Aluminum alloy pattern block low-pressure casting equipment and low-pressure casting and gravity feeding compound process

A pattern block and aluminum alloy technology, which is applied in the composite process of gravity feeding and low-pressure casting, can solve the problems of secondary pollution of aluminum liquid, achieve good production conditions, increase the rate of qualified products, and improve the working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

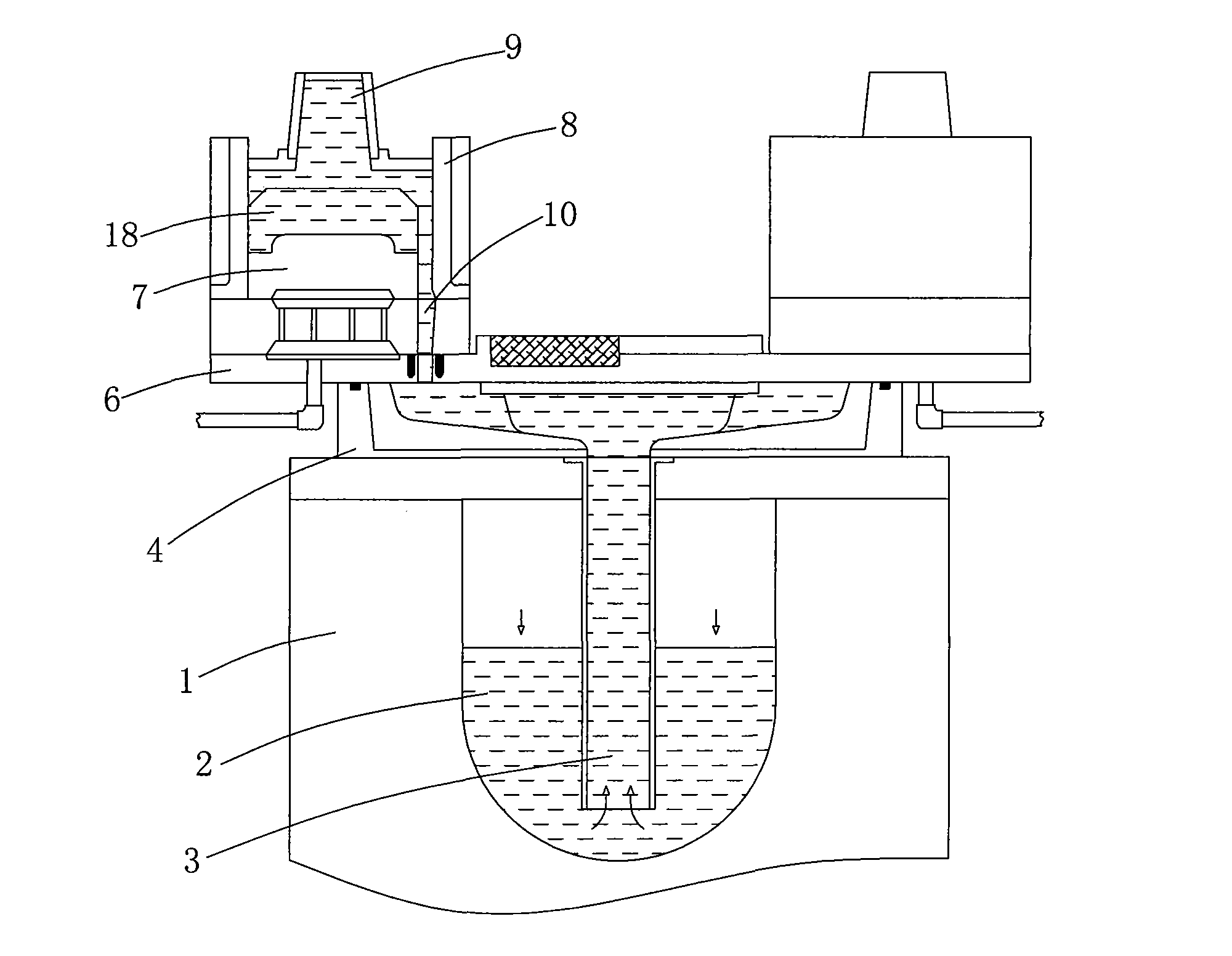

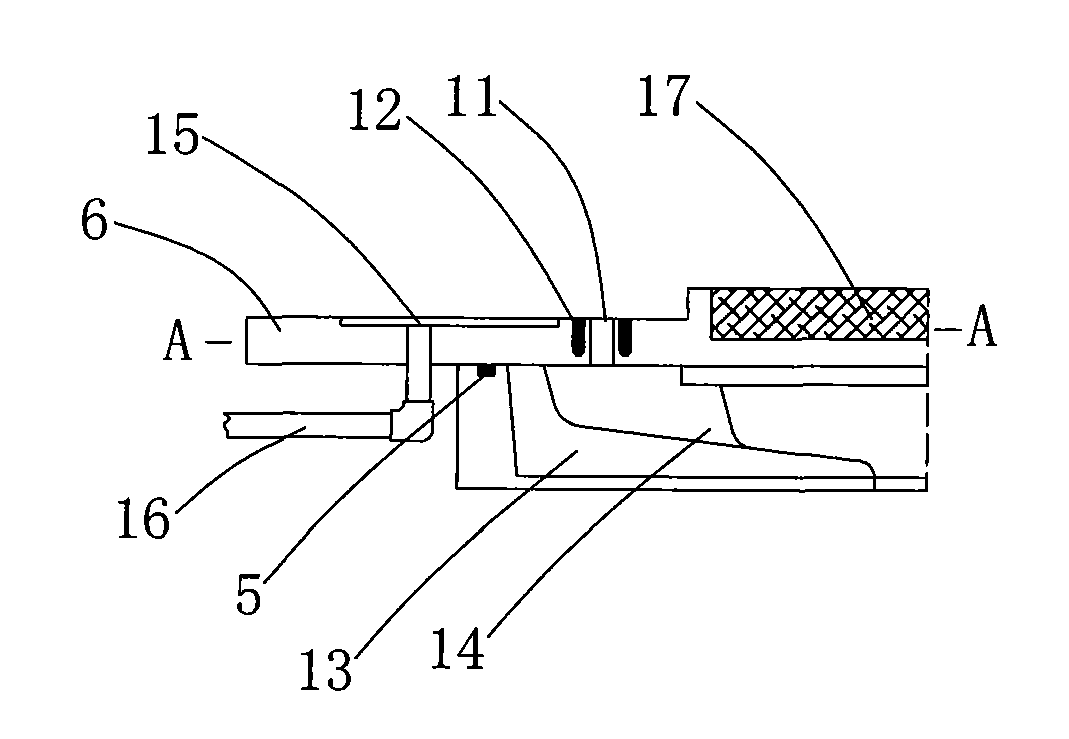

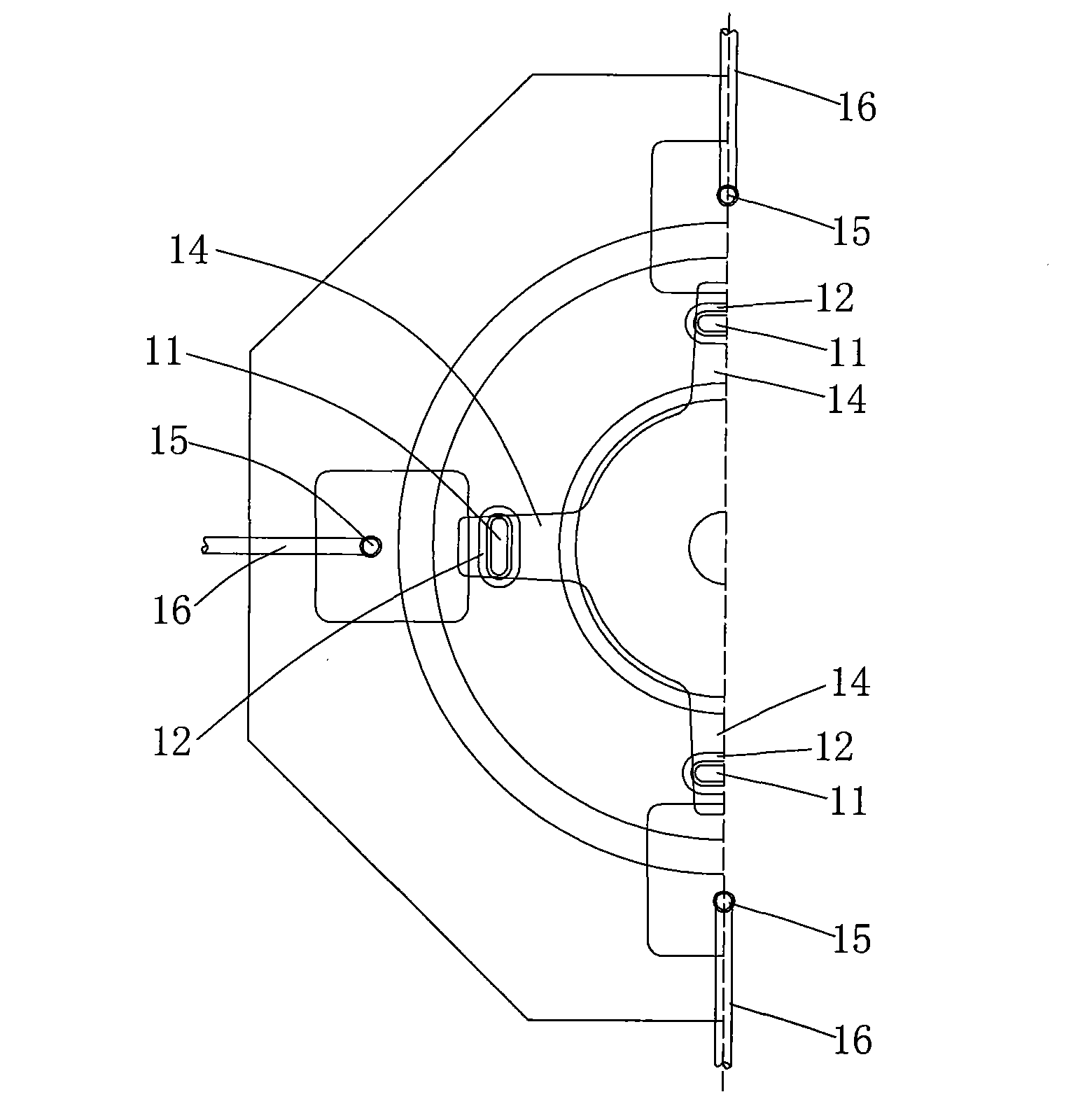

[0037] Example: Combine Figure 1-3 , the low-pressure pouring equipment for aluminum alloy pattern blocks of the present invention includes a crucible 2 and a riser 3 arranged in the furnace body 1, and a disc-type runner substrate 4 (processed from HT200 cast iron) is arranged on the crucible. A central hole is opened, and the lower end of the riser 3 passes through the central hole of the sprue base plate and extends into the crucible 2; the sprue base plate 4 is processed with a sealing groove 5 along the top, and when it is in contact with the sprue cover plate 6 after filling asbestos strips It plays the role of sealing the cavity of the main runner.

[0038] figure 1 As shown, the sprue base plate is sealed and covered with a sprue cover plate 6, and four molds 8 with gypsum cores 7 are symmetrically installed on the sprue cover plate 6, and the upper end of each mold is provided with a riser 9. Inner runners 10 are provided at the lower end, and vertical holes, that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com