Ceramic tile making method

A production method and ceramic tile technology, applied in the field of ceramic tile production, can solve the problems of large consumption of raw materials, large edging allowance for brick blanks, low output, etc., and achieve the effects of reducing processing costs, accurate cutting dimensions, and high material utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

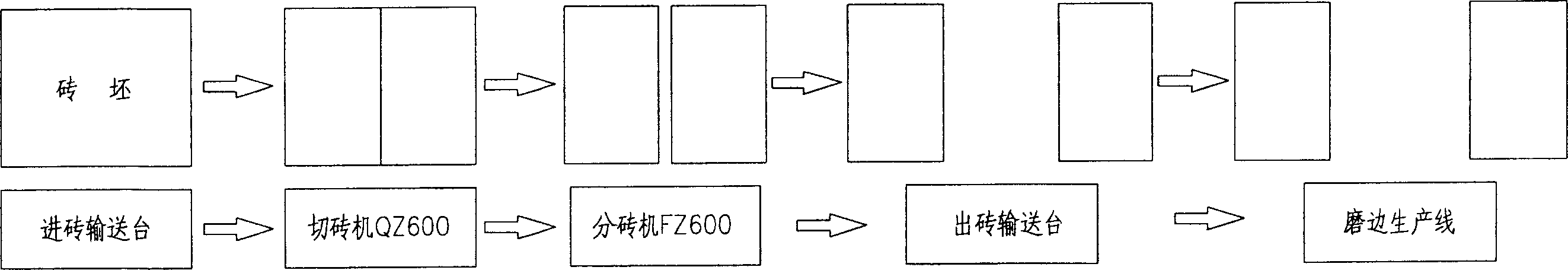

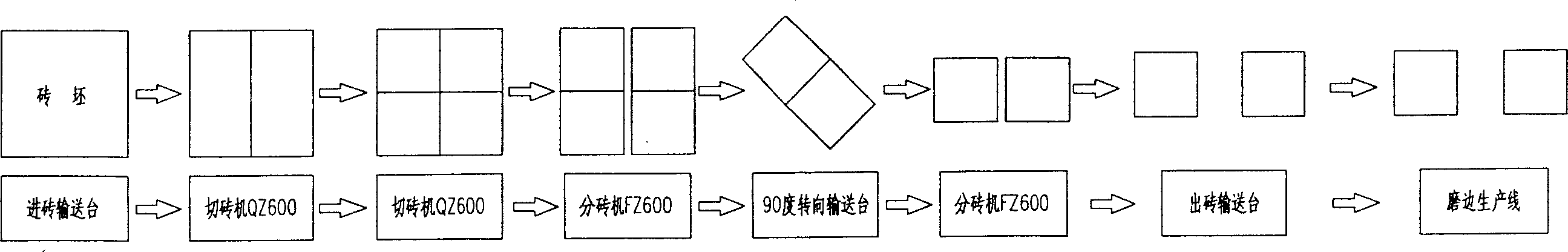

[0020] The ceramic tile dividing method of the present invention mainly adopts two kinds of equipment: one is a brick cutting machine, which mainly uses the physical characteristics of the arrangement of fired ceramic crystals to evenly cut out cutting lines on the surface of the tiles with a knife wheel of hard material; the other It is a brick splitting machine, and the brick cutting device is used to knock the cut tiles conveyed by the brick cutter, so that the mechanical force is transmitted along the cutting line and broken, just like cutting glass, and the tiles of the required specifications are obtained. The brick cutting machine and brick dividing machine of the present invention are not particularly limited, for example, QZ600 brick cutting machine and FZ600 brick dividing machine of Guangdong Keda Electromechanical Company can be used.

[0021] figure 1 Shown is the process flow chart of one-way split tiles of the present invention, the so-called one-way split refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com