Water circulation type cloth ironing and hot drying equipment

A technology of drying equipment and ironing heat, which is applied to the processing of textile material drums, textiles and papermaking, and fabric surface trimming. It can solve problems such as difficult processing, waste of fabric, and fabric pollution, so as to improve efficiency and increase fog output. , the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

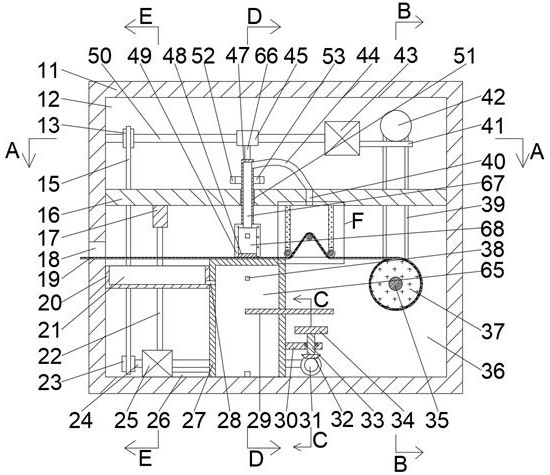

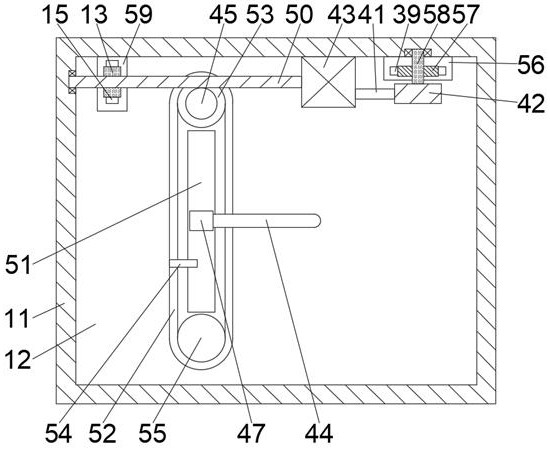

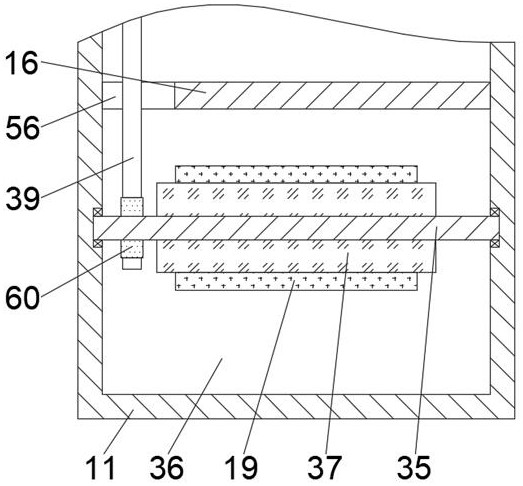

[0020] Combine below Figure 1 to Figure 7 The present invention will be described in detail. For the convenience of description, the following directions are specified as follows: figure 1 The vertical, horizontal, front, and rear directions of the projection relationship are the same.

[0021] The water circulation type cloth ironing heat drying equipment of the present invention includes a main body 11 in which a power cavity 12 and a processing cavity 36 are arranged, and the processing cavity 36 is located on the lower side of the power cavity 12 And the two are separated by a partition plate 16. A hot water tank 27 is fixed on the inner wall of the lower side of the processing chamber 36, and a pool 65 is provided in the hot water tank 27. A thermal resistance wire 29 is fixedly connected, and the thermal resistance wire 29 extends rightward to the right side of the hot water tank 27. A filter box 20 is fixedly connected to the left end surface of the hot water tank 27, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com