Efficient and stable shaping treatment system for fluff on surface of Shu velveteen fabric

A processing system and a technology for smoothing lint, which is applied in the field of textile fabric production equipment, can solve the problems of fabric surface fluff and surface downfall, fabric fluff finishing, and fabric fluff damage, etc., to achieve the effect of improving the three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

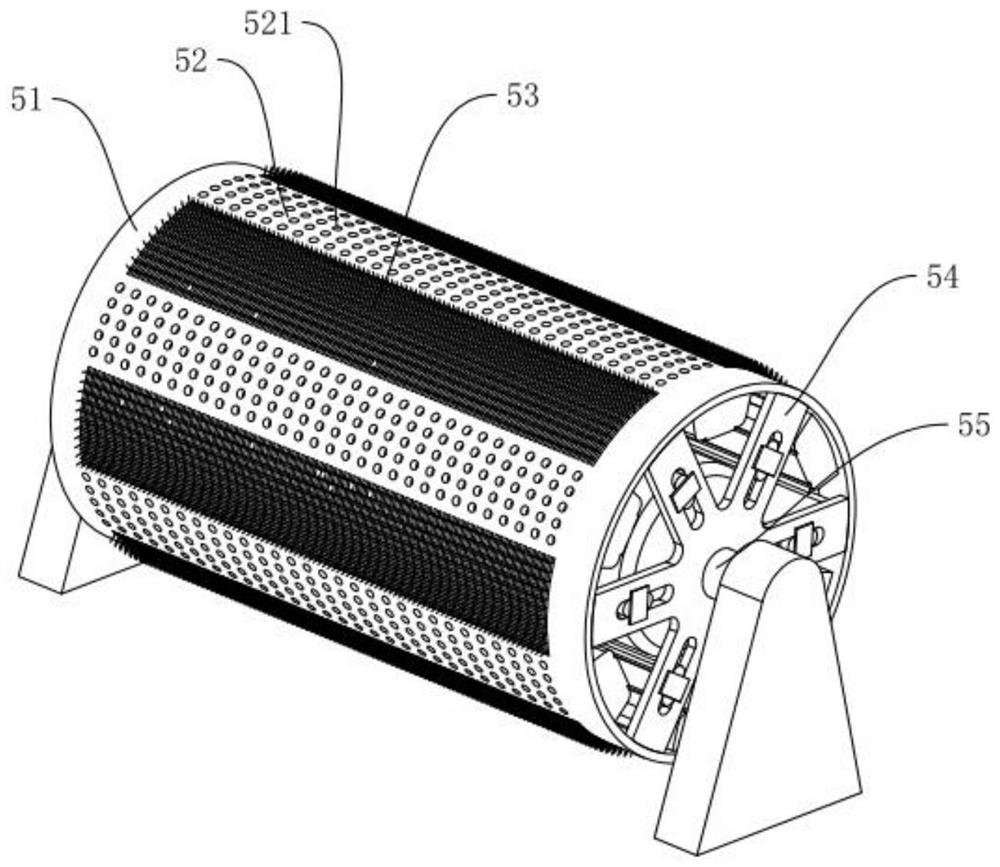

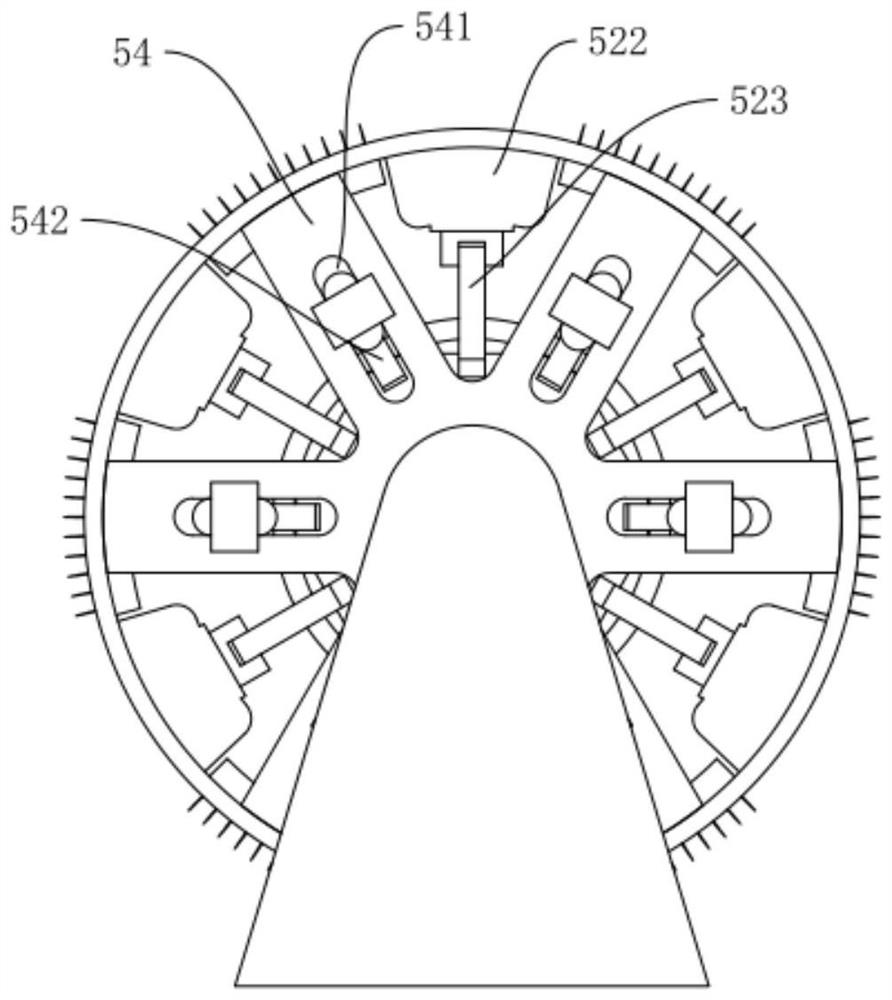

[0038] This embodiment discloses a surface combing device for fluffy fabrics, referring to Figure 1-4 As shown, it includes a combing roller 51 and a shaft assembly 55, and the two ends of the combing roller 51 are provided with support hubs 54, and the supporting hub 54 can support the whole combing roller 51; the shaft assembly 55 passes through the combing roller 51 and The supporting hub 54 drives the combing roller 51 to rotate, thereby combing the incoming fabric.

[0039] The outer peripheral surface of the carding roller 51 is divided into several heating parts 52 and combing parts 53, and the heating parts 52 and the combing parts 53 are alternately distributed around the axial direction, and can respectively heat and comb the fabric, so that the fluff on the surface of the fabric is more loose to form fluff. Then the surface of the fabric is heated by steam, which can be shaped to a certain extent and improve the standing degree of the combed fluff.

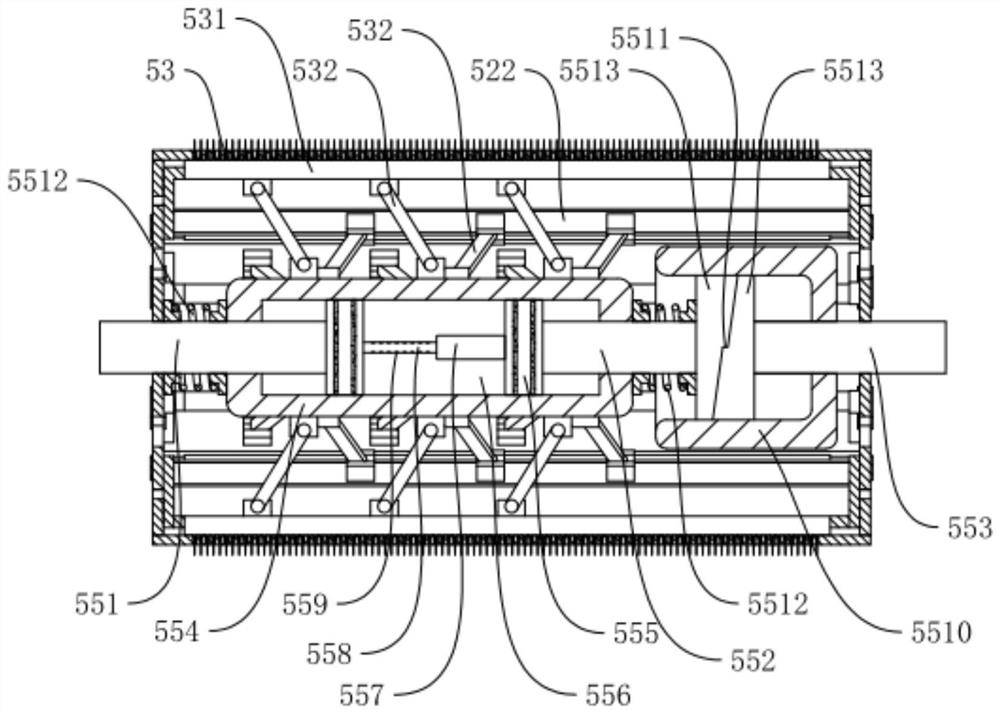

[0040] The co...

Embodiment 2

[0048] This embodiment discloses another kind of fleece fabric surface carding device, further optimizes the carding device 3 on the basis of embodiment one, refer to Figure 5-6 As shown, the structure of the combing needle 536 and the combing block 535 is specifically designed to be supplemented, combined with steam heating, so that the combing needle 536 can simultaneously heat to a certain extent during the combing process of the fabric, and steam blow the fluff on the surface of the fabric. The thorns make the fluff on the surface more fluffy and three-dimensional.

[0049] Each combing block 535 is also equipped with a steam pipe 101, the steam pipe 101 is hard, parallel to the slide bar 107, and one short is fixed on the side inner wall of the combing box 531, and the other end extends into the activity of the combing block 535 Among the chamber 100, the position where the steam pipe 101 extends is slidably sealed by a seal; a piston part 102 is arranged at the position...

Embodiment 3

[0058] This embodiment discloses another kind of fleece fabric surface carding device, further optimizes the carding device 3 on the basis of embodiment two, refer to Figure 5-6 As shown, under the steam treatment of the carding needle 536, adding a set of auxiliary steam heating components can increase the amount of steam ejected from the surface of the carding roller 51, maintain a higher stability in the carding process, and can also pass the spray of steam. Change the behavior of the fluff fiber on the surface of the fabric, and increase the non-linting effect of the fluff of the fabric.

[0059] The inside of the comb block 535 corresponds to the position where the slide bar 107 passes through to provide an air outlet chamber 106, and the inside of the air outlet chamber 106 is provided with a piston part 2 109, which is a high temperature resistant rubber material and is fixedly connected to the outer periphery of the slide bar 107 , and when the slide rod 107 moves axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com