Composite alterant of cast aluminum alloy for iron-enriched phase alteration and alteration method thereof

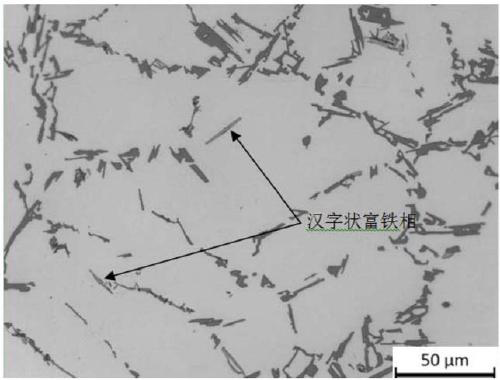

A technology of casting aluminum alloy and compound modifier, which is applied in the field of casting aluminum alloy modification, can solve the problem that the refinement of eutectic silicon phase has no obvious effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

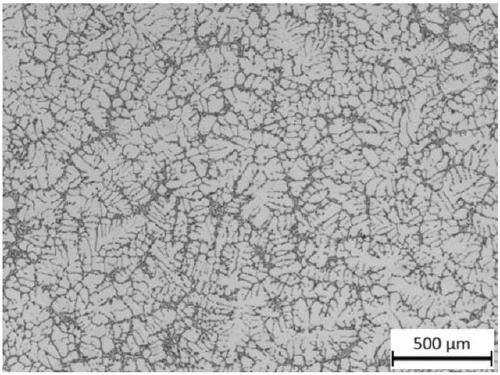

[0042] This embodiment provides a method for modifying a cast aluminum alloy with iron-rich phase modification, which includes:

[0043] S1: Put the prepared ZL101 alloy raw material into the melting furnace, heat the raw material to 500°C, keep it for 30 minutes, and then raise the temperature to 750°C;

[0044] S2: After all the raw materials are melted, take a sample to test the Fe content in the melt, wrap the Mn agent with aluminum foil and add it to the aluminum melt, the added Mn agent content is 80% of the Fe content, and press it in with a titanium tool Inside the melt, stir the melt after melting.

[0045] S3: Transfer the melt to the refining and holding furnace, adjust the melt temperature to 700°C, conduct online refining on the recycled aluminum melt, remove gas and impurities, and add Al-Sr and Al-RE that have been preheated and wrapped in aluminum foil Alloys, Sr and RE are added in proportions of 0.03% and 0.1% of the melt, which are pressed into the melt wit...

Embodiment 2

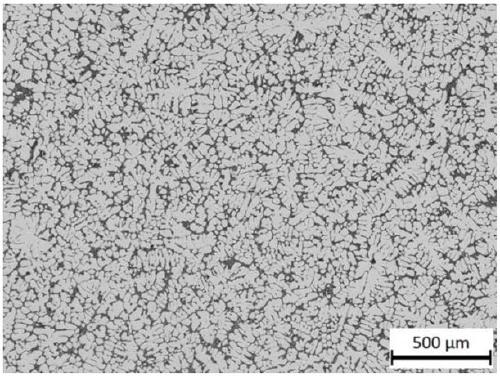

[0049] This embodiment provides a method for modifying a cast aluminum alloy with iron-rich phase modification, which includes:

[0050] S1: Put the prepared ZL101 alloy raw material into the melting furnace, heat the raw material to 500°C, keep it warm for 30 minutes, and then raise the temperature to 760°C;

[0051] S2: After all the raw materials are melted, take a sample to test the Fe content in the melt, wrap the Mn agent with aluminum foil and add it to the aluminum melt. The added Mn agent content is 60% of the Fe content, and press it in with a titanium tool Inside the melt, stir the melt after melting.

[0052] S3: Transfer the melt to the refining and holding furnace, adjust the melt temperature to 710°C, conduct online refining on the aluminum melt, remove gas and impurities, and add Al-Sr and Al-RE master alloys that have been preheated and wrapped in aluminum foil , The addition ratio of Sr and RE is 0.02% and 0.2% of the melt, press it into the melt with a tita...

Embodiment 3

[0056] This embodiment provides a method for modifying a cast aluminum alloy with iron-rich phase modification, which includes:

[0057] S1: Put the prepared ZL111 alloy raw materials into the smelting furnace, heat the raw materials to 500°C, keep them warm for 30 minutes, and then raise the temperature to 790°C;

[0058] S2: After all the raw materials are melted, take a sample to test the Fe content in the melt, wrap the Mn agent with aluminum foil and add it to the aluminum melt. The content of the added Mn agent is 50% of the Fe content, and press it in with a titanium tool Inside the melt, stir the melt after melting.

[0059] S3: Transfer the melt to the refining and holding furnace, adjust the melt temperature to 710°C, conduct online refining on the aluminum melt, remove gas and impurities, and add Al-Sr and Al-RE master alloys that have been preheated and wrapped in aluminum foil , The addition ratio of Sr and RE is 0.03% and 0.06% of the melt, and it is pressed int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com