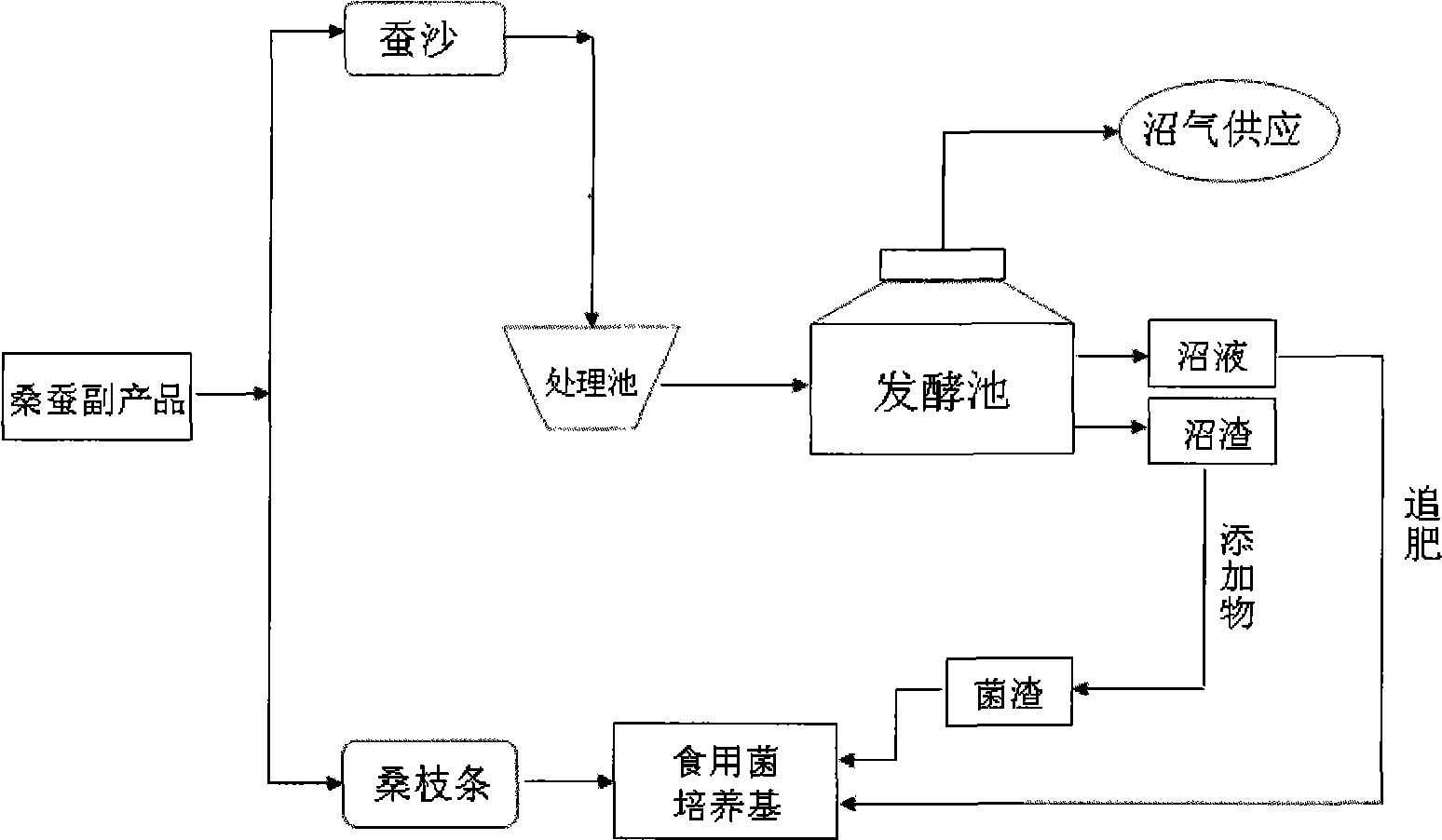

Application of silkworm and mulberry by-product silkworm excrement fermentation wastes in edible fungus cultivation

A technology of by-products and edible fungi, which is applied in the field of application of sericulture by-product silkworm excrement fermentation waste in the cultivation of edible fungi, to achieve the effects of reducing production costs, protecting the environment, and increasing agricultural added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: Application of Sericulture By-products in Fungus Cultivation

[0024] The cutting time of mulberry branches in Chenglin mulberry garden coincides with the rainy season. The mulberry branches should be collected in time and stacked in a ventilated and dry place to prevent rain and mildew. After oversummer, it is crushed into mulberry chips, using mulberry chips, bean cake powder, bran and gypsum powder as raw materials, and the mass percentage ratio of the four is: 87% of mulberry chips, 2.0% of bean cake powder, and 10% of bran 1.0% gypsum powder, add 55% water of the total mass of the above-mentioned raw materials, mix evenly, then bag and sterilize, and sterilize under normal pressure at 100°C for 8-10 hours. The inoculation starts when the temperature of the material bag drops below 30°C. Generally, the appropriate age strains suitable for local natural conditions and mulberry cuttings cultivation are selected, and the inoculation operation is carried o...

Embodiment 2

[0028] Embodiment 2: the application of sericulture by-products in mushroom cultivation

[0029] The cutting time of mulberry branches in Chenglin mulberry garden coincides with the rainy season. The mulberry branches should be collected in time and stacked in a ventilated and dry place to prevent rain and mildew. After oversummer, it is crushed into mulberry chips, using mulberry chips, bean cake powder, bran and gypsum powder as raw materials, and the mass percentage ratio of the four is: mulberry chips 88%, bean cake powder 2.1%, bran 9% , 0.9% gypsum powder, add 60% water of the total mass of the above-mentioned raw materials, mix evenly, then bag and sterilize, and autoclave at 0.138 MPa for 2 hours. The inoculation starts when the temperature of the material bag drops below 30°C. Generally, the appropriate age strains suitable for local natural conditions and mulberry cuttings cultivation are selected, and the inoculation operation is carried out in a sterile environment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com