Steam shaping device for stab-resistant garment production

A technology for steam setting and stab-proof clothing, which is applied in the direction of fabric steam/tweed treatment, textile and papermaking, fabric surface trimming, etc. It can solve the problems of not ensuring the flatness of the fabric, affecting the quality of the fabric, and the existence of wrinkles, so as to speed up the setting. Efficiency, ensuring the quality of shaping, and the effect of convenient unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

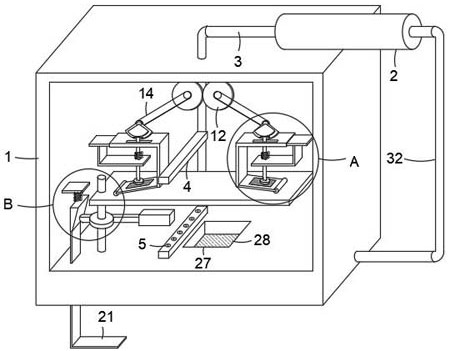

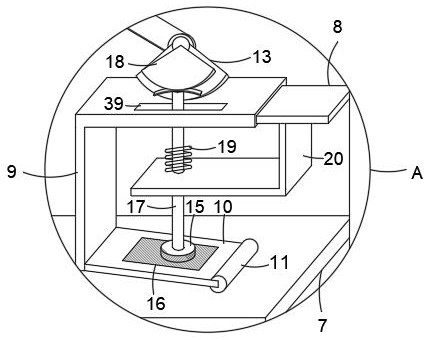

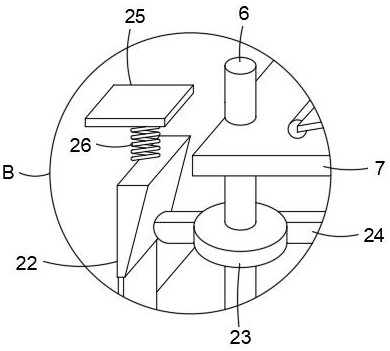

[0032] refer to Figure 1-5 , a steam setting device for the production of stab-resistant clothing, comprising a box body 1, a steam generator 2 is fixedly installed on the upper side wall of the box body 1, an air delivery pipe 3 is connected to the output end of the steam generator 2, and the end of the air delivery pipe 3 part of the upper side wall of the box body 1 and extends to the inside of the box body 1, and two connecting plates 4 are connected to the outer wall of the gas delivery pipe 3, and the opposite sides of the two connecting plates 4 are provided with a connection with the inside of the gas delivery pipe 3. The nozzle 5 and the steam generator 2 work to generate steam through the air pipe 3, and then spray out through the nozzle 5 and contact the cloth on the cover plate 7 to carry out the steam setting work of the cloth;

[0033] A rotary rod 6 is installed inside the box body 1, and a sleeve plate 7 is fixedly set on the outer wall of the upper end of the...

Embodiment 2

[0043] refer to Figure 6 , the difference from Example 1 is:

[0044] The cover plate 7 is composed of an end plate 33 and two adjusting plates 34 which are slidably arranged at the ends of the end plate 33. An adjusting spring 35 is fixedly connected between the two adjusting plates 34. The end plate 33 is equipped with a threaded rod 36 and two guide rods. 37, the threaded rod 36 is threaded with a trapezoidal block 38, the trapezoidal block 38 is an isosceles trapezoidal setting, the trapezoidal block 38 is slidingly sleeved on the outer walls of the two guide rods 37, and the distance between the two adjusting plates 34 is adjusted To prevent work with the installation of different sizes of cloth, turn the threaded rod 36, the trapezoidal block 38 moves inwardly or outwardly, when the trapezoidal block 38 moves inwardly, squeeze the two adjustment plates 34 to move outward, and the distance between the adjustment plates 34 increases. Large, suitable for larger cloth. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com