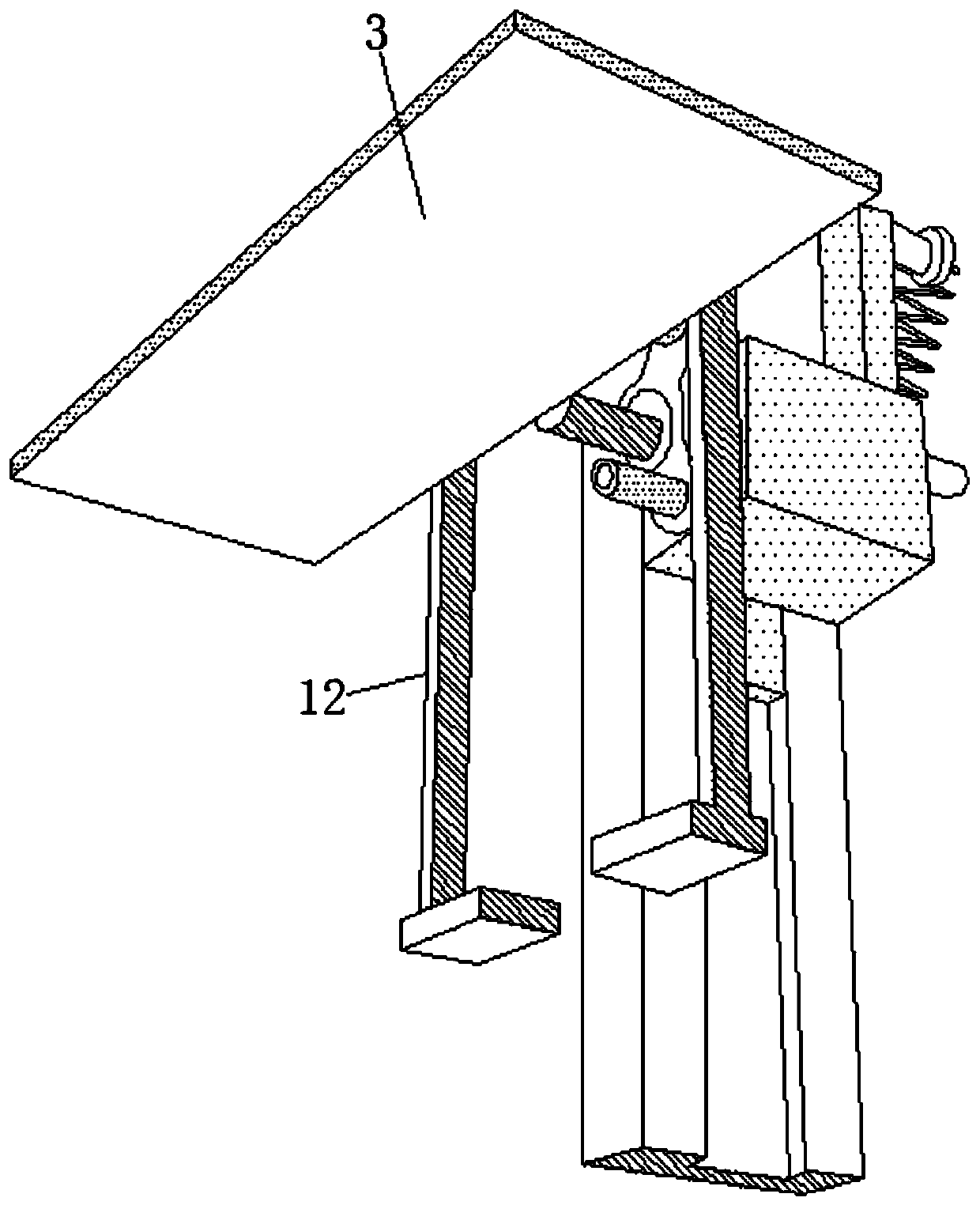

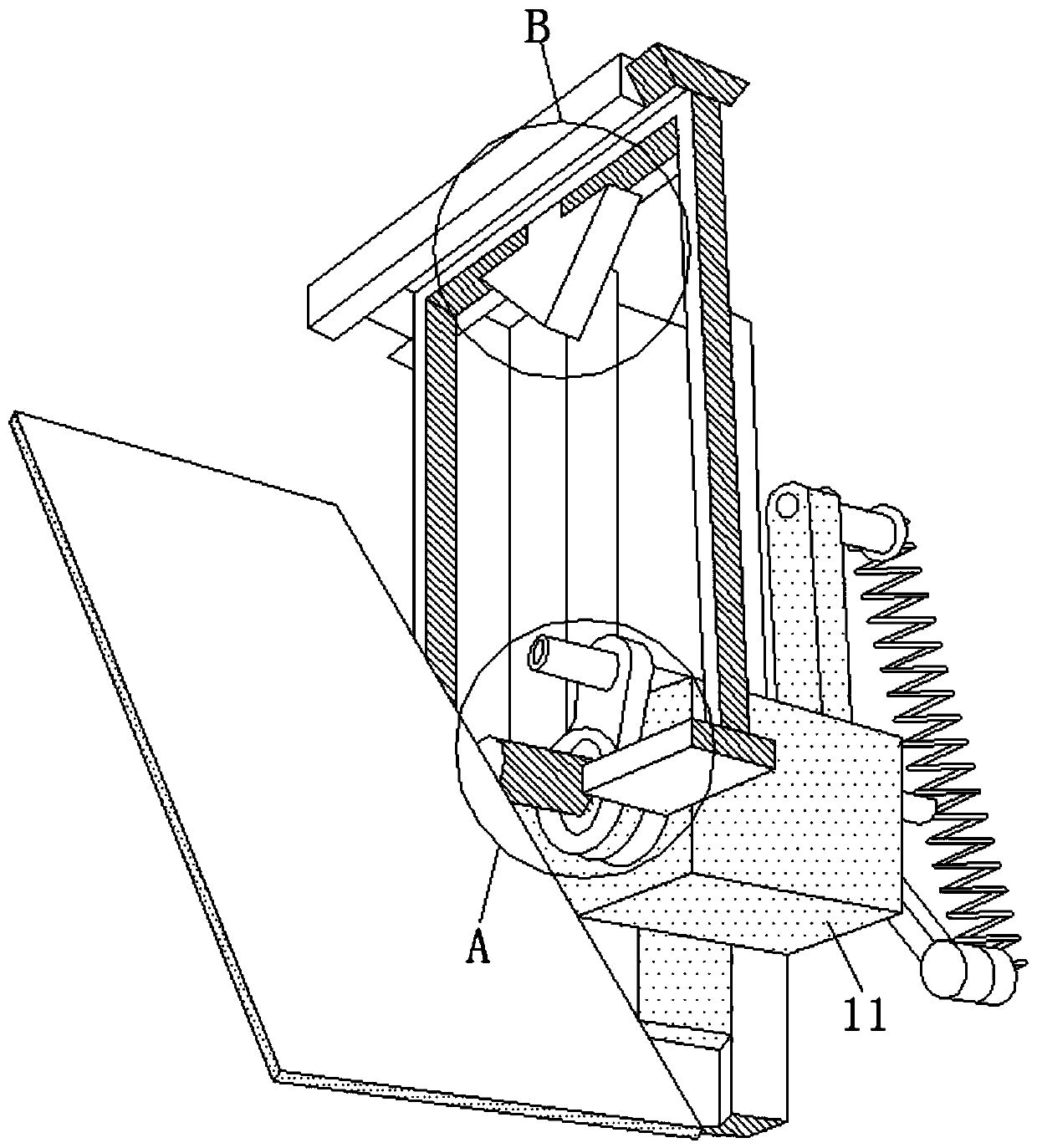

InactiveCN108729176ARealize automatic foldingRealize fully automatic sticky hair ironingIroning boardsHousehold cleanersEngineering

The invention discloses a hair sticking and ironing all-in-one machine. The hair sticking and ironing all-in-one machine comprises a machine body, and a lifting and overturning integrated transmissionmechanism which is mounted and fixed on the machine body, wherein the lifting and overturning integrated transmission mechanism is provided with a lifting ironing seat and an apparel fabric overturning mechanism; the machine body is provided with an ironing positioning mechanical arm; the ironing positioning mechanical arm is provided with a hair sticking and ironing seat. According to the hair sticking and ironing all-in-one machine, the hair sticking and ironing seat is positioned through the ironing positioning mechanical arm and clothes can be automatically ironed; two hair sticking barrels are arranged on the hair sticking and ironing seat and can be used for sticking hairs and ironing at the same time; meanwhile, people do not need to hold an ironing machine by hand to carry out ironing for a long time, and the problems of an existing clothes ironing process that the hairs need to be stuck and then the clothes can be ironed so that the ironing speed is relatively low, and scaldsare caused by the fact that the ironing machine is held by hand are solved.

Owner:NANTONG YOUYUAN ART PATTERN DESIGN CO LTD

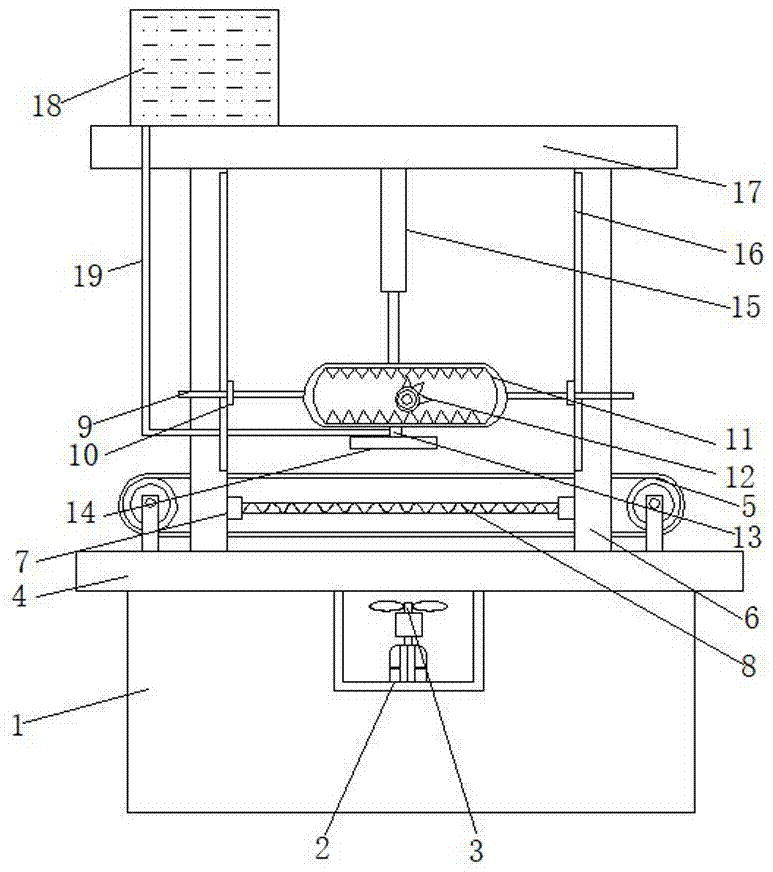

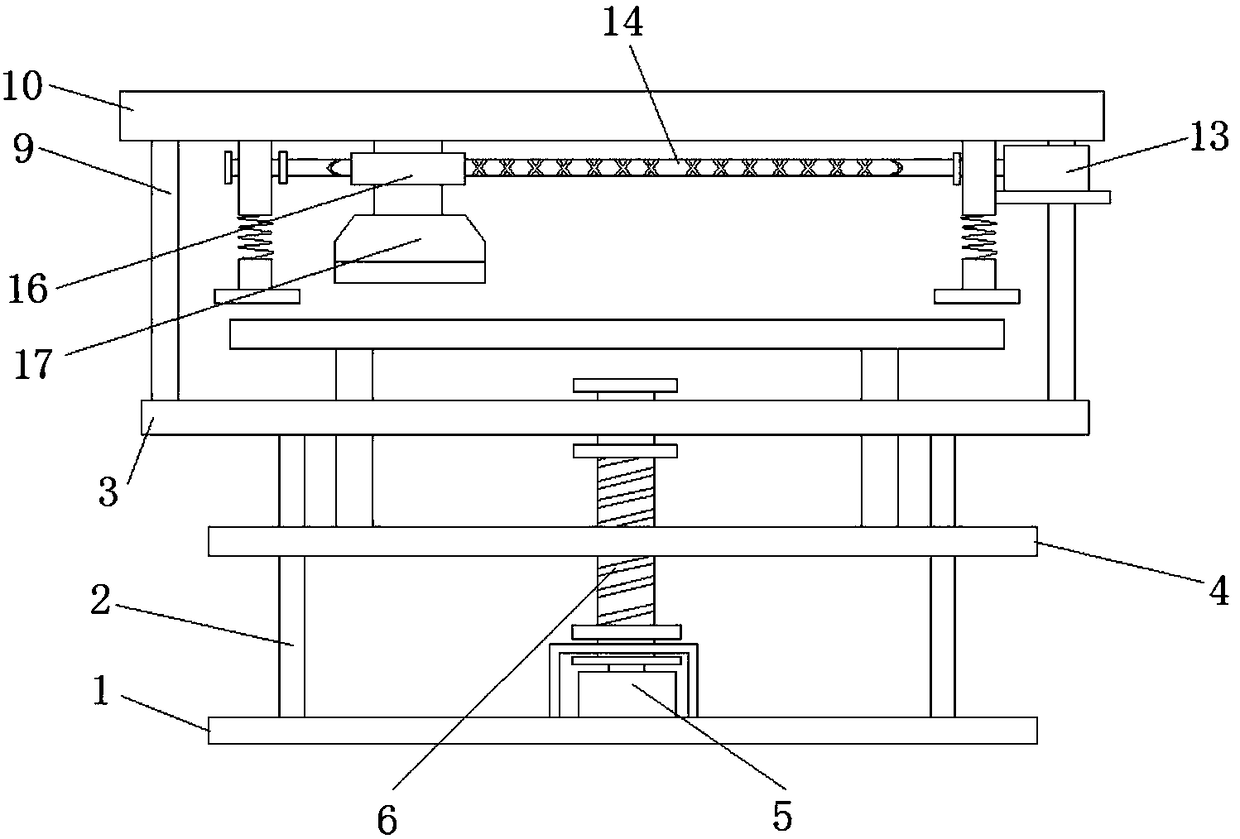

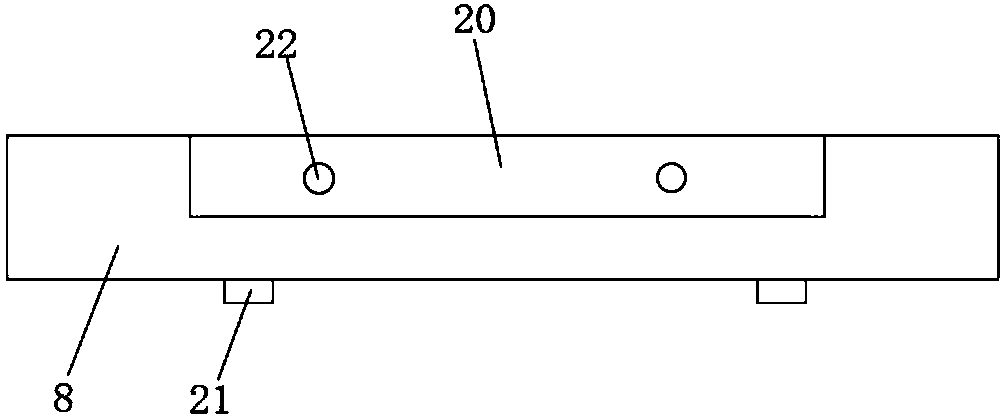

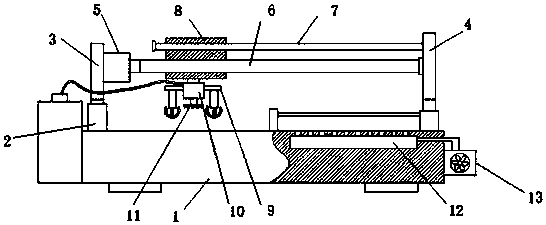

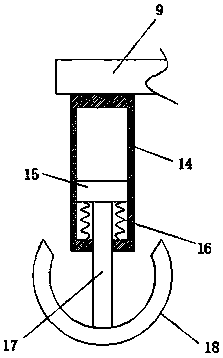

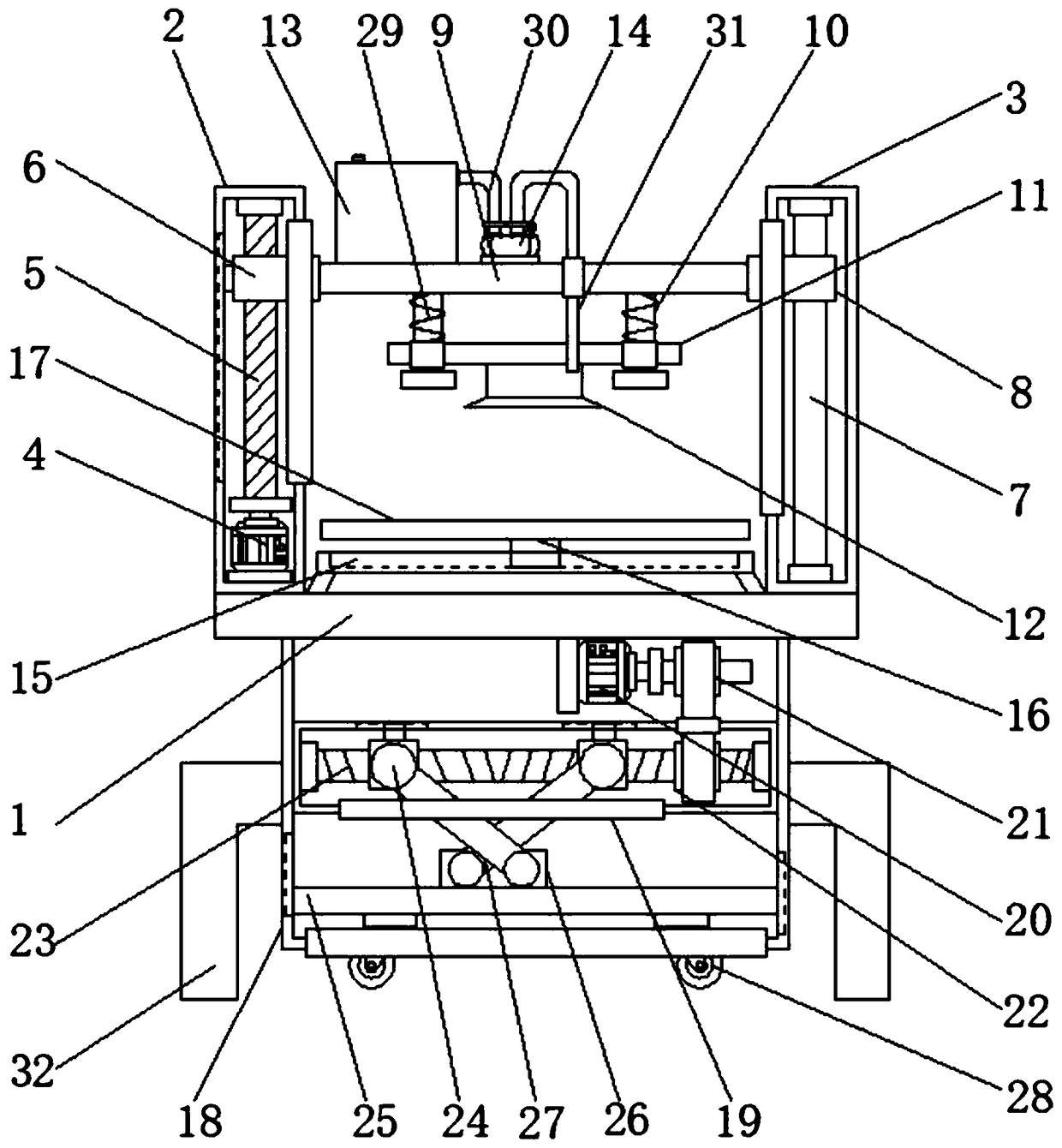

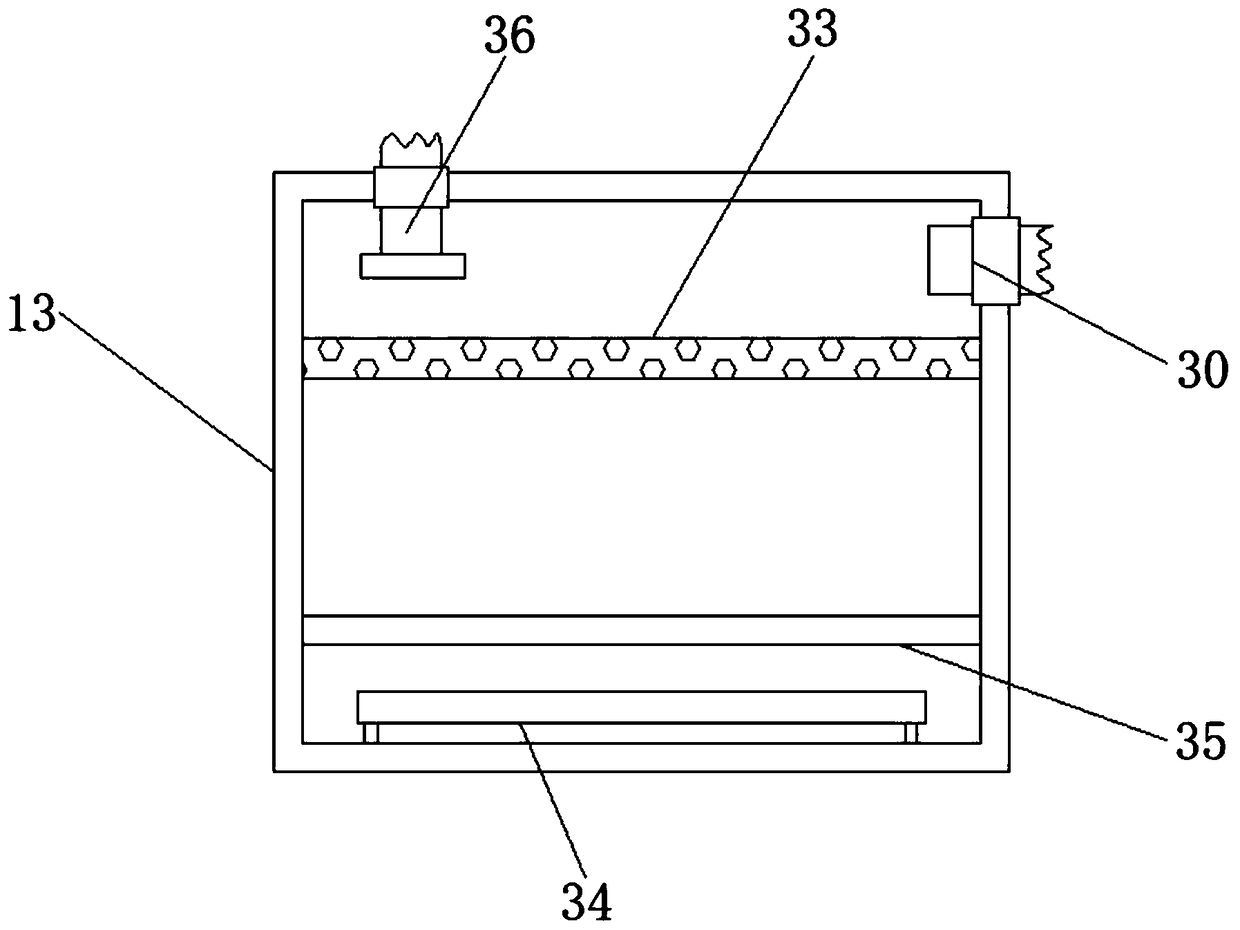

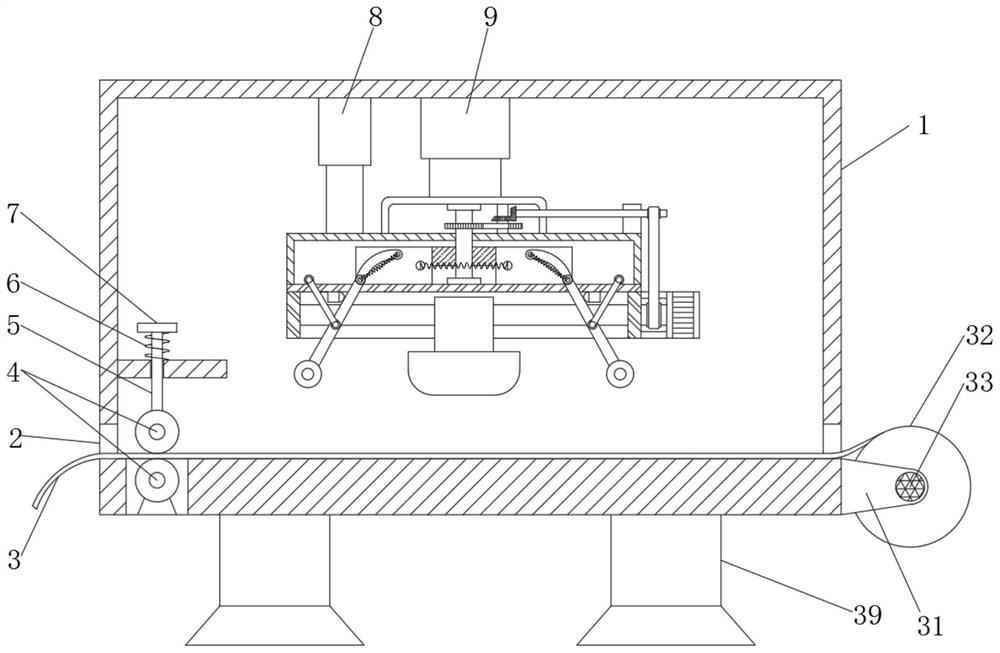

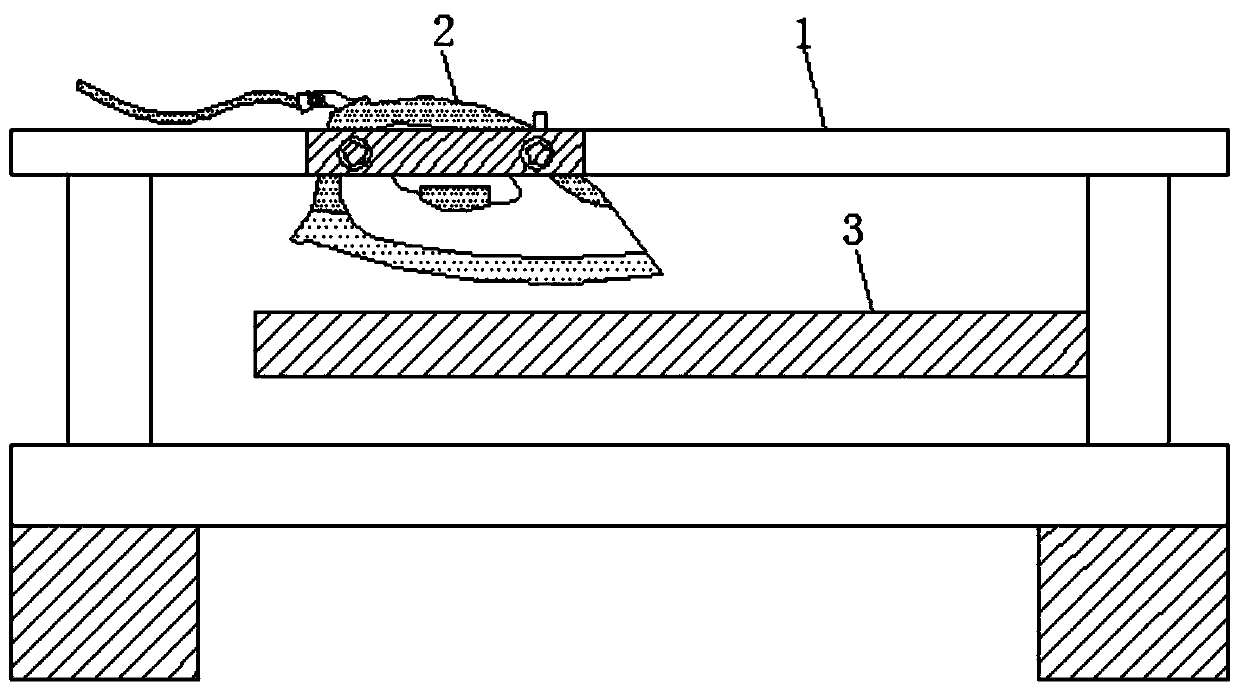

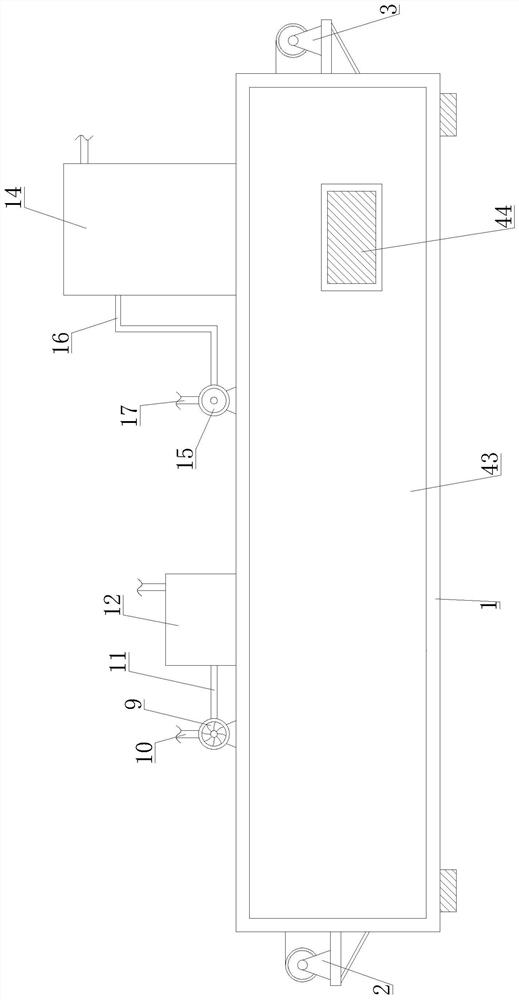

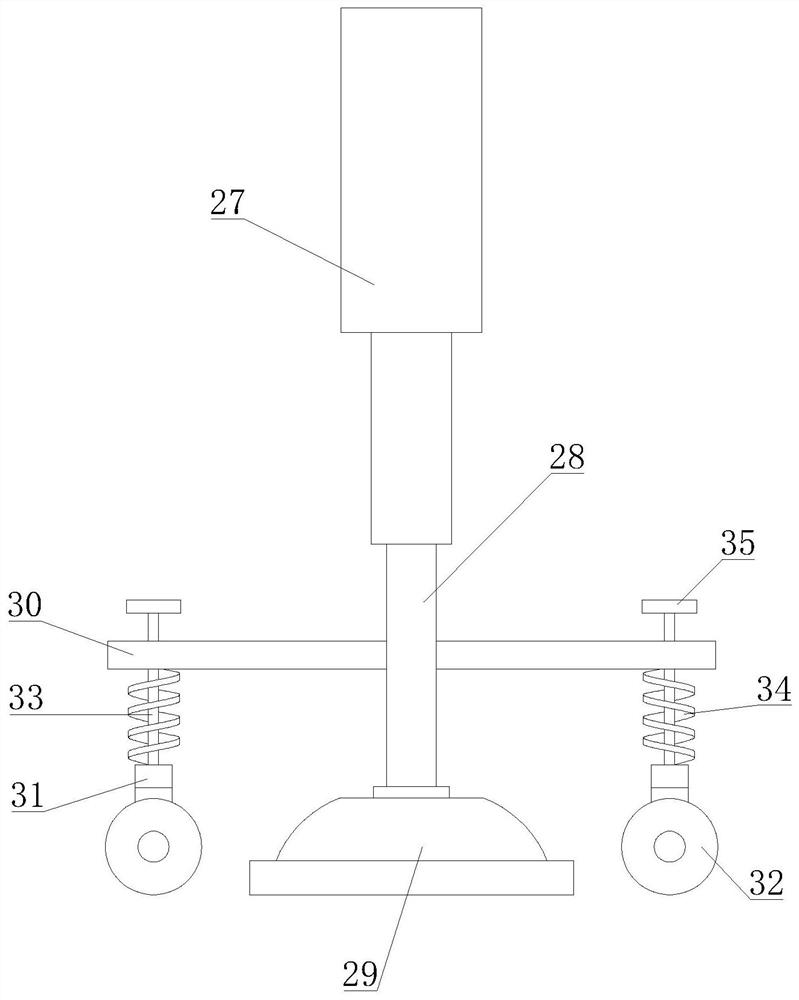

Convenient-to-iron textile fabric processing device

InactiveCN108221220ARealize the uniform wetting function of the areaAchieve fast ironing functionTextile treatment machine arrangementsTextile treatment by spraying/projectingWater storage tankDrive shaft

The invention provides a convenient-to-iron textile fabric processing device, which comprises a left supporting frame, a base, a supporting stage, a right supporting frame, a wetting mechanism and anironing mechanism. The left supporting frame is fixed to the left portion of the upper lateral side of the base, the supporting stage is fixed to the upper surface of the base under the left supporting frame, and the right supporting frame is fixed to the right portion of the upper surface of the base. The wetting mechanism is arranged on the inner upper surface of the right supporting frame and comprises a water storage tank, a main water pipe, a screw rod, a carrier plate, a connection hose, an atomizing nozzle, a nut seat, an opening and a mounting plate. The ironing mechanism is arranged on the inner upper side of the right supporting frame and comprises a driving motor, a guide groove, a driving shaft, a rack, a gear, a groove, a lifting cylinder, a lower fixing plate, springs, an ironing machine, a travel switch, linear slide rails and linear sliders. Compared with the prior art, the convenient-to-iron textile fabric processing device has advantages that an uniform area wetting function is realized, a quick fabric ironing function is achieved as well, and high ironing efficiency is realized.

Owner:中山市恒辉自动化科技有限公司

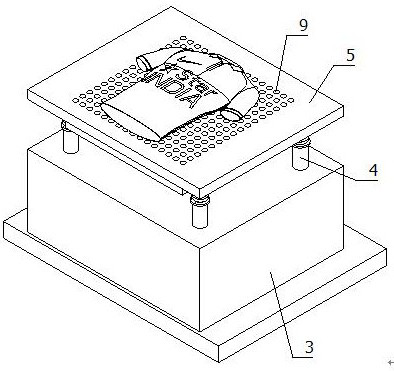

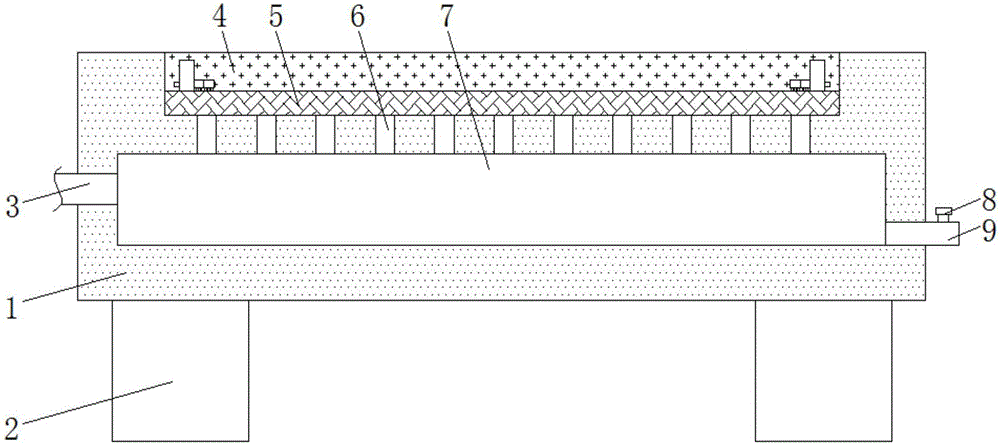

Ironing device for garment production

InactiveCN107237110AAvoid excessive heat shrinkImprove ironing efficiencyIroning machinesTextiles and paperEngineeringSupport plane

The invention discloses an ironing device for garment production. The ironing device comprises a base. The base is of a hollow cuboid-shaped structure. An installing cavity is formed in the middle of the top of the base. A fan is fixedly installed in the middle of the bottom of the installing cavity. The top of the base is fixedly connected with an ironing table. A conveying mechanism is arranged on a supporting frame of the ironing table. Supporting plates are fixedly connected to the two sides of the top of the ironing table. Threaded holes are formed in the two sides of the supporting plates. The middles of the threaded holes are sleeved with heating rings in a threaded mode. Multiple heating wires are evenly distributed on the heating rings. Sponge layers are arranged in the outer rings of the heating rings. Plastic layers are arranged on the two sides of the exteriors of the sponge layers. The middles of the exteriors of the plastic layers are fixedly connected with screws. The screws are symmetrically arranged on the two sides of the exteriors of the plastic layers. Sliding rods are connected to the supporting plates in a sliding mode. The design is reasonable, automatic ironing in the garment production process is achieved, the ironing time is saved, the production cost is reduced, and the ironing efficiency is improved.

Owner:湖州安姐实业股份有限公司

Industrial ironing machine

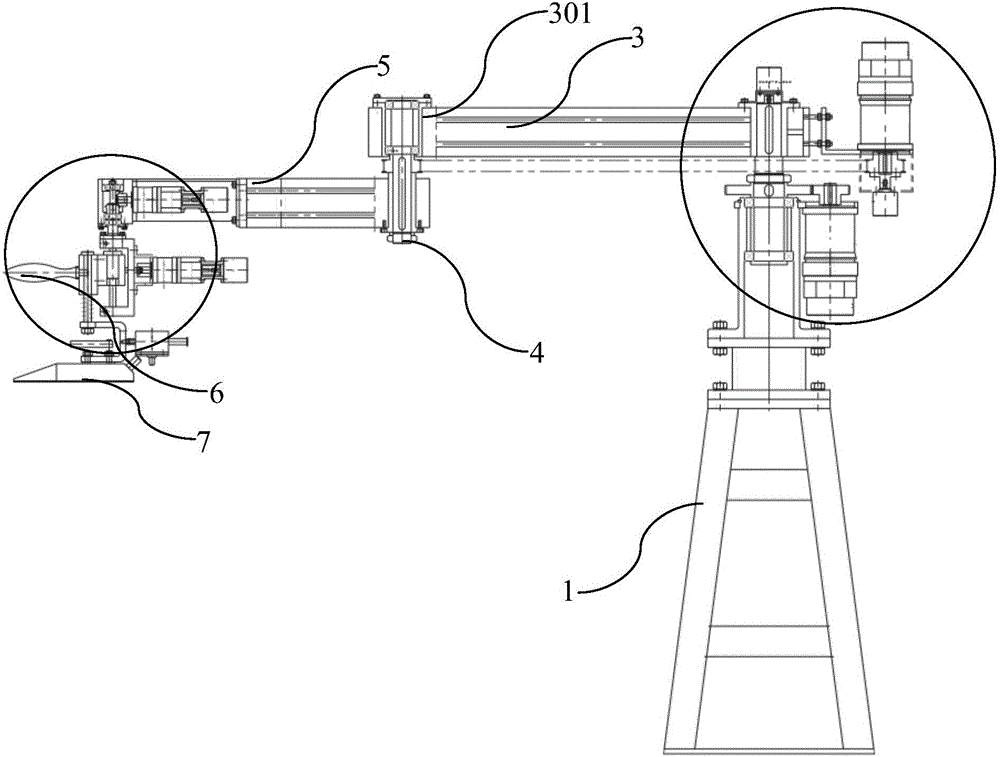

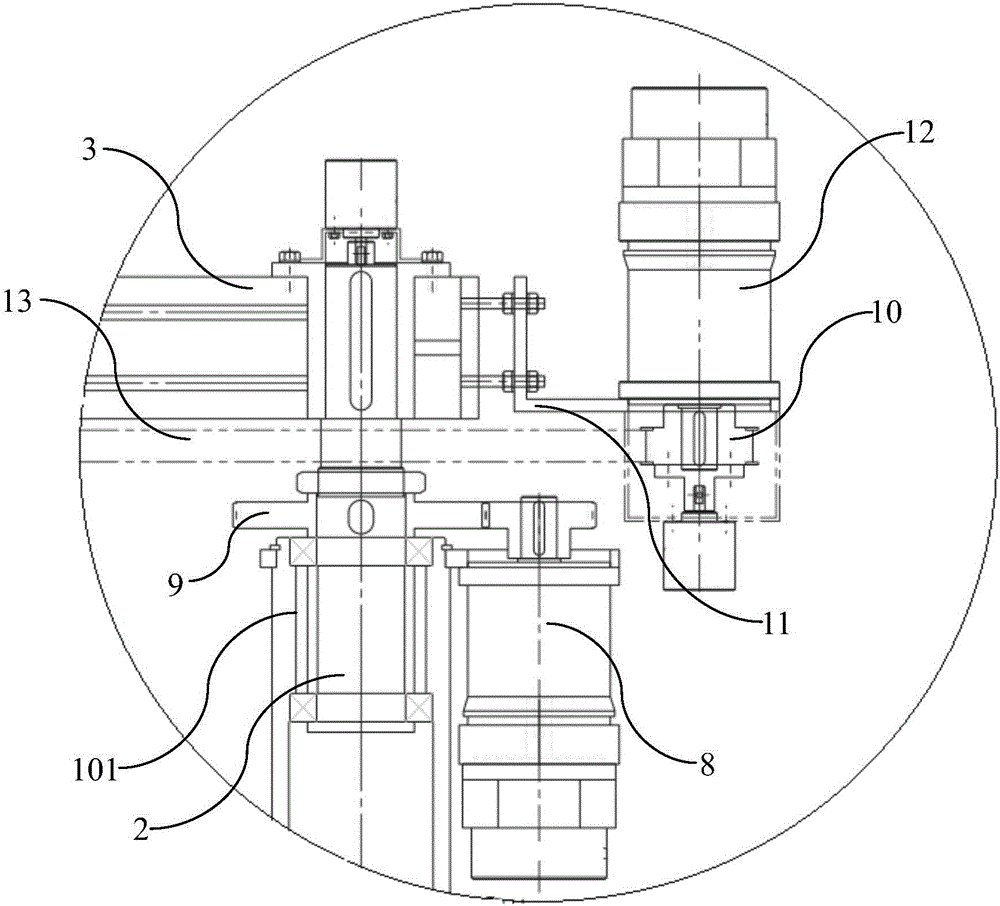

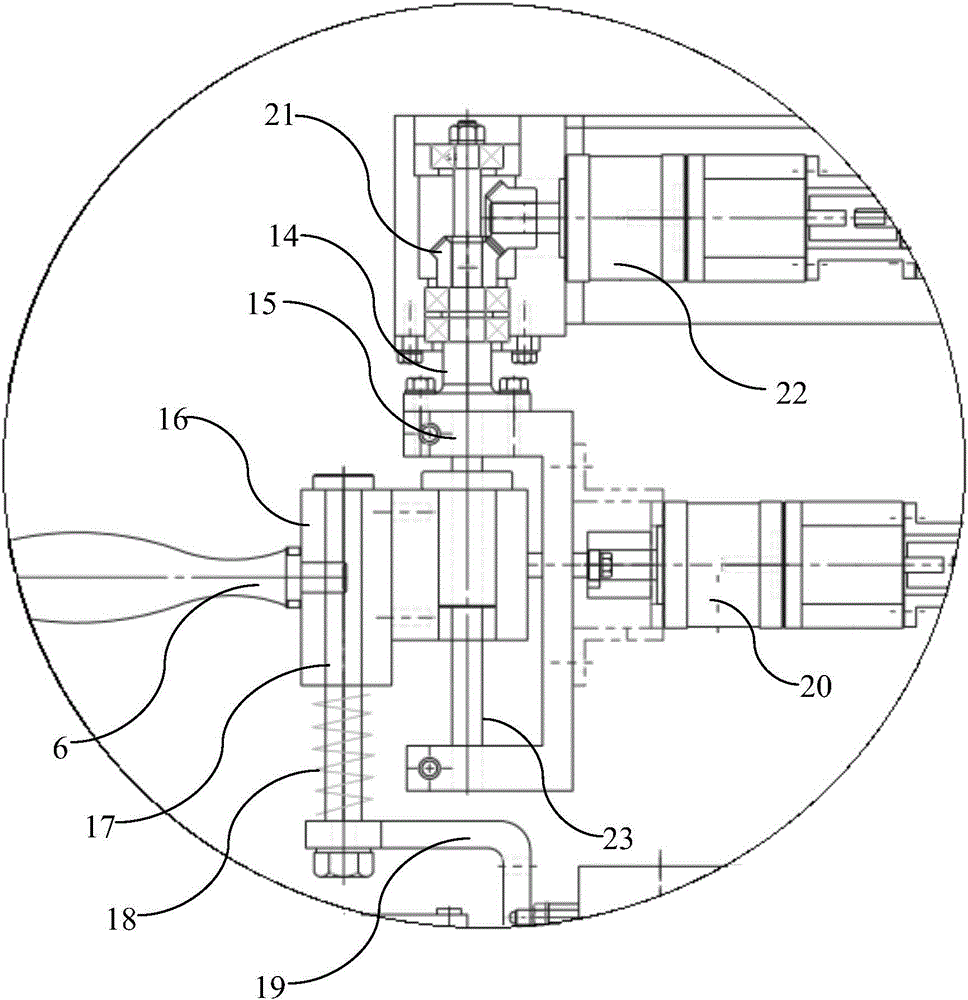

ActiveCN106811947AImprove ironing qualityImprove ironing efficiencyProgramme-controlled manipulatorIroning machinesRobot handMachine

The invention discloses an industrial ironing machine. The industrial ironing machine comprises an ironing machine body and a mechanical arm, and the ironing machine body and the mechanical arm are connected so that the mechanical arm can be utilized to control the ironing machine body to work. According to the industrial ironing machine, the ironing machine mechanical arm capable of recording a movement locus of manually ironing clothes and the ironing machine body matched with the mechanical arm are designed, the ironing machine mechanical arm can control the movement of the ironing machine body through the movement locus, and an ironing movement which is the same as a manual ironing movement is automatically conducted; meanwhile, through automatic ironing of the mechanical arm, the ironing efficiency is sharply improved, the labor workload is reduced, and ironing quality of the clothes is improved at the same time.

Owner:福州肆菱智能科技有限公司

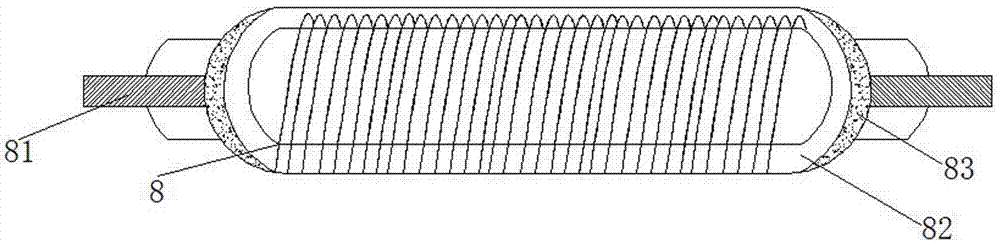

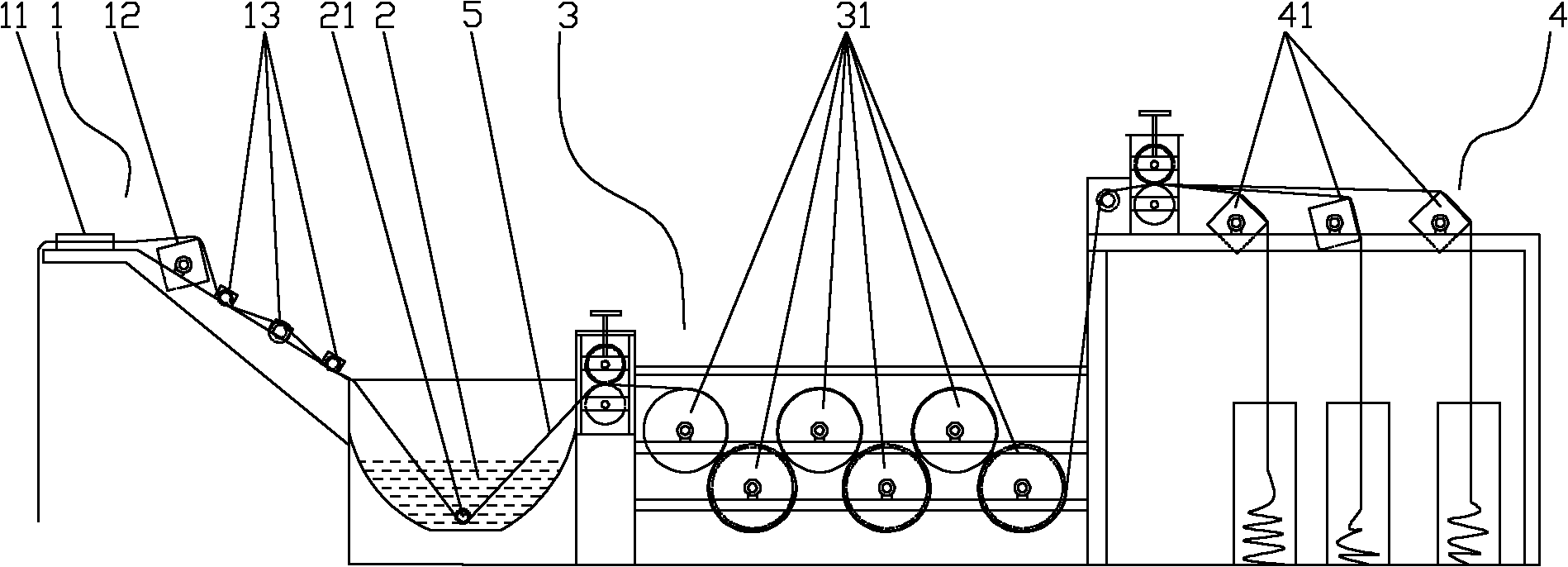

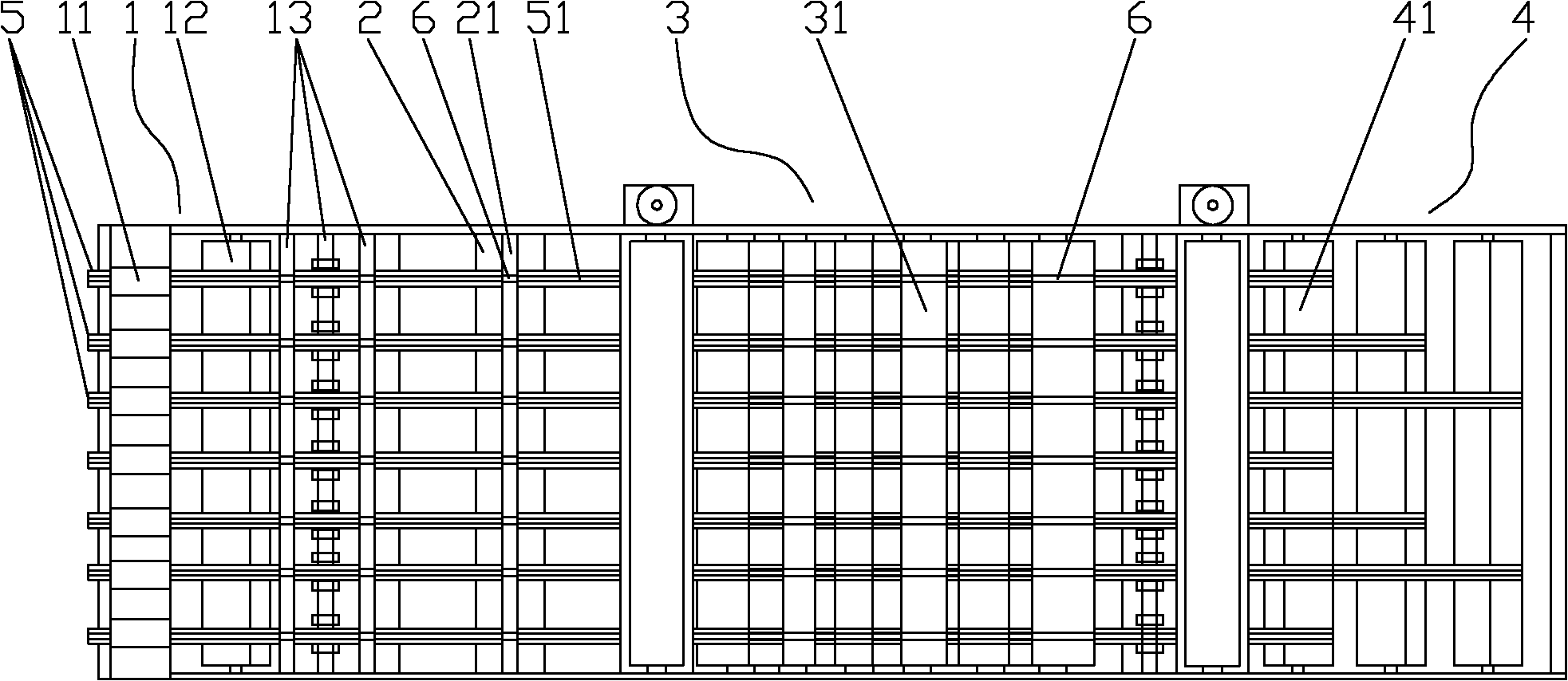

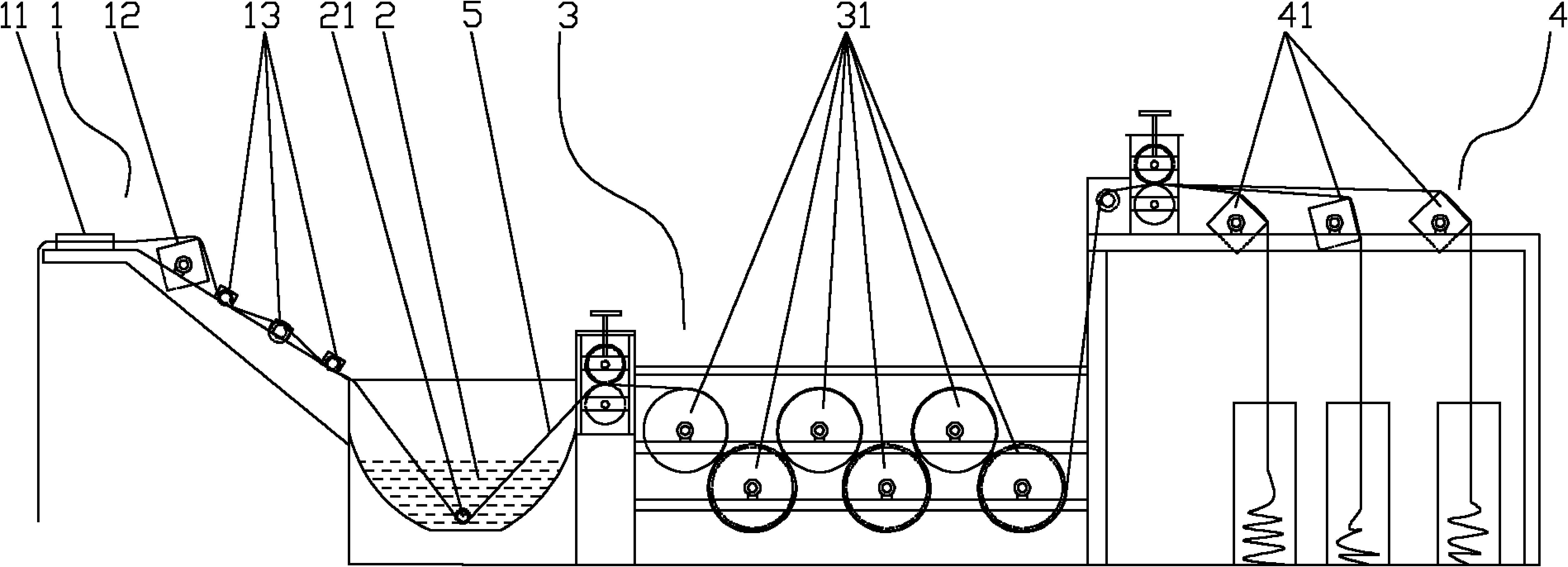

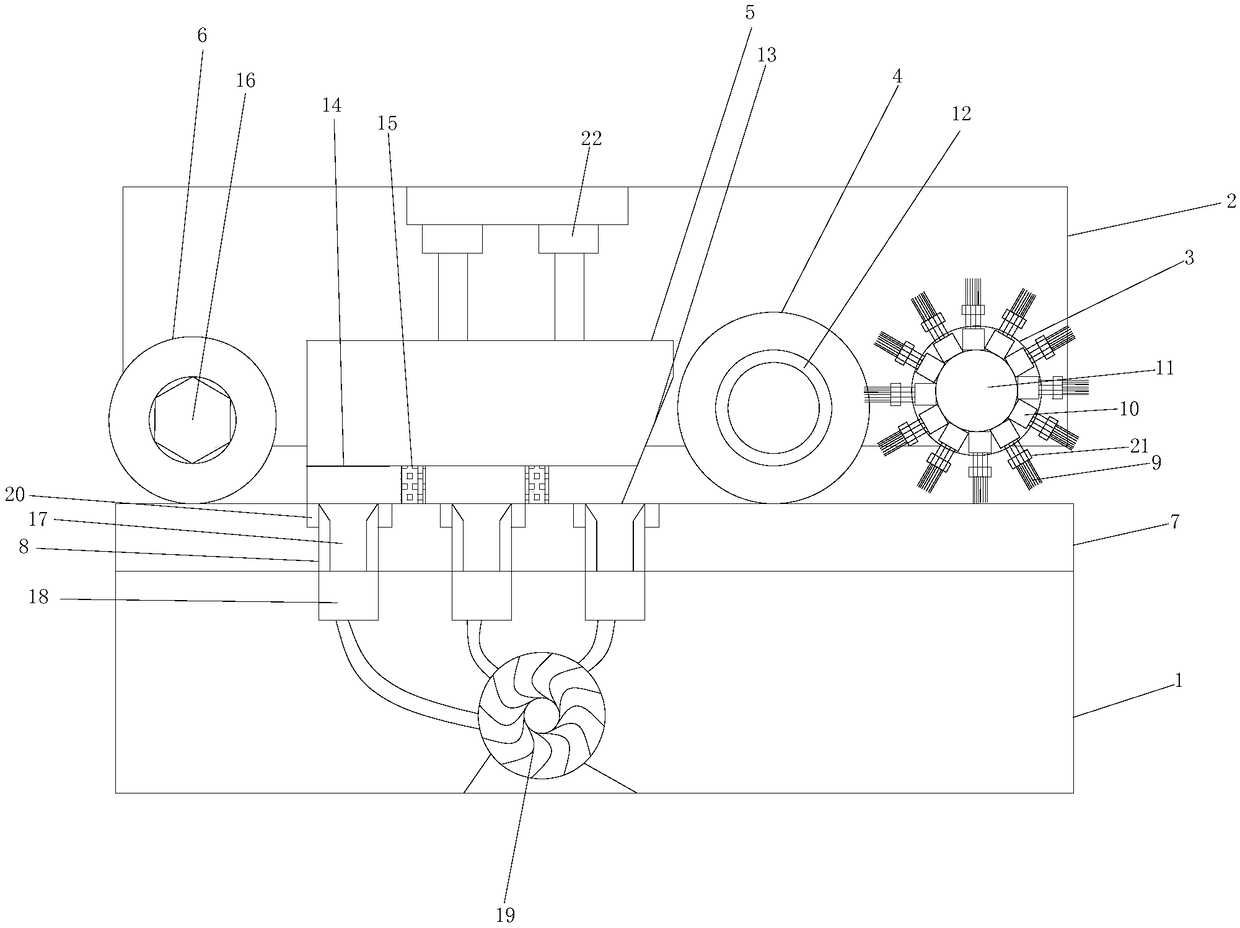

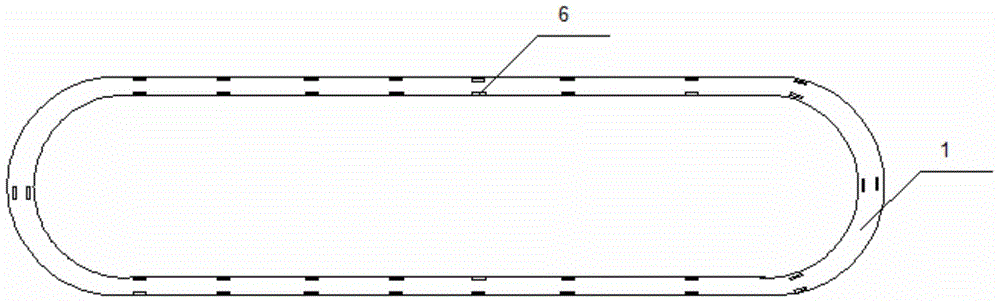

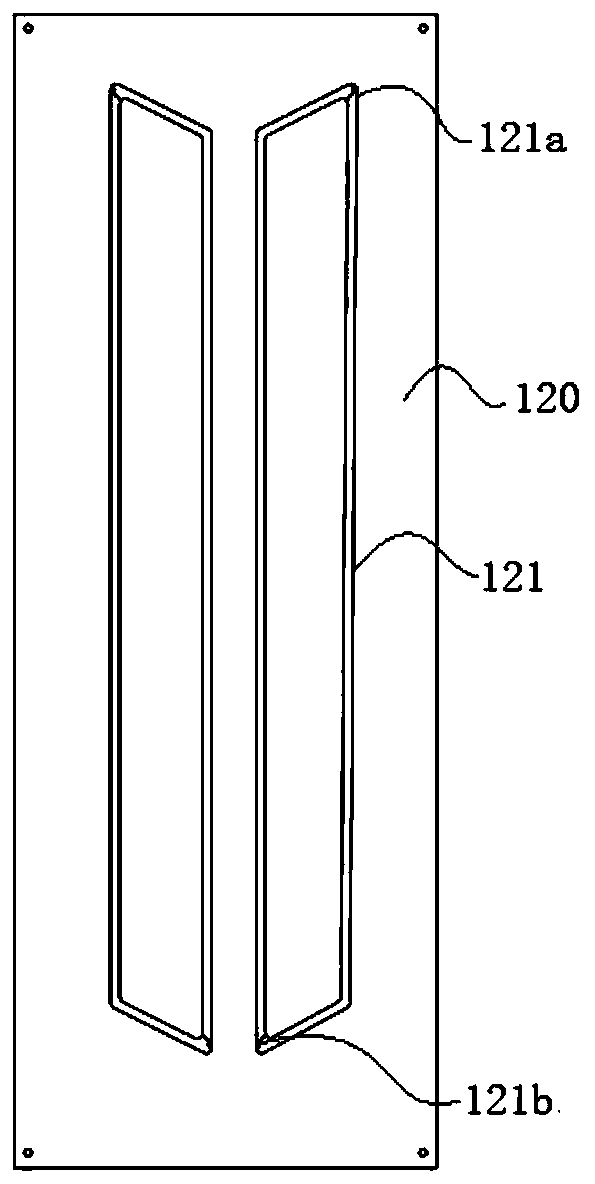

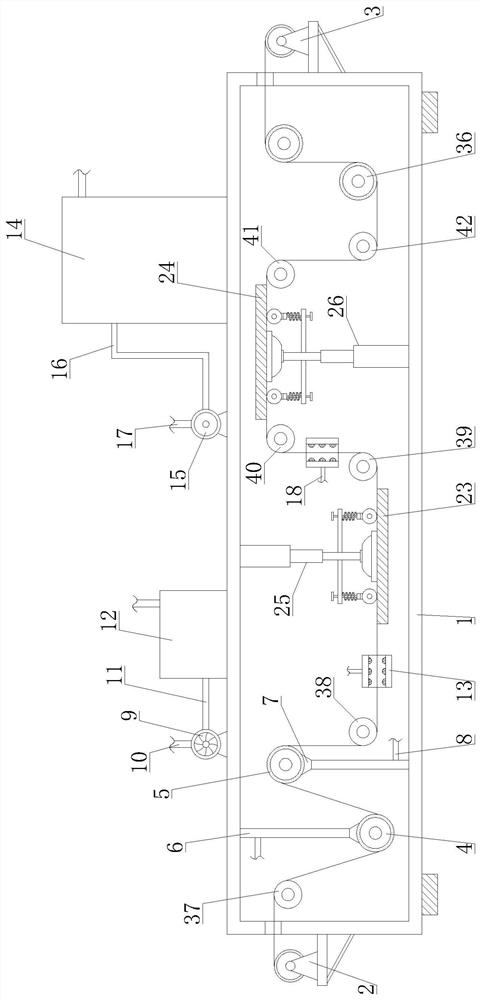

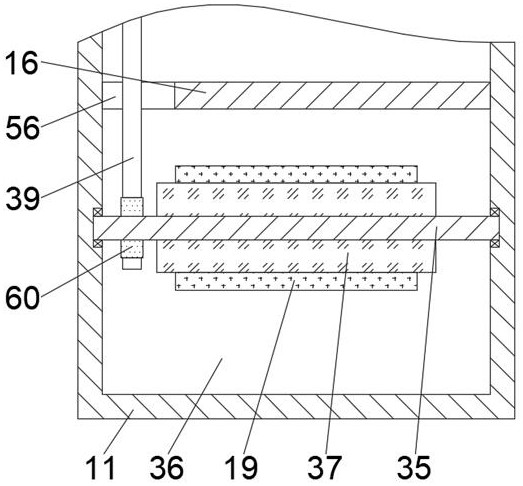

High-efficiency ironing machine for zipper cloth belt

ActiveCN101864660AIncrease feed rateNot intertwinedSlide fastenersIroning machinesTemperature controlEnergy conservation

The invention discloses a high-efficiency ironing machine for zipper cloth belts, which comprises a water trough, an ironing mechanism and a packaging mechanism. The zipper cloth belts are arranged in parallel and sequentially pass through the water trough, the ironing mechanism and the packaging mechanism. The ironing mechanism consists of parallel electric heating rollers which are continuously arranged in a staggering way from top to bottom. The zipper cloth belts are wounded on the electric heating rollers in S-shape. The packaging mechanism consists of parallel friction rollers. The electric heating rollers and the friction rollers rotate at the same speed to drive the zipper cloth belts to move towards the direction of the packaging mechanism. The invention has the advantages that since the ironing machine irons the zipper cloth belts through the electric heating rollers which are arranged in parallel, the temperature control is accurate and the energy is saved; and since a plurality of zipper cloth belts can be transversely arranged and are not twisted with each other, the ironing efficiency is effectively improved.

Owner:XIANGXING FUJIAN BAG ANDLUGGAGE GRP CO LTD

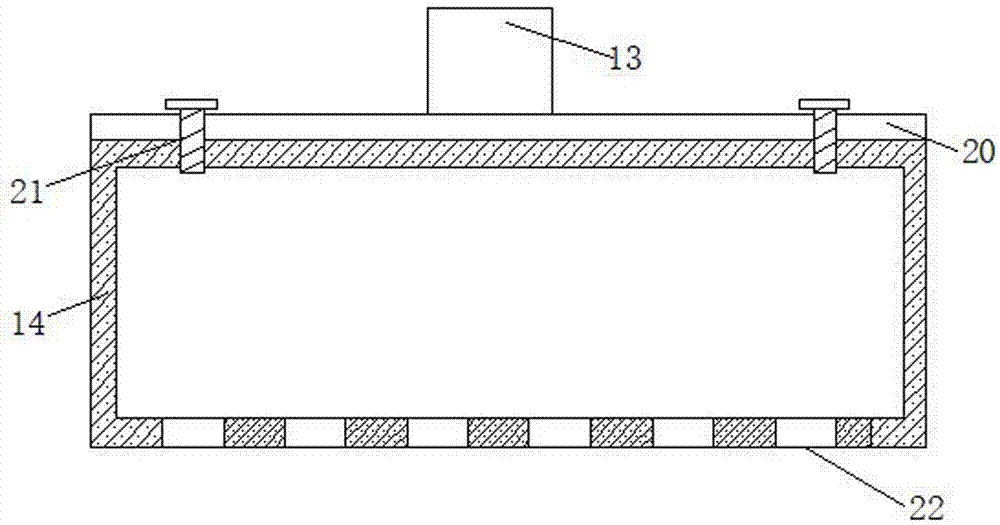

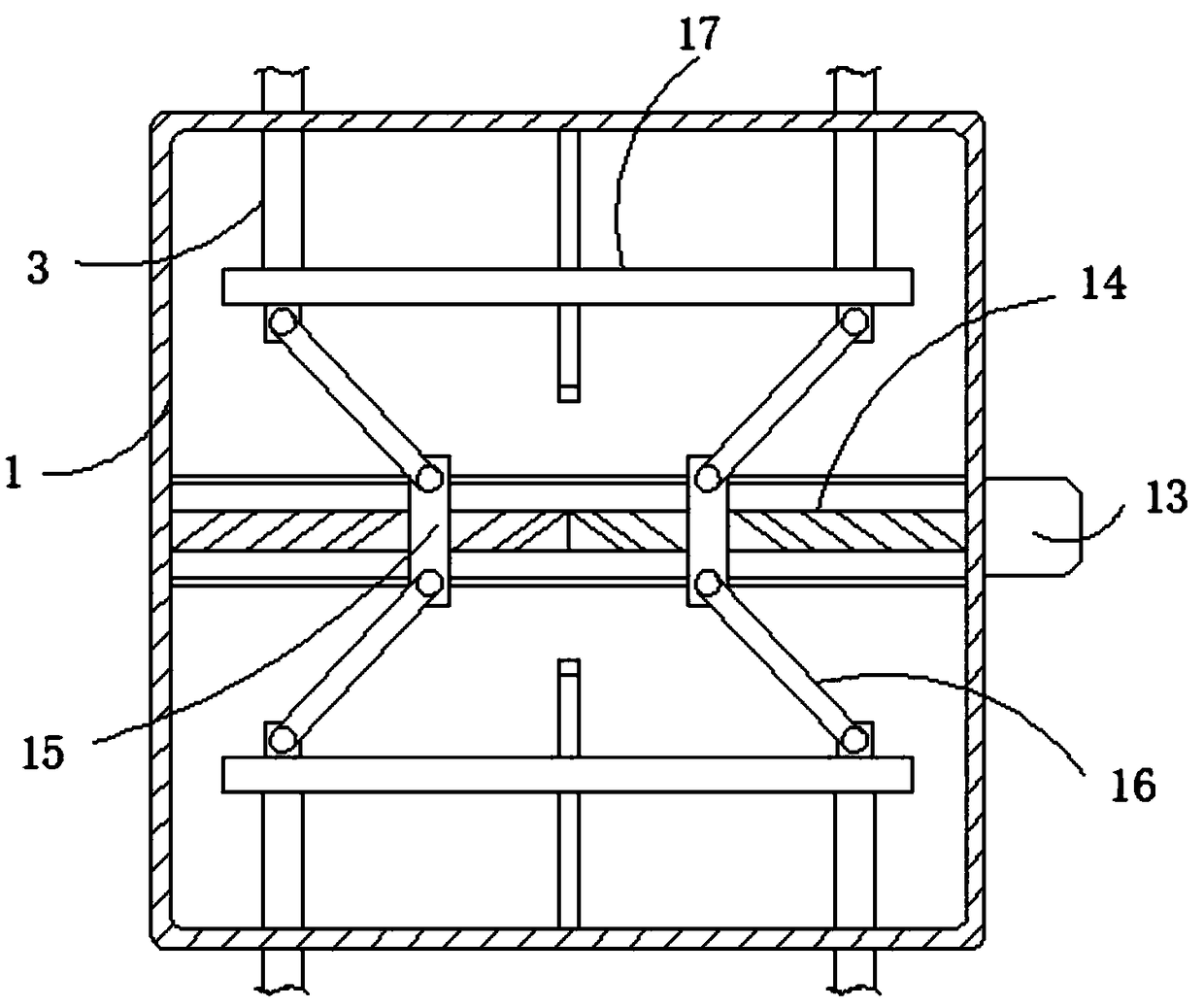

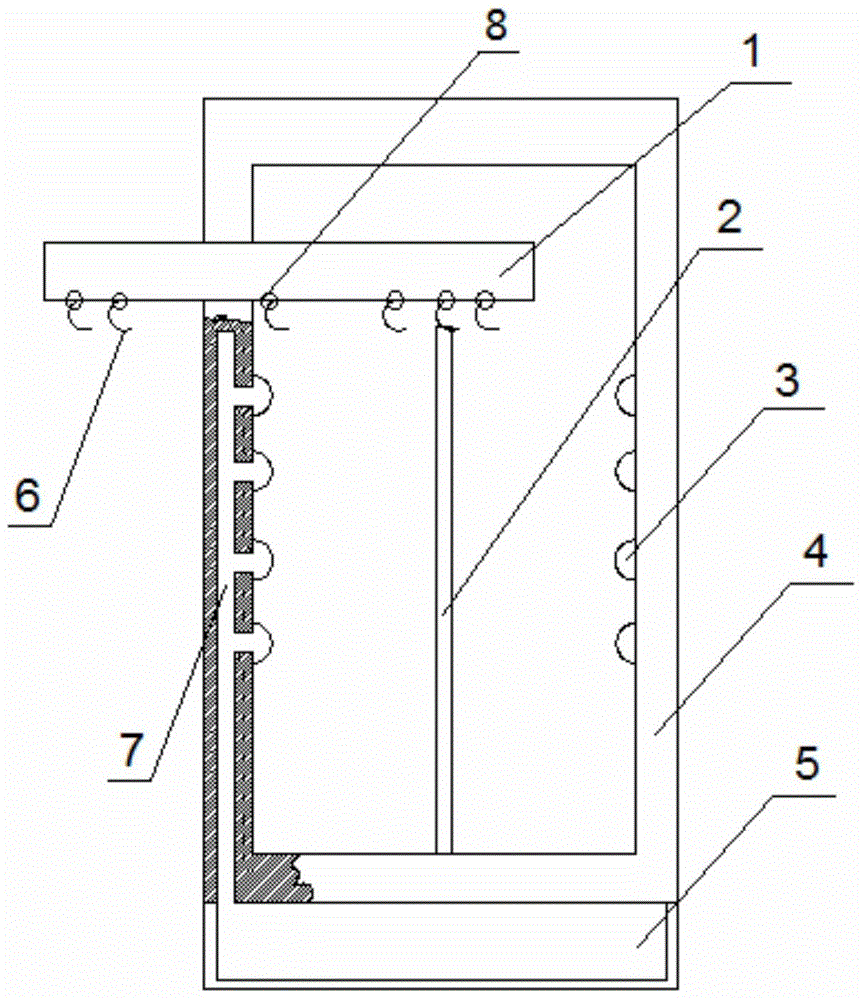

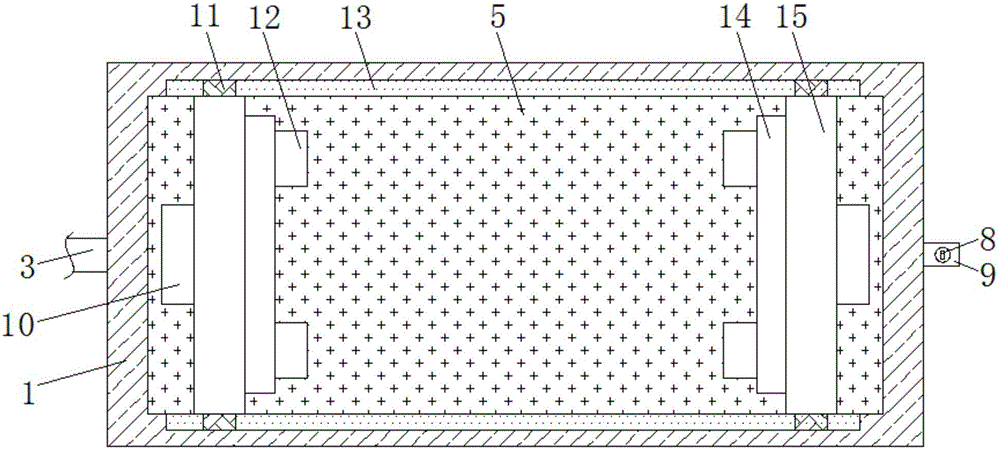

Ironing device for processing bedding textile products

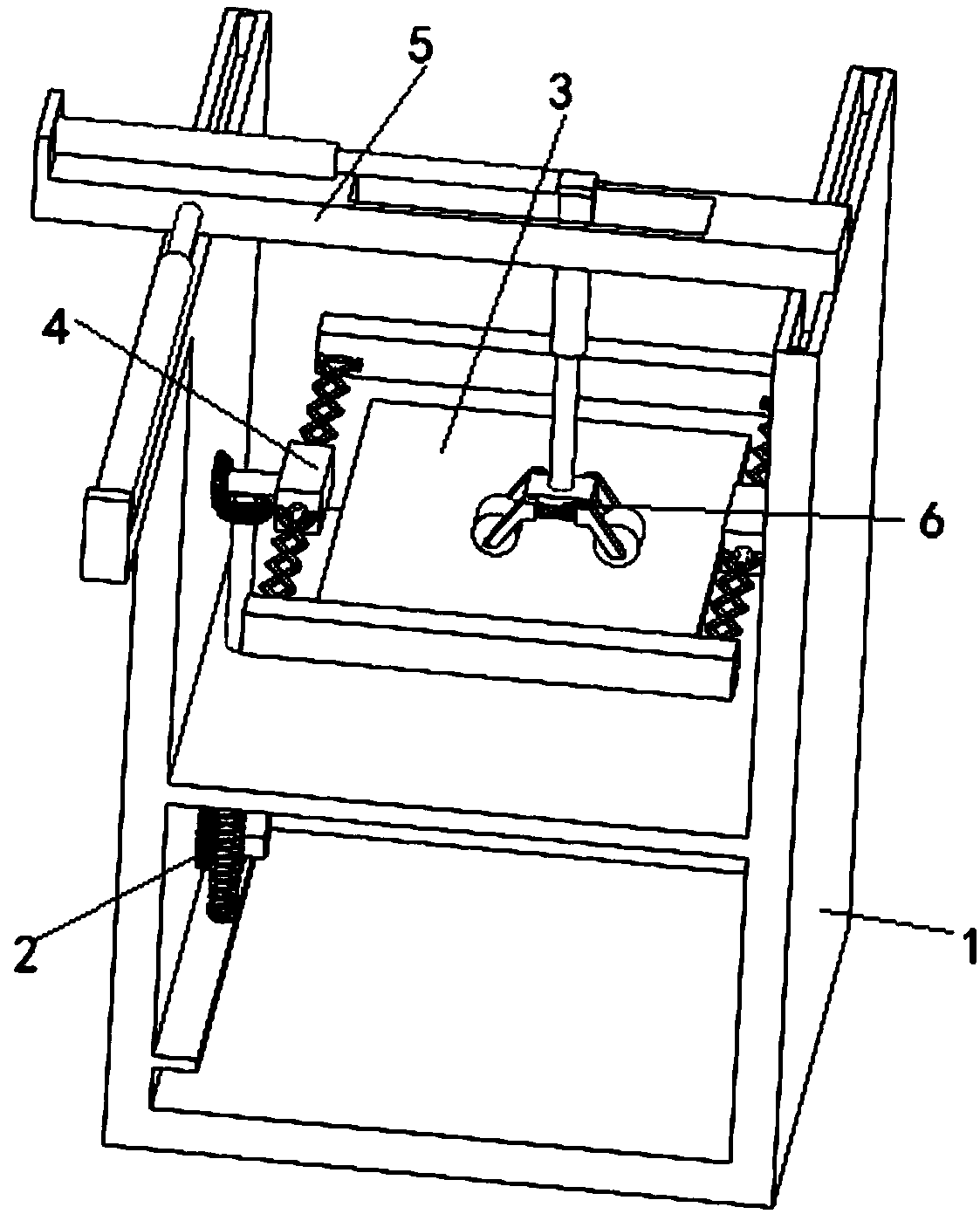

InactiveCN109162061AEasy ironingImprove ironing efficiencyStretchingMechanical engineeringBed sheets

The invention relates to the technical field of processing of textile products and discloses an ironing device for processing bedding textile products. The ironing device for processing the bedding textile products comprises a control box; two rail plates are fixedly arranged at the top and the bottom of the control box; vertical rods are movably arranged at the top and the bottom of the control box; the vertical rods are in sliding connection with the rail plates; transverse plates are movably arranged on the rail plates; one end of each vertical rod is fixedly connected with each transverseplate; sliding grooves are formed in the transverse plates; two adjusting blocks are arranged on the sliding grooves in a sliding way; the adjusting blocks are fixedly connected with transverse rods;the transverse rods are in sliding connection with the transverse plates; one end of each transverse rod is fixedly connected with a clamping block; vertical plates are welded on the transverse plates; a push rod motor is arranged on each vertical plate; and a moving block is arranged on each vertical plate in a sliding way. The ironing device for processing the bedding textile products can realize stretching and unfolding of bed sheet fabric, is suitable for bed sheets with different length and width, is labor-saving, facilitates ironing of the bed sheet fabric, improves the ironing efficiency of the bed sheet fabric and is easy to popularize.

Owner:CHANGXING JUFENG SILK WEAVING FACTORY

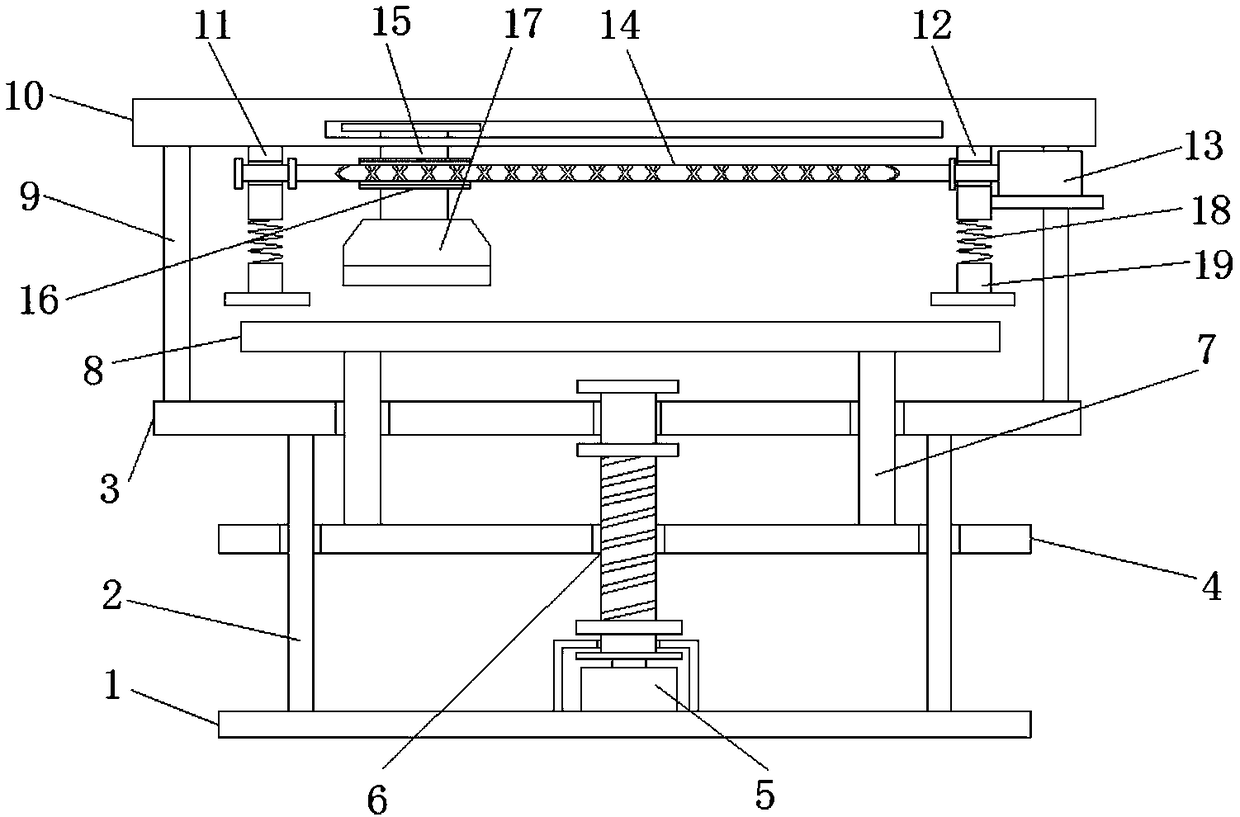

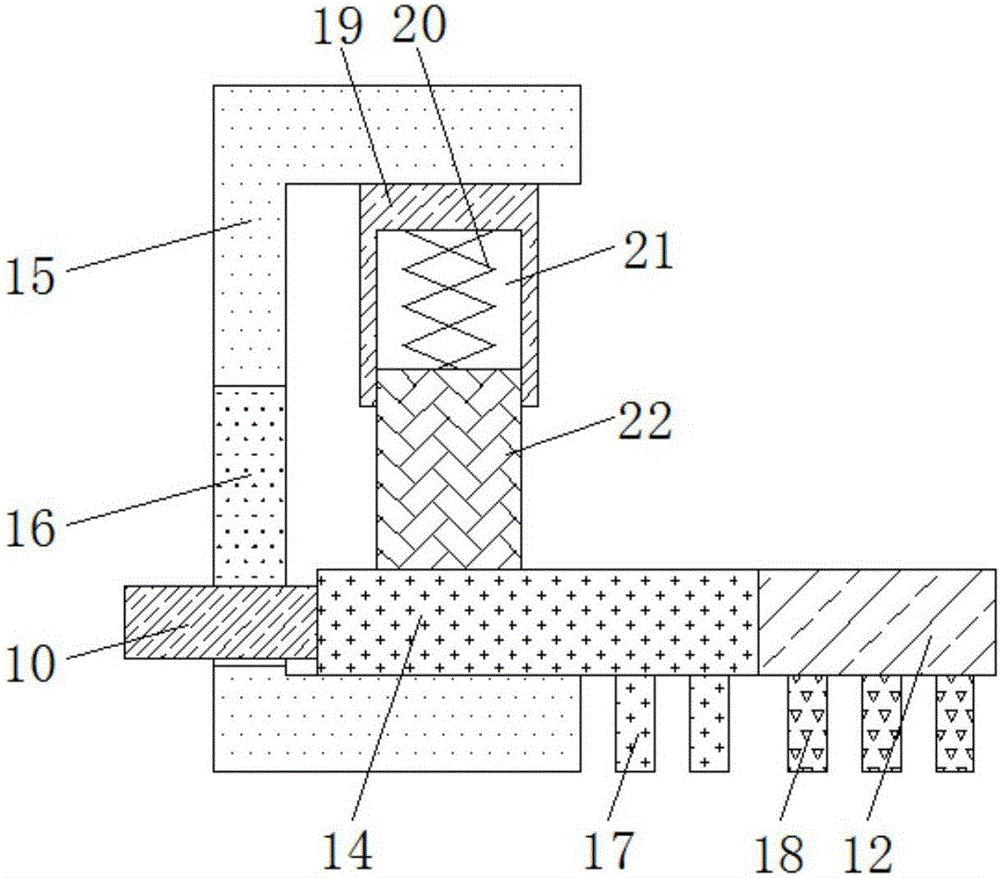

Ironing device for textile fabric processing

InactiveCN108330640AIngenious structureImprove ironing efficiencyTextile shapingArchitectural engineeringThreaded rod

The invention discloses an ironing device for textile fabric processing. The ironing device comprises a support bottom plate, wherein four first support rods in vertical arrangement are fixedly arranged on the top end of the support bottom plate; a support plate in horizontal arrangement is fixedly arranged among the top ends of the four first support rods; four second support rods in vertical arrangement are fixedly arranged on the top end of the support plate; an installing plate is fixedly arranged among the top ends of the four second support rods; an installing frame is fixedly arranged on the top end of the support bottom plate; a threaded rod in vertical arrangement is rotationally arranged between the top end of the installing frame and the bottom end of the support plate; the topend of the support bottom plate is positioned inside the installing frame and is fixedly provided with a first rotating motor; an output shaft of the first rotating motor is fixedly connected with thethreaded rod; an ascending and descending plate in horizontal arrangement is arranged between the support plate and the support bottom plate; four first guide holes are formed in the ascending and descending plate. The ironing device has the advantages that the structure is ingenious. Compared with manual ironing, the ironing device has the advantages that the ironing efficiency is higher; the labor cost can be greatly reduced.

Owner:马道道

Pretreatment device for textile fabric printing and dyeing and using method thereof

InactiveCN112709059AKeep clean and tidyEffective absorptionMechanical cleaningPressure cleaningTextile printerElectric machinery

Owner:绍兴慧行智能科技有限公司

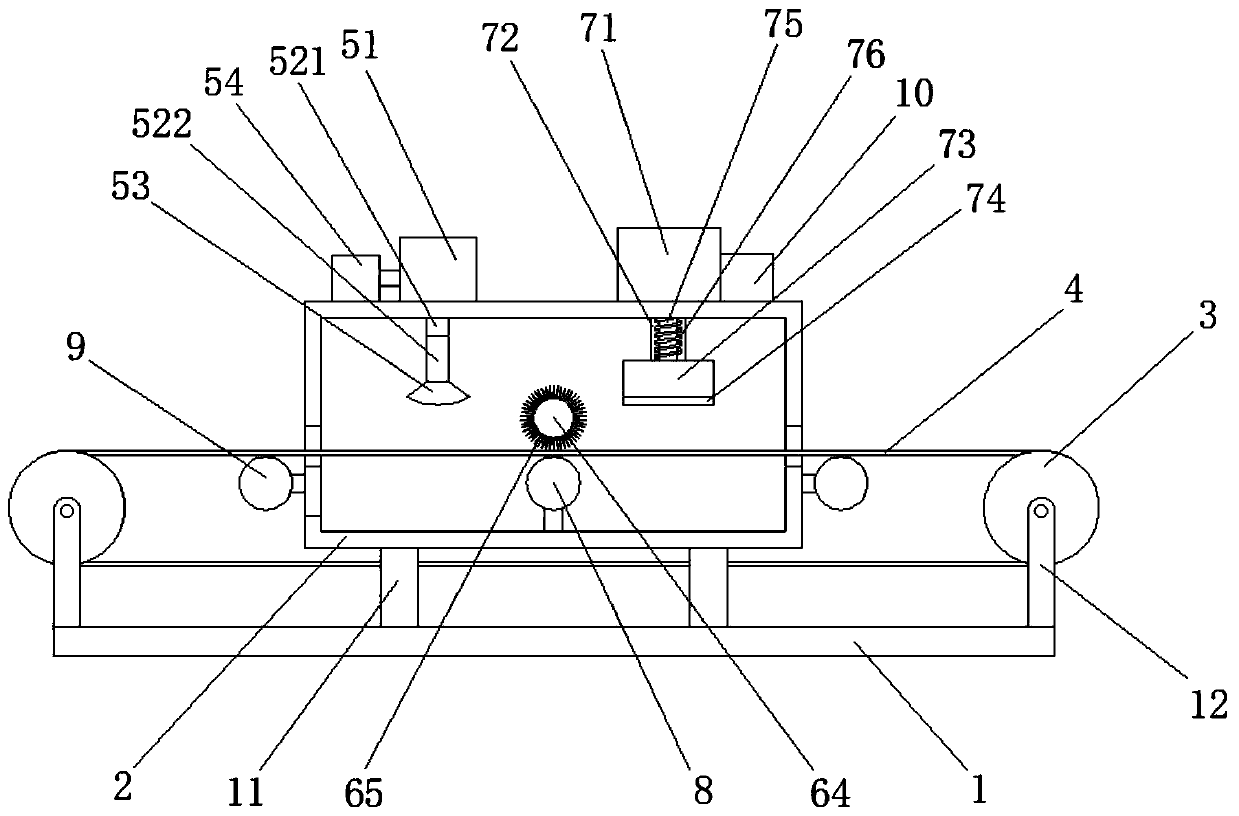

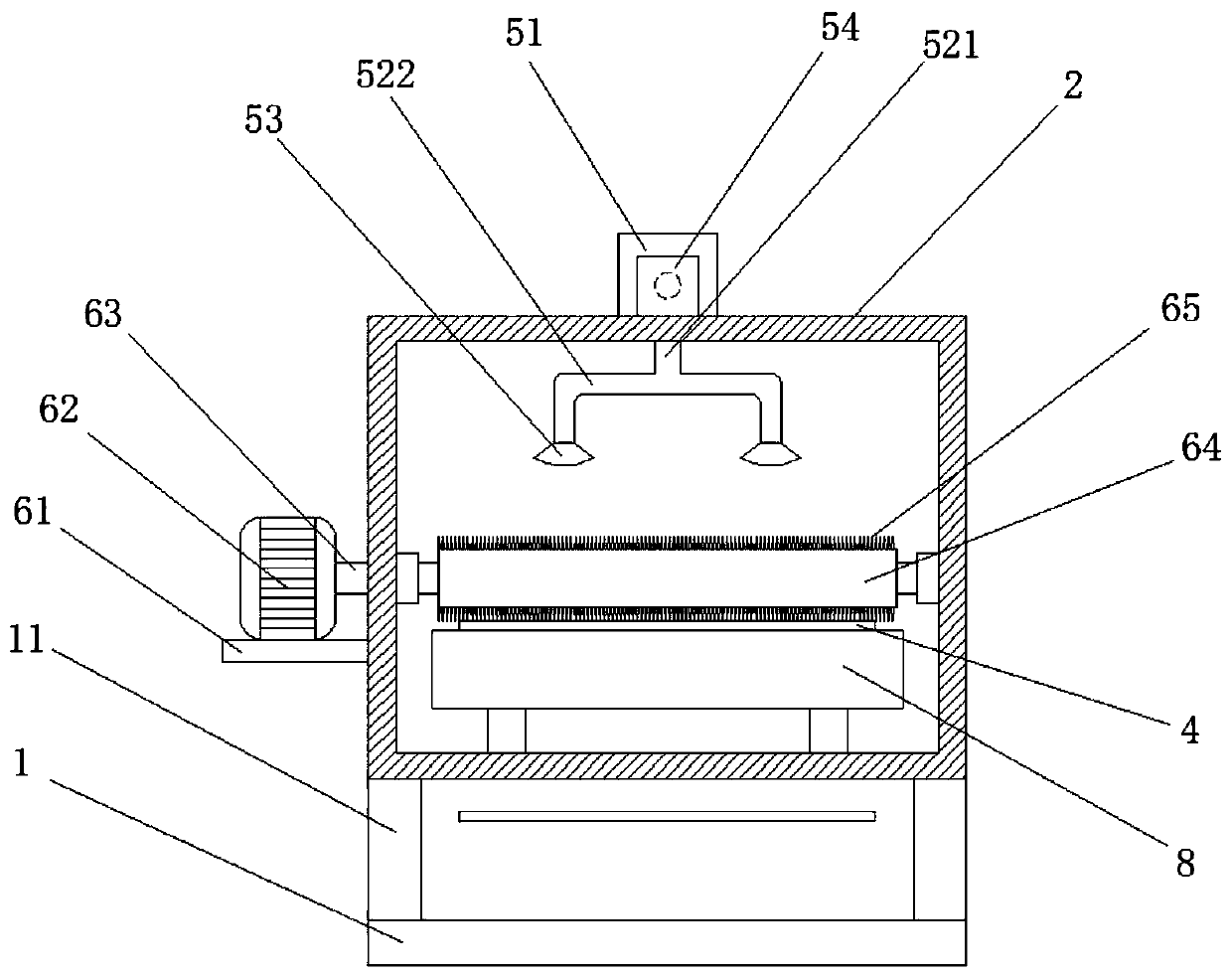

Ironing device with air suction and dust removal functions

InactiveCN110172811AImprove cleanlinessEasy ironingMechanical cleaningPressure cleaningBristlePulp and paper industry

The invention discloses an ironing device with an air suction and dust removal functions. The ironing device comprises a base; a plurality of fixing columns are arranged in the middle of the base; a working box is arranged on the fixing columns; roller brackets are arranged at two ends of the base; rollers are erected on the roller brackets; conveyor belts are arranged on the rollers, and pass through the working box in the transverse direction; an air suction device, a bristle device and an ironing device body are sequentially arranged at parts, above the conveyor belt, in the working box inthe feeding direction; the air suction device comprises an induced draft fan, a dust removal pipeline, an air suction opening and a dust collection chamber; the bristle device comprises a bottom plate, a motor, a rotating shaft, a bristle roller and bristles; and the ironing device comprises an air cylinder, a piston rod, a steam chamber, an ironing board, a telescopic rod and a reset spring. Theironing device can be convenient for clearing and collecting dust on the surface of clothing, keeps clothing clean, is convenient for ironing of clothing, further keeps fabric smooth, improves the recovery effect, improves the operation stability and the safety, is high in ironing efficiency, and is suitable for batch production.

Owner:HAIYAN WEIBOYA KNITTING CLOTHING

Cloth ironing device

PendingCN108950966AAvoid scaldingPrevent affecting ironing effectMechanical cleaningPressure cleaningEngineeringPre treatment

Owner:HAIYAN OULI CLOTHING

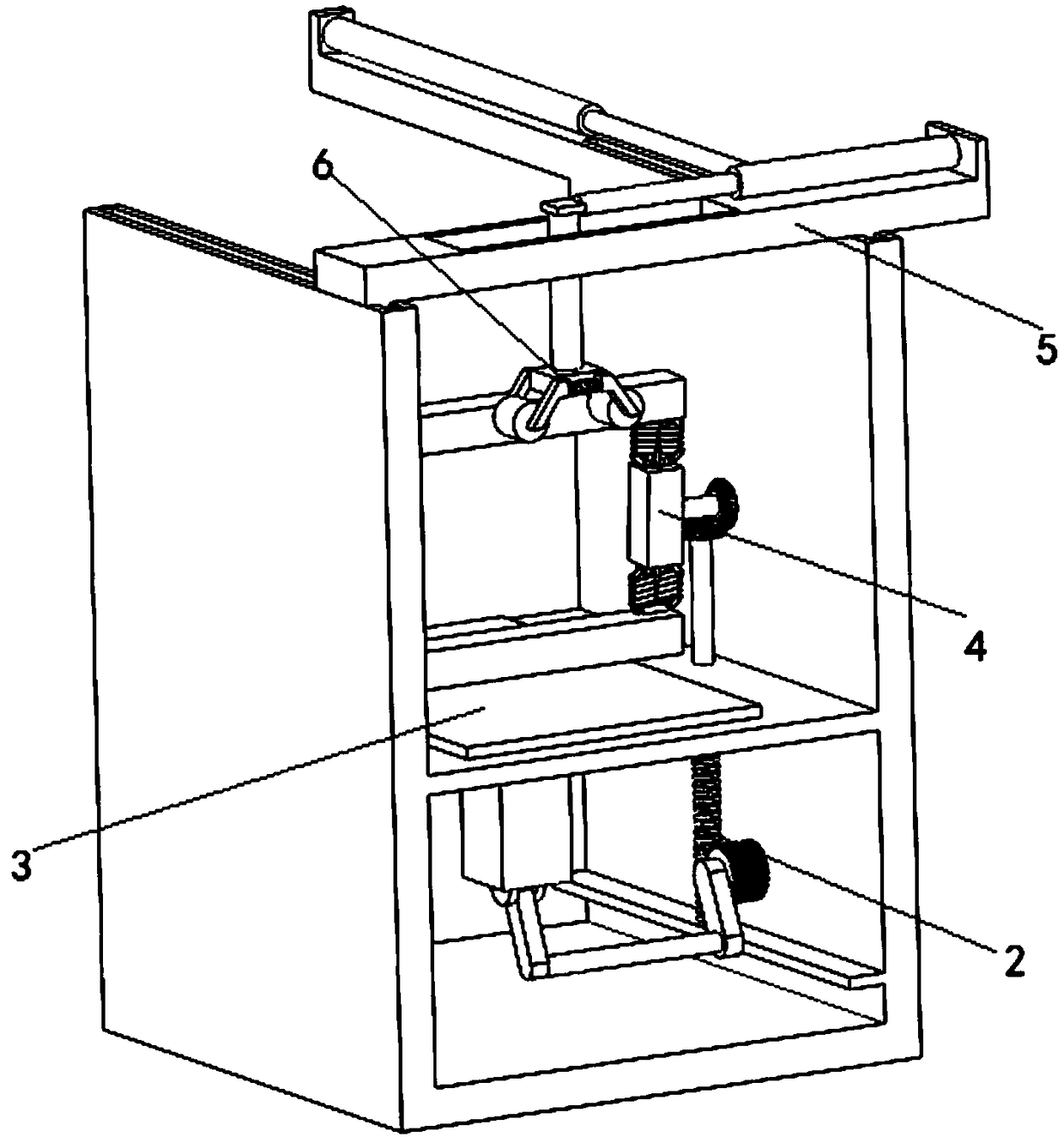

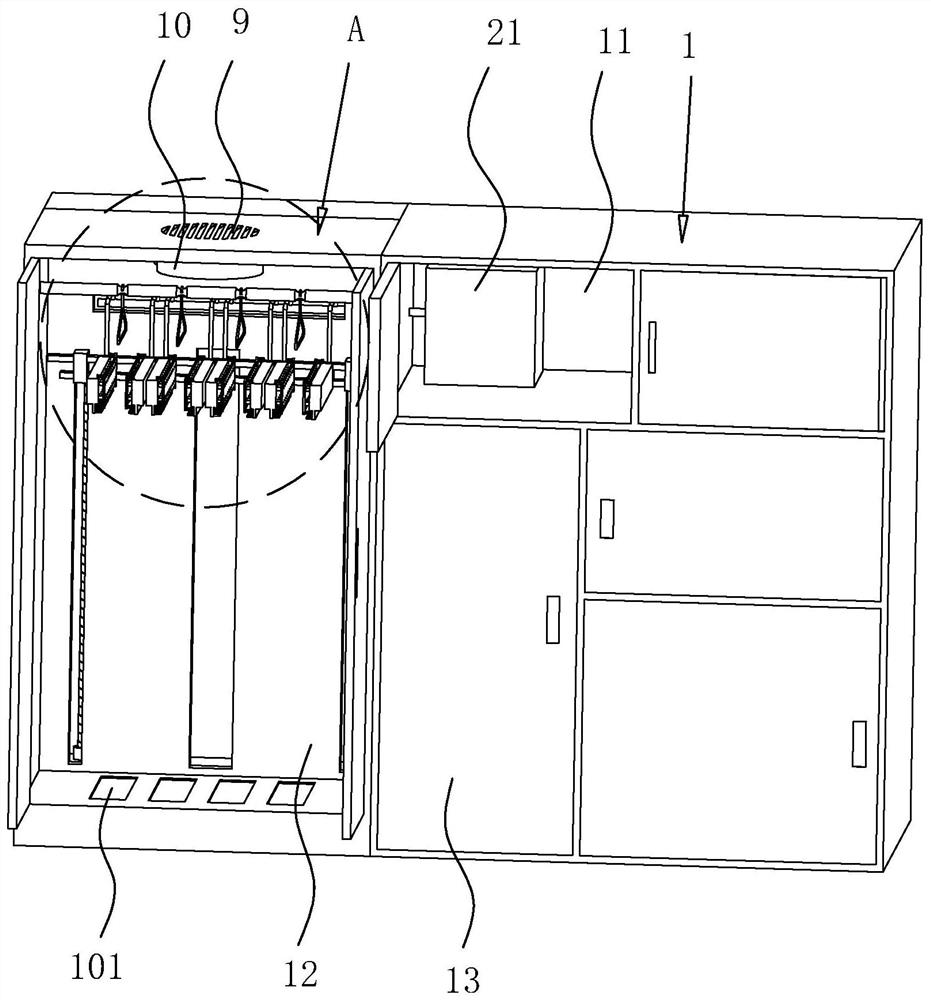

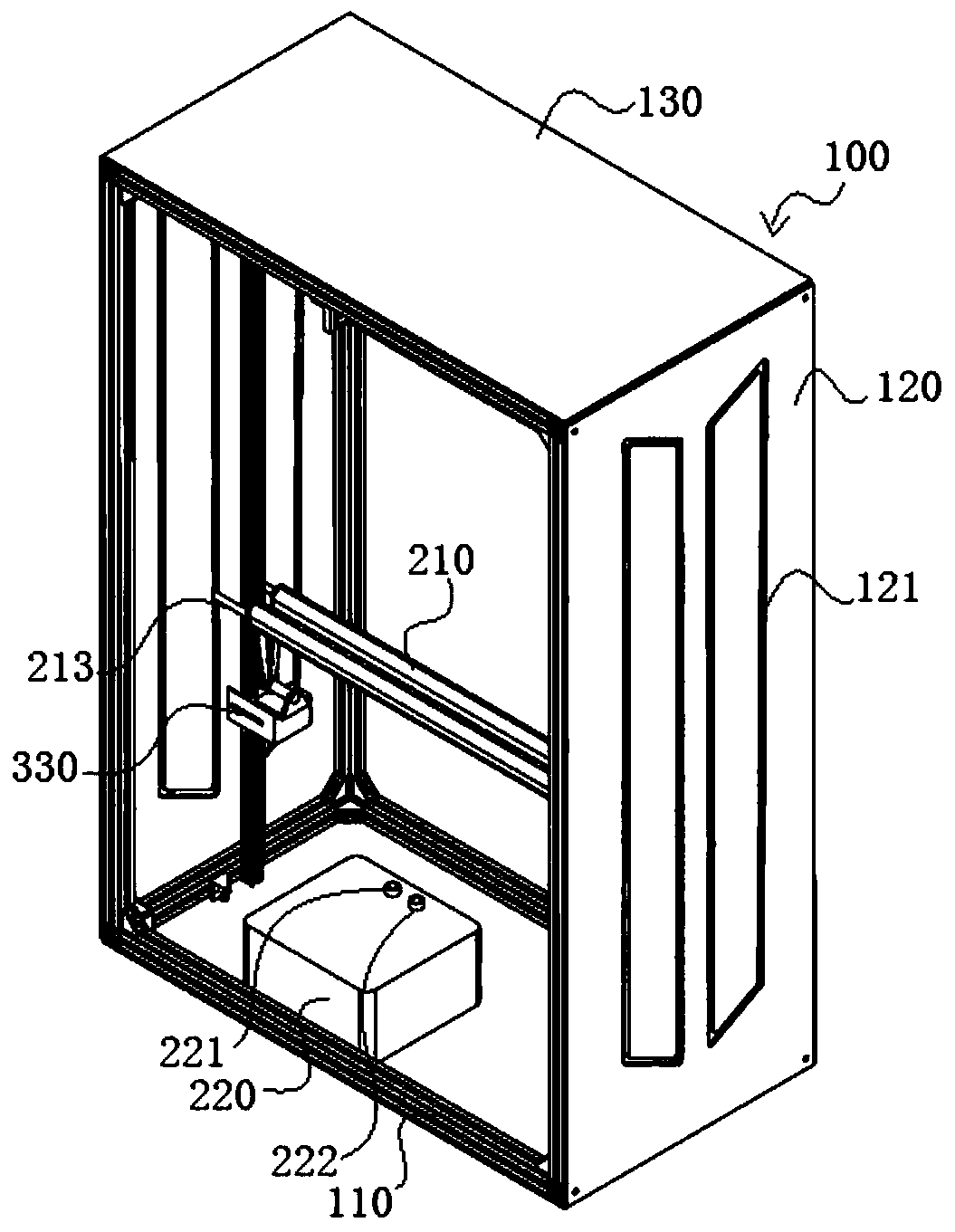

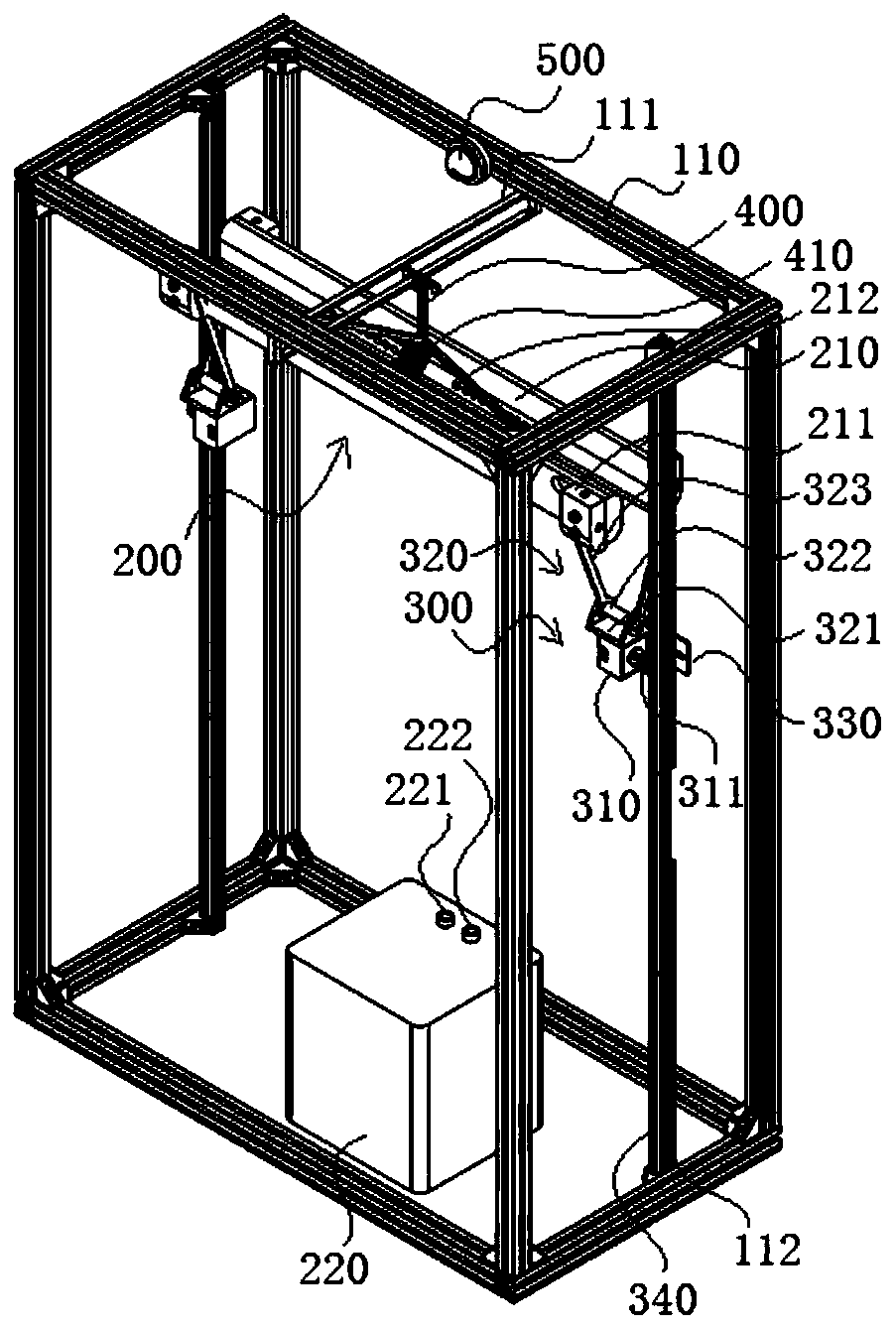

Wardrobe with clothes ironing function

ActiveCN112011984AImprove ironing efficiencyPrevent moistureWardrobesHousehold cleanersEngineeringMechanical engineering

The invention relates to a wardrobe with a clothes ironing function, relates to the field of wardrobe, and aims to solve the problem of low ironing efficiency during clothes ironing in existing wardrobes. The wardrobe comprises a cabinet body and an ironing assembly, the cabinet body comprises a storage area and a hanging ironing area, a hanging rod is arranged on the upper portion of the hangingironing area, the ironing assembly comprises a steam ironing machine arranged on the cabinet body, a steam pipeline connected to the steam ironing machine and a spray head connected to the end, away from the steam ironing machine, of the steam pipeline, and an air hole is formed in one side of the spray head; the steam pipeline comprises a fixed pipeline and a plurality of steam hoses connected tothe fixed pipeline, each steam hose is correspondingly provided with a spray head, the spray heads are arranged in rows in the hanging ironing area in the horizontal direction, every two adjacent spray heads form a group, and the surfaces, provided with the air holes, of the two spray heads in each group are opposite to each other; and the wardrobe also comprises a longitudinal moving assembly driving the spray heads to move in the vertical direction, and a transverse moving assembly driving the spray heads in the same group to move relatively. The wardrobe has the effect that the garment ironing efficiency is improved while garments are stored.

Owner:杭州乔金斯科技集团有限公司

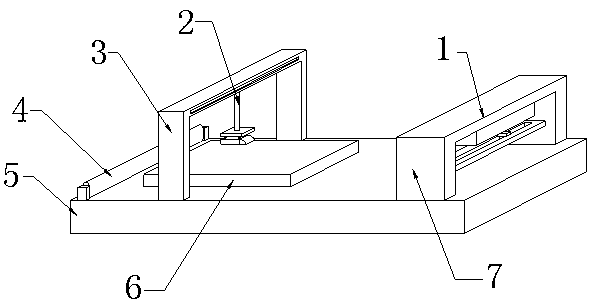

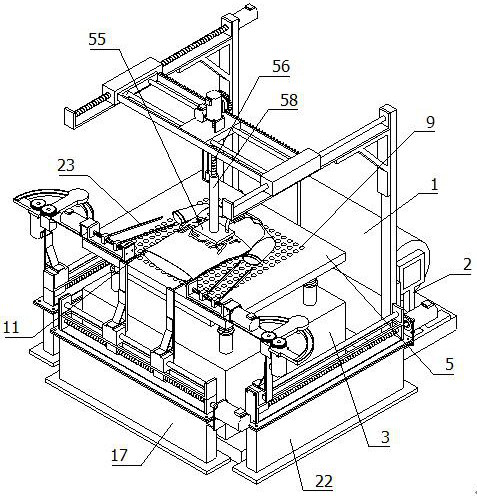

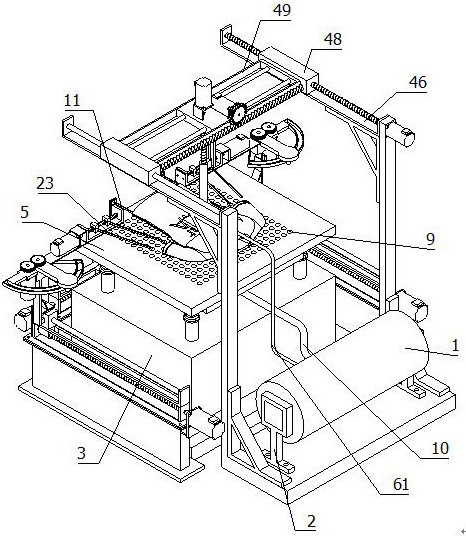

Automatic ironing equipment with tension adjusting function and used for garment processing

InactiveCN112281439AImprove ironing efficiencyAvoid harmIroning apparatusTextiles and paperEngineeringCuff

The invention relates to the field of garment processing, in particular to automatic ironing equipment with a tension adjusting function and used for garment processing. The automatic ironing equipment comprises an ironing table, a bottom opening expanding assembly, two cuff expanding assemblies, an automatic ironing assembly and a steam tank; the ironing table is used for placing wrinkled clothes; the bottom opening expanding assembly is used for supporting and flattening the bottom openings of clothes; the two cuff expanding assemblies are the same in structure, and are used for supporting and flattening the cuffs of the clothes; the two cuff expanding assemblies are symmetrically arranged on the two sides of the ironing table; the automatic ironing assembly is used for automatically ironing the clothes on the ironing table and arranged above the ironing table; the steam tank is used for providing steam for the automatic ironing assembly and the ironing table; and the steam tank is arranged at one end, away from the bottom opening expanding assembly, of the ironing table through a bottom frame. By means of the automatic ironing equipment, the problems that the traditional manualgarment ironing efficiency is low, and an operator is prone to being hurt are solved, the garment ironing efficiency is improved, and manual injuries are avoided.

Owner:宁波奉化腾菲工艺品厂

Ironing device for garment factory

InactiveCN105177961APlay the role of ironingReduce manufacturing costIroning apparatusTextiles and paperSprayerEngineering

Owner:陈伟强

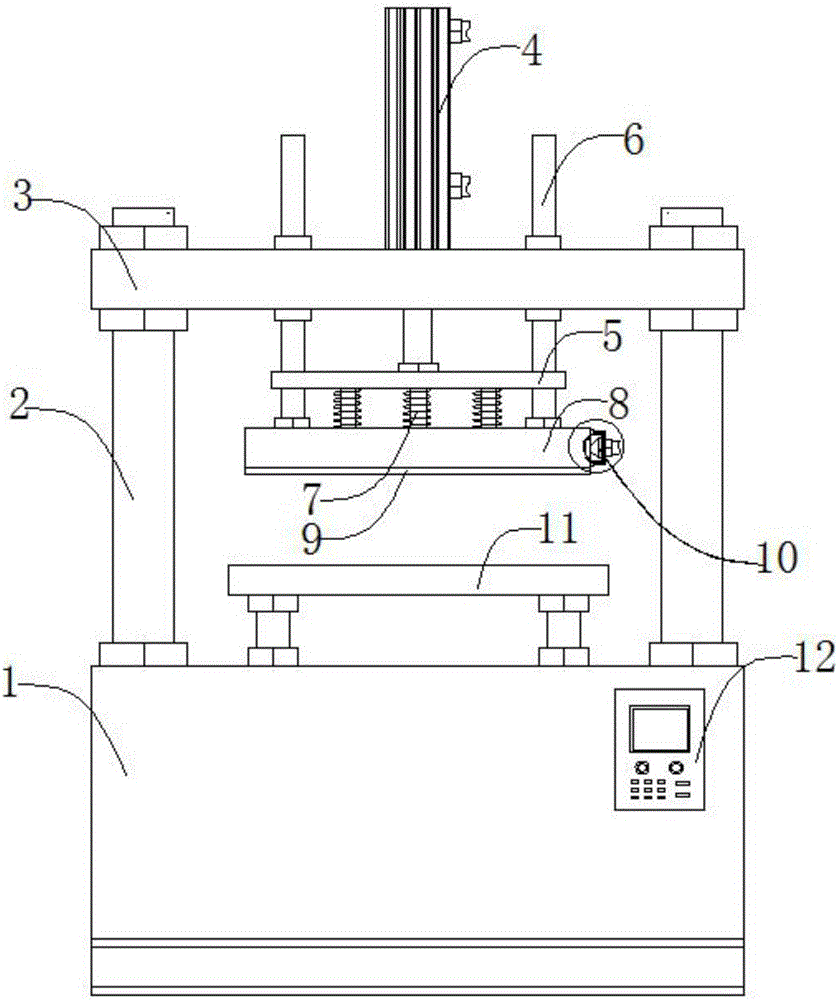

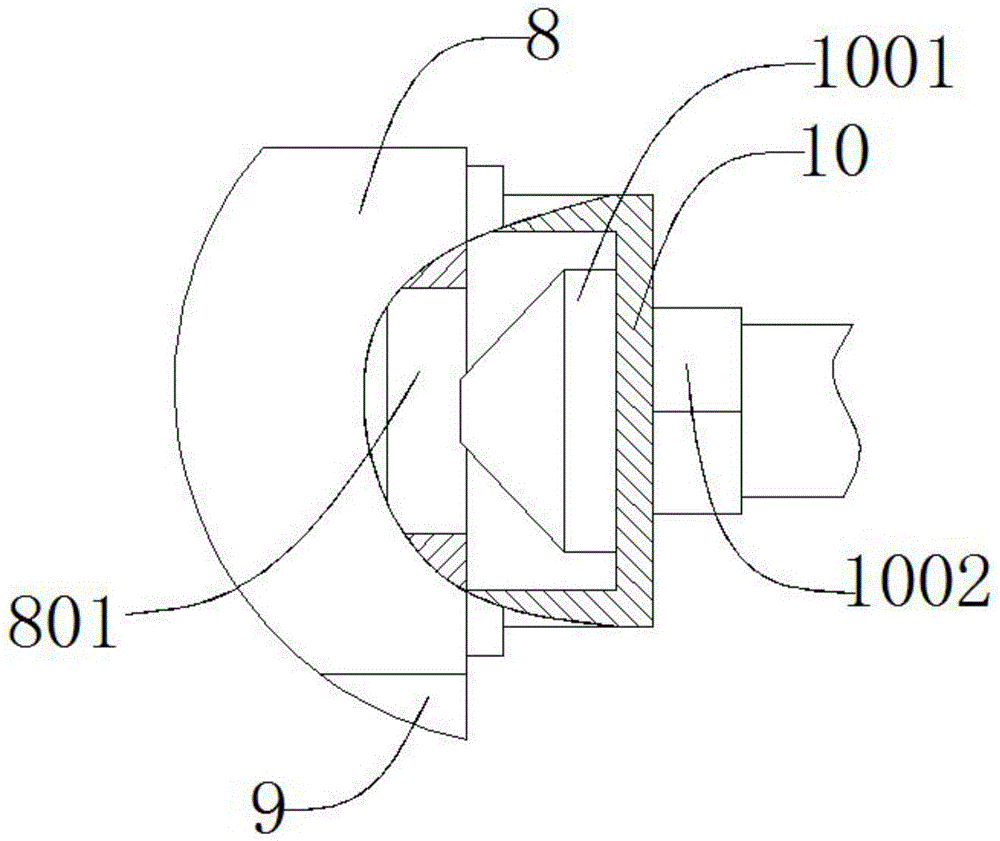

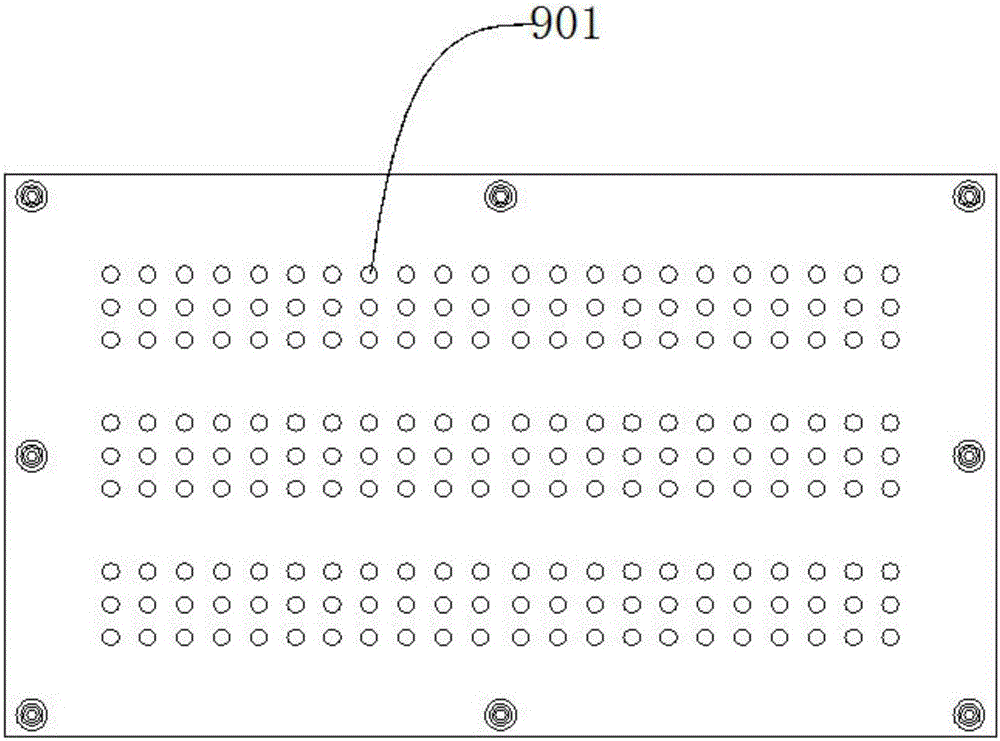

Press fitting type clothes ironing device

InactiveCN106498685ASimple structureImprove ironing effectIroning apparatusTextiles and paperHeat conductingEngineering

The invention discloses a press fitting type clothes ironing device. The press fitting type clothes ironing device comprises an engine base, stand columns, a supporting plate, an air cylinder, a sliding plate, guide rods, no less than 3 springs, a steam box, an upper heat conducting plate, a buffering box, a lower heat conducting plate and a controller; clothes are put on the lower heat conducting plate and are flatly laid; the controller is used for controlling the air cylinder to work and the air cylinder pushes the sliding plate to move downward, so that the steam box, which is fixedly connected with the springs, is pushed to move downward; when the air cylinder is moved in place, the springs are deformed, so that the clothes are tightly pressed; meanwhile, steam enters the buffering box through an air pipe, and then the steam enters the steam box through an air inlet after the steam is collected and guided through an air collection cover, so that the upper heat conducting plate is heated; then the steam in the steam box is sprayed to the clothes through air spraying holes formed in the upper heat conducting plate; the clothes are ironed flatly under a pre-pressing effect of the springs and a heating effect of the steam. The device disclosed by the invention is simple in structure; a pre-pressing type steam ironing manner is adopted, so that the ironing effect is good; meanwhile, the automation degree is high and the ironing efficiency is extremely improved.

Owner:池州海琳服装有限公司

Ironing device for processing novel textile fabric

InactiveCN108660666AScientific and reasonable structureEasy to useTextile shapingMotor driveEngineering

The invention discloses an ironing device for processing a novel textile fabric. The device comprises a frame, the front side of the bottom end of the frame is fixedly connected with a dehumidifier, motors is arranged at the inner bottom end of the dehumidifier, the top end of every motor is rotatably connected with fan blades, a second carding roller is arranged at a position, close to the dehumidifier, in the frame, a first carding roller is arranged above the second carding roller, and a carding driven gear is mounted at one end of the second carding roller. The ironing device has a scientific and reasonable structure, and high-temperature steam is generated by a steam generated and is conveyed into an ironing plate in order to comprehensively iron the fabric, so the artificial labor intensity is reduced, and the production efficiency is improved; and the motors drive the fan blades to rotate in order to dry the textile fabric, so the processing cost is reduced, the ironing efficiency is improved, the ironing quality is improved, and the ironing device is suitable for being comprehensively promoted and used.

Owner:XIANGSHUI YONGTAI TEXTILE GARMENT CO LTD

Ironing device for spinning

InactiveCN107604581AEasy to dryAvoid burnsLiquid/gas/vapor removal by gas jetsTextile shapingHydraulic cylinderDrive motor

The invention discloses an ironing device for spinning, comprising a worktable, wherein a group of hydraulic cylinders arranged in parallel are fixed at the top of the worktable, a first mounting plate and a second mounting plate are respectively fixed on the piston rods of the hydraulic cylinders; a driving motor is fixed on one side, close to the second mounting plate, of the first mounting plate; a threaded rod in rotatable connection with the second mounting plate is fixed on the output shaft of the driving motor, a mounting block is in threaded socket with the outer side of the threaded rod, a steam generator is fixed at the bottom of the mounting block, and a symmetrically arranged leveling structure is fixed at two sides of the steam generator. According to the invention, by the matched use of structures including the hydraulic cylinders, the driving motor, the threaded rod, the mounting block, the steam generator, a steam outlet head, a leveling block and a spring, a material can be both ironed and leveled, and manual holding for an iron for operation is not needed, thus not only avoiding scald, but also being high in ironing efficiency and good in effect.

Owner:南陵百绿汇农业科技有限公司

Ironing device for clothing processing

InactiveCN108691182AImprove ironing efficiencyReasonable structural designIroning apparatusTextiles and paperThreaded rodOperations management

The invention discloses an ironing device for clothing processing, which comprises a workbench, two sides of the top of the workbench are fixedly connected with a first mounting frame and a second mounting frame respectively, the bottom of the inner wall of the first mounting frame is fixedly connected with a first motor, and the output shaft of the first motor is fixedly connected with a first threaded rod, the surface of the first threaded rod is connected with a first moving block, a fixing rod is fixedly connected with the top part and the bottom part of the inner wall of the second mounting frame, and the device relates to the technical field of clothing processing equipment. According to the ironing device for clothing processing, the ironing device is used to ironing clothing, and asliding block can be driven by a sliding rail to change the angle of the clothing for ironing. The whole device is reasonable in structural design, the ironing efficiency is high, and the practicability is strong, the whole ironing device moves through universal wheels, the flexibility of the whole device is enhanced, the while ironing device has complete functions and is suitable for popularization of market clothing industry development.

Owner:宿松晴朗服饰有限公司

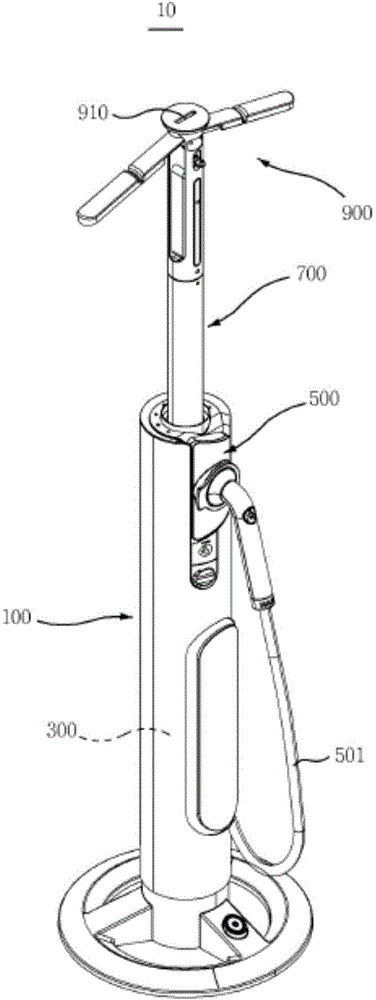

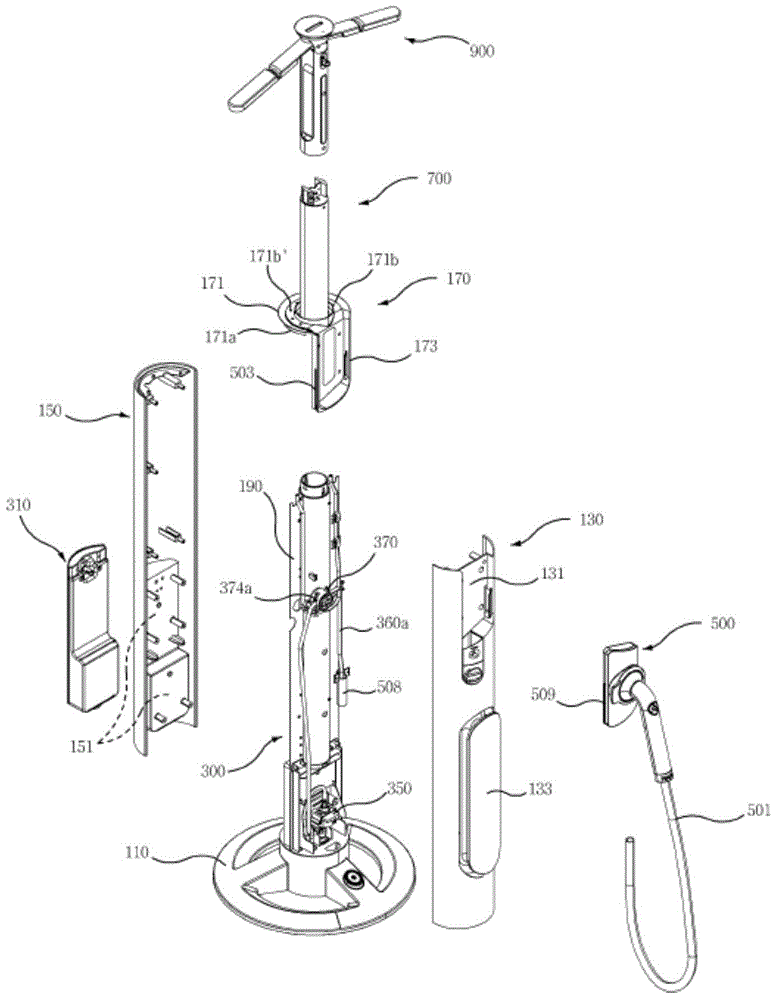

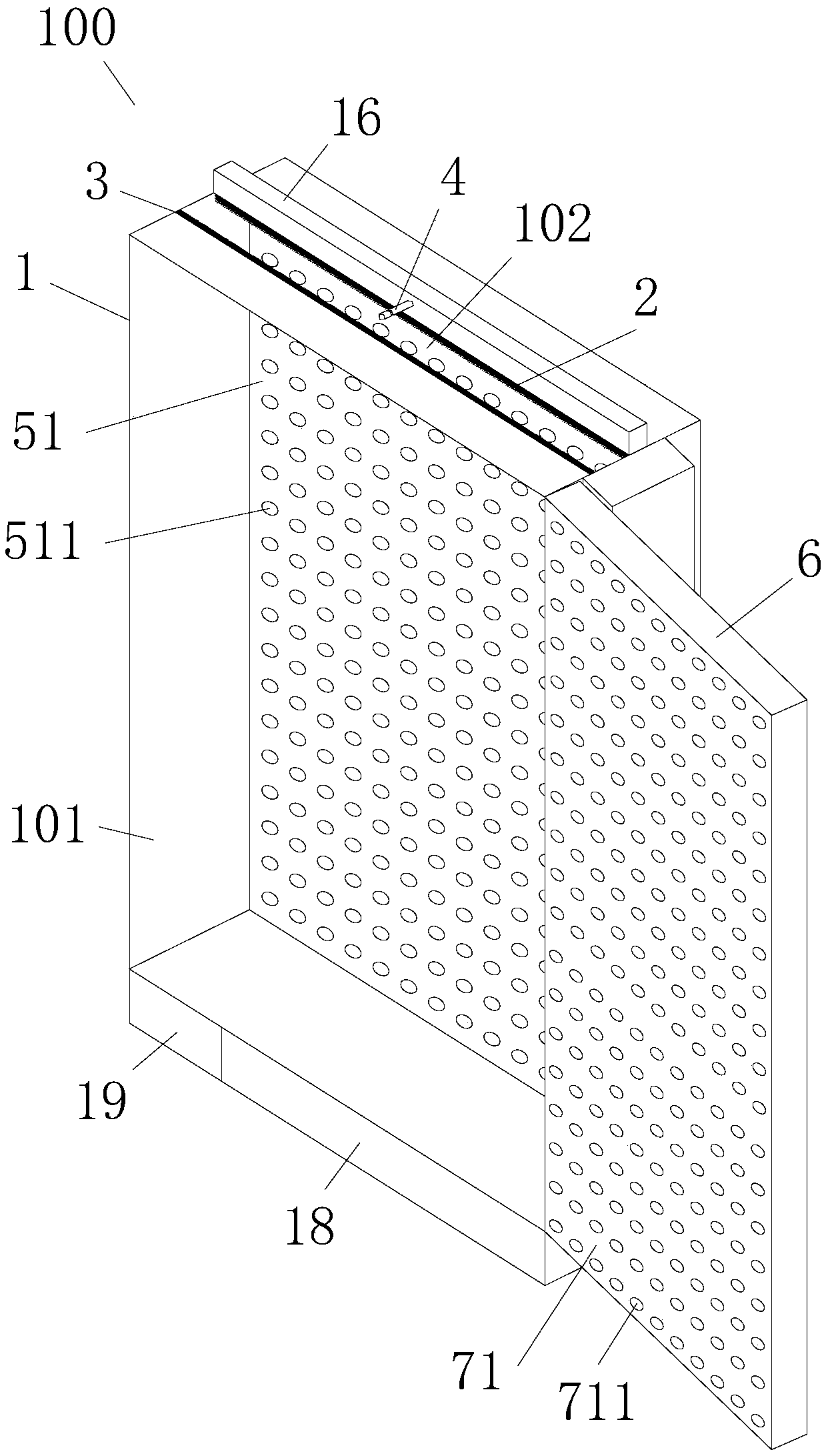

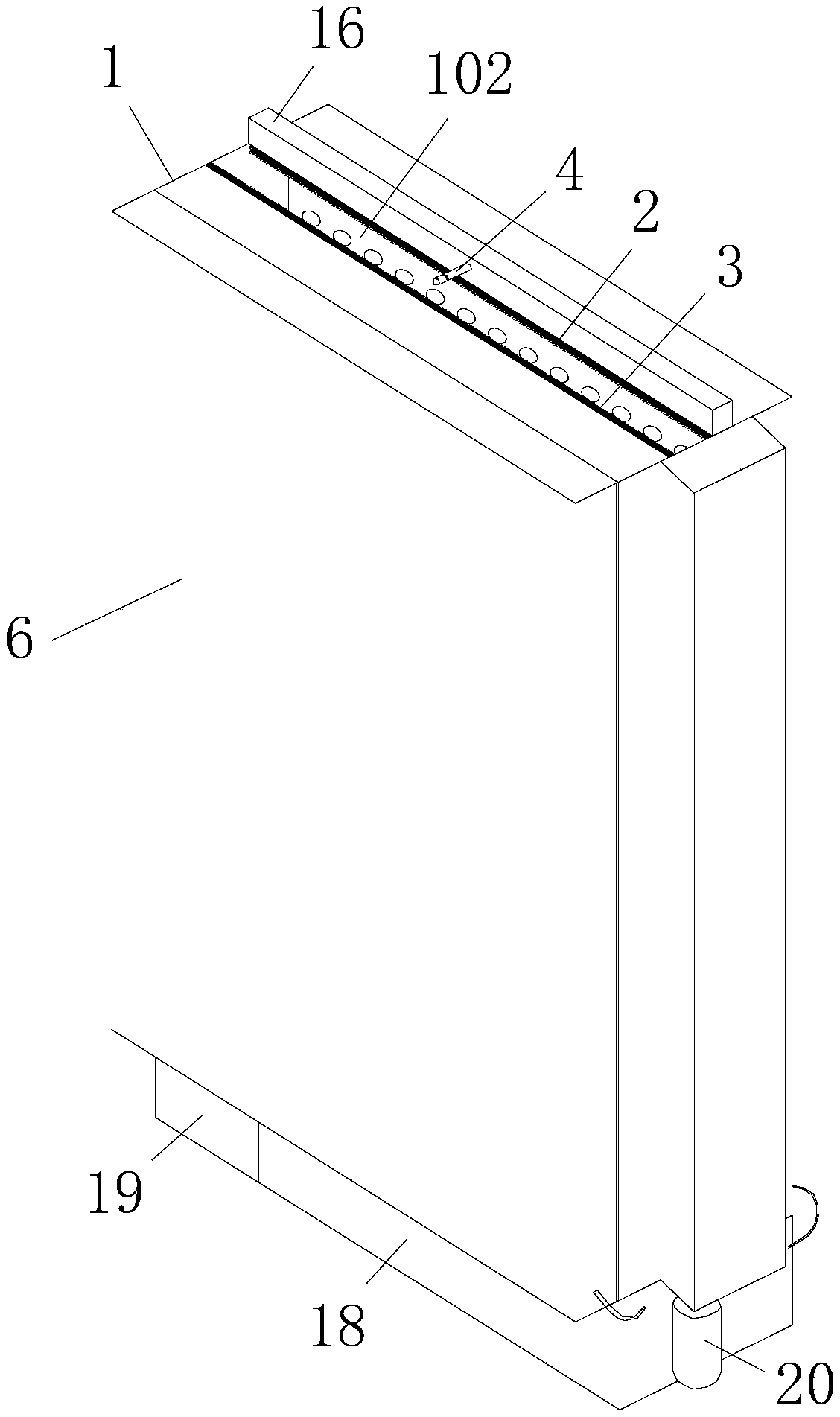

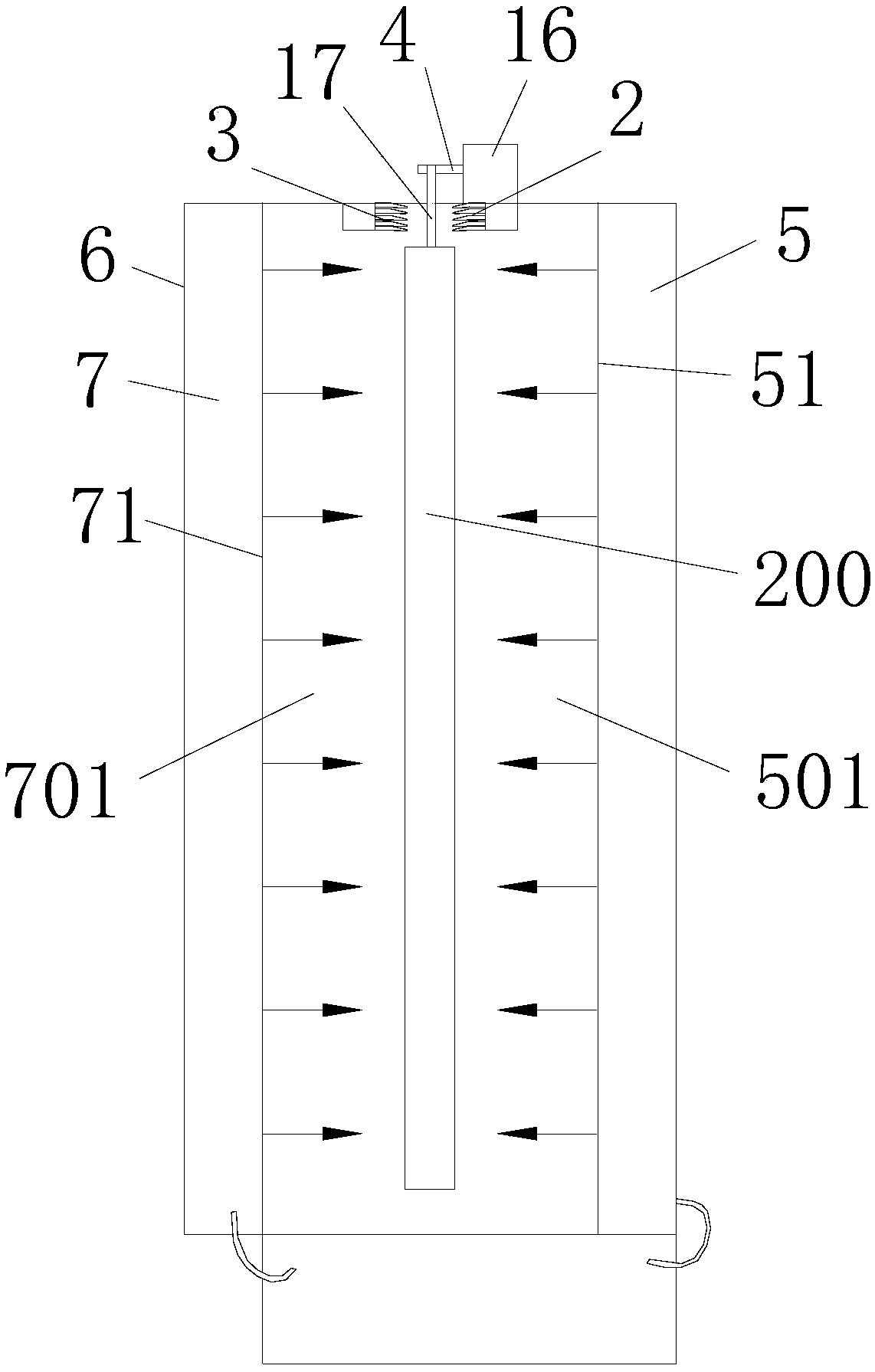

Quick and convenient intelligent ironing equipment

ActiveCN110004690AConvenient for ironing workReduce labor intensityIroning apparatusTextiles and paperControl systemBiochemical engineering

The invention discloses quick and convenient intelligent ironing equipment. The quick and convenient intelligent ironing equipment comprises an ironing tank, an ironing mechanism and an intelligent identification control system and is characterized in that a tank door is arranged on a frame, lateral plates are arranged on two sides of the frame, a top plate is arranged at the top of the frame, theupper end of the frame is provided with a hanging rod for hanging a clothes hanger, and the clothes hanger is provided with a two-dimensional code corresponding to the texture information of to-be-ironed clothing hung on the clothes hanger; the ironing mechanism comprises a steam generator and ironing plates clamping two sides of the to-be-ironed clothing, the ironing plates are provided with steam channels inside along the length direction of the ironing plates, and the upper sides of one ends of the ironing plates are provided with steam inlets communicated with the steam channels. The quick and convenient intelligent ironing equipment has the advantages that the washed clothing is directly hung on the corresponding clothes hanger, the ironing mechanism can be controlled by the intelligent identification control system to automatically iron the clothing, high automation level is achieved, and operator labor intensity is lowered while the ironing efficiency of the ironing equipment is increased.

Owner:SHANGHAI UNIV OF ENG SCI

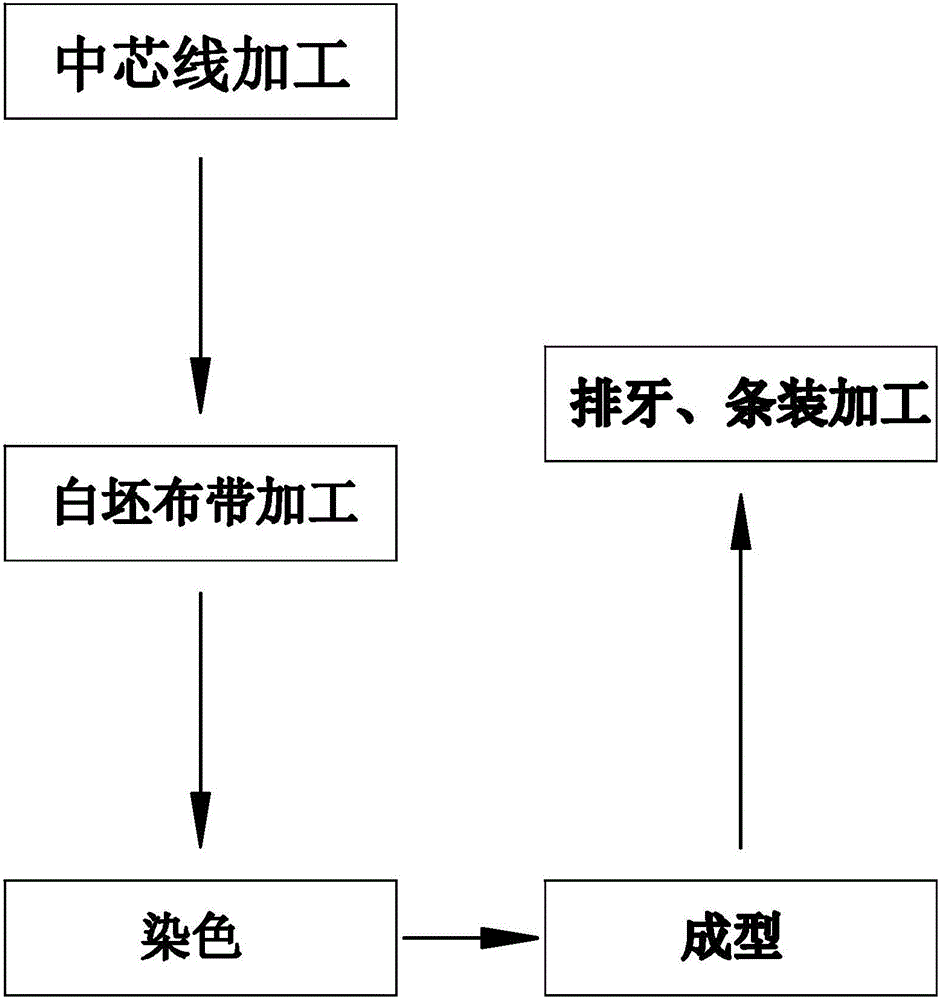

Processing technology of plastic-steel zipper

InactiveCN105029836AImprove flatnessTo meet the requirements of higher quality clothingSlide fastenersEngineeringDyeing

The invention provides a processing technology of a plastic-steel zipper. The technical problems that when a plastic-steel zipper in the prior art is applied to top fly of coat clothing, zipper teeth are prone to hunching up; if steam ironing is carried out through an iron, the hunch-up phenomenon can be more serious; meanwhile, the phenomenon that the size is reduced occurs, and the appearance of the clothing is seriously influenced are solved. The processing technology of the plastic-steel zipper comprises the following steps of A, center core wire processing, B, grey cloth strip processing, C, dyeing, D, molding and E, tooth arrangement and strip-shaped packaging processing. The processing technology has the advantages of being capable of solving the problem that zipper teeth hunch up and shrink, and improving the flatness of the zipper.

Owner:ZHEJIANG JKJ ZIPPER TECH CO LTD

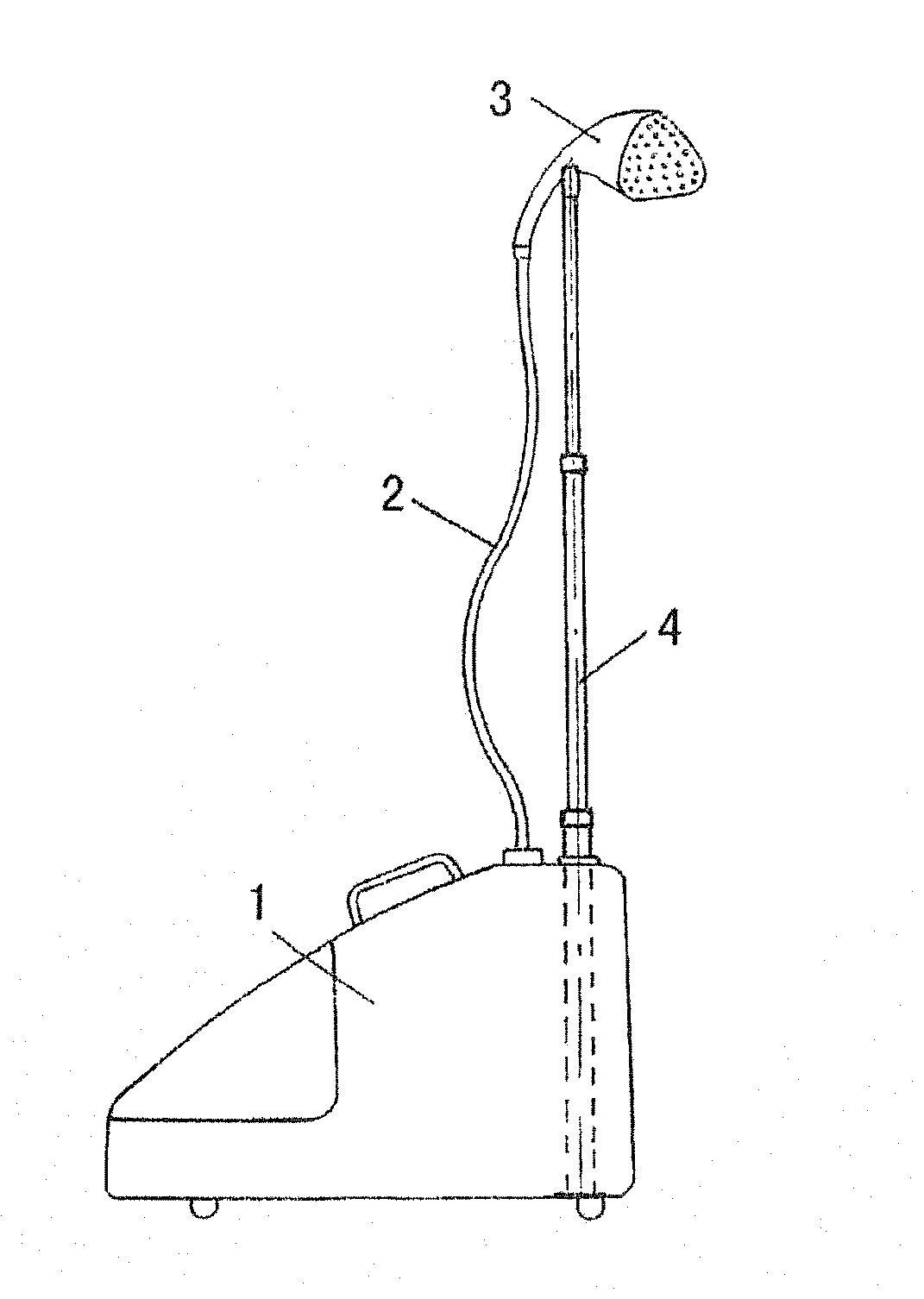

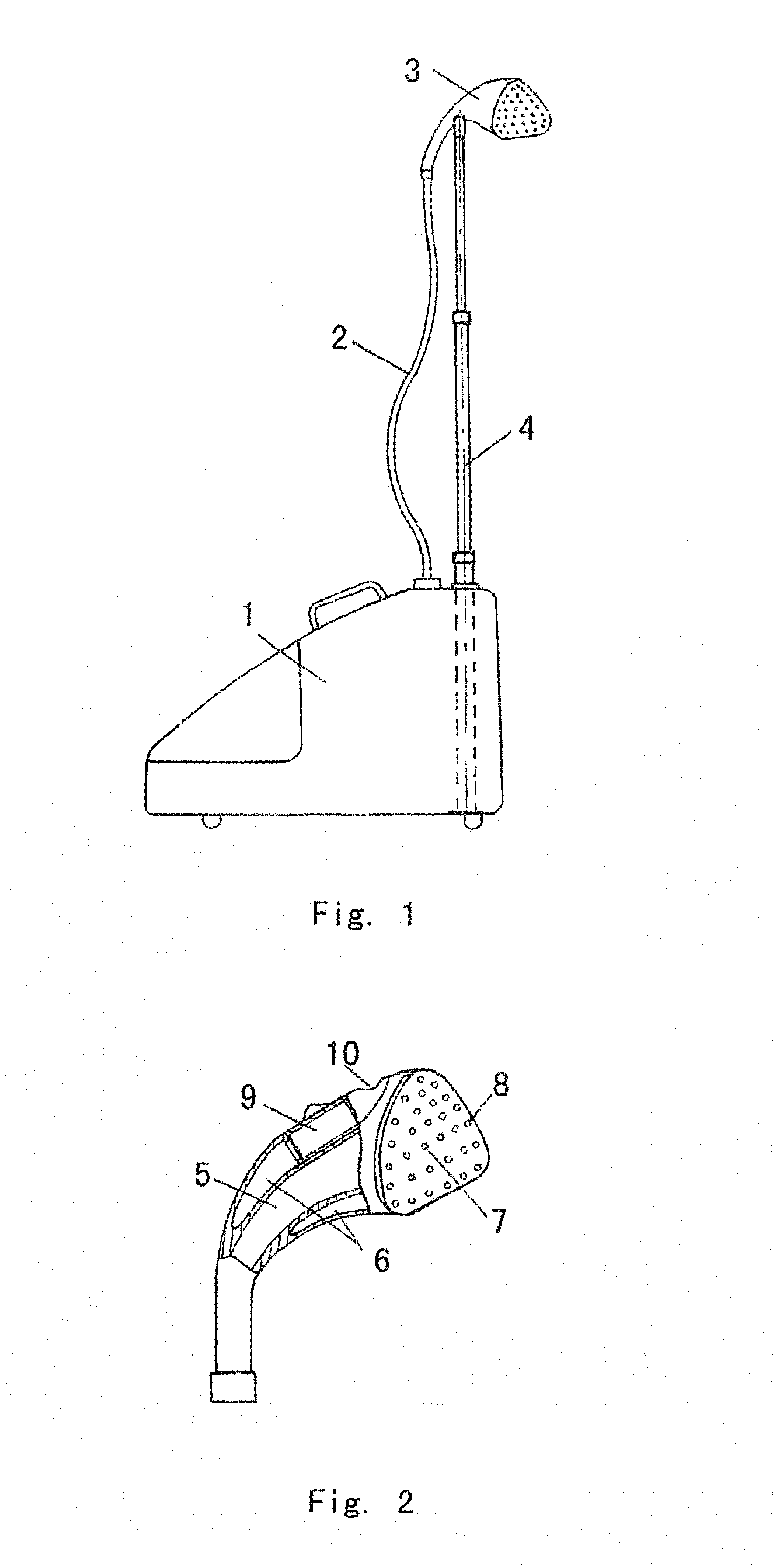

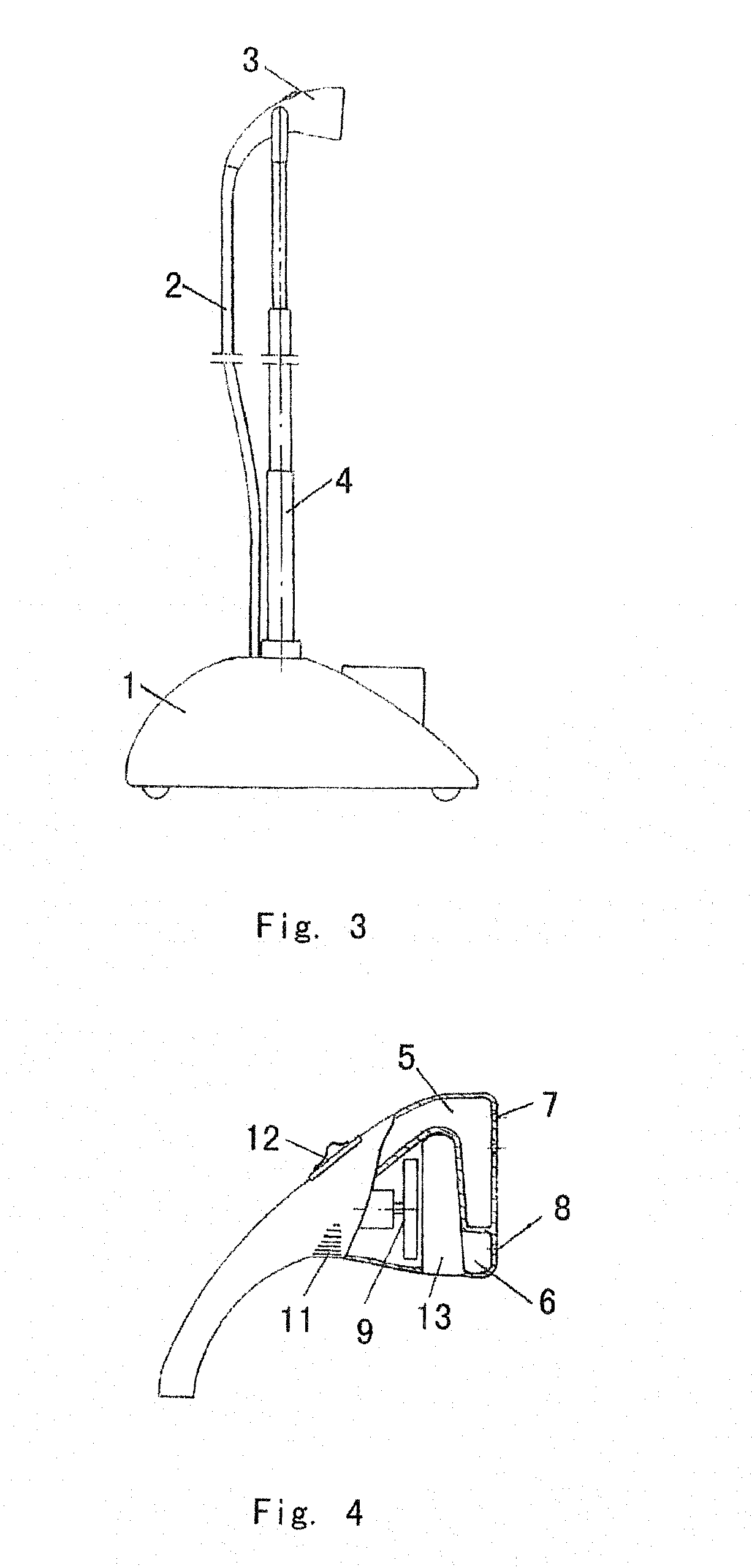

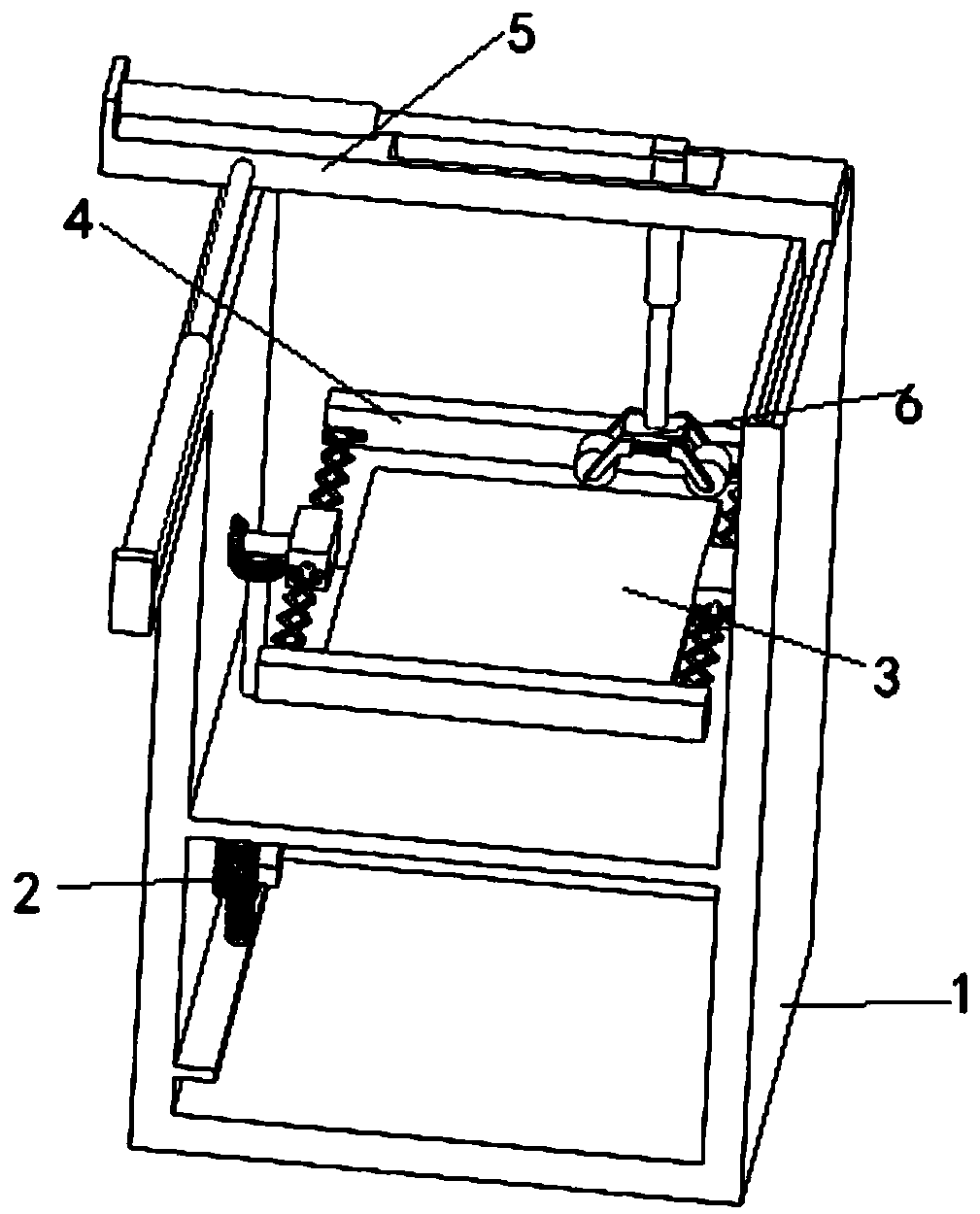

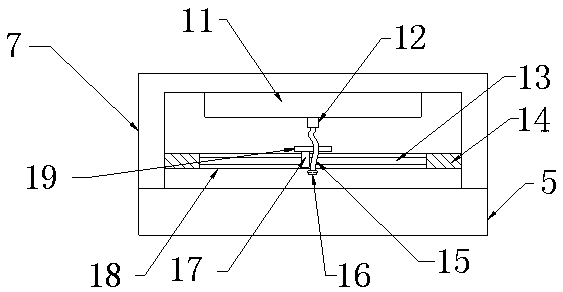

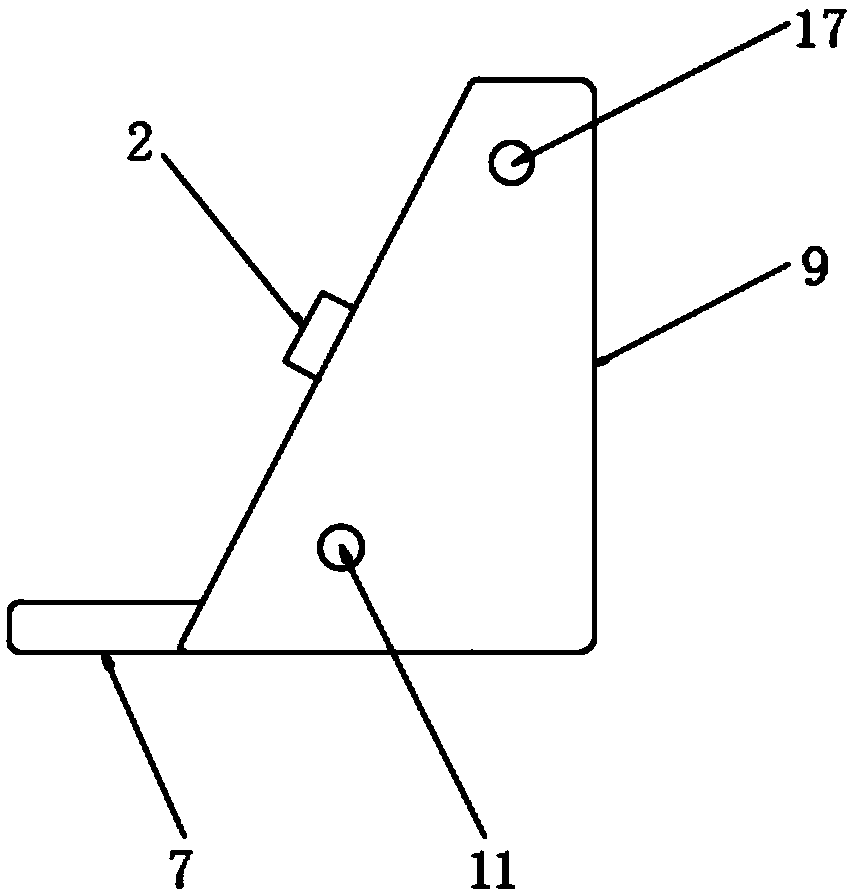

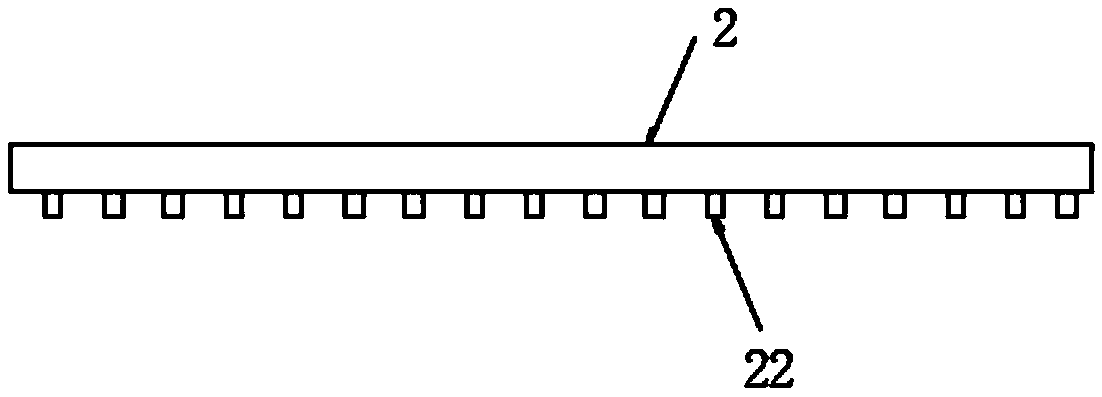

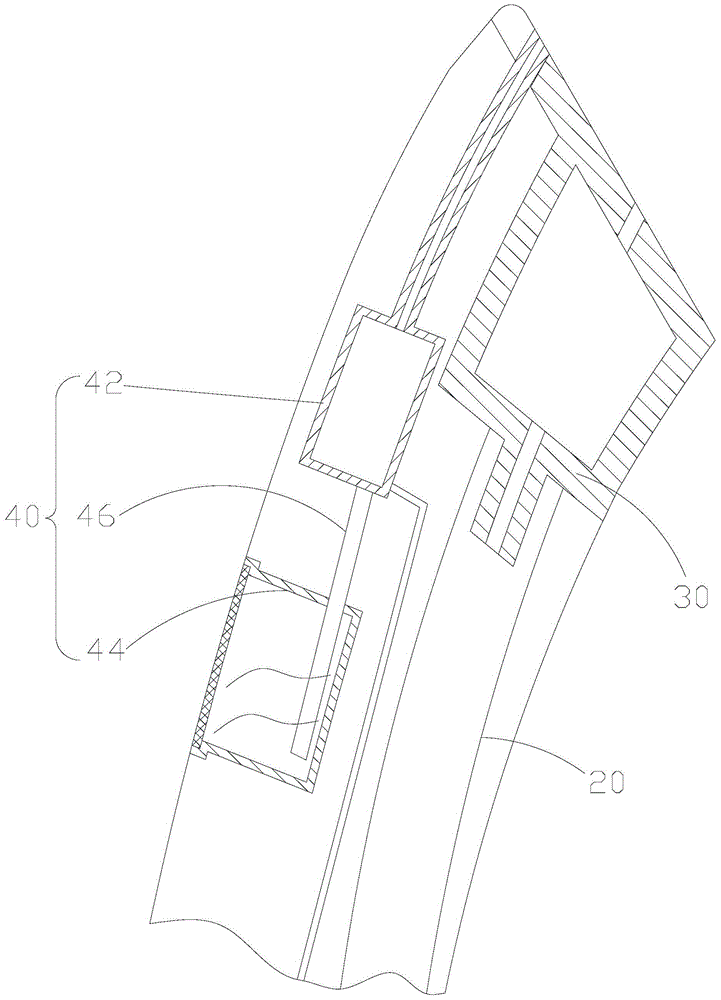

Steam Nozzle Of Steam Iron

The invention relates to a steam nozzle of a steam iron. The steam nozzle comprises a handle and a nozzle head assembly connected with the handle, wherein the steam nozzle further comprises a fixed head device fixedly connected with the handle; and the fixed head is arranged in the nozzle head assembly. The steam nozzle is characterized in that the nozzle head assembly can rotate relatively to the fixed head device; the nozzle head assembly can rotate on the handle; stand type ironing or pressing ironing can be finished via one steam nozzle; the nozzle head assembly is rectangular; when stand type ironing is required, the nozzle head assembly can rotate along the width direction and then ironing work can be completed; ironing efficiency can be improved; when pressing ironing is required, the nozzle head assembly can rotate along the length direction and then ironing work can be completed; same as the common ironing methods, at the pressing ironing state, push-pull ironing can be conducted; and ironing efficiency can be effectively improved.

Owner:SUZHOU HAAN TECH +1

Cloth anti-wrinkle ironing equipment for garment production

InactiveCN112281384AGood rolling and fixing effectAchieve repeated ironingTextile shapingEngineeringMechanical engineering

The invention relates to the technical field of clothing production, and discloses cloth anti-wrinkle ironing equipment for garment production. The cloth anti-wrinkle ironing equipment comprises a machine body; a through hole is formed in the left side of the machine body; cloth is placed below the through hole; leveling pressing rollers are arranged on the upper side and the lower side of the cloth; a driving shaft is arranged in a winding drum; a movable pin is rotatably connected into the winding drum; a movable block is fixedly connected to the surface of the movable pin; a fourth spring is fixedly connected into the movable block; a clamping strip is fixedly connected to the right side of the fourth spring; and a groove is formed in the winding drum. According to the cloth anti-wrinkle ironing equipment for garment production, a worker enables cloth to penetrate through the space between the two flattening pressing rollers, the right end of the cloth is placed in the groove of thewinding drum, the movable block moves into the groove through the movable pin to extrude the cloth, and then the cloth is clamped in the clamping groove through the clamping strip; and due to the acting force of the fourth spring, the cloth is extruded in the clamping groove all the time, and therefore the rolling fixing effect is good.

Owner:东阳梦凡特时装有限公司

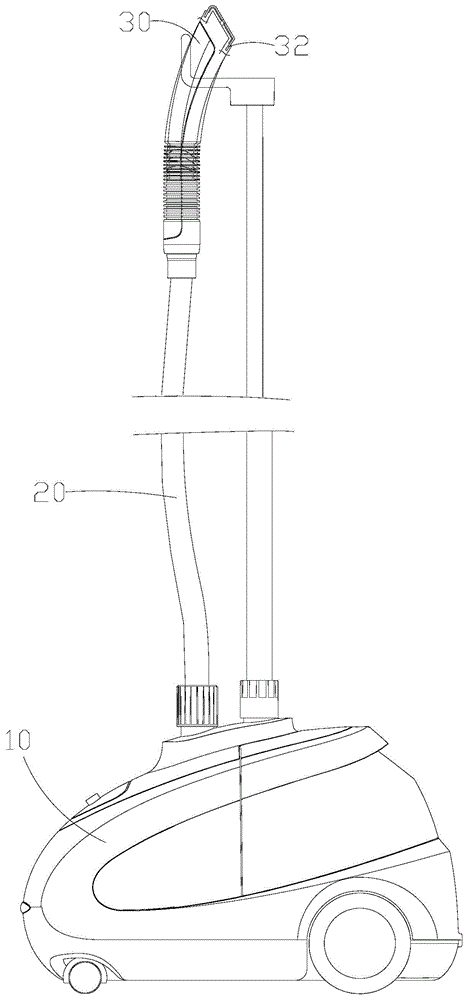

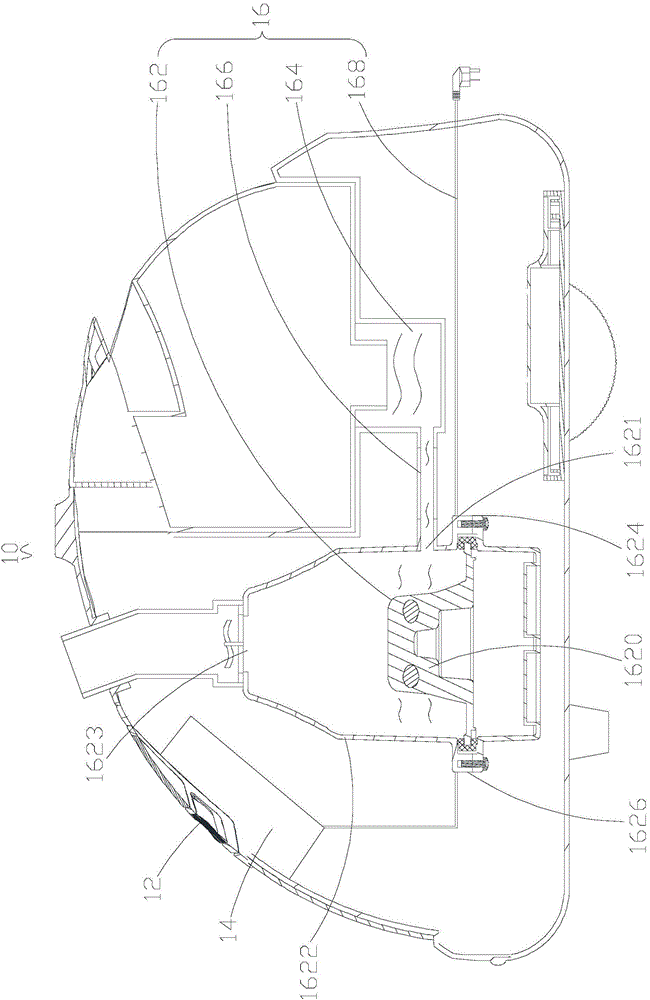

Garment steamer and control method thereof

ActiveCN104805667AImprove ironing efficiencySave ironing timeIroning apparatusTextiles and paperSteam generationControl engineering

The invention is applicable to the technical field of household electrical appliance, and provides a garment steamer and a control method thereof. The control method of the garment steamer comprises the following steps: providing the garment steamer comprising a main machine, an ironing head, a steam conduit, a main machine switch and a main control panel, wherein a steam control module and an auxiliary agent control module are arranged inside the main control panel, the steam control module controls a steam generating component, and the auxiliary agent control module control an auxiliary agent activation component; switching on the main machine switch for selectively starting the steam control module and / or the auxiliary agent control module; and ironing. By selectively starting the steam control module and / or the auxiliary agent control module, different work modes can be selected based on different fabric materials, such as only starting the steam control module, or only starting the auxiliary agent control module, or simultaneously starting the steam control module and the auxiliary agent control module, so as to meet the requirements on different ironing temperatures for different fabrics, and accordingly the ironing efficiency can be increased and the ironing time can be saved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

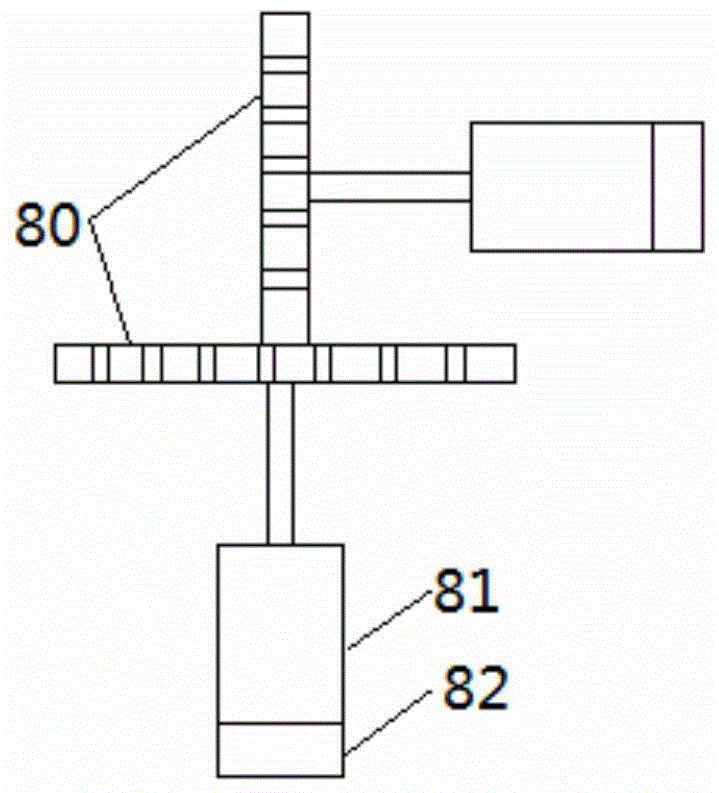

Double-sided ironing device capable of overturning based on reciprocating motion

InactiveCN110965248AQuality improvementImprove efficiencyTextile shapingReciprocating motionGear wheel

The invention relates to the technical field of clothing, and discloses a double-sided ironing device capable of overturning based on reciprocating motion. The double-sided ironing device comprises asupport rod, wherein the support rod is used for supporting and stabilizing an iron; a fabric is arranged on the outer side of the iron in a sleeving mode; by virtue of matched use of limiting columns, a limiting frame and a transverse rod, an ironing plate can be turned over automatically in the ironing process, two-side ironing of the fabric can be achieved, and the quality and efficiency of ironing are improved; when an inner gear rotates, the transverse rod is driven to move left and right intermittently, therefore, the iron is driven to move synchronously, so that the fabric can be automatically ironed left and right, and the ironing efficiency is improved; the ironing plate is driven to move downwards and turned over in a movement stopping process by virtue of matched use of the ironand the ironing plate, and excessive fabric ironing caused when the iron stays in the same place for a long time is prevented; and by virtue of the matched use of a connecting column, the limiting frame and the limiting columns, the ironing plate is automatically turned over in the ironing process, and the ironing working efficiency is improved.

Owner:绍兴市德帏纺织科技有限公司

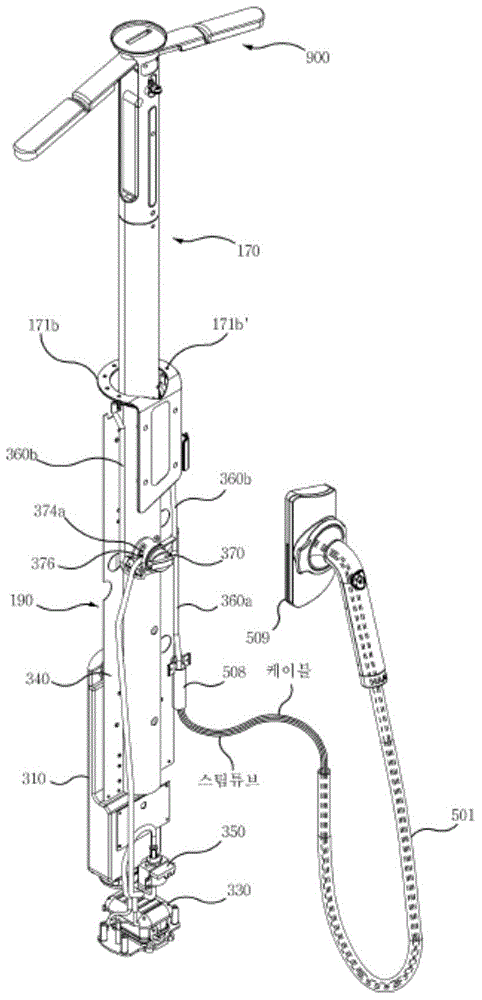

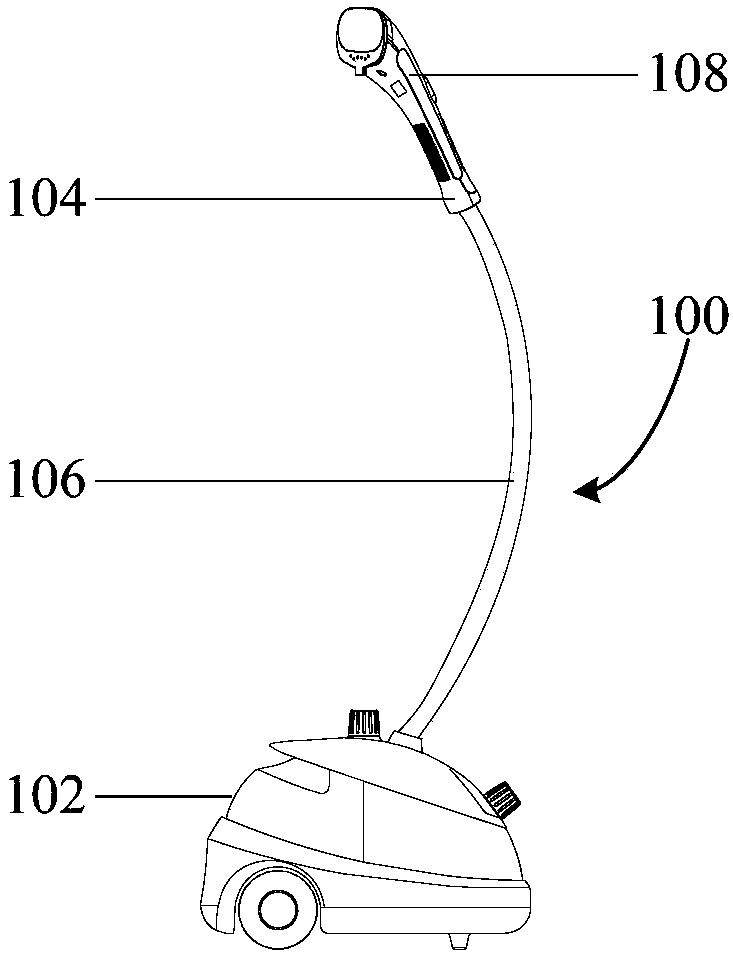

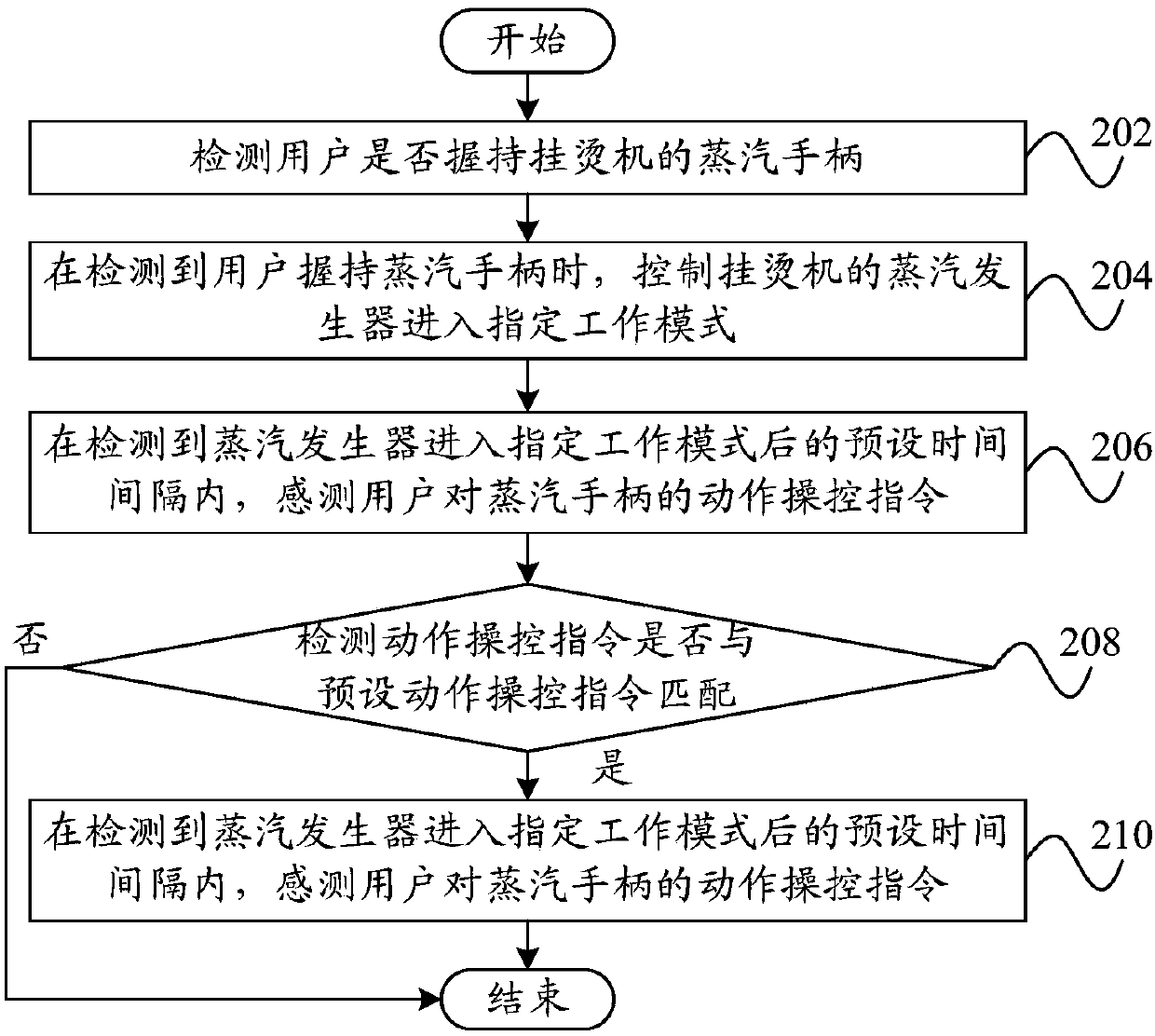

Garment steamer and control method and system

ActiveCN107663762AEasy to operateImprove user experienceIroning apparatusTextiles and paperControl systemComputer module

The invention provides a garment streamer and a control method and system. The garment streamer comprises a motion sensor, the motion sensor is arranged on a holding portion of a stream handle and isconnected to a control module, and the motion sensor is used for detecting motion operation commands of a user to the stream handle to trigger the control module to switch the state and working mode of a stream generator through the motion operation commands. According to the technical scheme, operation of users is facilitated, the ironing efficiency is improved, and the use experience of the useris improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

Anti-slip anti-wrinkling ironing platform for clothes processing

InactiveCN106498690AEffective clampingPrevent slidingIroning boardsTextiles and paperComputer engineeringC shaped

The invention discloses an anti-slip anti-wrinkling ironing platform for clothes processing. the platform comprises an ironing table body, a cavity is formed in the ironing platform body, a containing groove is formed in the top of the ironing table body, through holes distributed at equal intervals are formed in the inner bottom wall of the containing groove and communicated with the cavity, a smooth cotton pad is fixedly connected with the inner bottom wall of the containing groove, two symmetric sliding grooves are formed in the inner side wall of the containing groove, two symmetric movable blocks are arranged on the top of the smooth cotton pad, each movable block is in a C shape, and the outer side face of the bottom end of each movable block is fixedly connected with a slider matched with the corresponding sliding groove. The anti-slip anti-wrinkling ironing platform for clothes processing can effectively clamp clothes, effectively prevents sliding and wrinkling of the clothes and is good in clamping performance, the clothes do not need to be flat laid and set right frequently, workers are effectively prevented from being scalded, effective ironing of the clothes is ensured, and ironing efficiency is high.

Owner:浙江于雁服饰有限公司

Textile raw material conveying and ironing equipment

ActiveCN112195631AQuality improvementAchieve double-sided cleaningMechanical cleaningPressure cleaningWater storage tankIndustrial engineering

The invention discloses textile raw material conveying and ironing equipment. The equipment comprises a processing box, an impurity removing roller, a first ironing device and a second ironing device.The impurity removing roller is longitudinally arranged in the processing box, and an adhesion layer is arranged on the peripheral surface of the impurity removing roller; a dust collection head is arranged on a negative pressure pipe and is in contact with the impurity removing roller; an opening is formed in a connecting piece; a water collecting cavity is formed in the connecting piece, and aheating device is arranged in the water collecting cavity; a spray head is communicated with the water collecting cavity; a water pumping pipe and a water conveying pipe are arranged on a water pump;the water pumping pipe communicates with a water storage tank; a water conveying branch pipe is arranged on the connecting piece, is communicated with the water collecting cavity and is connected withthe water conveying pipe; and a first bearing plate and a second bearing plate are arranged in the processing box, the first ironing device is located above the first bearing plate, and the second ironing device is located below the second bearing plate. The textile raw material conveying and ironing equipment is diverse in function, capable of conducting double-sided impurity removing and cleaning operation on textile raw materials and conducting double-sided ironing on the textile raw materials, stable in ironing process and good in ironing effect.

Owner:SUZHOU BABEL TEXTILE TECH CO LTD

Water circulation type cloth ironing and hot drying equipment

InactiveCN111962237AIncrease contact areaWon't flow outLiquid/gas/vapor removal by gas jetsTextile treatment rollersThermodynamicsWater vapor

The invention discloses water circulation type cloth ironing and hot drying equipment. The equipment comprises a boy. A power cavity and a processing cavity are formed in the body. The processing cavity is located on the lower side of the power cavity, and the processing cavity and the power cavity are spaced by a spacer plate. A hot water box is fixedly connected to the inner wall of the lower side of the processing cavity. A water pool is arranged in the hot water box, and the inner wall of the right side of the water pool is fixedly connected with a heat resistance wire. According to the equipment, after being rinsed, ironed and dried, cloth is wound, the cloth bypasses three supporting rollers which are not on the same horizontal plane, it is guaranteed that water vapor generated during cloth drying cannot flow out, and meanwhile the contact area of hot air and the cloth is increased. When the cloth is dried, generated water vapor flows back into a vapor collection cavity through aconnection pipe, water utilization is circulated, the mist discharging quantity of ironing is improved, and ironing efficiency is improved.

Owner:SHANGHAI MEIQIN KNITTING CO LTD

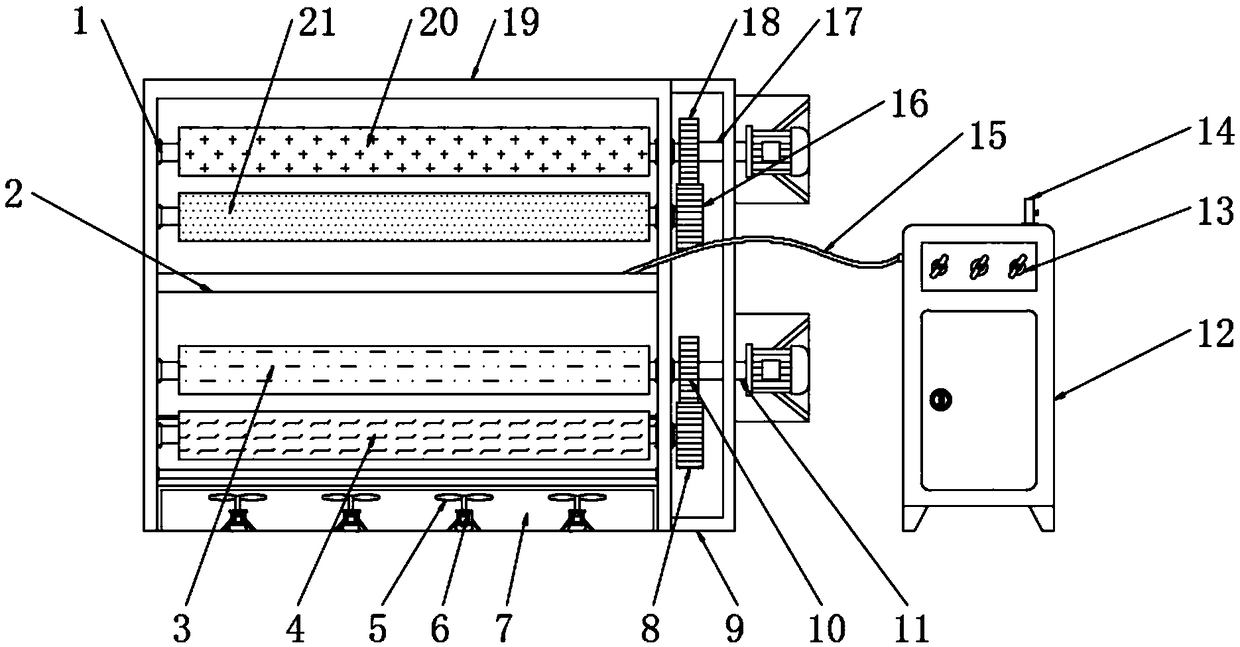

Clothing ironing equipment

ActiveCN108755044AIncrease productivityImprove ironing efficiencyTextiles and paperLaundry driersEngineeringClosest relatives

The invention discloses clothing ironing equipment, and relates to the field of clothing ironing. The main purpose is to solve the technical problems in the prior art that ironing equipment can only iron the single face of clothing at a time, and the ironing efficiency is low. According to the main technical scheme, the clothing ironing equipment comprises a cabinet body, a first hairbrush and a second hairbrush; the cabinet body is provided with a first side and a second side which are opposite in the horizontal direction; the first side is provided with a first steam chamber; a first air outlet plate is opposite to a first face of the hung clothing; the second side of the cabinet body is provided with an opening and a cabinet door capable of being opened or closed relative to the opening, and the cabinet door is internally provided with a second steam chamber; a second air outlet plate is opposite to a second face of the hung clothing when the cabinet door is closed; the first hairbrush is opposite to the second hairbrush, and the first hairbrush and the second hairbrush can both move up and down relative to the cabinet body, and are used for cooperating with each other to move from top to bottom simultaneously to iron and brush the first face and the second face of the clothing.

Owner:拓川(无锡)科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com