Apparatus for continuous decatizing in autoclave

A technology of autoclave and equipment, which is applied in fabric steaming/desteaming treatment, heating/cooling of fabrics, textiles and papermaking, etc. It can solve the problems of fabrics not getting durable luster and touch, short treatment time, etc., and achieve the best steaming The effect of steaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

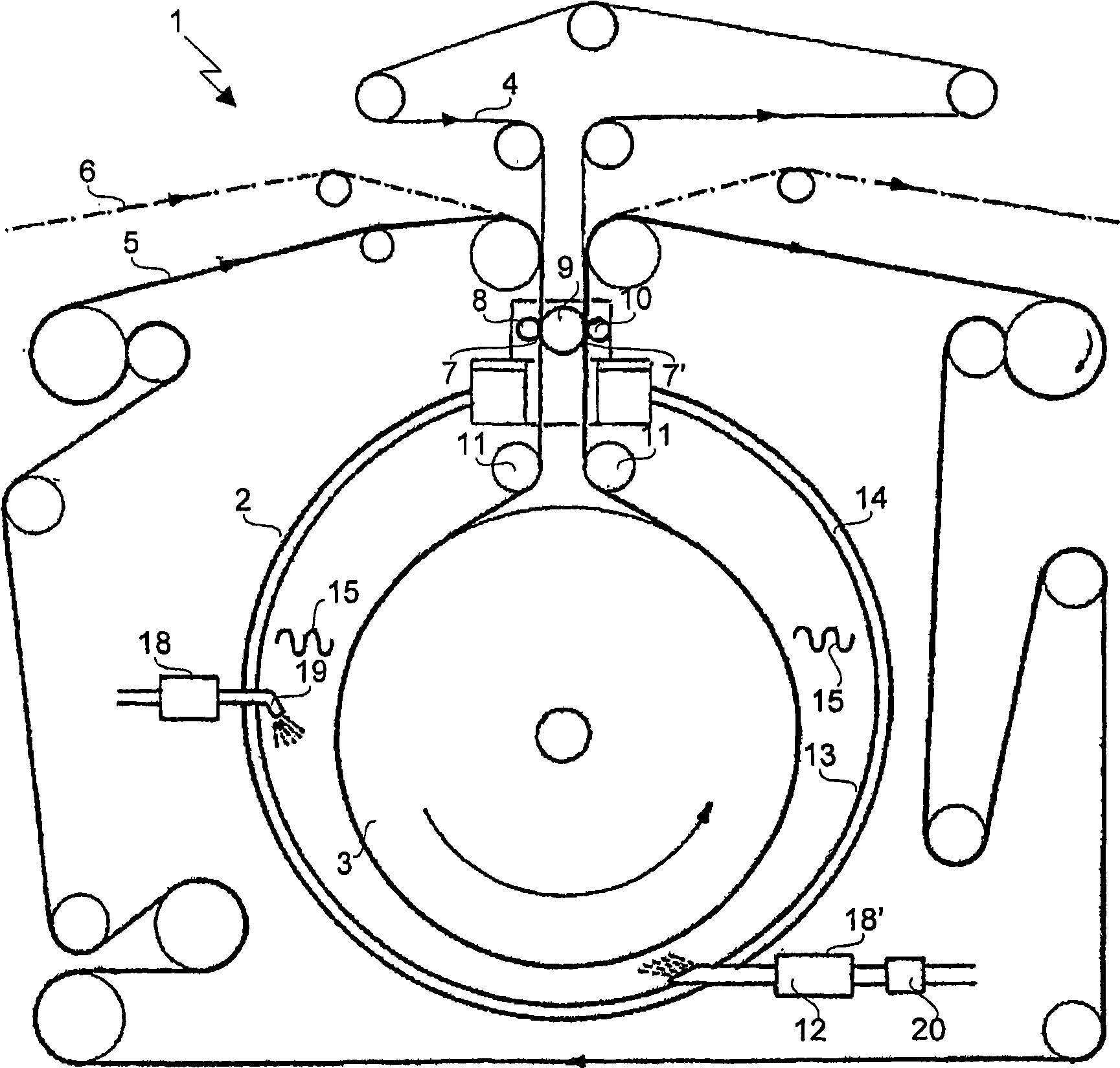

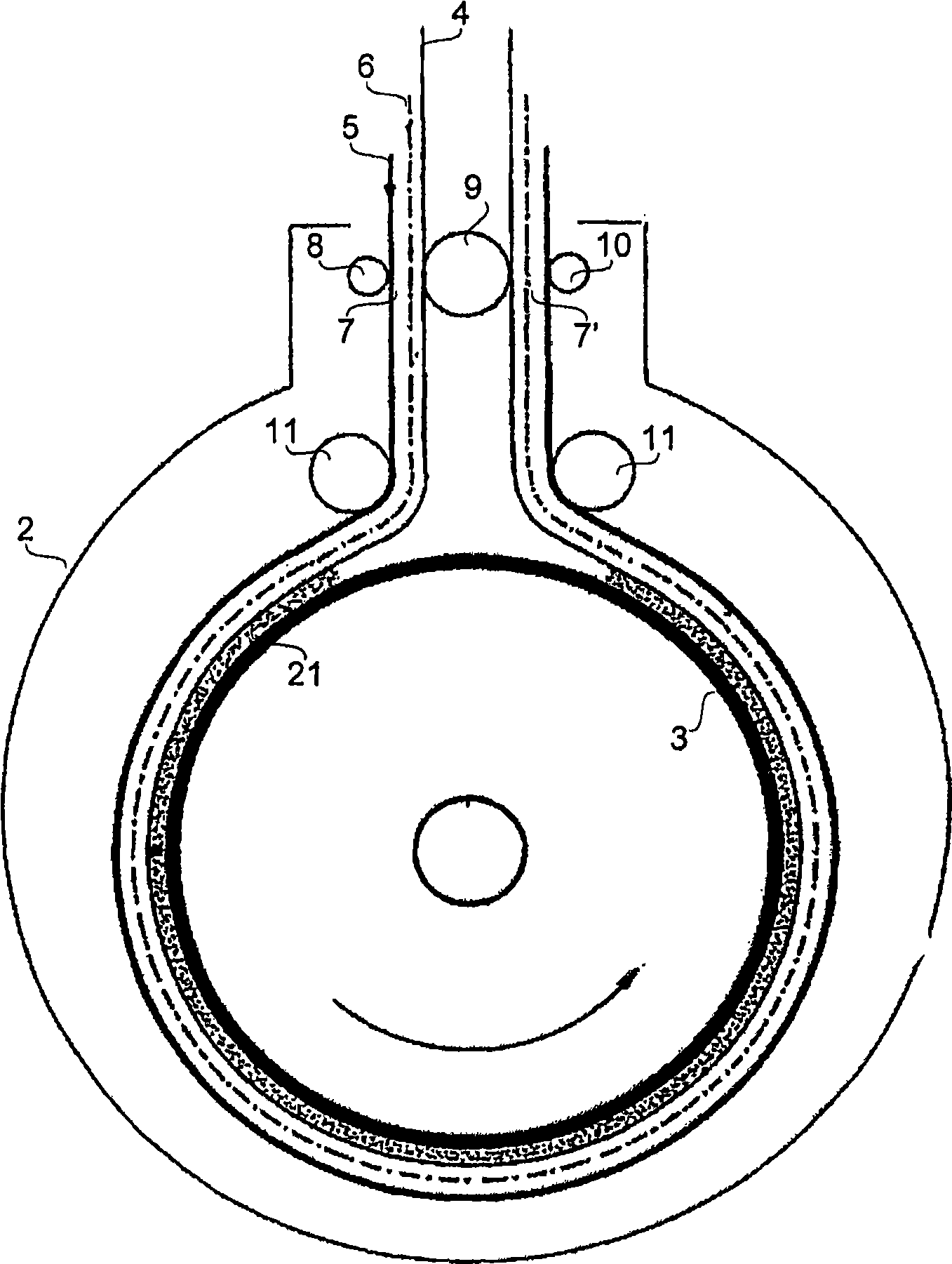

[0018] figure 1 A continuous autoclave steaming plant 1 is shown comprising an autoclave 2 equipped with a cylinder 3 which is heated and rotatable about its axis. The apparatus 1 also comprises a first conveyor belt 4 and a second conveyor belt 5 supported by suitable rollers and adapted to sandwich the fabric 6 to be treated between them and passing through the inlet sealing groove 7 The fabric 6 is brought into the autoclave 2 and then taken out of the autoclave 2 through the outlet sealing groove 7'. The inlet sealing groove 7 and the outlet sealing groove 7 ′ can, for example, be nips formed between suitable sealing rollers 8 , 9 and 10 . Inside the autoclave 2, one or more rollers 11 may be arranged, suitable for supporting conveyor belts 4 and 5 which sandwich the fabric 6 to be treated between them. The conveyor belts 4 and 5 are arranged so as to surround the cylinder 3 and adhere to most of its cylindrical sides.

[0019] As is well known, the autoclave 2 of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com