Labeling device used for machining petroleum pipeline

A technology for oil pipelines and rulers, which is applied in the field of auxiliary processing devices for oil pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Such as figure 1 The shown marking device for oil pipeline processing includes a left bracket and a right bracket. Both the left bracket and the right bracket include an arc-shaped mounting seat 1 at the upper end, a support column 4 at the middle end, and a fixed disc 6 at the lower end. Support and right support are connected by scale rod 8, and described scale rod 8 two ends are respectively connected with the support column 4 of left support and right support horizontally, on scale rod 8, be covered with two vertically arranged marking rulers 7, described The two scales 7 can slide axially along the scale rod 8 .

[0021] When this embodiment is used, the device is placed in a suitable position in advance, the oil pipeline is placed flat on the arc mounting seats 1 of the left bracket and the right bracket, the length scale is engraved on the scale rod 8, the position of the pipeline is adjusted, and then according to The size to be marked moves the marking ruler ...

Embodiment 2

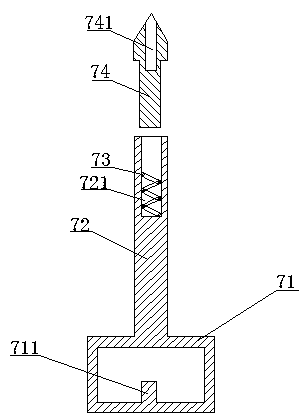

[0023] see figure 2 with image 3 , the present embodiment optimizes the structure of the scale on the basis of Embodiment 1, specifically: the scale 7 includes a sliding sleeve 71 and a vertical rod 72 connected to the upper end of the sliding sleeve 71, and the upper end of the vertical rod 72 is provided with a Spring mounting hole 721, a compression spring 73 is set in the spring mounting hole 721, a marking pen 74 is also installed in the spring mounting hole 721, the lower end of the marking pen 74 is located at the upper end of the compression spring 73, and a refill mounting hole is set at the upper end of the marking pen 74 741.

[0024] The sliding sleeve 71 of this embodiment fits on the scale rod 8 and can move axially along the scale rod 8. The marking pen 74 compresses the compression spring 73 and is installed in the spring mounting hole 721. The pen core mounting hole 741 can be placed with different colors To mark the refill, when marking, the upper end of...

Embodiment 3

[0027] In this embodiment, the following structure is added on the basis of embodiment 1 or embodiment 2: arc-shaped rubber pads 2 are provided on the inner arc surfaces of the arc-shaped mounting seats 1 of the left bracket and the right bracket.

[0028] The rubber pad 2 of this embodiment can reduce the mutual friction between the oil pipeline and the arc-shaped mounting seat 1, reduce wear, and at the same time facilitate the rotation of the oil pipeline, excellently protect the outer wall of the oil pipeline, and improve safety.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com