Full-automatic plate shearing machine

A shearing machine, fully automatic technology, applied in the field of steel plate processing, can solve the problem of spending a lot of man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

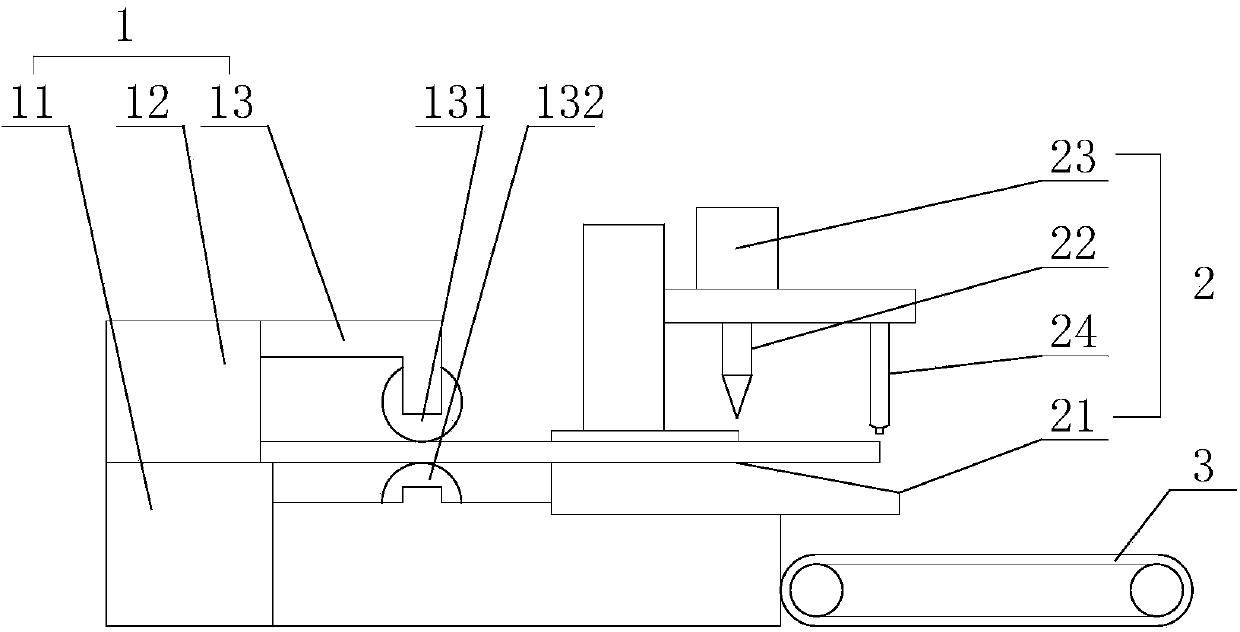

[0016] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a fully automatic shearing machine proposed by the present invention.

[0017] refer to figure 1 , a kind of fully automatic plate shearing machine that the present invention proposes, comprises: feeding device 1, shearing device 2, discharge conveyor belt 3;

[0018] The feeding device 1 comprises a raw material rack 11, a first drive mechanism 12, and a limit mechanism 13. The first drive mechanism 12 is used to drive the raw material rack 11 to feed, and the limit mechanism 13 is used to limit the position of the steel strip during the feeding process. Mechanism 13 includes an upper roller 131 and a lower roller 132, the distance between the upper roller 131 and the upper roller 132 is consistent with the thickness of the steel plate to be processed, the surface of the upper roller 131 and the lower roller 132 is provided with rubber material, and the upper roller 131 and the lower roller 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com