Textile fabric ironing flattening device

A cloth ironing and flattening technology, which is applied to textiles and papermaking, fabric surface trimming, fabric steaming/desteaming treatment, etc., can solve the problems of large ironing and flattening tools, which are not suitable for home use, etc. Achieve the effect of simple structure, simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021] The parts and components described below are all products that are readily available on the market.

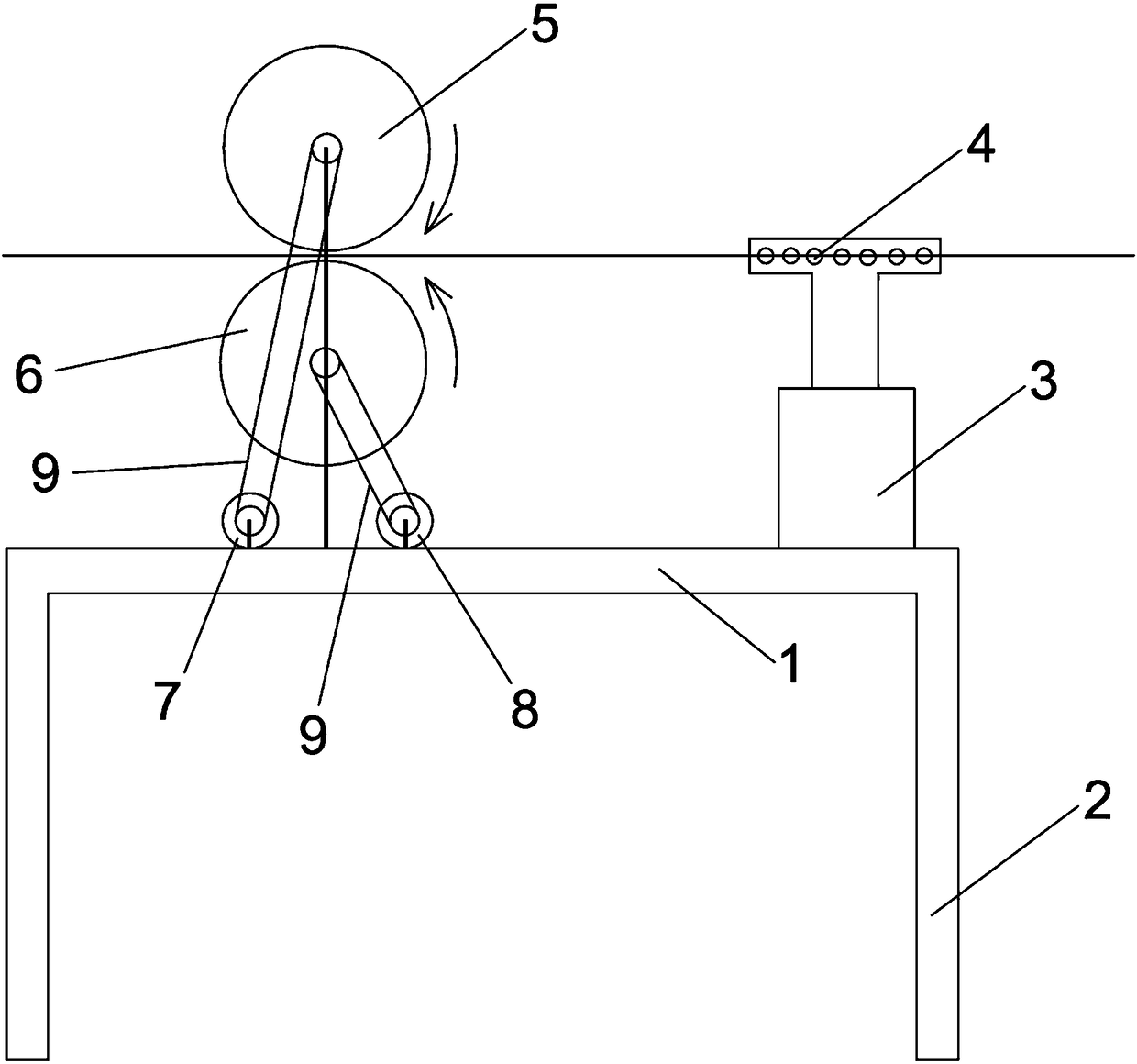

[0022] Such as figure 1 Shown, a kind of textile cloth ironing flattening device comprises:

[0023] A frame, the frame includes a workbench 1 and four machine feet 2 supporting the workbench 1, and a silicone anti-vibration pad is arranged under the machine feet 2.

[0024] The ironing and flattening device is fixed on the frame, and the ironing and flattening device includes an ironing and pressing part.

[0025] The ironing section includes a steam generator 3 and a steam spray head 4 connected with the steam generator 3 .

[0026] In this embodiment, the steam generator 3 includes a heater, and the heater is controlled by a circuit board, and the circuit board is connected to the mains. The steam generator 3 in the present invention is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com