Multifunctional cloth loosening machine

A loose cloth machine, multi-functional technology, applied in textiles and papermaking, transportation and packaging, fabric surface trimming, etc., can solve the problems of reduced production efficiency, single function, unfavorable cutting and processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

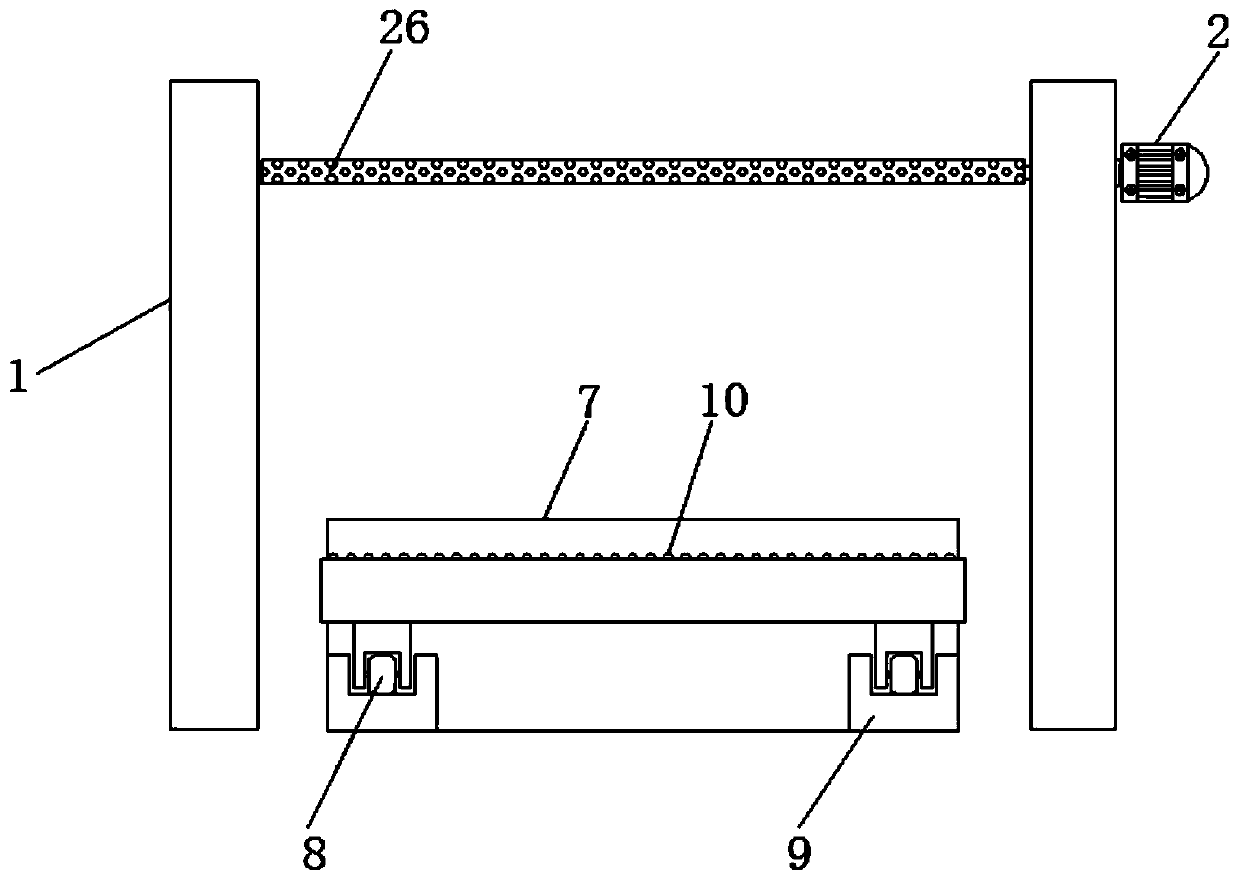

[0026] Embodiment one, with reference to Figure 1-4 , a multi-functional loose cloth machine, comprising a bracket 1 and a platform board 11, a platform board 11 is fixedly installed on the top surface of one side of the bracket 1, the installation height of the platform board 11 is not more than 1.6 meters, and loose cloth is arranged between the inside of the bracket 1 Roller 26 and extrusion roller 27, loose cloth roller 26 connection end runs through support 1 side surface and is connected with the output end of loose cloth roller motor 2 fixedly connected with support 1 side surface, loose cloth roller motor 2 drives loose cloth roller 26 to rotate , and one side of the loose cloth roller 26 is provided with a squeeze roller 27, the surface of the bracket 1 is provided with a moving groove 4, and the inside of the moving groove 4 is slidingly connected with a bearing 5, and the bearing 5 is connected to the inner wall of the moving groove 4 through the first cylinder 3, ...

Embodiment 2

[0027] Embodiment two, refer to figure 1 , the top surface of the platform plate 11 is located between the pressure rollers 12 and is provided with an ironing box 14, and the inside of the ironing box 14 is provided with an ironing board 17, and the bottom surface of the ironing board 17 is provided with an air vent 19, and the top of the ironing board 17 The surface is connected to the inner top surface of the ironing box 14 through the third cylinder 15, and the top surface of the ironing board 17 is located between the third cylinders 15 and is connected with an air inlet 18, wherein the two ends of the ironing board 17 are provided with raised ends 16, and the bottom surface of the ironing board 17 is a smooth structure, and the ironing board 17 and the lifting end 16 are of an integral structure, the lifting end 16 prevents the cloth from being scratched, and is convenient for the cloth to pass through, wherein the air inlet 18 connects the hose and the steam The air outl...

Embodiment 3

[0028]Embodiment three, refer to figure 1 , Loose cloth roller motor 2, drive motor, first cylinder 3, second cylinder 6, third cylinder 15, steam generator are all opened and closed by the control switch control, because the control structure is comparatively common, do not repeat too much here.

[0029] Working principle: move the device to a suitable position, turn on the power for the device, and when inspecting and loosening the cloth, place the cloth roller on the top surface of the carrying roller 25, lead out one end of the cloth roller, bypass the guide roller 23, and Put one end of the cloth roller under the pressure roller 12, start the pressure roller 12, and the pressure roller 12 rotates to drive the cloth to the other end of the platform plate 11 through friction. The lamp 21 illuminates the cloth, and the staff can see the defects of the cloth by standing under the transparent glass 13, and inspect the cloth. At this time, the first cylinder 3 stretches and pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com