Automatic cutting machine of aluminum profile

A technology of aluminum profiles and cutting machines, applied in metal sawing equipment, metal processing machinery parts, measuring/indicating equipment, etc., can solve problems such as low work efficiency, easy size, uneven aluminum profile heads, etc., and reduce manpower The output, improve work efficiency, the effect of accurate cutting size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

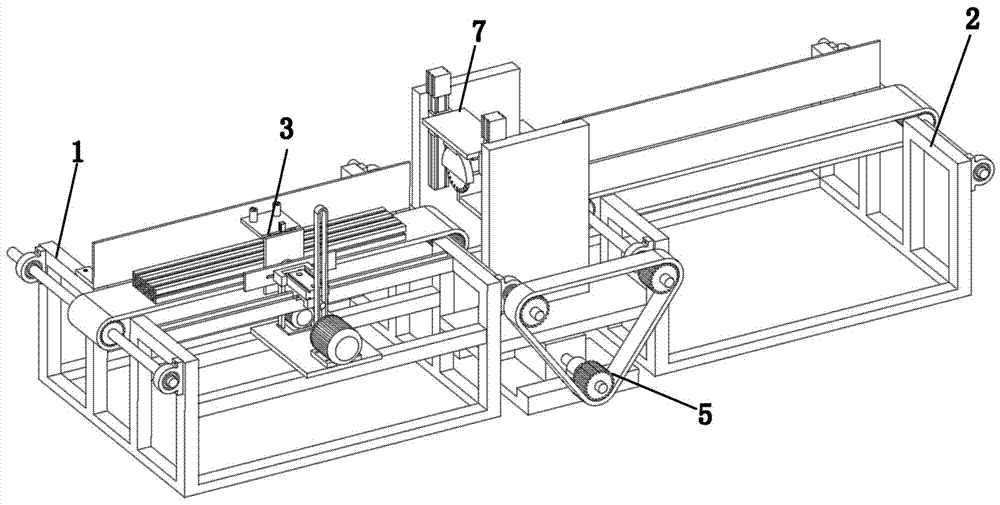

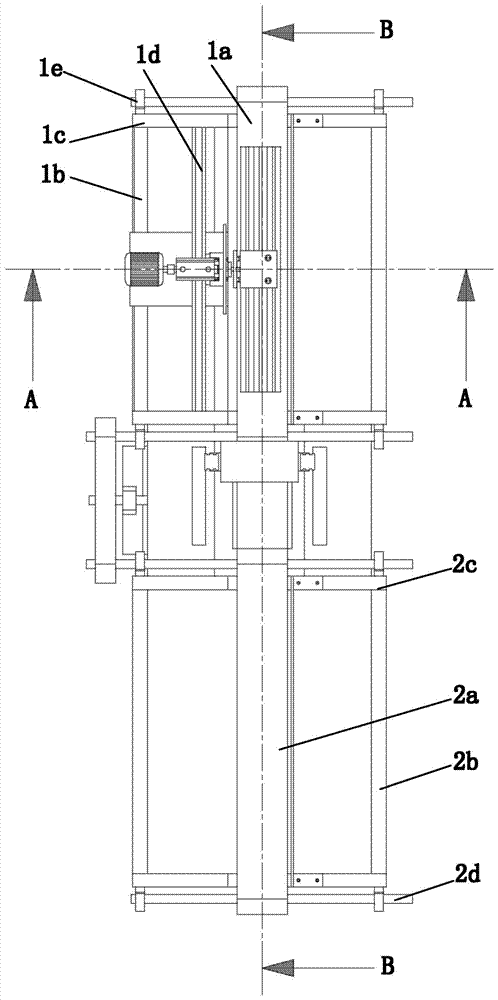

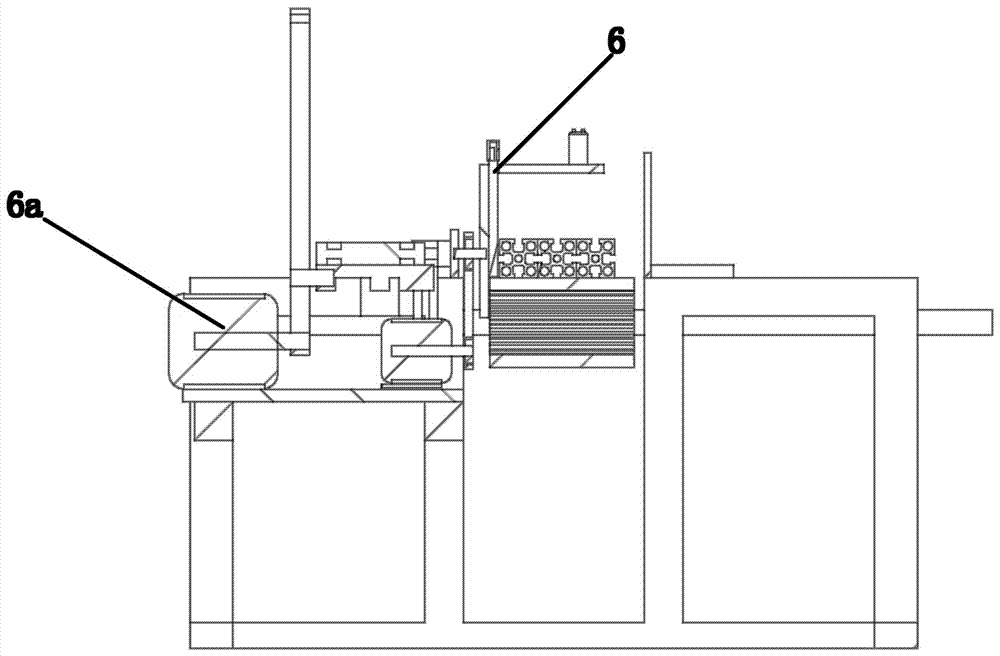

[0032] refer to Figure 1 to Figure 13The shown automatic cutting machine for aluminum profiles includes a feeding conveyor 1, an unloading conveyor 2, a quantitative limit device 3, a lifting device 4 and a transmission device 5, and the feeding conveyor 1 includes a Convey the feeding conveyor belt 1a for aluminum profiles to be cut, the discharge conveyor table 2 is provided with a discharge conveyor belt 2a for transferring the cut aluminum profiles, the transmission of the loading conveyor belt 1a and the discharge conveyor belt 2a The direction is the same and the output end of the feeding conveyor belt 1a is facing the input end of the unloading conveyor belt 2a. The quantitative limit device 3 includes a positioning component 6 and a cutting component 7 for pushing and limiting the aluminum profile to be cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com