Processing method of permanent crepe fabric

A processing method, a permanent technology, applied in the treatment of textile materials, dyeing, fabric surface trimming, etc., can solve the problems of losing the advantages of crepe fabrics, fabric loss of strength, and disappearance of crepe effects, etc., to achieve a natural and rough crepe feeling , improve the sense of quality, and consolidate the effect of fabric crepe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0033] As a preferred embodiment of the present invention, the specific process of mechanical rope wrinkling is:

[0034] First, the fabric is placed in a steaming cylinder for a creping. The lye prepared by mixing liquid caustic soda and water is placed in the steaming cylinder, wherein the content of liquid caustic is 1.5% owf, and the temperature in the steaming cylinder is controlled when creping 100℃, time is 45min;

[0035] Next, crepe the fabric once creped by a rope twisting machine;

[0036] Finally, the creped fabric is placed in a steaming box at 110°C for 60 minutes, and it is complete.

[0037] As a preferred embodiment of the present invention, the steam setting process is specifically as follows: first use steam pretreatment for 30 minutes, control the relative humidity to 90%, and the temperature to 100°C, and then place the pretreated fabric on the setting machine For setting treatment, control the setting temperature to 190℃ to complete the whole steaming setting pr...

Embodiment 1

[0044] A permanent crepe fabric processing method. After weaving the warp and weft yarns into a fabric weave, the fabrics are then sequentially subjected to original creping, pre-setting, washing, drying, mechanical rope creping, steaming setting, and secondary weight reduction. , Dyeing and setting to obtain the permanent crepe fabric.

[0045] The warp yarns and weft yarns described in this embodiment are all twisted or highly elastic fiber yarns made of 100% PET, and the yarn counts of the warp yarns and weft yarns are both 75D.

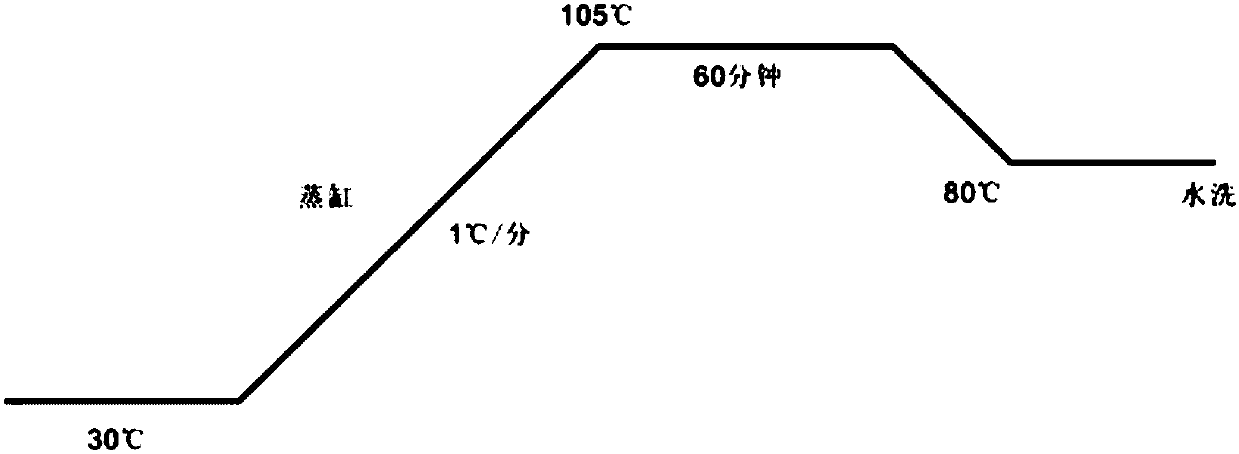

[0046] The original wrinkling process in this embodiment is as figure 1 As shown, specifically:

[0047] Place the fabric in a creping solution containing 1.5-2.0wt% of 30% NaOH liquid caustic soda, 0.8wt% of dispersant and 1% of creping agent, and control the bath ratio to 1:20, and then, from 30 to 1 The speed was increased to 105°C / min, and the temperature was kept for 60 minutes, and then the temperature was lowered to 80°C and washed with water.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com