Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Operation mechanization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

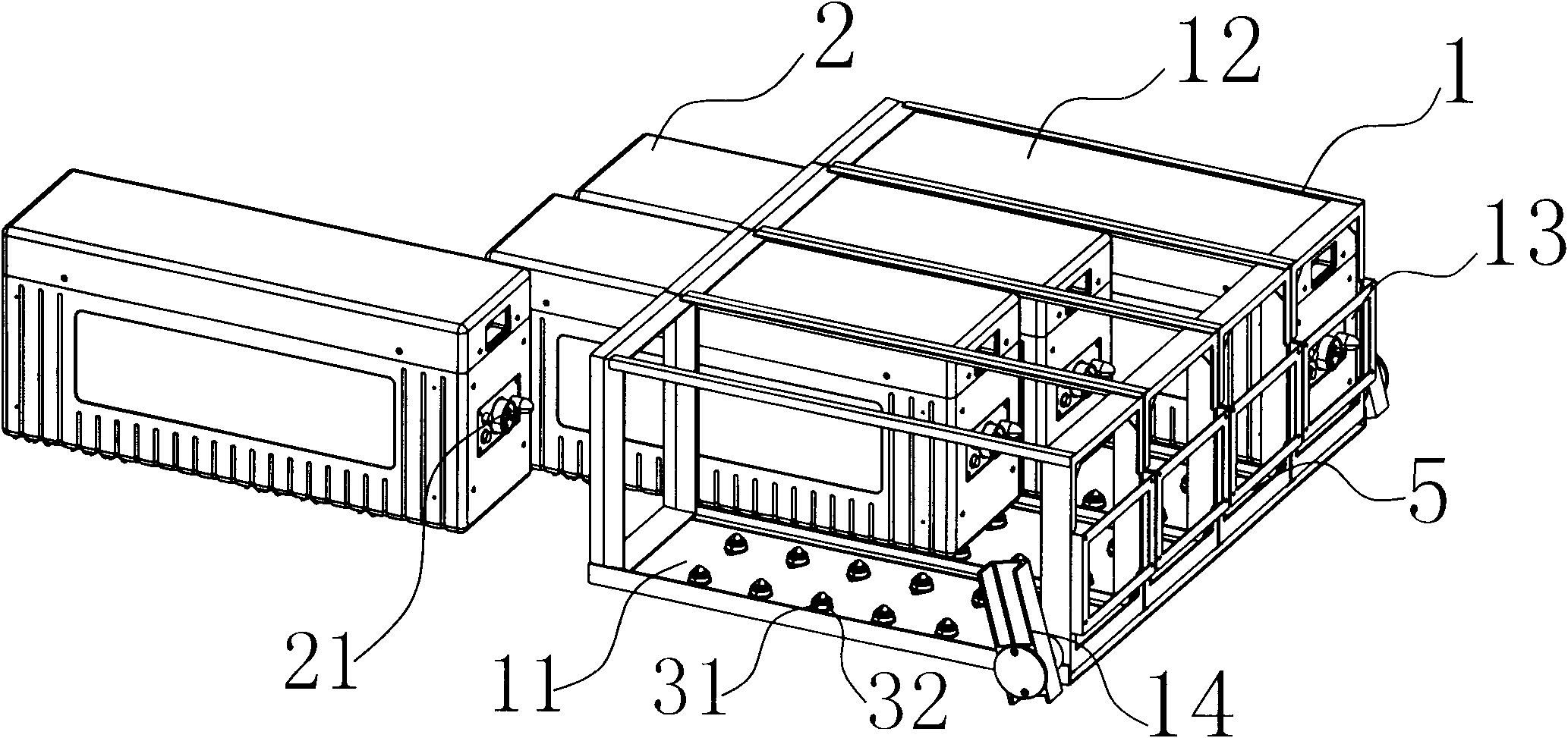

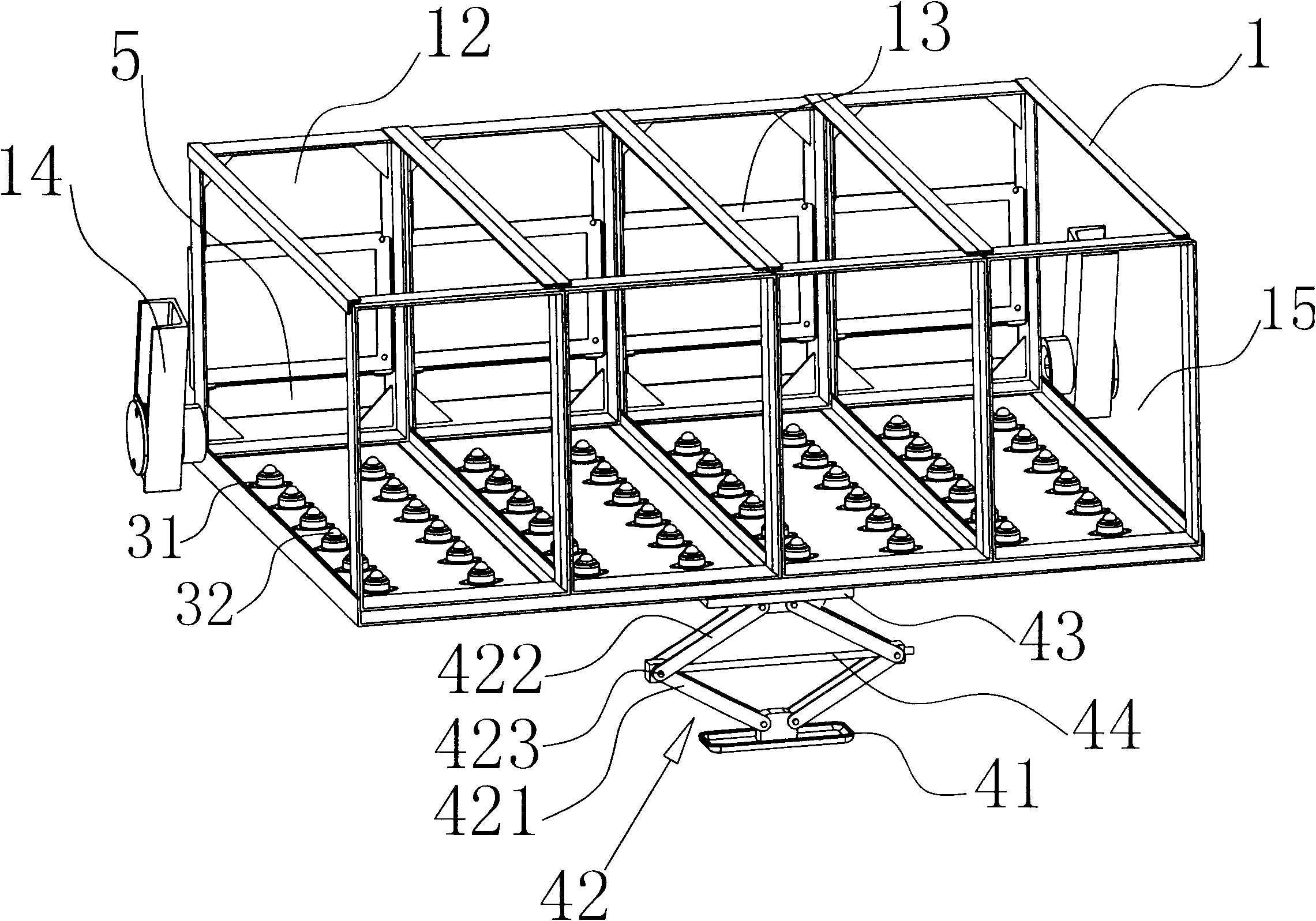

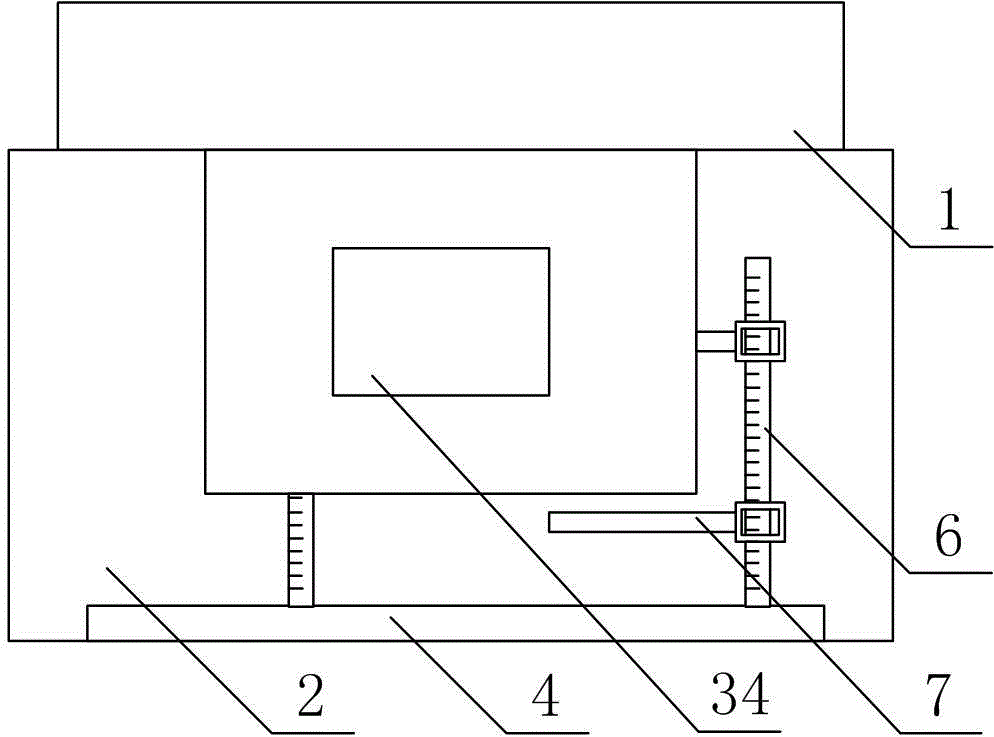

Electric automobile power battery quick-change mechanism

InactiveCN101890901AEasy to pick and placePrevent rush outElectric propulsion mountingCell component detailsPower batteryWorkload

The invention discloses an electric automobile power battery quick-change mechanism which has simple structure, time-saving and labor-saving operations and use and convenient and quick battery change. The technical problems of time consumption, labor consumption, troublesome procedures, low efficiency, heavy workload and the like during battery removal, installation and change in the prior art is solved. The mechanism comprises a battery installing frame fixed on an automobile chassis and a battery pack arranged on the battery installing frame. One side of the battery installing frame is pivoted on the automobile chassis through a horizontal connecting shaft, the bottom of the battery installing frame is provided with a lifting mechanism which can drive the battery installing frame to rotate around the horizontal connecting shaft, and the other side of the battery installing frame opposite to the horizontal connecting shaft is provided with a battery pack inlet. The battery pack passing through the battery pack inlet is loaded to and unloaded from the battery installing frame through a sliding mechanism between a bottom board of the battery installing frame and the bottom surface of the battery pack, and a sliding stop mechanism capable of stopping the sliding of the battery pack is arranged in the battery installing frame corresponding to the battery pack inlet.

Owner:纽贝耳文化创意(杭州)有限公司

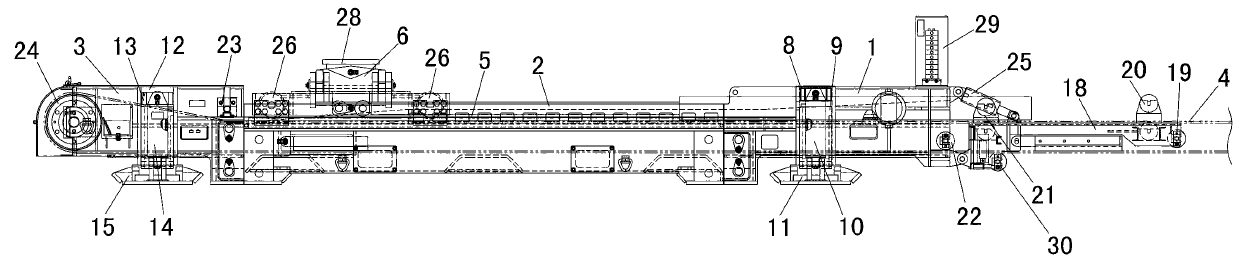

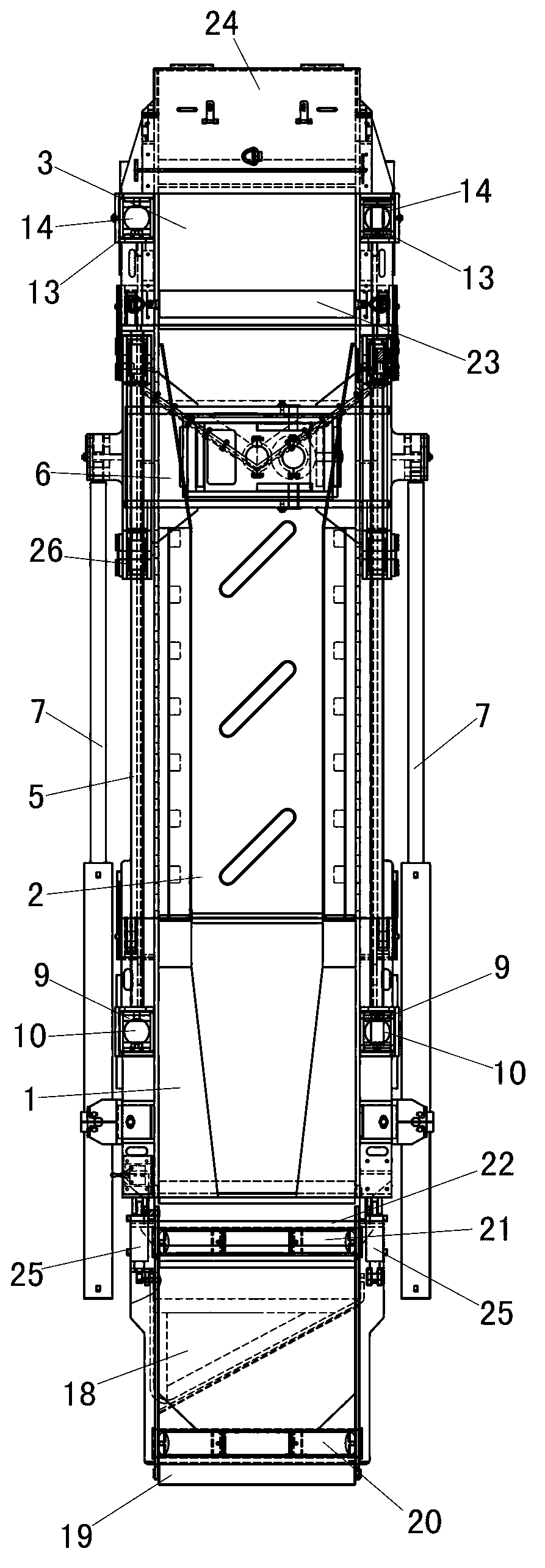

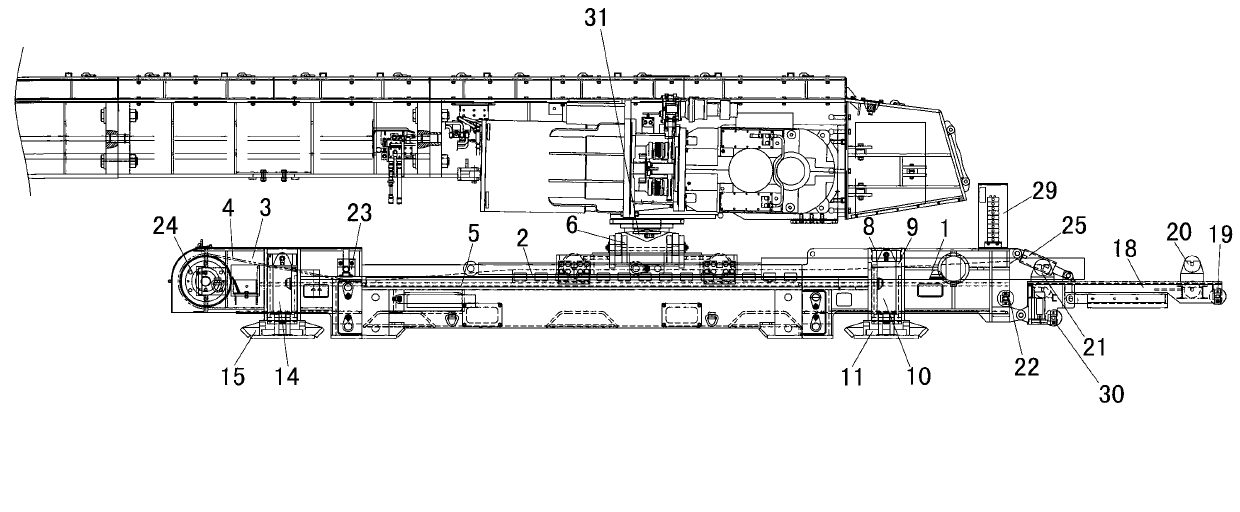

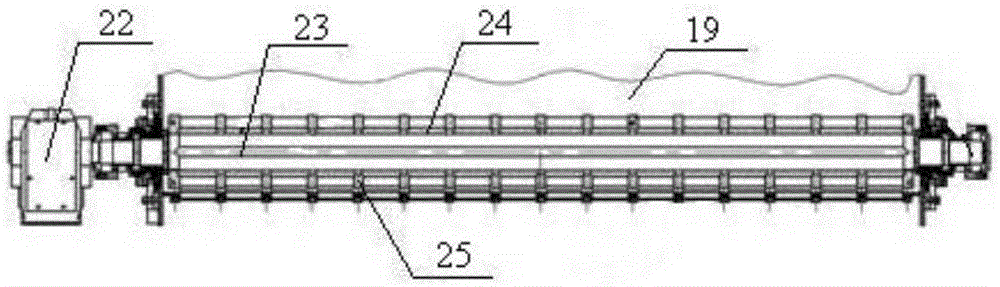

Hydraulic self-moving tail device

InactiveCN103144924AReduce manual operationsImprove work efficiencyConveyorsControl systemEngineering

The invention relates to a hydraulic self-moving tail device, which belongs to the technical field of transporters in mines. The hydraulic self-moving tail device comprises a head, a rail and a tail, wherein the head, the rail and the tail are connected in sequence from front to back; a belt of a belt conveyor is installed on the head, the rail and the tail; a track is arranged on the upper surface of the rail; a trolley which can slide back and forth and is connected with a head of a reversed loader together is arranged on the track; the left and right sides of the trolley are respectively and fixedly connected with one end of each pushing cylinder, and the other ends of the two pushing cylinders are respectively and fixedly connected with the left and right sides of the head; the pushing cylinders are connected with a hydraulic control system; and the contractility provided by the two pushing cylinders is greater than the friction force when the reversed loader is pulled forward and less than the friction force when the reversed loader is pushed backward. According to the hydraulic self-moving tail device disclosed by the invention, self movement is realized through mechanized operation and control, so that the tail of the belt conveyor is moved, manual operation is omitted, the work efficiency is high, and the use is safe and convenient.

Owner:TRIUMPH HEAVY IND

Coal mine underground grooving machine

PendingCN107559003ASolve the problem of difficult slotting operationsEasy to cutDriving meansPropulsionVehicle frameMining engineering

The invention discloses a coal mine underground grooving machine, which comprises a carriage, wherein the carriage is provided with a traveling mechanism, a hydraulic oil tank, a cab assembly, a hydraulic system, an electrical system, a pneumatic system, a dust removal system, a power device and a grooving device; the grooving device is arranged on the rear end of the carriage. According to the coal mine underground grooving machine disclosed by the invention, the problem that an existing coal mine underground tunnel is difficult in grooving operation is thoroughly solved, mechanical operationis realized, a driving working condition and a grooving operation working condition can be simultaneously met, the coal mine underground grooving machine has the characteristics of high driving speed, high operation efficiency, convenience, flexibility, convenience in operation, safety and reliability and the like, the efficiency of the type of operation is improved, an underground construction mechanization rate is improved, and labor cost is lowered.

Owner:LIANYUNGANG TIANMING EQUIP

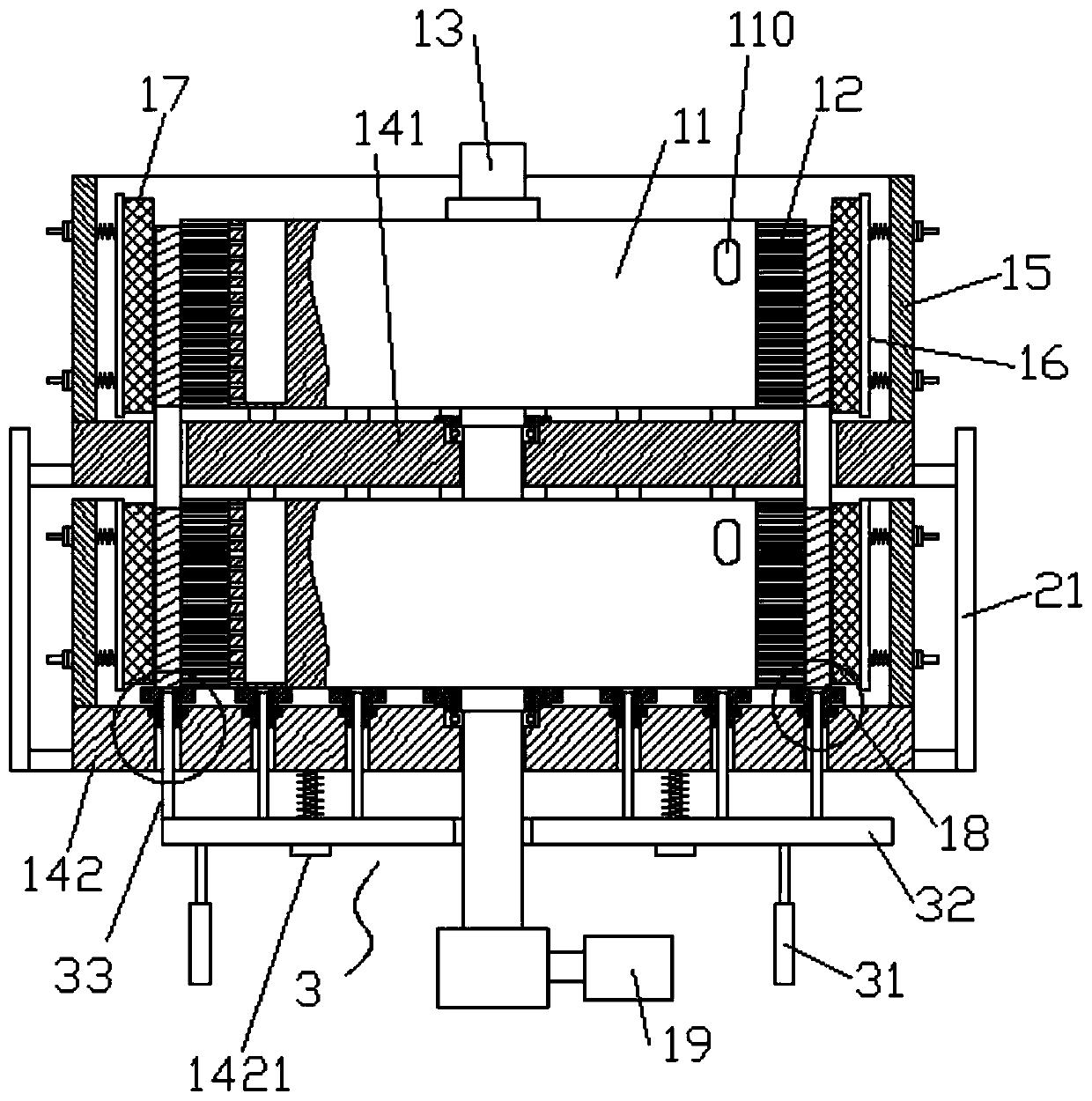

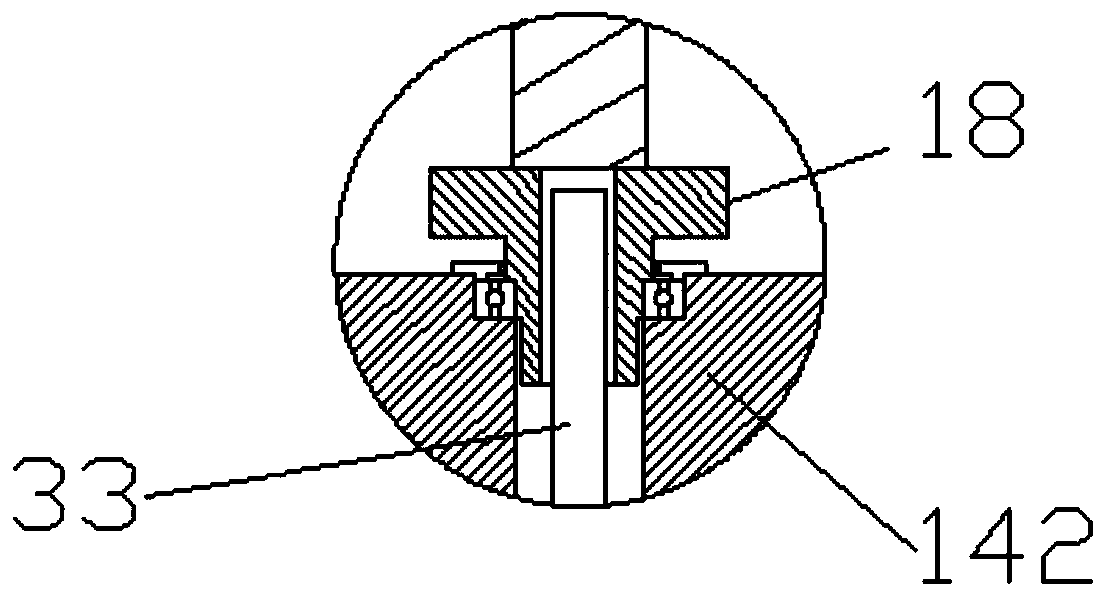

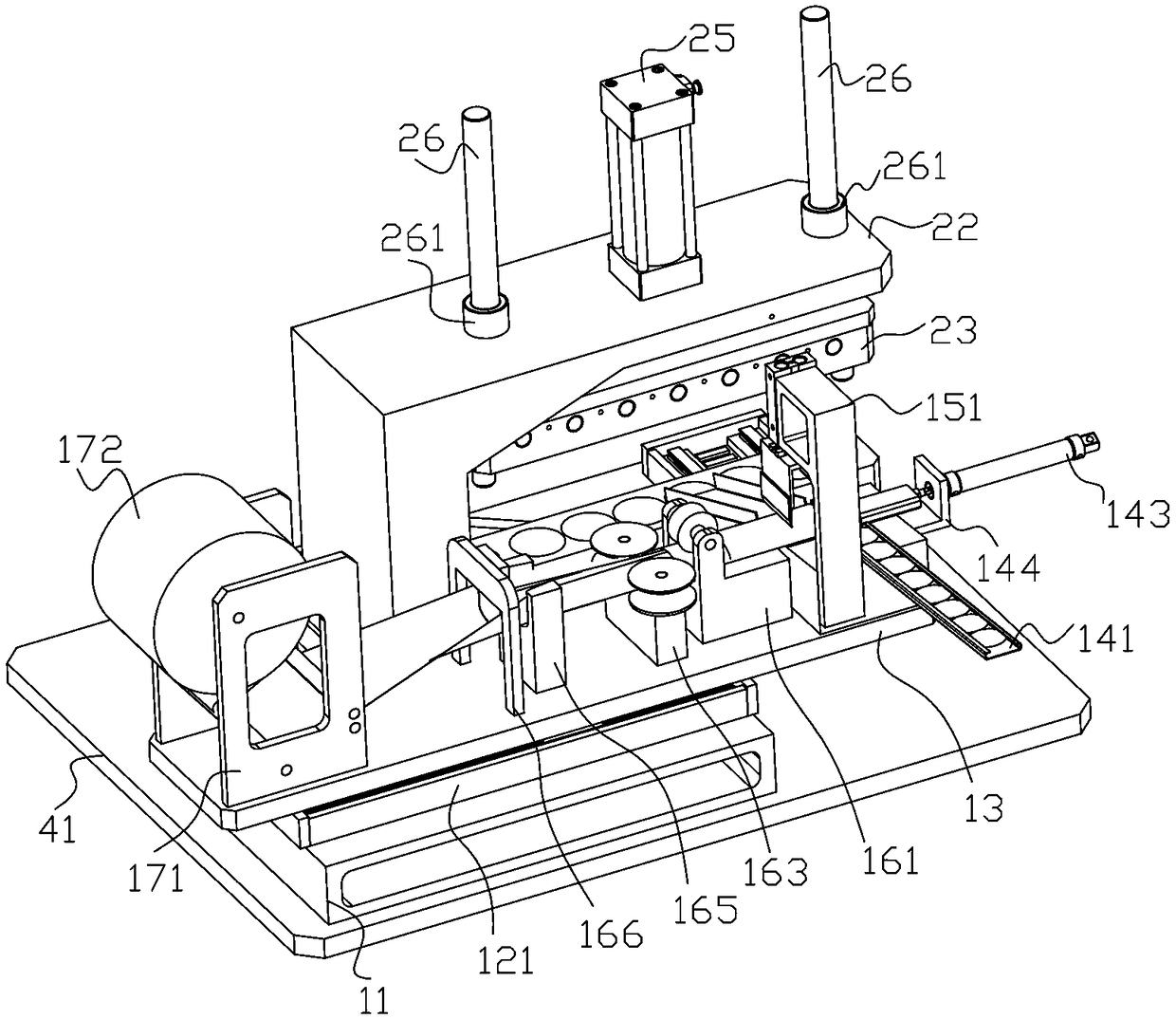

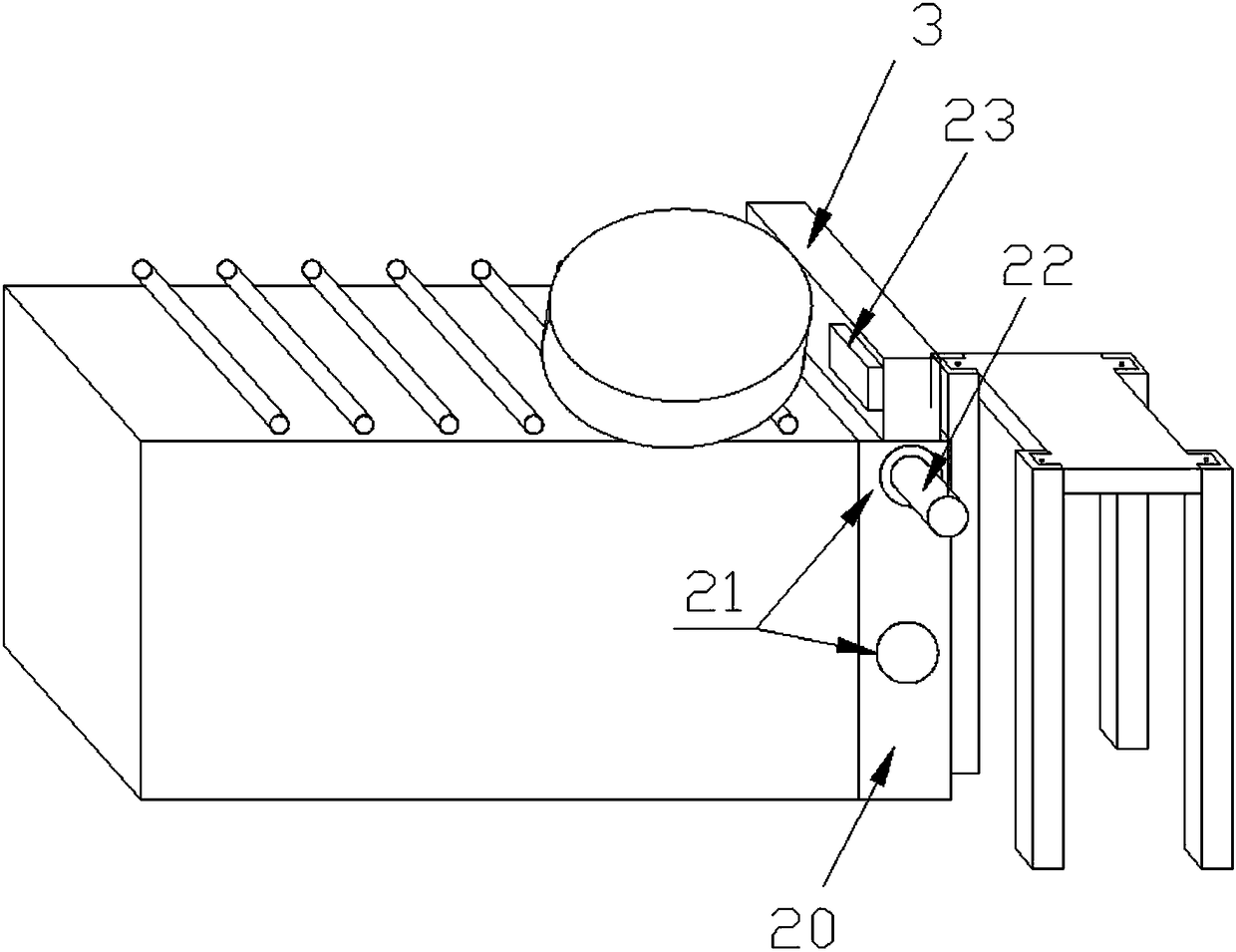

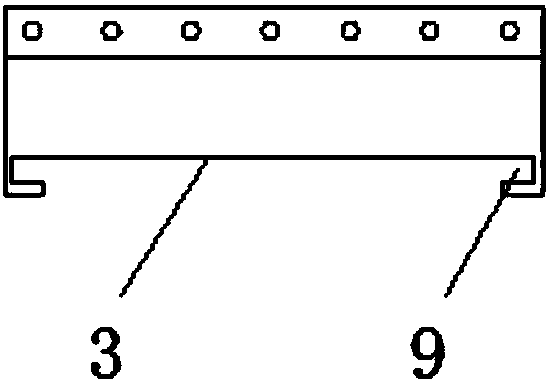

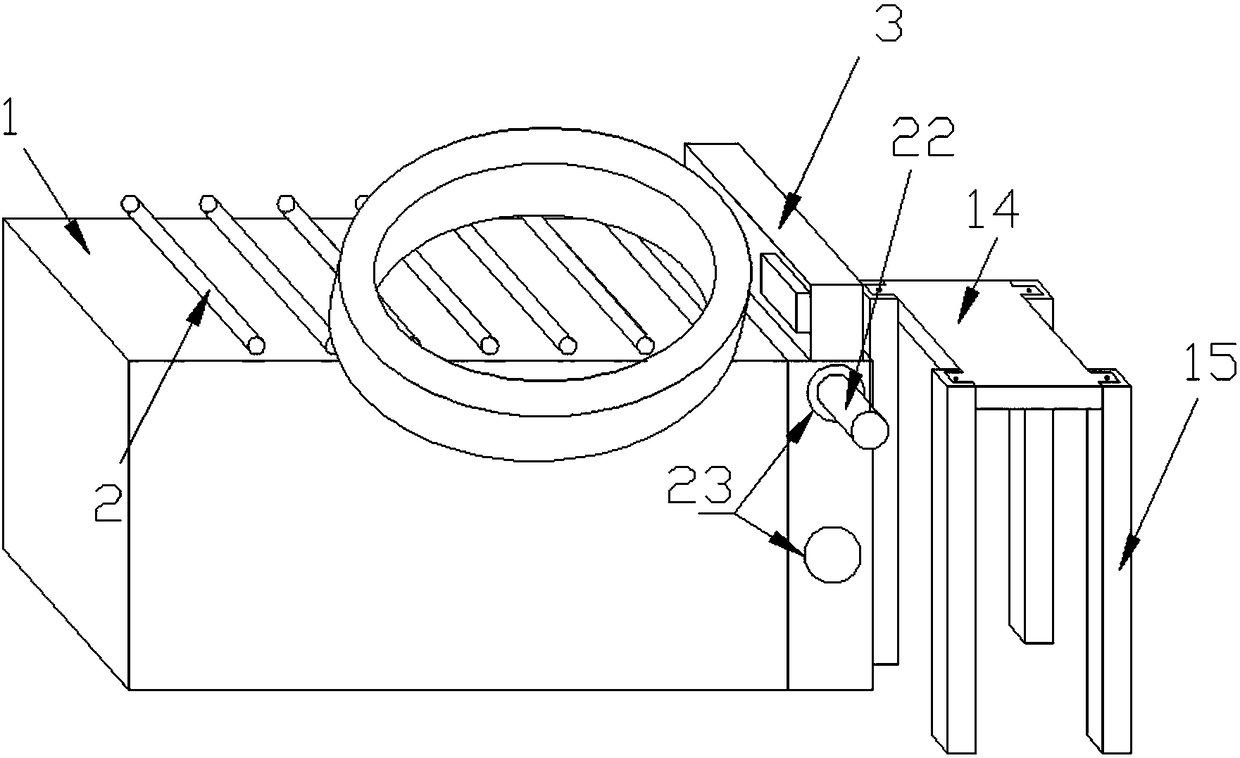

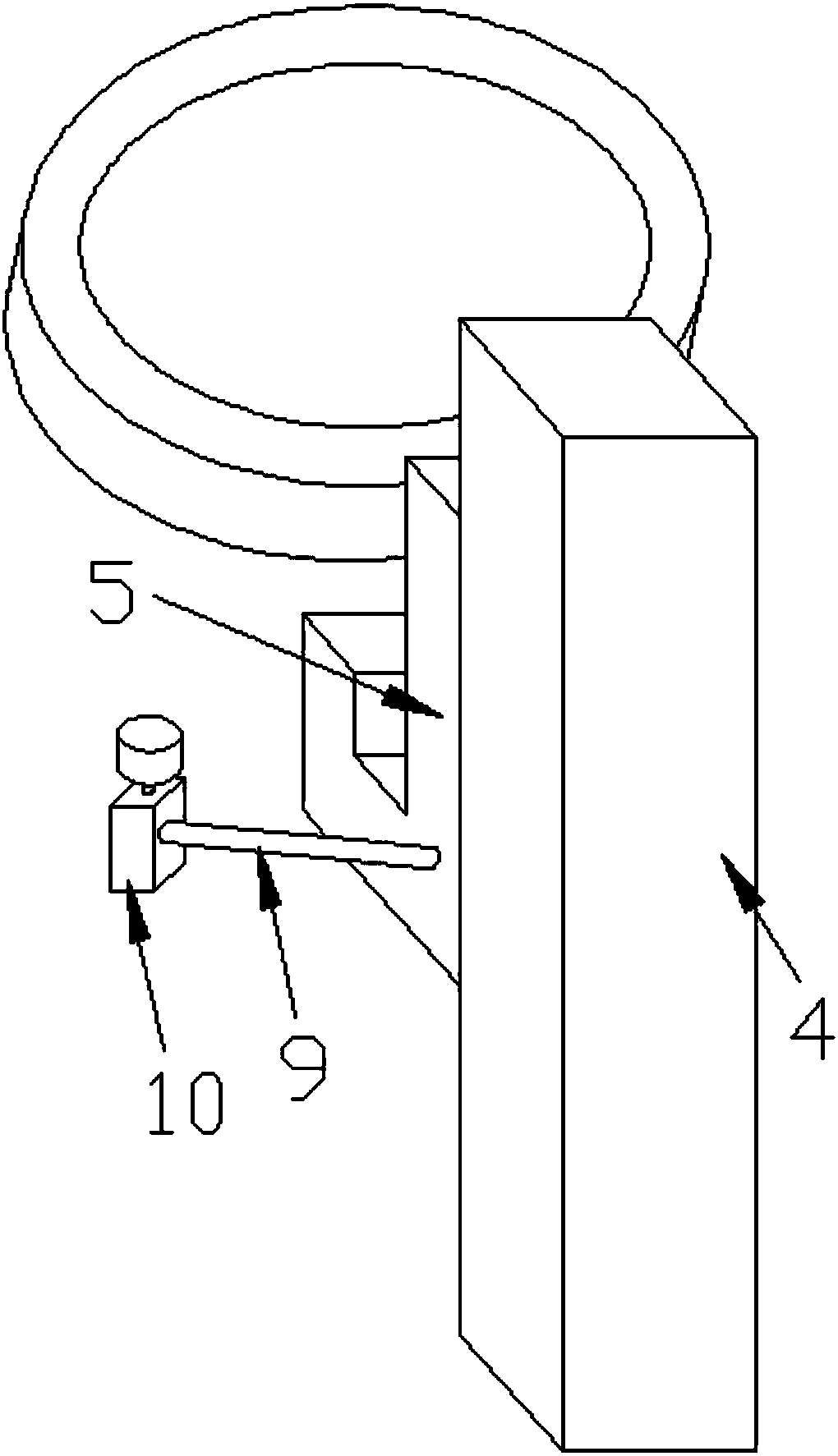

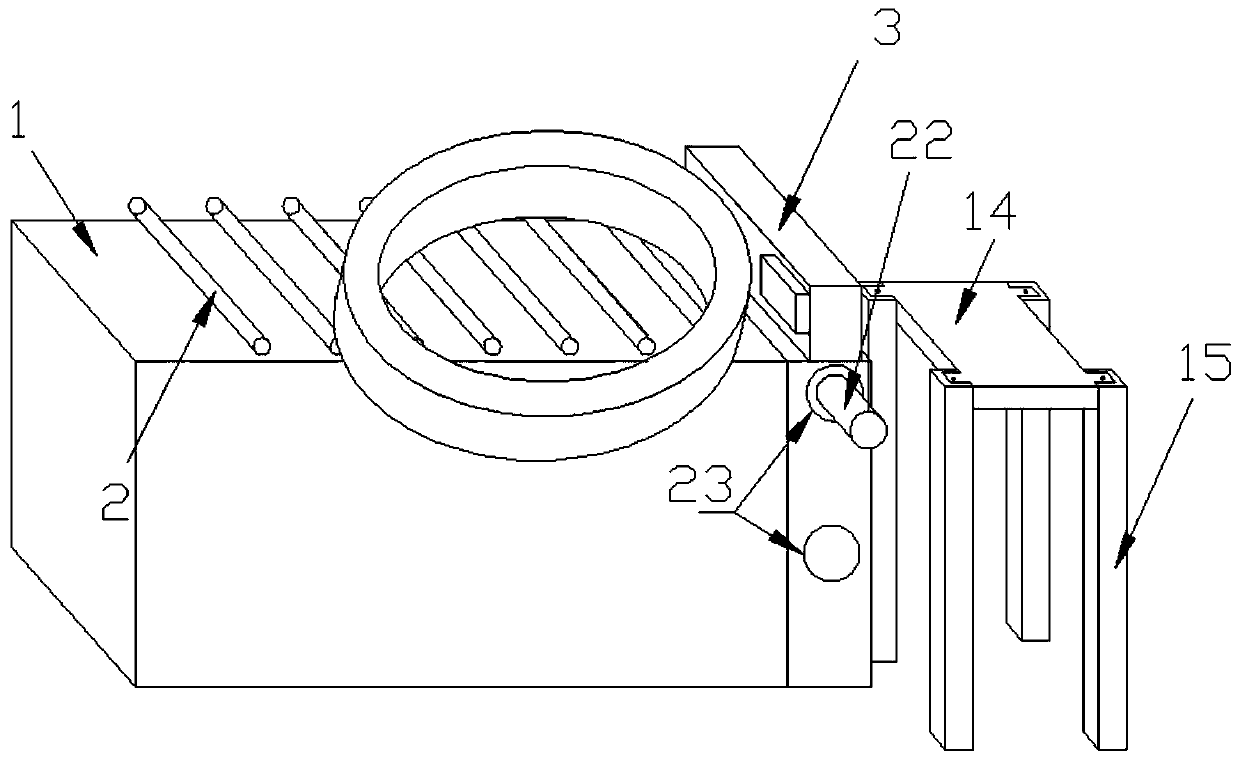

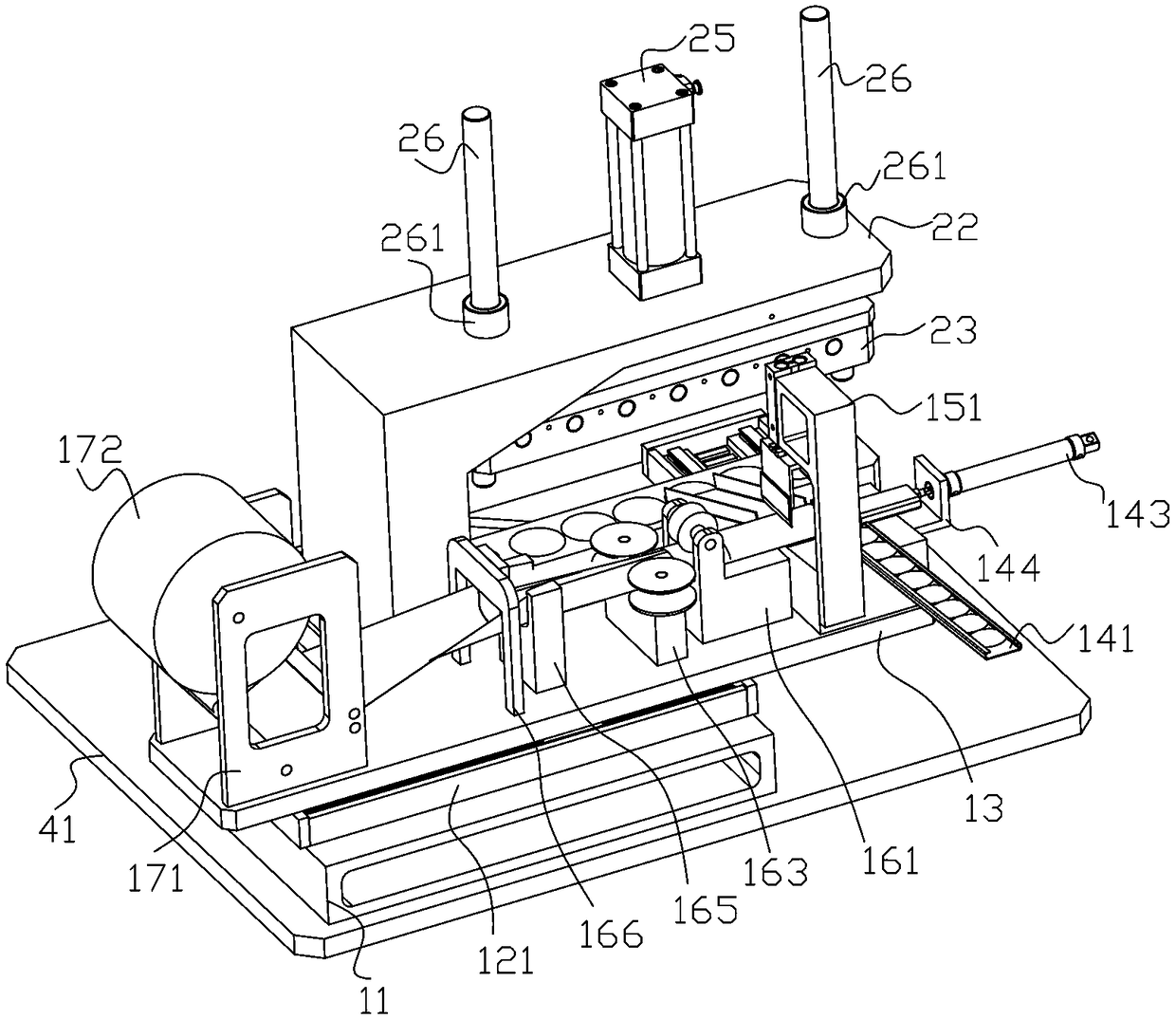

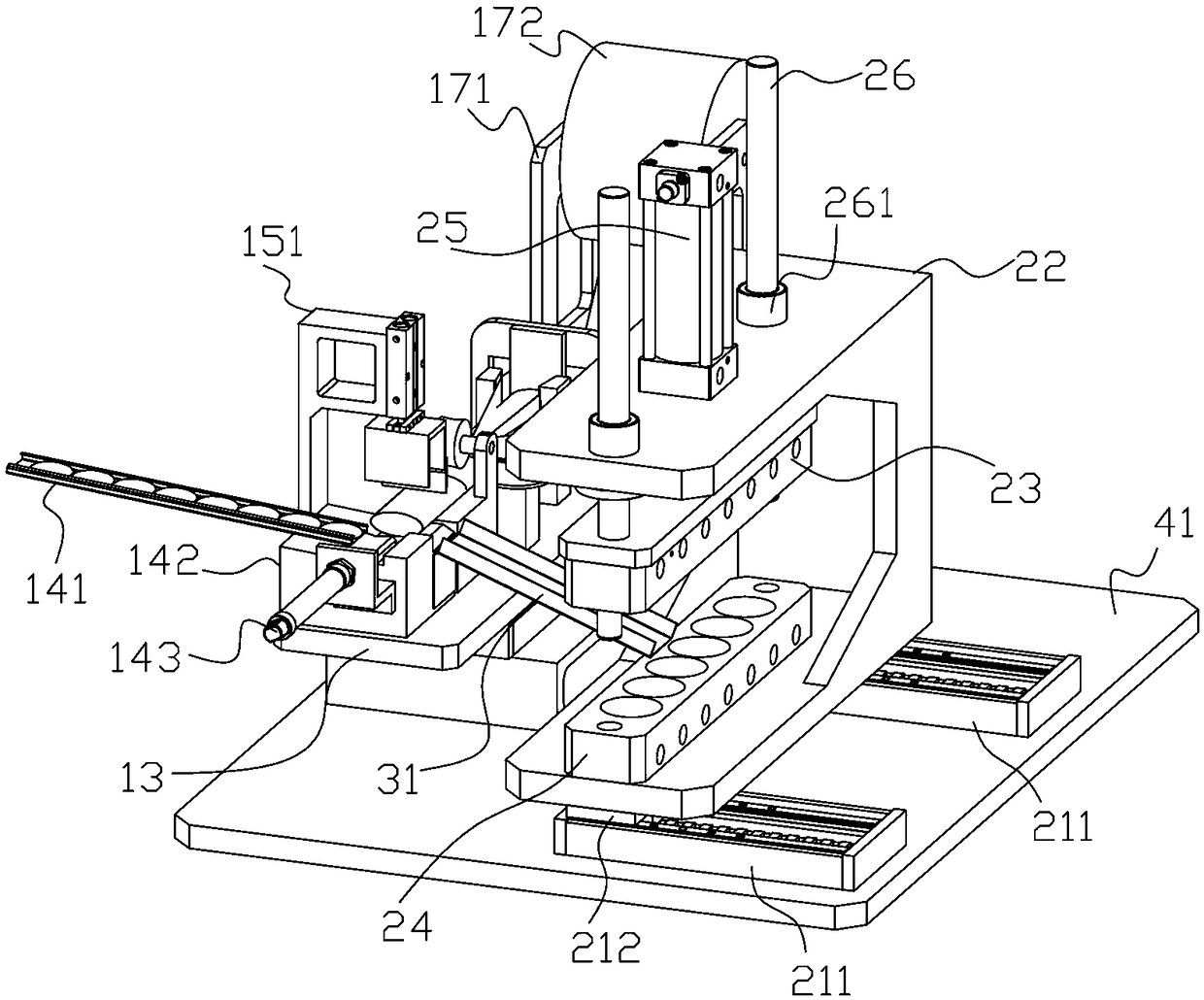

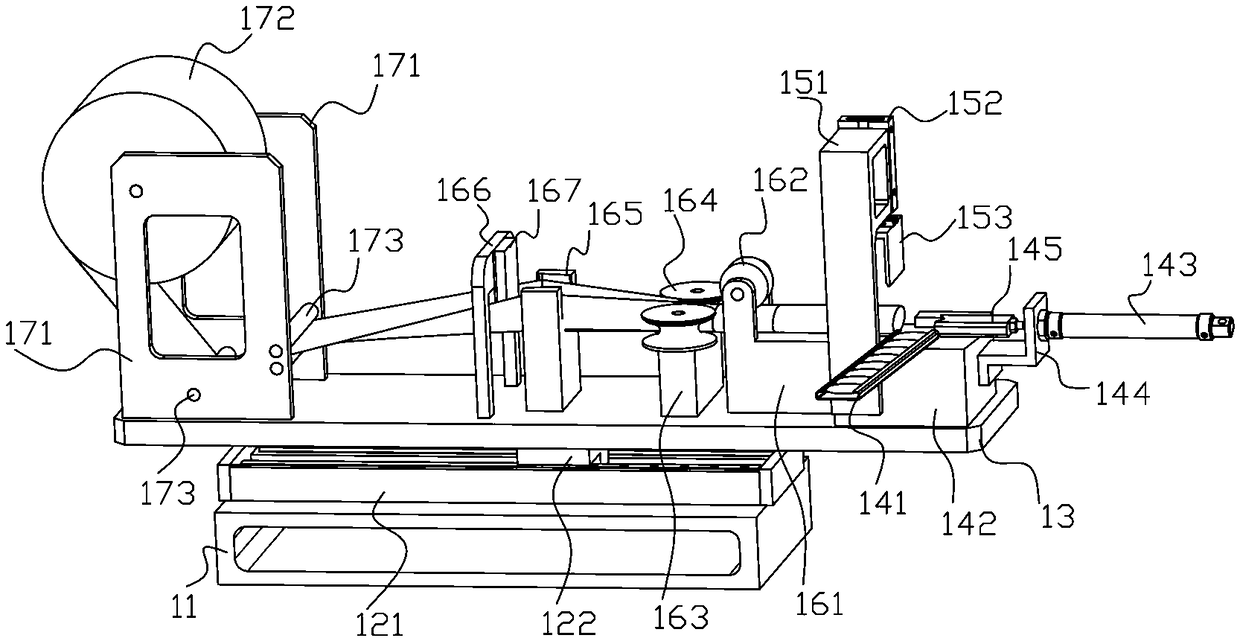

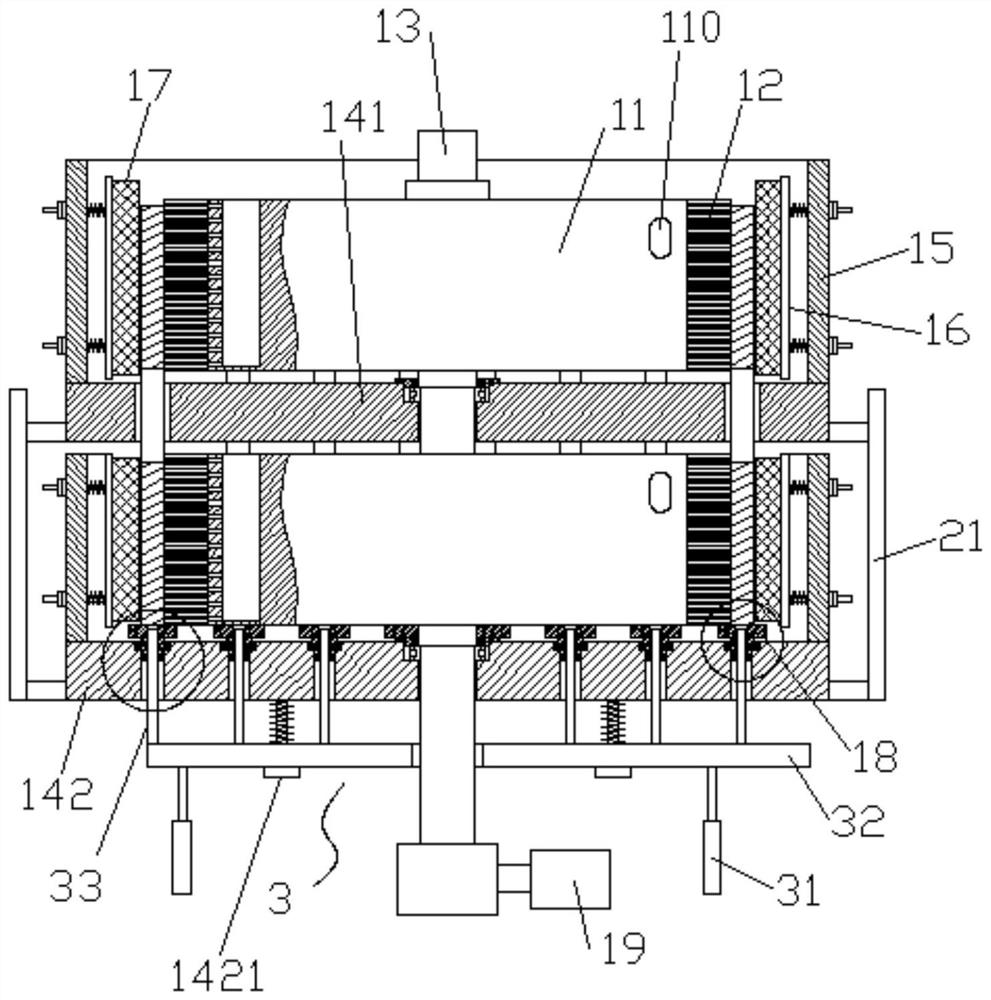

Bolt surface oil coating system

ActiveCN110773369ASmear satisfiedReduce labor intensityLiquid surface applicatorsCoatingsBristleCoating system

The invention discloses a bolt surface oil coating system. Bolts are inserted into an upper mounting plate, the bottom surfaces of the bolts are supported on a tray, a motor drives a rotating shaft torotate through a speed reducer, the rotating shaft drives two rotating cylinders to rotate together, and grease coating on the threaded connecting surfaces of the bolts is achieved through bristles.In the coating process, the bolts can rotate on the tray along with the bristles, so that uniform coating of the bolts is convenient to achieve. After bolt coating is completed, a cylinder shaft of acylinder extends out, a push plate and a push rod are pushed to move upwards, the push rod pushes the bolt upwards, and then the bolts can be conveniently taken out of the system. According to the bolt surface oil coating system, a plurality of bolts can be coated at a time, the coating of the threaded surfaces at the two ends of the bolts can be met at a time, and the efficiency is high; and themechanical operation is achieved, the labor intensity of workers is relieved, and the using effect is good.

Owner:JIANGSU YONGHAO HIGH STRENGTH BOLT

Bending machine for steel pipes

The invention discloses a bending machine for steel pipes, which comprises a pressing plate, a hydraulic cylinder, a hydraulic driving device, a storage box, a motion frame, a turntable, a workbench, a support plate, a half-toothed gear, a base, a fixed plate, a limit pin, The second transmission shaft, the second motor, the first motor, the first transmission shaft, the motor mounting plate and the connecting rod are characterized in that, the upper surface of the base is fixedly connected with a motor mounting plate, and one side of the motor mounting plate A first electric motor is fixedly connected. This product can reduce the work intensity of the workers, improve the bending efficiency, and the bending degree is fixed, the bending quality is controllable, and will not affect the assembly of the subsequent process; this product has a storage box, which can facilitate the temporary storage of workers' items. The design is more user-friendly; the fixed height of the workbench of this product can be adjusted, allowing workers to bend steel pipes at a comfortable working height, thereby reducing the discomfort of workers and improving the bending efficiency of steel pipes.

Owner:王祖友

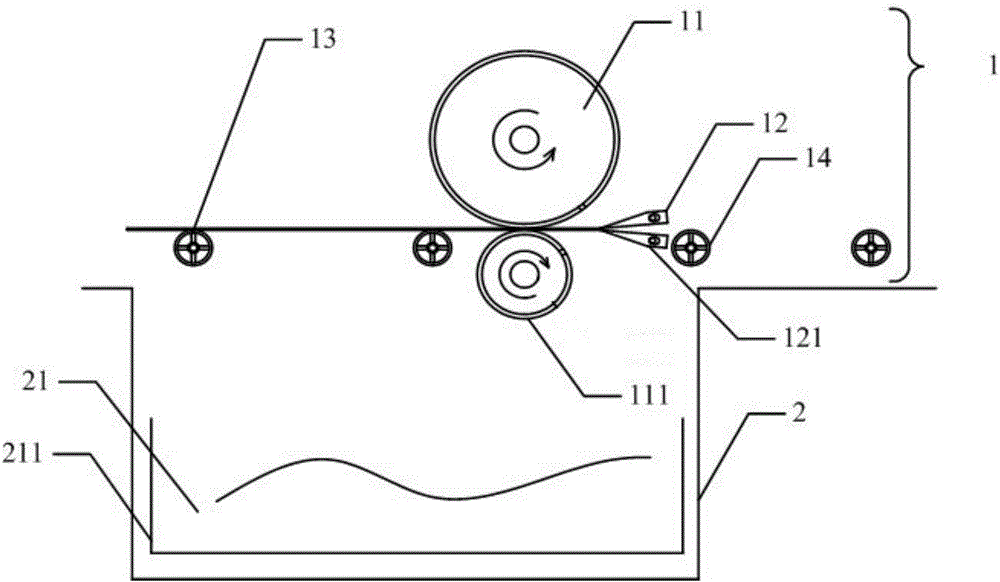

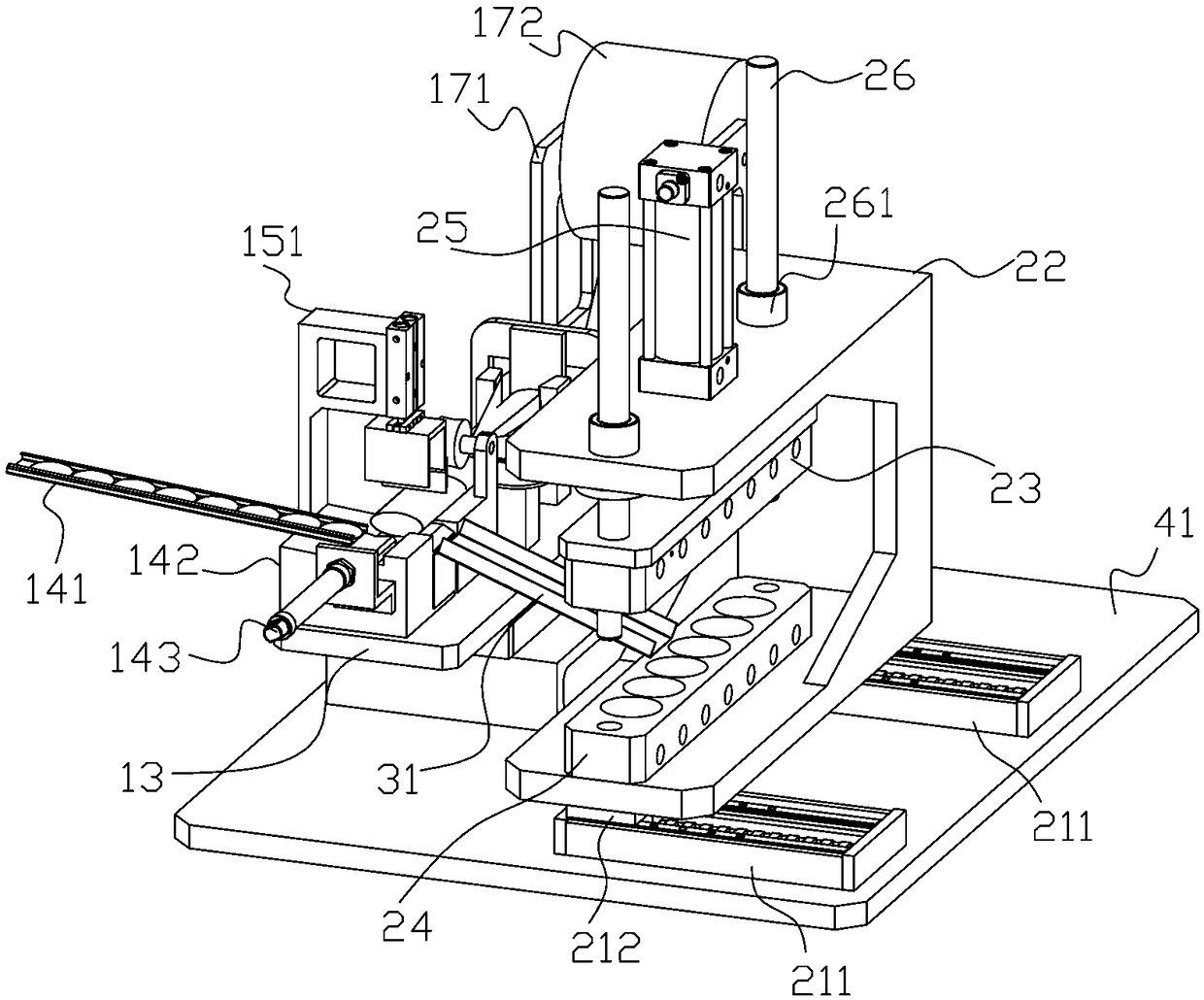

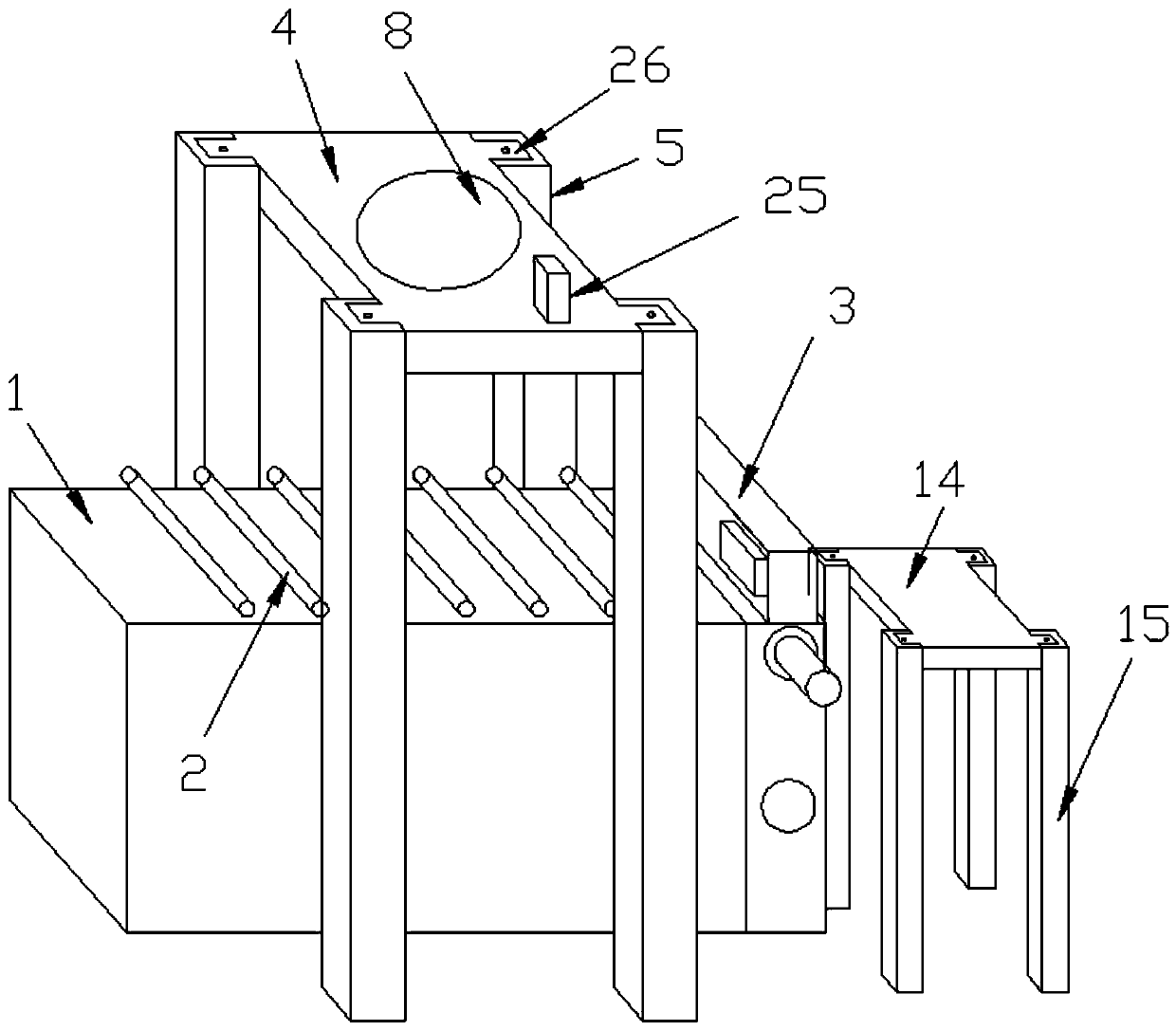

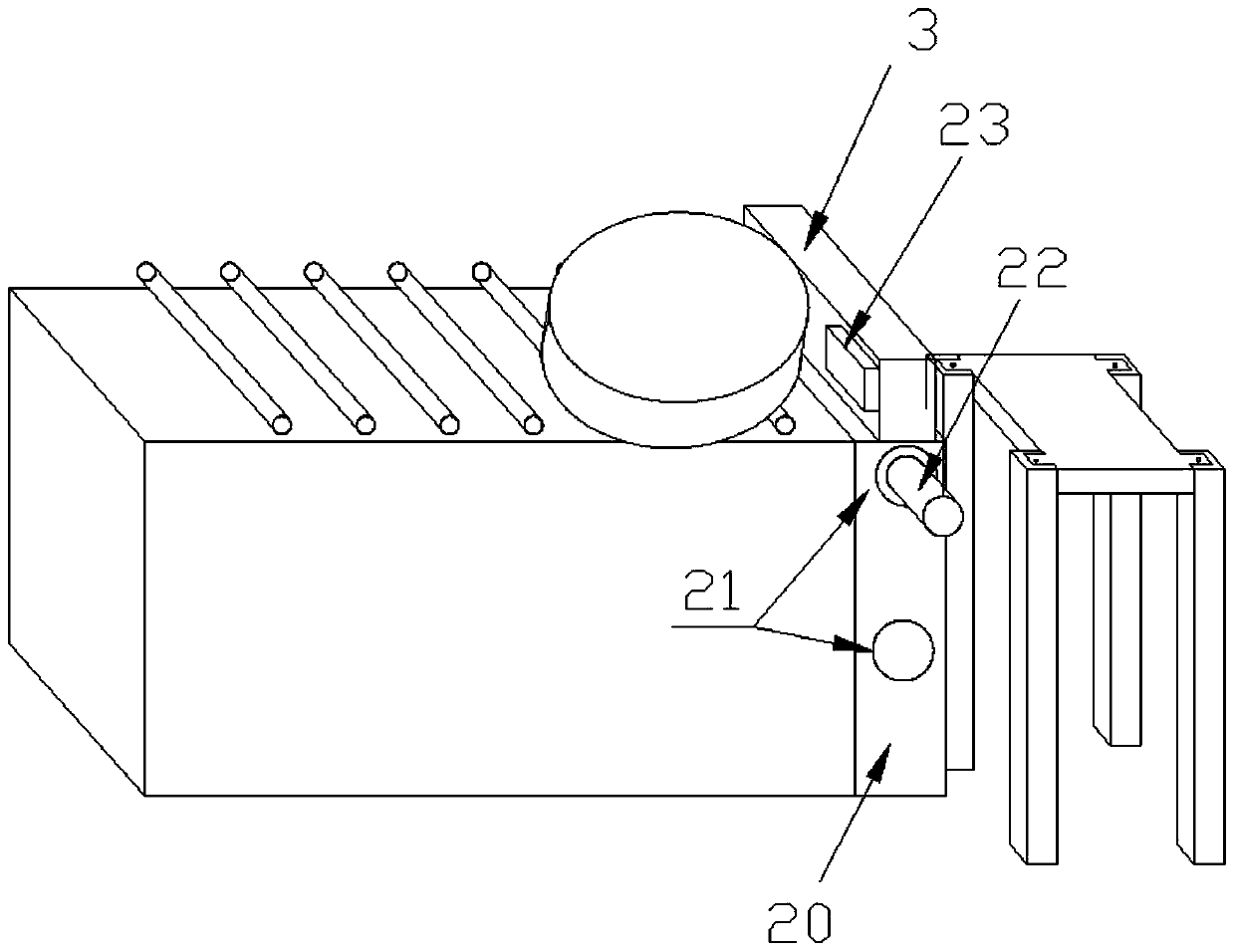

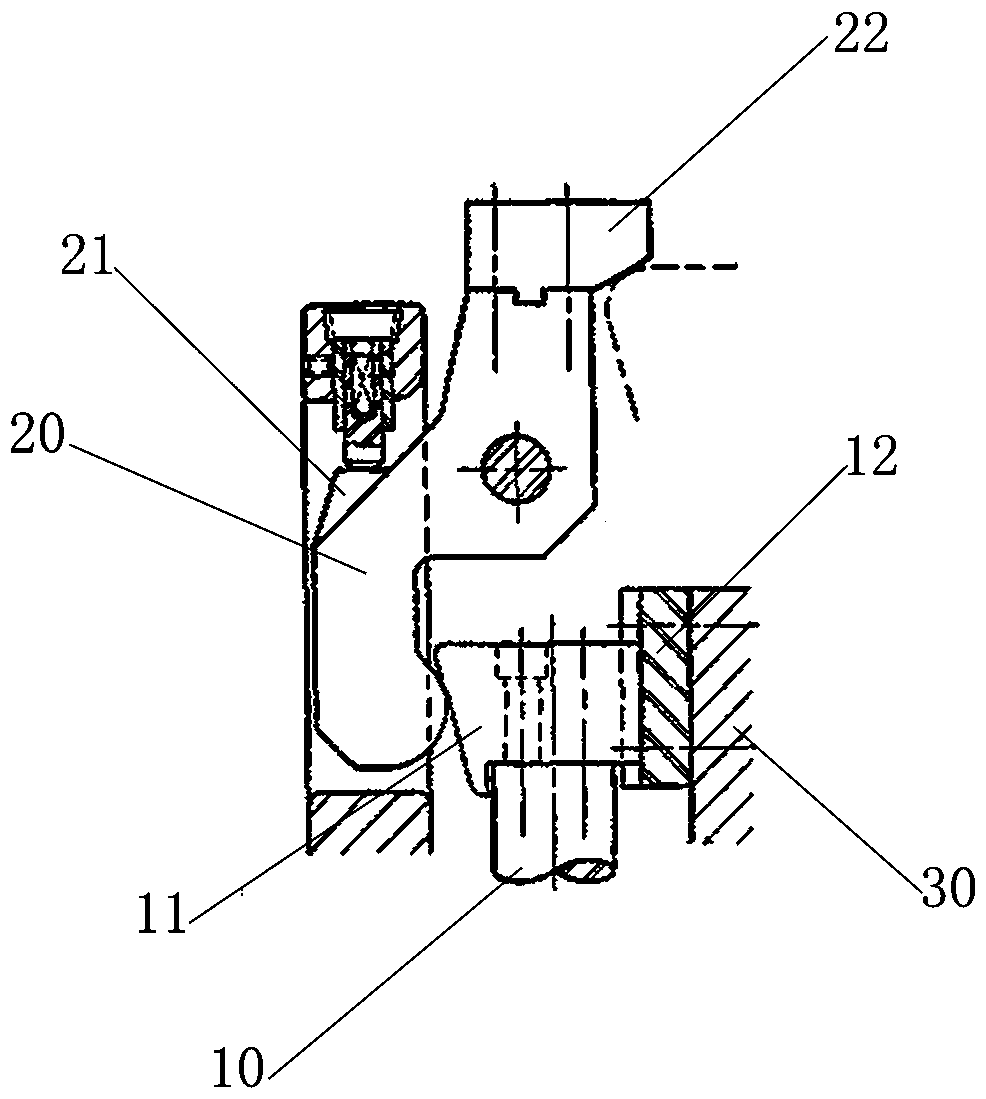

Film-tearing apparatus

InactiveCN106211589AThe film tearing process is complete and easyOperation mechanizationConductive material chemical/electrolytical removalFault rate

The invention discloses a film-tearing apparatus. The film-tearing apparatus can ensure a complete, simple and convenient film tearing process, a mechanical operation and low fault rate, and can lower loss and improve the film-tearing efficiency. The film-tearing apparatus provided by the invention comprises a film-tearing part (1) and a film-collecting part (2), wherein the film-tearing part (1) comprises a film-collecting roller (11) and an edge remover (12); the edge remover (12) can be used for removing a protection film from a circuit board; the film-collecting roller (11) is used for tearing the protection film which is removed by the edge remover (12); and the film-collecting roller (11) and the edge remover (12) are positioned on the same side of the circuit board.

Owner:广州炬森自动化设备有限公司

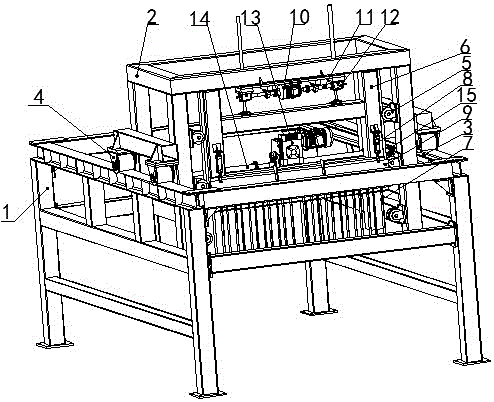

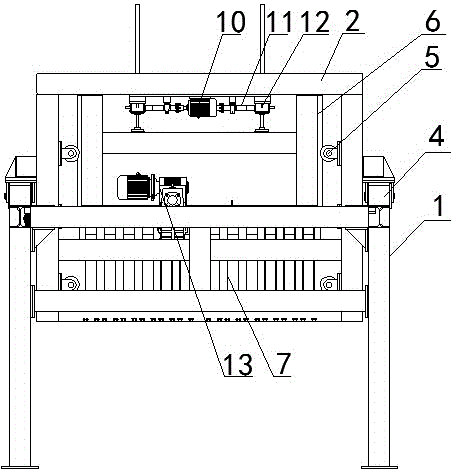

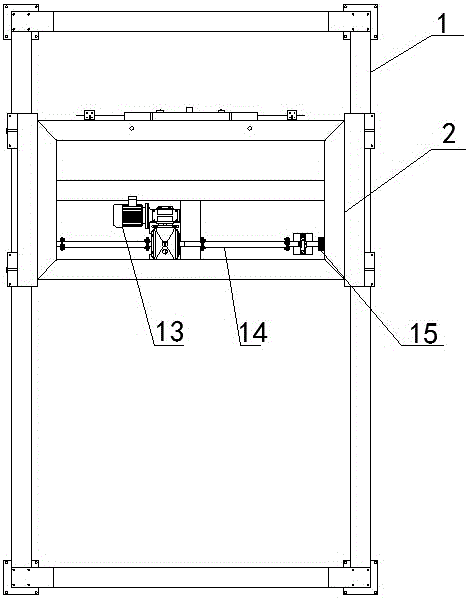

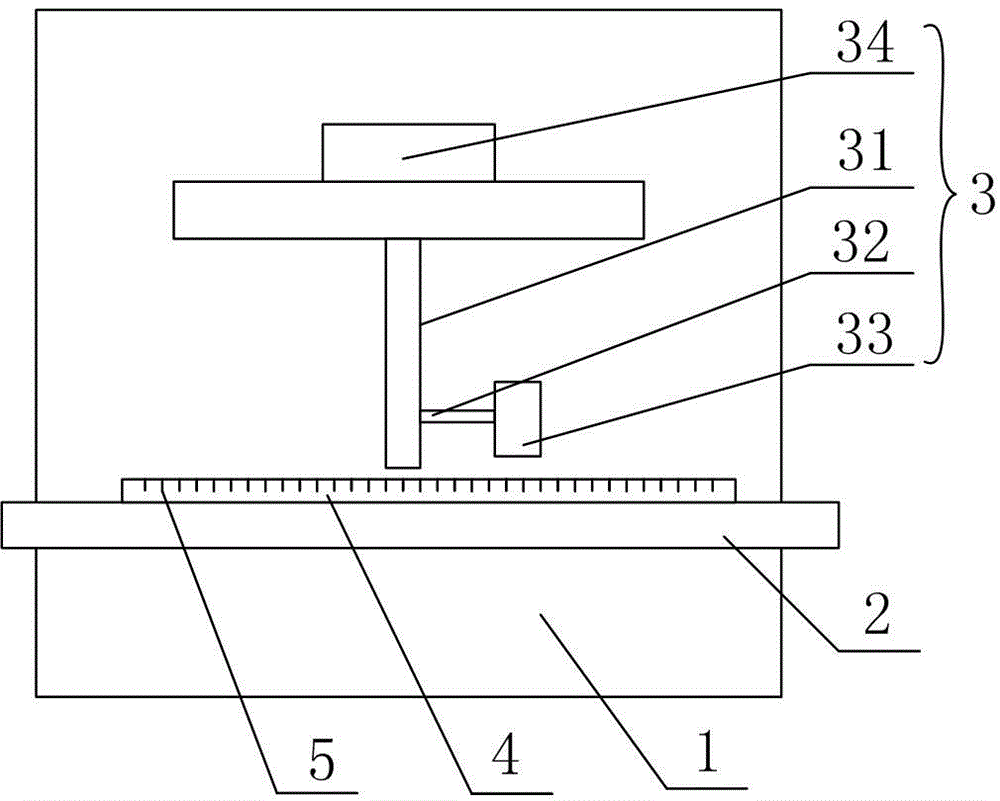

Pore removing device for light-weight wallboard

InactiveCN106182334AWalking smoothlyStable jobAuxillary shaping apparatusHorizontal transmissionDrive shaft

The invention discloses a pore removing device for a light-weight wallboard. The pore removing device comprises a rack; runners of a transverse walking support are arranged at the upper portions of a left vertical beam and a right vertical beam of the rack, at least three vertically-moving wheels are symmetrically arranged at the positions, on the inner walls of the two vertical beams, of the front end of the transverse walking support, a vertical beam is arranged on the inner side of each vertically-moving wheel, and a plurality of vibration plates are connected to the bottoms of the two vertical beams; air cylinders are arranged at the middle portions of the side walls of the front sides of the two vertical beams, the lower ends of the air cylinders are connected with a scraping plate; a double-shaft motor is arranged on the lower side of a transverse beam at the upper portion of the back end of the transverse walking support, and an output end of the double-shaft motor is connected with two screw lifters through lifter transmission shafts; and a hollow shaft reducer is arranged at the lower portion of the transverse walking support, a horizontal transmission shaft is connected to the hollow shaft reducer, and a gear is arranged at the end of the horizontal transmission shaft and meshed with racks arranged on the inner walls on the left side and the right side of the rack. By means of the above structure, the effects of being simple in structure, safe, high in efficiency, flexible in operation and higher in automation degree, saving time and labor, achieving mechanization and being capable of removing bubbles so as to guarantee the wallboard quality are achieved.

Owner:SHANDONG TIANYI MACHINERY

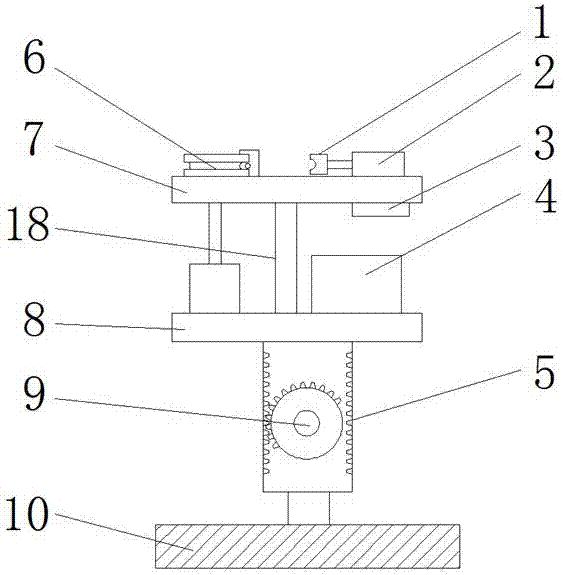

Machining device suitable for cutting round stainless steel sheet

InactiveCN105252126ASolve the problem of manually cutting stainless steel plates to obtain circular stainless steel platesEffective resizingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringScrew thread

The invention discloses a machining device suitable for cutting a round stainless steel sheet. The machining device comprises a cutting machine installing rack, a sheet fixing platform and a plasma cutting mechanism, wherein the sheet fixing platform and the plasma cutting mechanism are arranged on the cutting machine installing rack. The machining device is characterized in that the plasma cutting mechanism comprises a rotary rod with the top end connected to the cutting machine installing rack, and a plasma cutting head fixed to the bottom end of the rotary rod through a transversely-stretching rod; the transversely-stretching rod comprises an inner rod with an external thread and two outer rods; and one end of one outer rod is in threaded connection with the inner rod, the other end of one outer rod is fixedly connected with the bottom end of the rotary rod, one end of the other outer rod is in threaded connection with the inner rod, and the other end of the other outer rod is fixedly connected with the plasma cutting head. The machining device has the beneficial effects that operation is easy and convenient, and raw materials are saved.

Owner:CHENGDU XINDU SANLI PLASTIC CO LTD

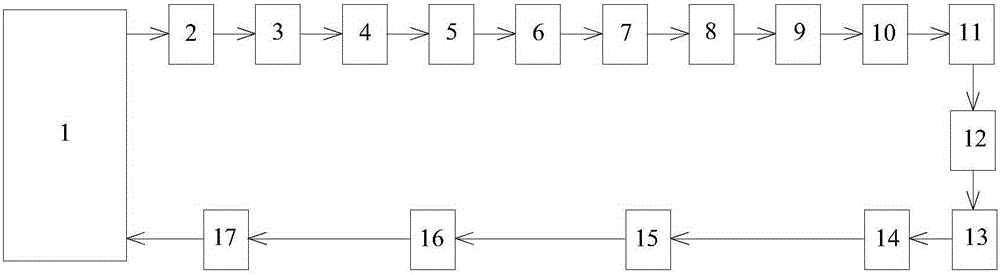

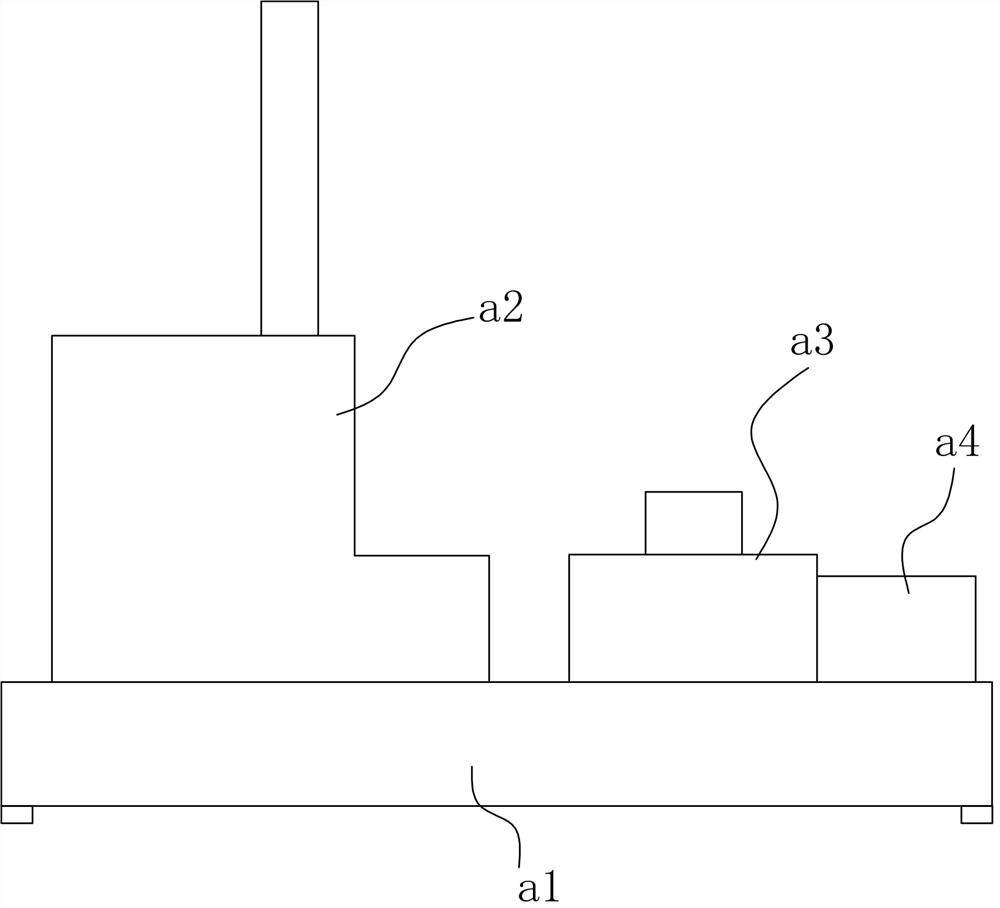

Production systems for concrete elements

ActiveCN104057537BReduce labor intensitySimple structureDischarging arrangementCeramic shaping plantsPre treatmentWaste management

A concrete member production system comprises a formwork table conveying device, formwork table pre-treatment equipment, a first spreader, a second spreader, post-spreading treatment equipment, a maintenance storehouse and an edge-on bottom formwork removal device, wherein a formwork removal station, a formwork pre-treatment station, a first spreading station and a vibro-compacting station are sequentially arranged on the formwork table conveying device and at the exit of the maintenance storehouse; a post-spreading treatment station, a second spreading station and an insulation board placing station are sequentially arranged on the formwork table conveying device and at the entrance of the maintenance storehouse; the edge-on bottom formwork removal device, the formwork table pre-treatment equipment, the first spreader, a formwork vibrating device, the second spreader and the post-spreading treatment equipment are correspondingly arranged on the formwork removal station, the formwork pre-treatment station, the first spreading station, the vibro-compacting station, the second spreading station and the post-spreading treatment station respectively to form a circulating production system. The concrete member production system is operated mechanically, achieves continuous production, saves time and labor and improves the working efficiency.

Owner:HEBEI XUELONG MACHINERY MFG

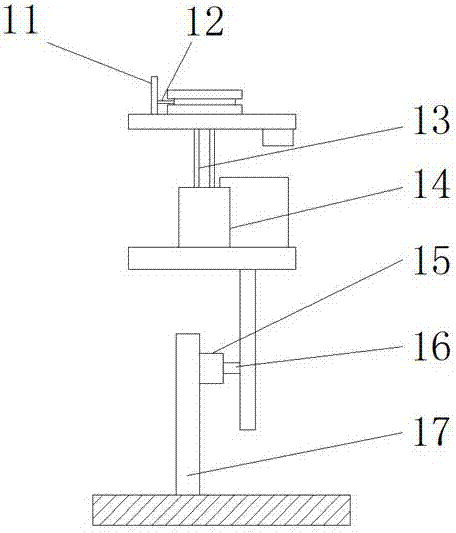

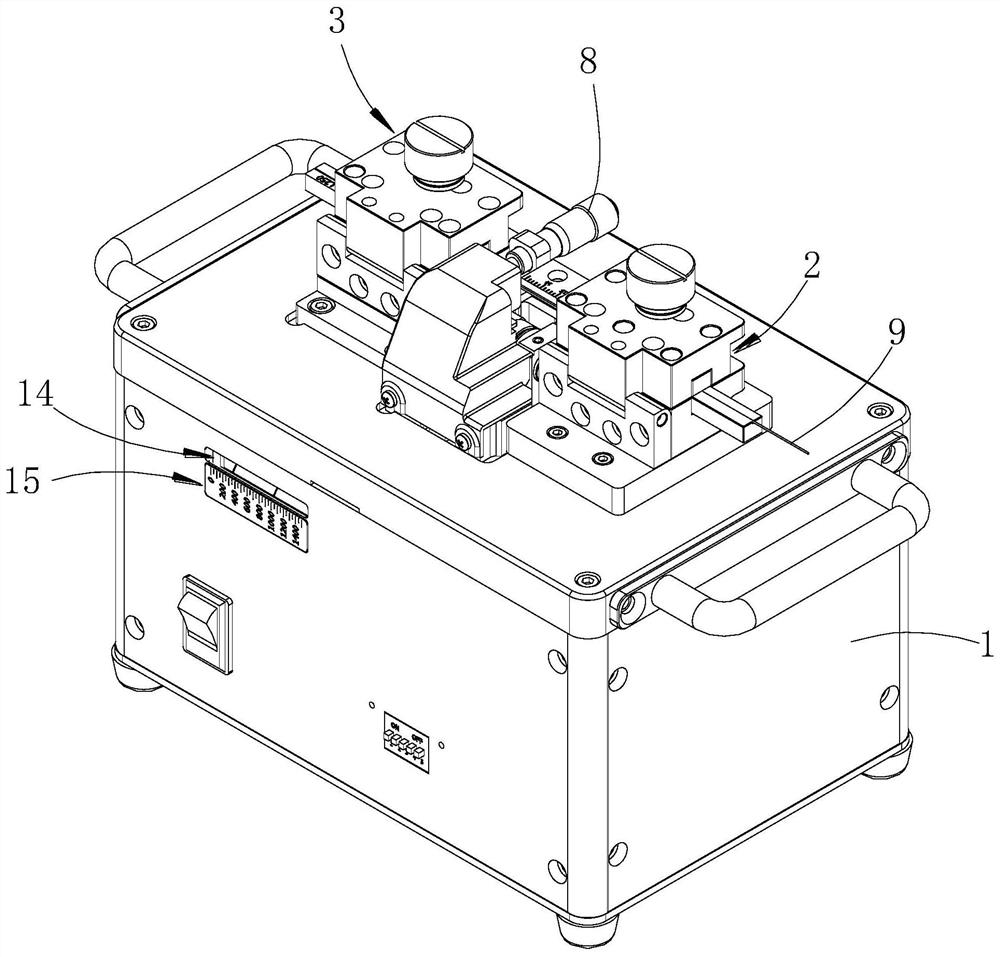

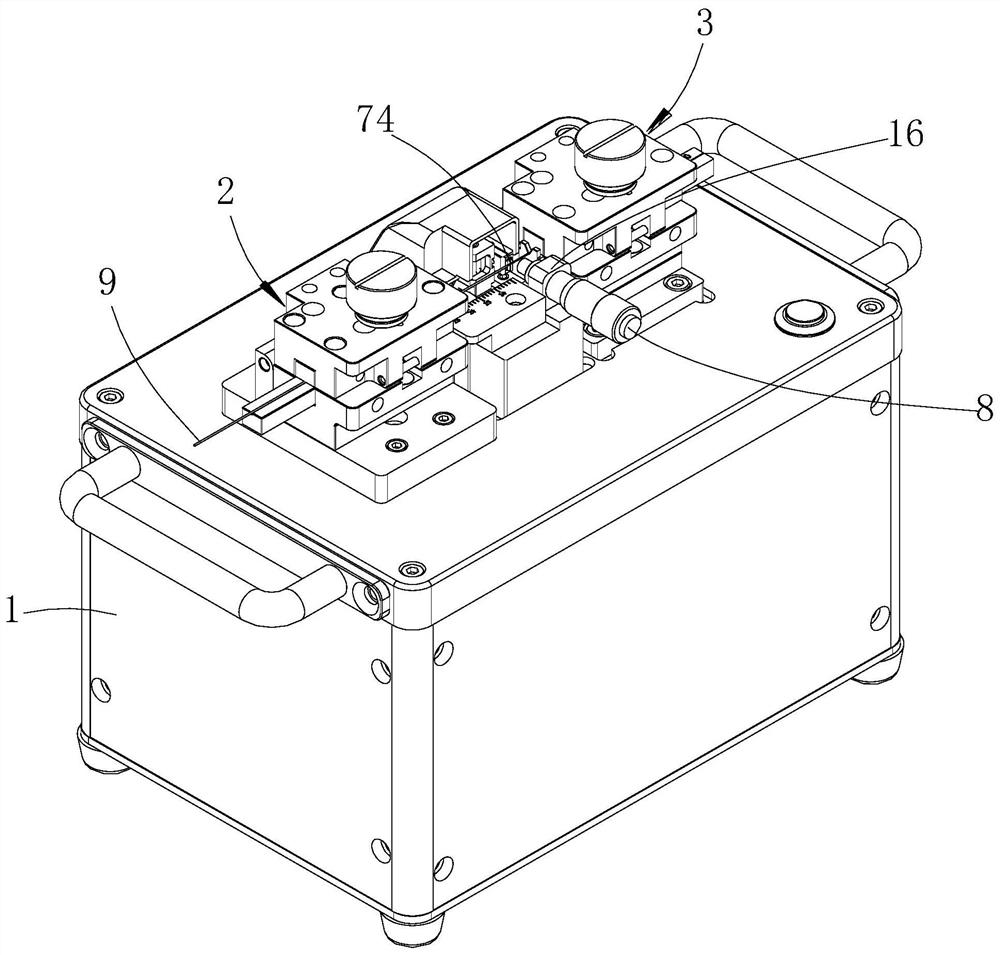

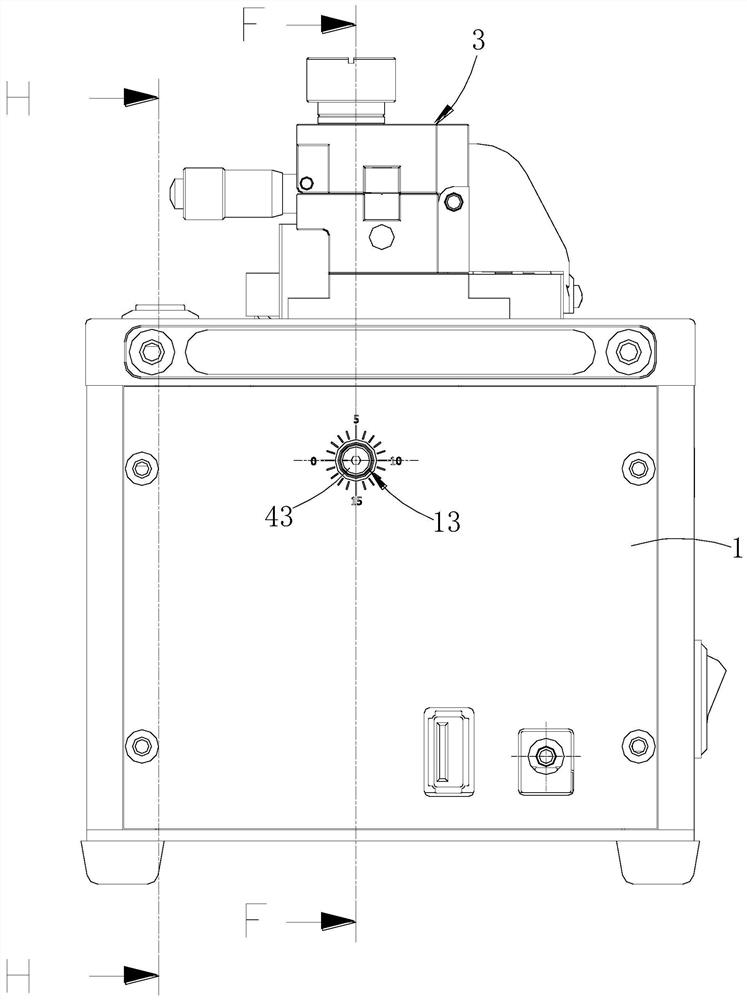

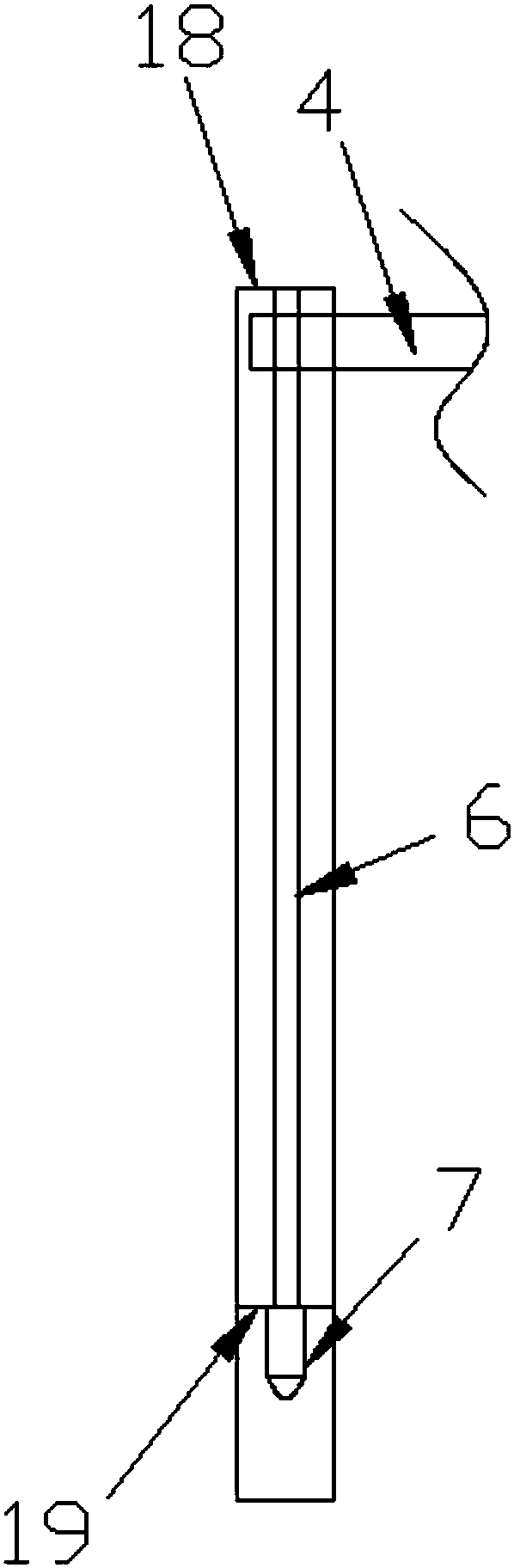

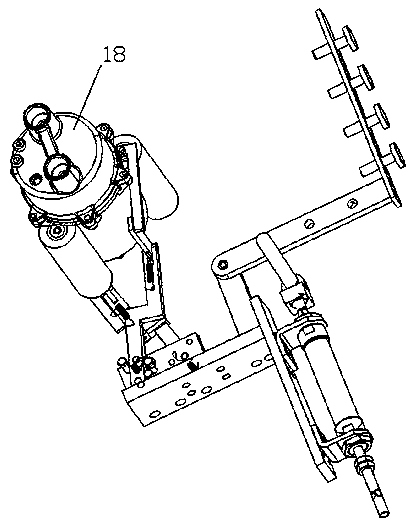

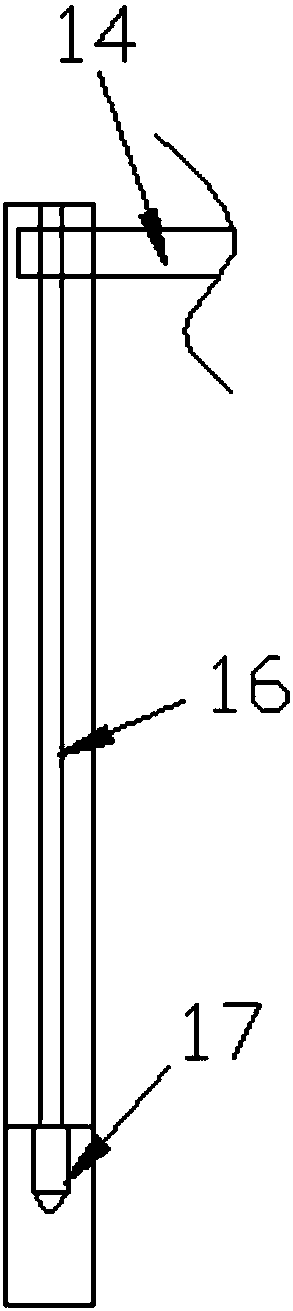

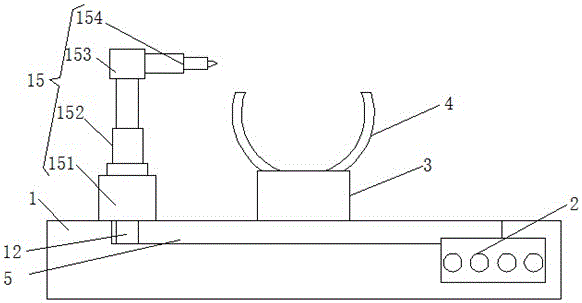

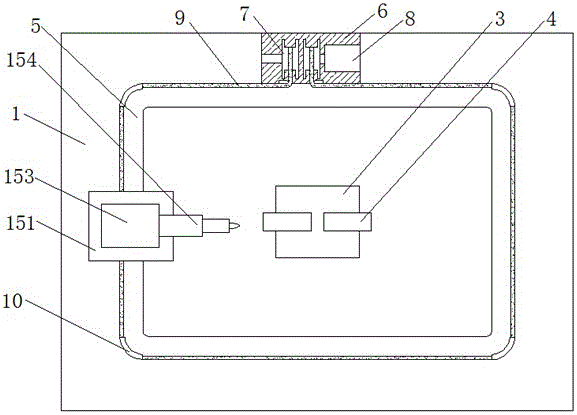

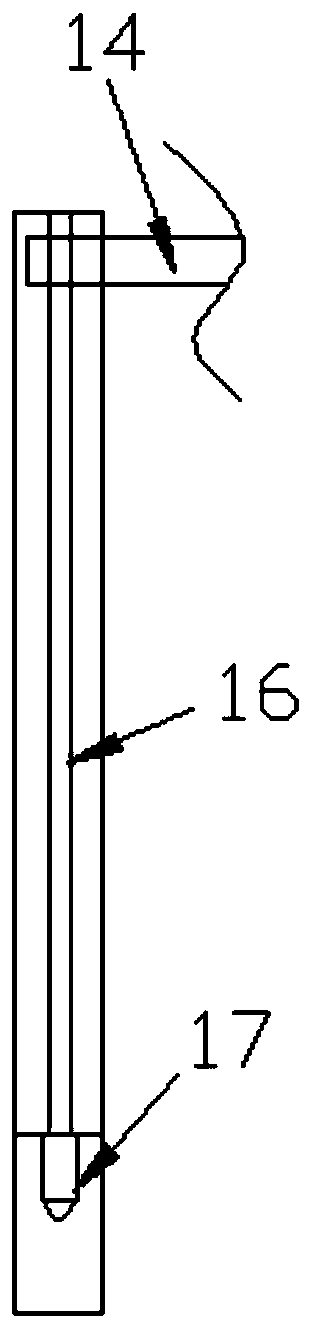

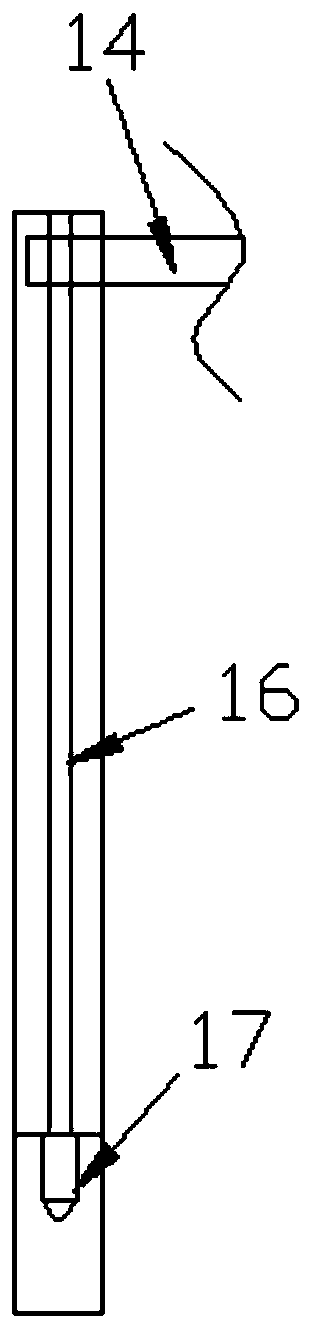

Optical fiber cutting device

PendingCN111694097AReasonable structureOperation mechanizationCoupling light guidesGlass productionMechanical engineeringPhysics

The invention provides an optical fiber cutting device. The optical fiber cutting device comprises a cutter, a first clamping mechanism, a second clamping mechanism, a box body, a pre-pulling assemblyand an ultrasonic cutting assembly, the first clamping mechanism is fixedly connected to the upper end surface of the box body; the upper end of a connecting plate of the pre-pulling assembly is fixedly connected with the second clamping mechanism; a kidney-shaped hole allowing a connecting plate to move is formed in the upper end face of the box body, the connecting plate stretches into a cavityof the box body, a guide plate is fixed in the cavity of the box body, an adjusting bolt is matched with a threaded hole of the guide plate, one end of a pre-tensioning spring is fixed to the connecting plate, and the other end of the pre-tensioning spring is fixed to the end of the adjusting bolt. The two ends of a rotating shaft of an ultrasonic cutting assembly are supported on the box, the cutter is fixedly installed on the rotating shaft, and a servo motor rotates through a rotating shaft of a conveying belt. The optical fiber cutting device has the advantages that operation is simple, the optical fiber end surface quality and the optical fiber cutting efficiency are improved, the ultrasonic cutting assembly can be used to cut optical fibers with different sizes and diameters flexibly, and the limitation on the optical fiber size during manual cutting is avoided.

Owner:蚌埠锐光仪器设备有限公司

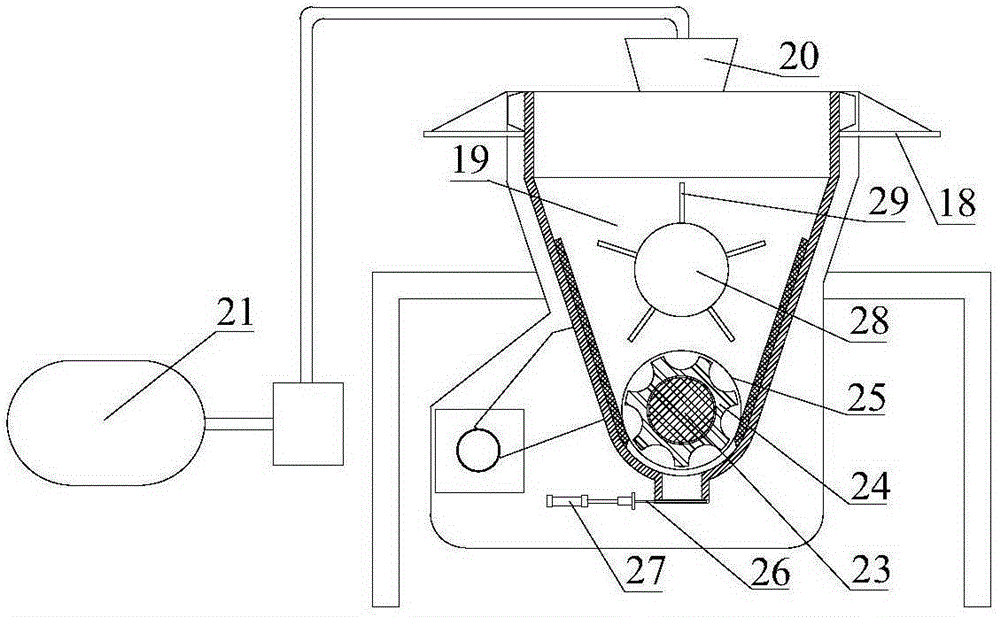

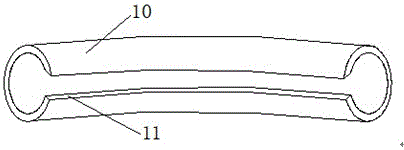

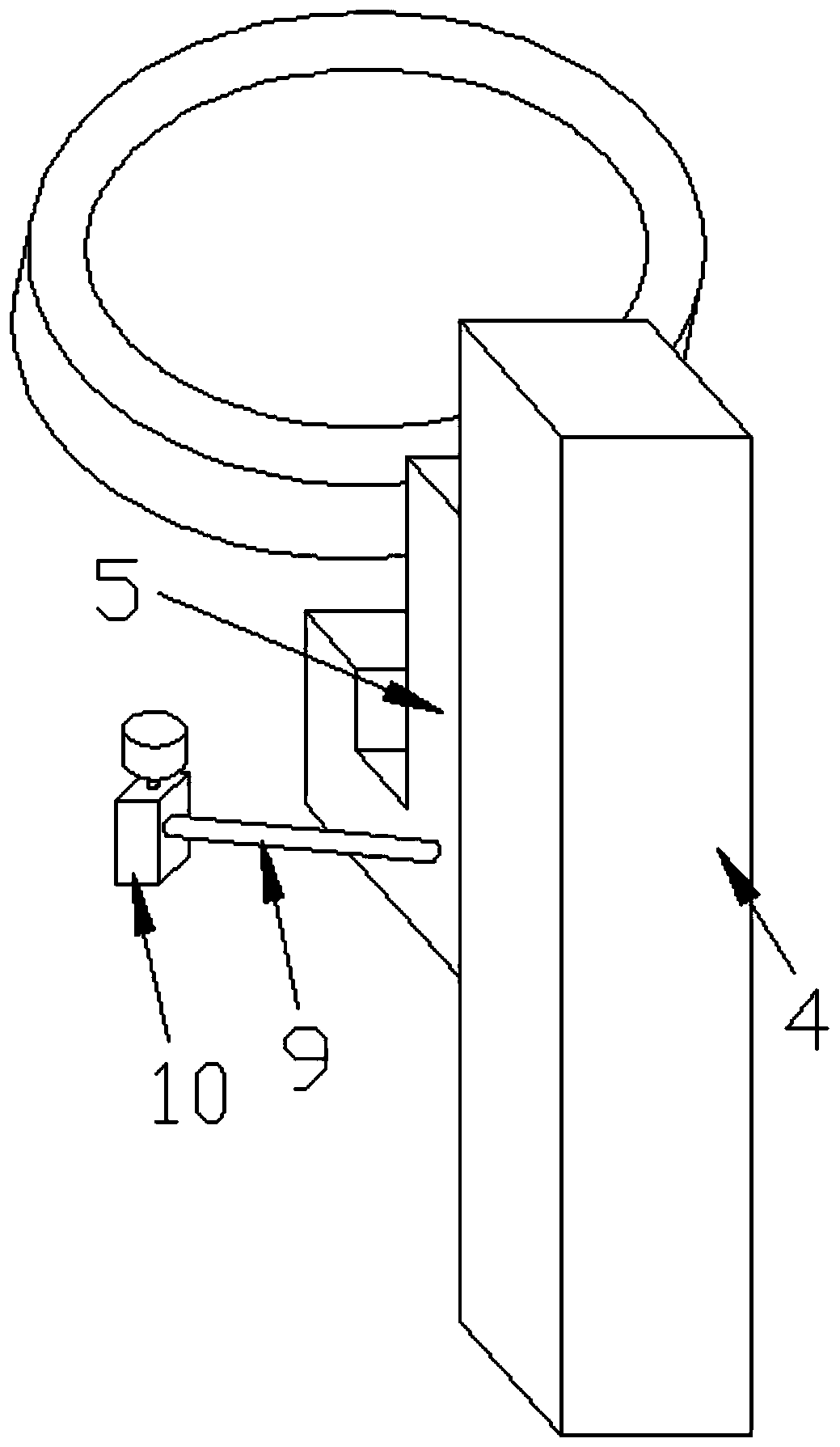

Complete film coating machine for solar heat collection shuttle

The invention discloses a complete film coating machine for a solar heat collection shuttle. The complete film coating machine comprises a feeding mechanism, a vacuum plastic suction mechanism and a discharge groove, wherein the feeding mechanism comprises a first linear motion device, a moving plate, a heat shrinkage film feeding device, a heat collection shuttle feeding device and a heat sealingdevice; the moving plate is arranged on the first linear motion device; the heat shrinkage film feeding device is located at one end of the moving plate; the heat collection shuttle feeding device islocated at the other end of the moving plate; the heat sealing device is connected with the heat collection shuttle feeding device; one end of the discharge groove is connected with the heat collection shuttle feeding device; the vacuum plastic suction mechanism comprises a second linear motion device, a plastic suction frame, an upper mold, a lower mold and a mold-closing cylinder; the plastic suction frame is arranged on the second linear motion device; the mold-closing cylinder is arranged on the plastic suction frame; the lower mold is arranged on the plastic suction frame; the upper moldis connected with the mold-closing cylinder; the upper mold and the lower mold are respectively provided with hemispherical pits and through holes communicating with the pits; and the other end of the discharge groove is inclined downward and can be located between the upper mold and the lower mold. The complete film coating machine provided by the invention realizes mechanized operation and hashigh production efficiency.

Owner:DONGGUAN SONGYAN ZHIDA IND DESIGN CO LTD

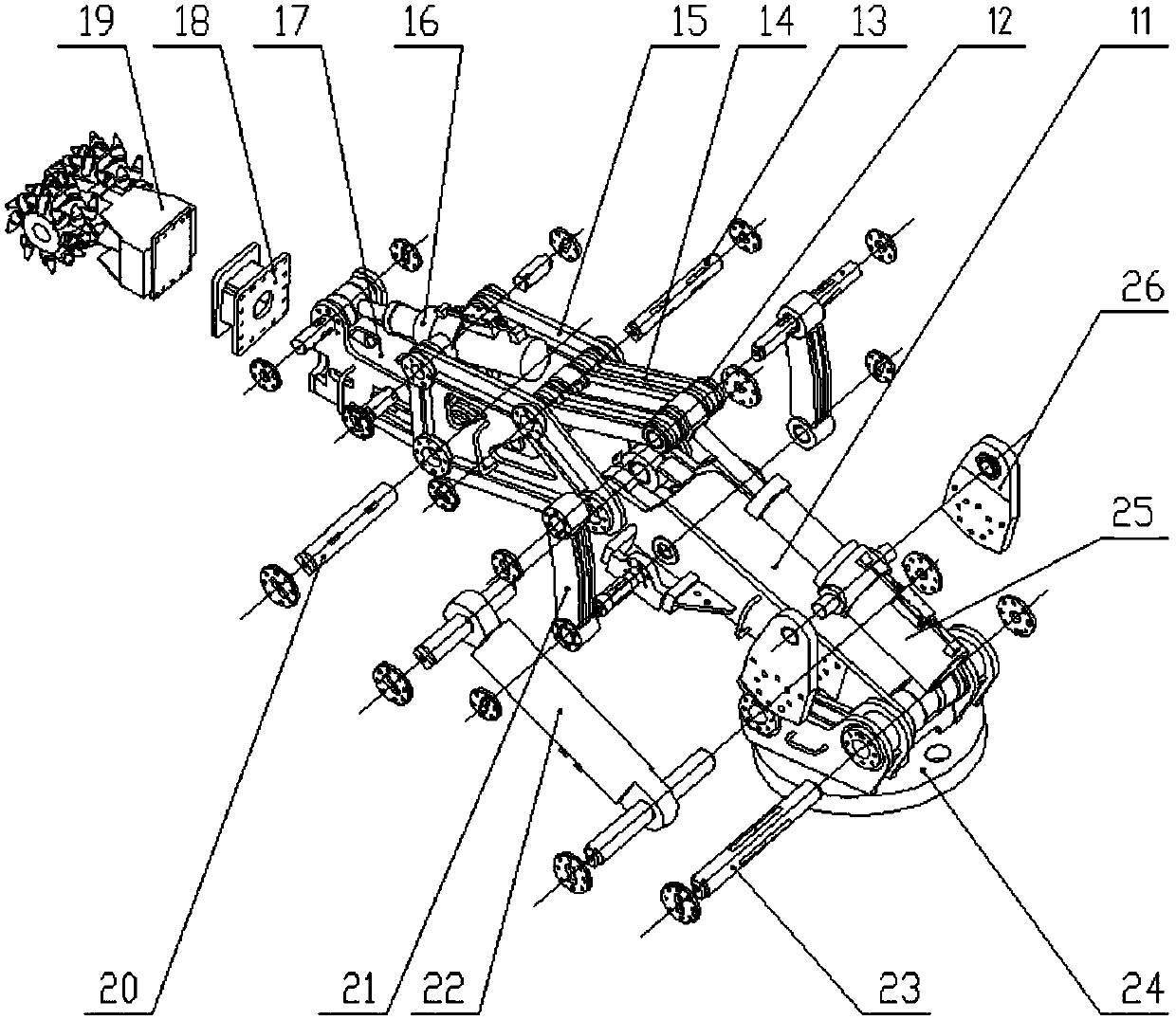

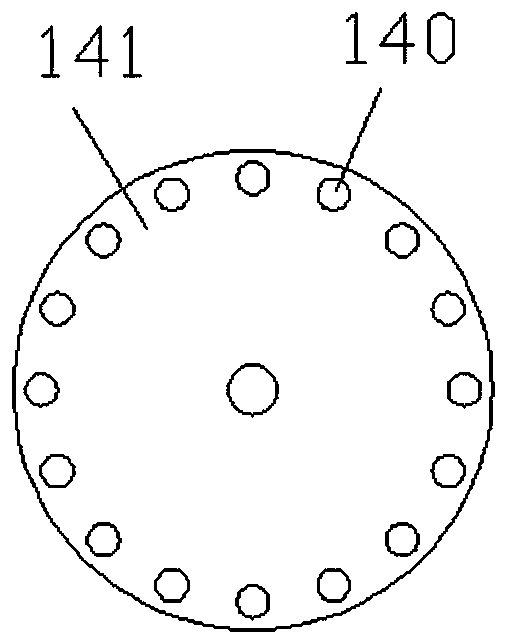

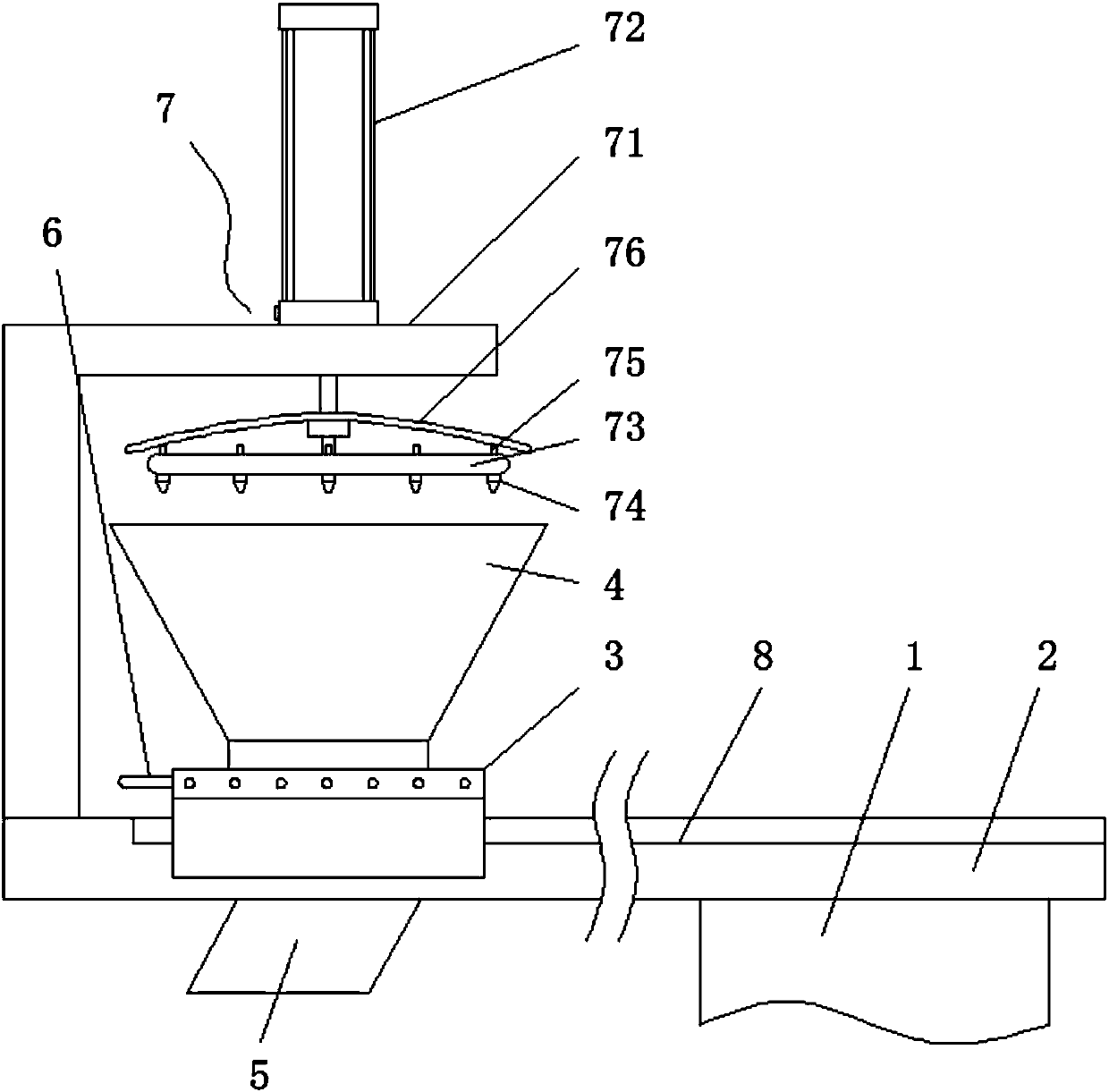

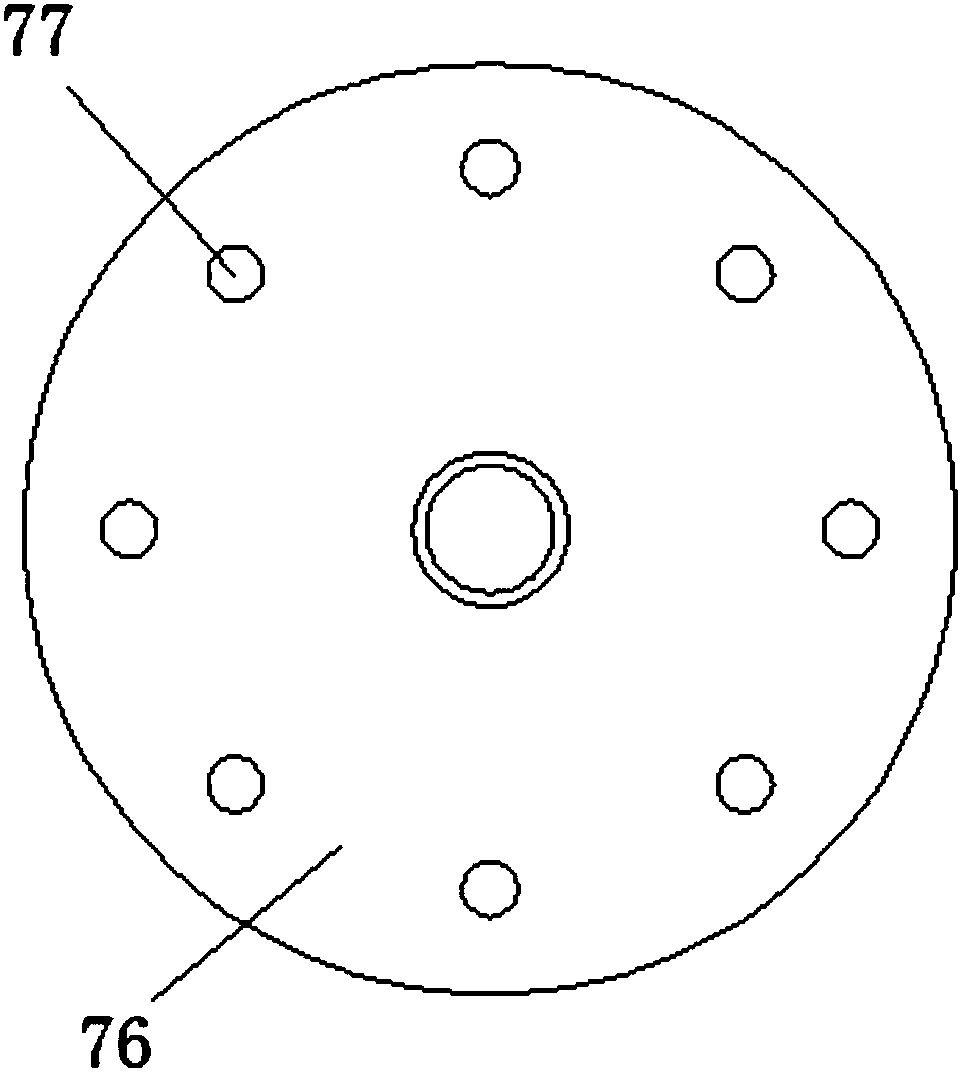

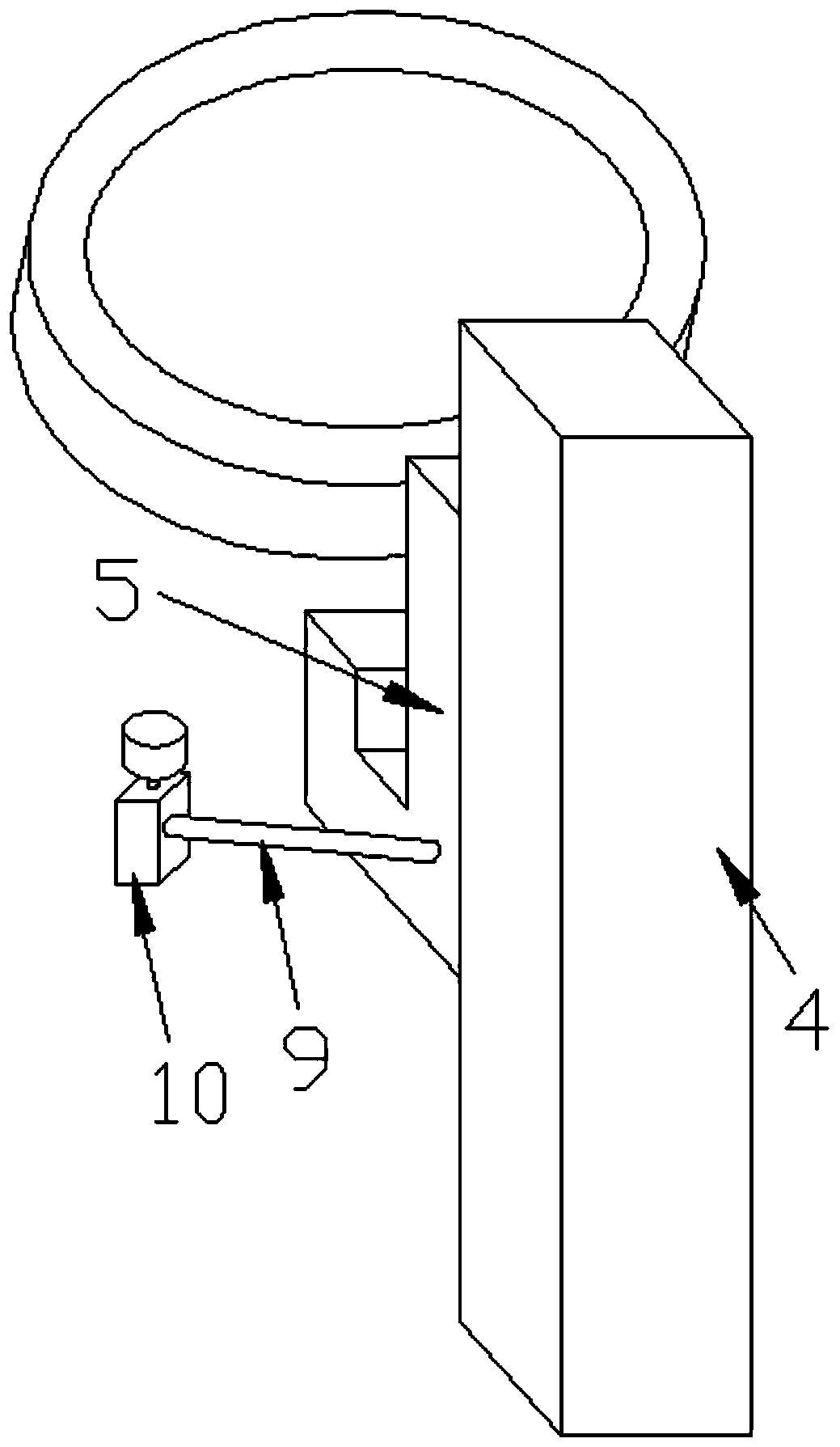

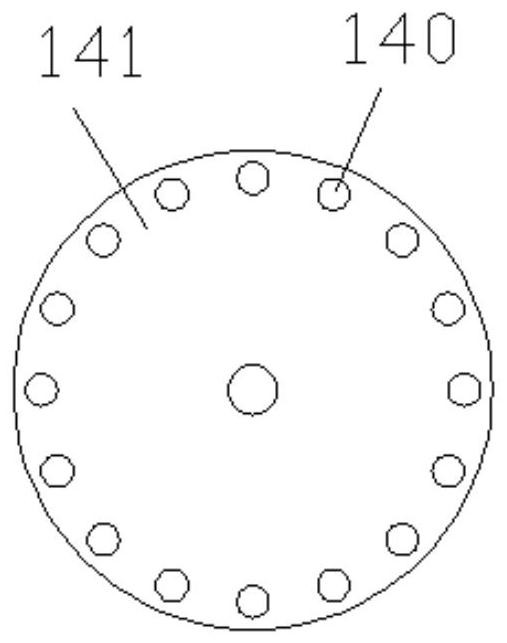

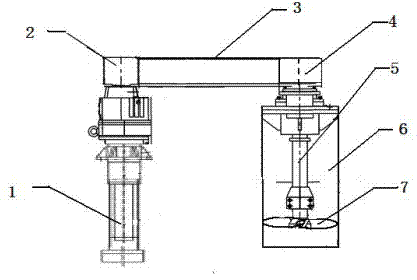

Automation device for wind power spindle flanges before hoisting

ActiveCN108217054AIncrease in sizeReduce manufacturing costConveyorsControl devices for conveyorsElectricityThrust bearing

The invention discloses an automation device for wind power spindle flanges before hoisting. The automation device comprises a frame, a conveying device, a limiting baffle, a hole aligning plate, a lifting screw rod, a first motor, a flange stacking and storing frame, a second lifting screw rod and a second motor, wherein the limiting baffle is not higher than the flange; the hole aligning plate is slidably arranged on the hole aligning frame; the lifting screw rod is arranged inside the hole aligning frame and is used for driving the hole aligning plate to slide downwards; the first motor isarranged inside the hole aligning frame and is used for driving the lifting screw rod to rotate; the hole aligning plate is connected with a disc-like rotating plate by virtue of a first thrust bearing; the rotating plate is fixedly connected with at least one pair of sleeves; the top wall of each sleeve is fixedly connected with a spring; each spring is fixedly connected with one hole aligning column which can slide inside the corresponding sleeve; each hole aligning column is rotationally connected with an idler wheel; the diameter of each hole aligning column is smaller than that of the corresponding idler wheel; the diameter of each sleeve is smaller than the hole diameter of each mounting hole in the wind power flange; the flange stacking and storing frame is used for stacking flangeplates; and the second lifting screw rod is used for driving the stacked flange plates to slide up and down. By using the automation device disclosed by the invention, manual operations for aligning the mounting holes before a plurality of flanges are hoisted are reduced, the labor intensity of a worker is alleviated, relatively high efficiency is achieved, and extremely good safety is realized.

Owner:JIANGYIN ZENKUNG FORGING CO LTD

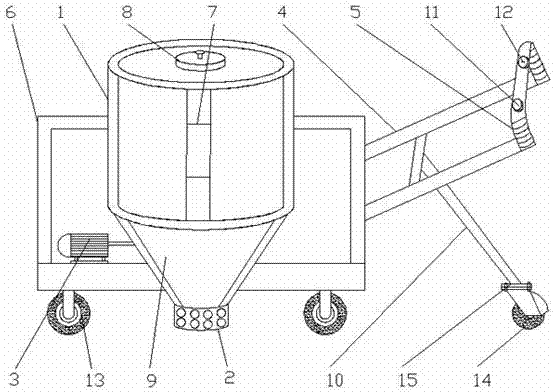

Injection molding machine feeding device convenient to discharge

InactiveCN107756730AEfficient removalGuaranteed purityHollow article cleaningAir pumpMixed materials

The invention discloses an injection molding machine feeding device convenient to discharge, and relates to the field of injection molding equipment. The injection molding machine feeding device comprises a feeding base plate, a hopper, a discharging outlet, a movable seat and a cleaning mechanism. The cleaning mechanism comprises a machine frame, an air cylinder, an annular bracket and spray heads; the machine frame is arranged on the feeding base plate and located over the discharging outlet; the air cylinder is arranged at the top of the machine frame, and an output rod of the air cylinderis connected with the annular bracket; and the multiple spray heads are arranged on the annular bracket in the circumferential direction and connected to an air pump through hoses. According to the injection molding machine feeding device convenient to discharge, by arranging the cleaning mechanism over the discharging outlet, the spray heads blows air so that the inner wall of the hopper can be cleaned, materials adhering to the inner wall of the hopper can be effectively removed, and the purity of mixed materials during material loading next time is ensured; and the annular bracket is drivenby the air cylinder to move up and down, mechanical operation is achieved, the efficiency is high, and the execution speed is high.

Owner:WUHU RONGJI IND

Novel multi-taste sandwich stone-like cake and making method thereof

PendingCN111838264AConducive to the formation of a unique tasteSatisfy taste needsDough treatmentModified nutritive productsBiotechnologyLayer cake

The invention discloses novel multi-taste sandwich stone-like cake and a preparation method thereof. The novel multi-taste sandwich stone-like cake is prepared from, by mass, 40-50 kg of coarse cerealpowder, 15-20 kg of radix puerariae, 65-75 kg of low-gluten wheat flour, 12-15 kg of sesame oil, 10-15 kg of eggs, 0.5-1 kg of lactic acid bacteria powder, 8-10 kg of dry yeast powder, 24-26 kg of butter and 13-18 kg of fruit pulp. The novel multi-taste sandwich stone-like cake disclosed by the invention is formed by dipping and coating double-layer cake crusts with sandwich fruit pulp fillings with various flavors, compared with a traditional stone-like cake with a single taste, the requirements of different consumers for tastes can be better met, meanwhile, the upper surface and the lower surface of the cake crust are baked to form recesses through the heat conduction stones in random arrangement, so that the unique taste of the stone cake is formed, the whole process flow is simple, mechanical operation can be realized, and the obtained stone-like cake has the traditional unique taste, also has multiple taste selections and has a good market prospect.

Owner:HENAN MIDUOQI FOOD

Fertilizer special for peanuts and preparation method thereof

InactiveCN107141141AIncrease soil organic matter contentImproved soilSuperphosphatesBio-organic fraction processingRare-earth elementHumic acid

The invention discloses a fertilizer special for peanuts and a preparation method thereof. The fertilizer special for peanuts is prepared from the following raw materials by weight: 65-67 parts of peanut shell organic fertilizer, 9-15 parts of plant ash, 6-7 parts of biological bacterial fertilizer, 2-3 parts of humic acid chelate fertilizer, 0.02-0.03 part of rare earth micronutrients, 6-7 parts of wormcast, 4.5-5 parts of ammonium dihydrogen phosphate, 1.3-1.6 parts of potassium sulfate, 0.13-0.16 parts of borax, 0.03-0.05 part of ammonium molybdate, 1.4-1.9 parts of calcium superphosphate, 0.05-0.07 part of ferrous sulfate, 0.05-0.07 part of zinc phosphate, 0.05-0.07 part of manganese sulfate, and 2-3 parts of an adhesive. Through reasonable proportioning of organic matters, inorganic matters, microbial bacteria, trace elements, rare earth elements and other nutrients, the fertilizer special for peanuts provided by the invention can increase the organic matter content of soil, loosen and improve soil, enhance soil fertility, strengthen the disease resistance of plants, increase crop yield and improve crop quality, has long effective period, lasting and mild fertility, can satisfy the requirement of mechanical operation, and has the advantages of low input, high output, high benefit and no pollution, etc.

Owner:LIAONING YUBAO AGRI TECH CO LTD

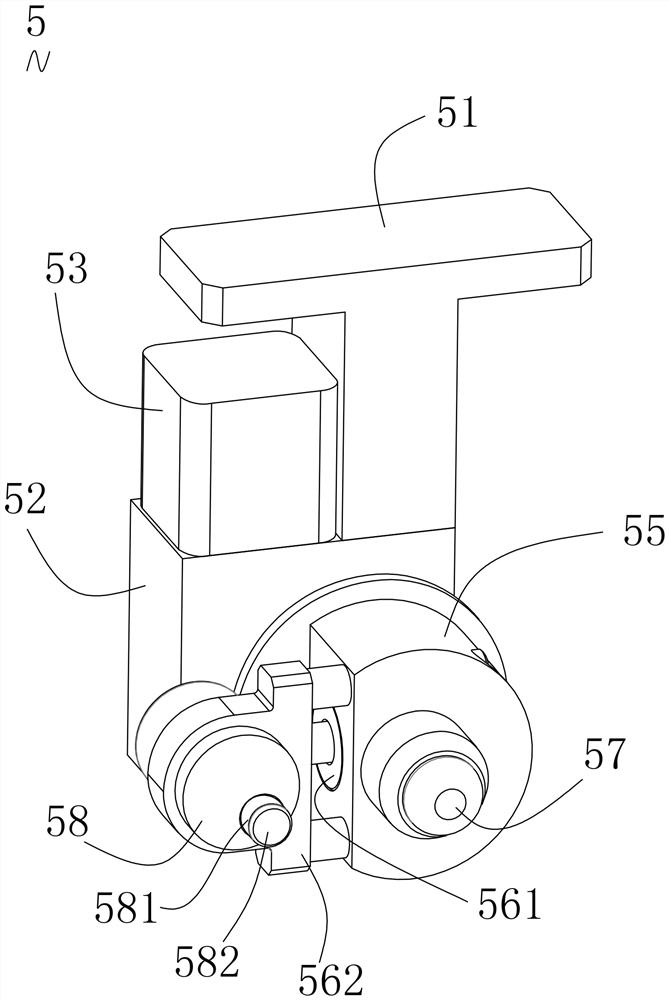

Self-adaptive pump body labeling leveling device

PendingCN109703856ASolve sheddingEnsure a smoothing effectLabelling machinesEngineeringSelf adaptive

The invention discloses a self-adaptive pump body labeling leveling device. The self-adaptive pump body labeling leveling device comprises a sucking disc, rolling cylinders, an installation seat, a telescopic driving device, a first swing arm and a second swing arm, L-shaped bending plates are separately connected to the front ends of the first swing arm and the second swing arm in a pin mode, therolling cylinders are separately arranged at the front ends of the L-shaped bending plates, and torsional springs connected with the first swing arm and the second swing arm are separately arranged on a swing arm installation plate. Pull springs connected with the corresponding L-shaped bending plates are separately arranged on the first swing arm and the second swing arm, the telescopic drivingdevice is arranged on one side of the installation seat, a connecting rod is connected between a connecting rod fixing seat and a third swing arm in a pin mode, and a sucking disc fixing plate locatedin front of the rolling cylinder is vertically arranged at the front end of the third swing arm. Through the mode, the self-adaptive pump body labeling leveling device performs the change and reset of the distance and angle of the two rolling cylinders through the torsional springs and the pulling springs, adapts to the outer size of the pump body and the structure of the circular, conical and the like, and the leveling effect is ensured.

Owner:苏州优得精智装备有限公司

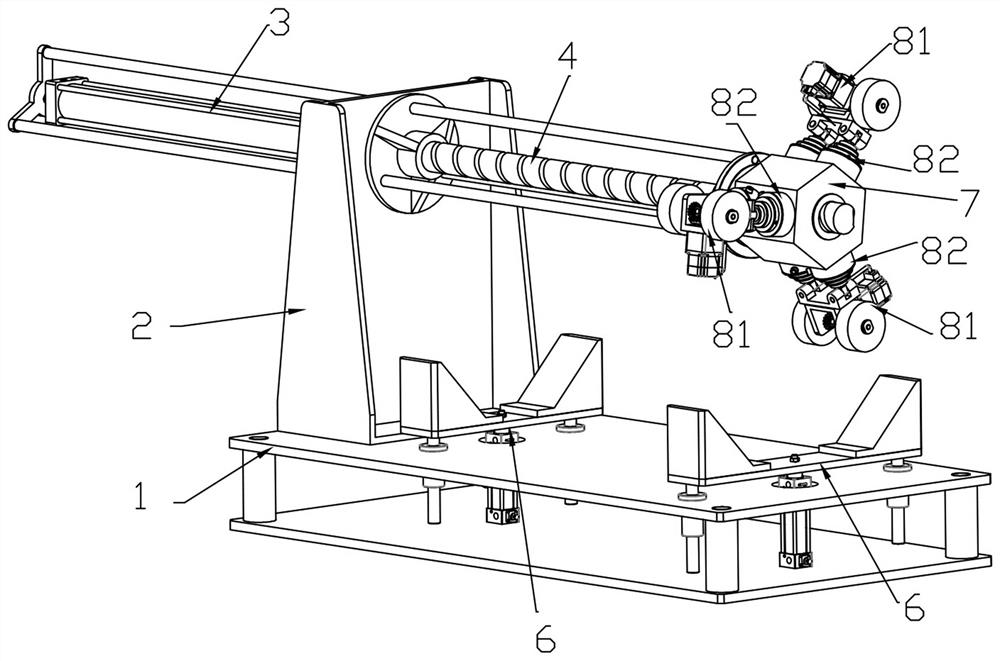

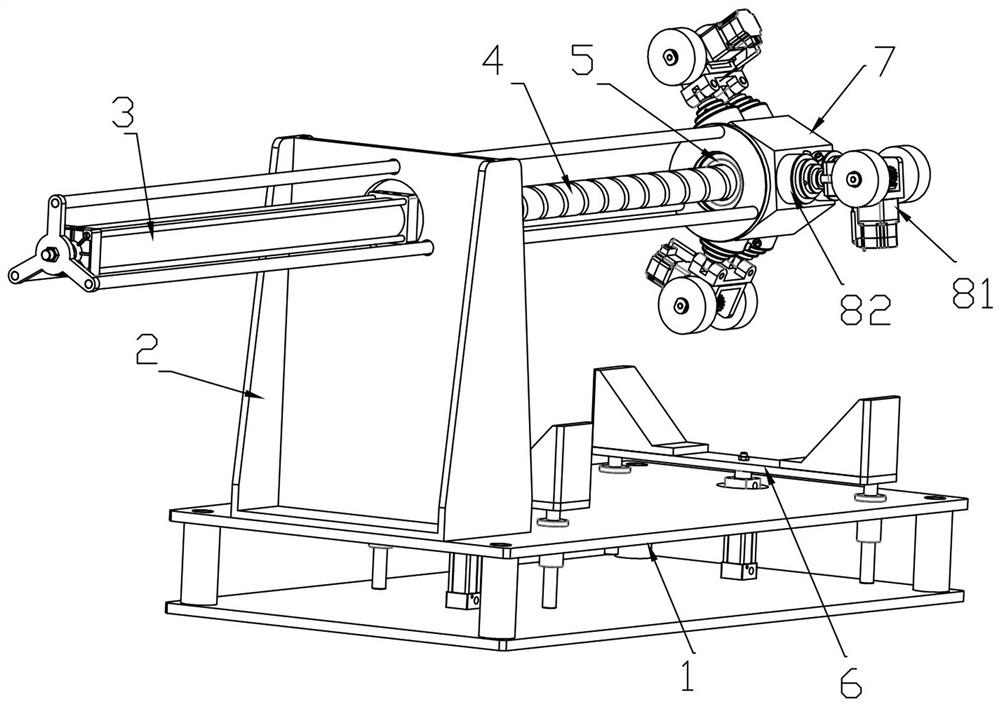

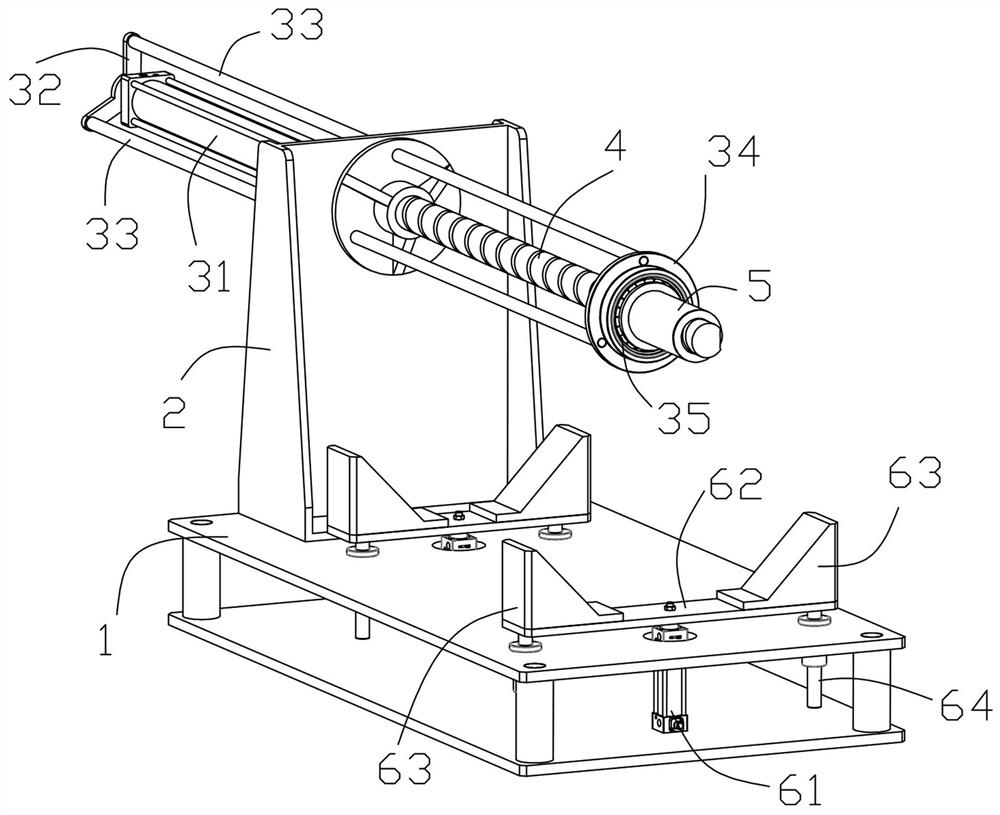

Taper pipe inner wall grinding method

InactiveCN112872936AAchieve grindingOperation mechanizationGrinding carriagesRevolution surface grinding machinesRotational axisScrew thread

The invention discloses a taper pipe inner wall grinding method. The method involves a bottom frame, a supporting seat, an axial driving device, a screw rod and a nut, wherein the supporting seat is fixed at one end of the bottom frame, two supporting assemblies are arranged on the bottom frame side by side and used for supporting the taper pipe, the axial driving device is arranged on one side of the supporting seat, one end of the screw rod is fixed to the other side of the supporting seat, a thread lead angle of the screw rod is larger than a thread self-locking angle, a nut is connected to the screw rod in a threaded mode and sleeved with a rotating shaft, three inner wall grinding devices are arranged on the outer wall of the rotating shaft in the circumferential direction at intervals, the axial driving device is used for driving the nut to move in the axial direction, each of the inner wall grinding device comprises a grinding assembly and two three-stage spring telescopic pieces, the two three-stage spring telescopic pieces are fixed to the rotating shaft side by side, and the grinding assembly is connected with the free ends of the two three-stage spring telescopic pieces. According to the taper pipe inner wall grinding method, mechanical polishing operation can be achieved, grinding efficiency is improved, and labor intensity is relieved.

Owner:JINGHAI LIANKE (NINGBO) INTELLIGENT EQUIP CO LTD

Automatic horizontal rotation device for wind power spindle flange plate

ActiveCN108217053AReduce labor intensityImprove efficiencyConveyorsControl devices for conveyorsElectricityEngineering

The invention discloses an automatic horizontal rotation device for a wind power spindle flange plate. The automatic horizontal rotation device comprises a rack. The work face of the rack is providedwith a flange conveying device. A lifting type limiting part is arranged at one end of the conveying device. The automatic horizontal rotation device comprises flange lifting mechanisms. The flange lifting mechanisms are arranged on the two sides of the flange conveying device, are located below flanges and are provided with rotation driving mechanisms driving the flanges to rotate. The automatichorizontal rotation device further comprises a flange storage frame provided with a flange storage table. A storage table lifting mechanism driving the flange storage table to rise and fall is arranged in the flange storage frame. The flange conveying device comprises a ball or a rolling column arranged on the work face of the rack. The work face of the rack is arranged obliquely. With the appearance of the automatic horizontal rotation device, manual operation of installation hole alignment before lifting of the multiple flanges is reduced, labor intensity of workers is reduced, efficiency ishigh, and safety is excellent. In addition, the flanges do not make contact with the conveying device below the flanges during hole alignment, and service life of the conveying device below the flanges is prolonged.

Owner:JIANGYIN ZENKUNG FORGING CO LTD

Plastic welding machine capable of achieving multi-angle welding

The invention discloses a plastic welding machine capable of achieving multi-angle welding. The plastic welding machine comprises an operation table, a controller is arranged on the surface of the operation table, a stand column is arranged at the center position of the top of the operation table, and a clamping piece is arranged at the top of the stand column; in addition, a sliding groove is further formed in the top of the operation table and located in the outer side of the stand column, annular lacing jackets are arranged at the four corners of the inner wall of the sliding groove, and annular openings are formed in the surfaces of the annular lacing jackets; and an object containing chamber is arranged in an inner cavity of the operation table and located on one side of the sliding groove, two cable clamps are arranged in the object containing chamber, the side face of one cable clamp is connected with an output shaft of a motor fixed to the inner wall of the object containing chamber, a steel cable is connected to the cable clamp connected with the motor, and the other end of the steel cable penetrates the annular lacing jackets to be connected with the other cable clamp. The plastic welding machine is simple in structure, mechanization operation is achieved, 360-degree all-dimensional welding is achieved, the preconceived effect can be achieved for a special portion needing reinforcing, and hidden dangers cannot be buried on use of products.

Owner:WUXI QIANZHOU XINGHUA MACHINERY

Flange alignment device for shaft end of wind power main shaft without damaging the conveying device

ActiveCN108217210BReduce labor intensityReduce manual workStacking articlesConveyor partsMachineWind power

Owner:JIANGYIN ZENKUNG FORGING CO LTD

Film coating mechanism for solar heat collection shuttle

The invention discloses a film coating mechanism for a solar heat collection shuttle. The film coating mechanism comprises a feeding mechanism, a vacuum plastic suction mechanism and a discharge groove, wherein the feeding mechanism comprises a first linear motion device, a moving plate, a heat shrinkage film feeding device, a heat collection shuttle feeding device and a heat sealing device; the moving plate is arranged on the first linear motion device; the heat shrinkage film feeding device is located at one end of the moving plate; the heat collection shuttle feeding device is located at the other end of the moving plate; the heat sealing device is connected with the heat collection shuttle feeding device; one end of the discharge groove is connected with the heat collection shuttle feeding device; the vacuum plastic suction mechanism comprises a second linear motion device, a plastic suction frame, an upper mold, a lower mold and a mold-closing cylinder; the plastic suction frame is arranged on the second linear motion device; the mold-closing cylinder is arranged on the plastic suction frame; the lower mold is arranged on the plastic suction frame; the upper mold is connectedwith the mold-closing cylinder; the upper mold and the lower mold are respectively provided with hemispherical pits and through holes communicating with the pits; and the other end of the discharge groove is inclined downwardly and may be located between the upper mold and the lower mold. The film coating mechanism provided by the invention realizes mechanized operation and has high production efficiency.

Owner:江苏海川光电新材料有限公司

Assembly and positioning device for wind power tower flange before transportation

ActiveCN108217052BReduce labor intensityReduce manual workConveyorsControl devices for conveyorsMachineTower

The invention discloses a wind power tower cylinder flange forming and positioning device before transportation. The device comprises a machine frame, a flange conveying device is arranged on the working surface of the machine frame, and a lifting type limiting baffle is arranged at one end of the conveying direction of the machine frame; the device also comprises flange lifting mechanisms, the flange lifting mechanisms are arranged on the two sides of the flange conveying device, and are positioned below flanges; rotary driving mechanisms for driving the flange to rotate are arranged on the flange lifting mechanisms; and the device further comprises a flange storage rack provided with a flange storage table, and a lifting mechanism for driving the flange storage table to ascend and descend is arranged in the flange storage frame. According to the wind power tower cylinder flange forming and positioning device before the transportation, the manual operation of aligning mounting holes of the plurality of flanges before hoisting is reduced, the labor intensity of workers is reduced, the efficiency is high, and the safety is excellent; and in the process of aligning hole, the flangesare not in contact with a lower conveying device, so that the service life of the lower conveying device is prolonged.

Owner:JIANGYIN ZENKUNG FORGING CO LTD

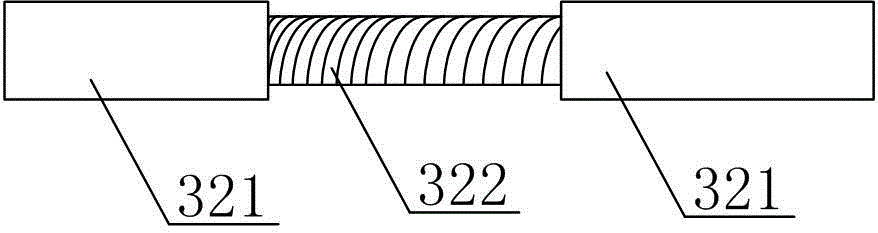

A bolt surface oiling system

ActiveCN110773369BSmear satisfiedReduce labor intensityLiquid surface applicatorsCoatingsBristleCoating system

The invention discloses a bolt surface oil coating system. Bolts are inserted into an upper mounting plate, the bottom surfaces of the bolts are supported on a tray, a motor drives a rotating shaft torotate through a speed reducer, the rotating shaft drives two rotating cylinders to rotate together, and grease coating on the threaded connecting surfaces of the bolts is achieved through bristles.In the coating process, the bolts can rotate on the tray along with the bristles, so that uniform coating of the bolts is convenient to achieve. After bolt coating is completed, a cylinder shaft of acylinder extends out, a push plate and a push rod are pushed to move upwards, the push rod pushes the bolt upwards, and then the bolts can be conveniently taken out of the system. According to the bolt surface oil coating system, a plurality of bolts can be coated at a time, the coating of the threaded surfaces at the two ends of the bolts can be met at a time, and the efficiency is high; and themechanical operation is achieved, the labor intensity of workers is relieved, and the using effect is good.

Owner:JIANGSU YONGHAO HIGH STRENGTH BOLT

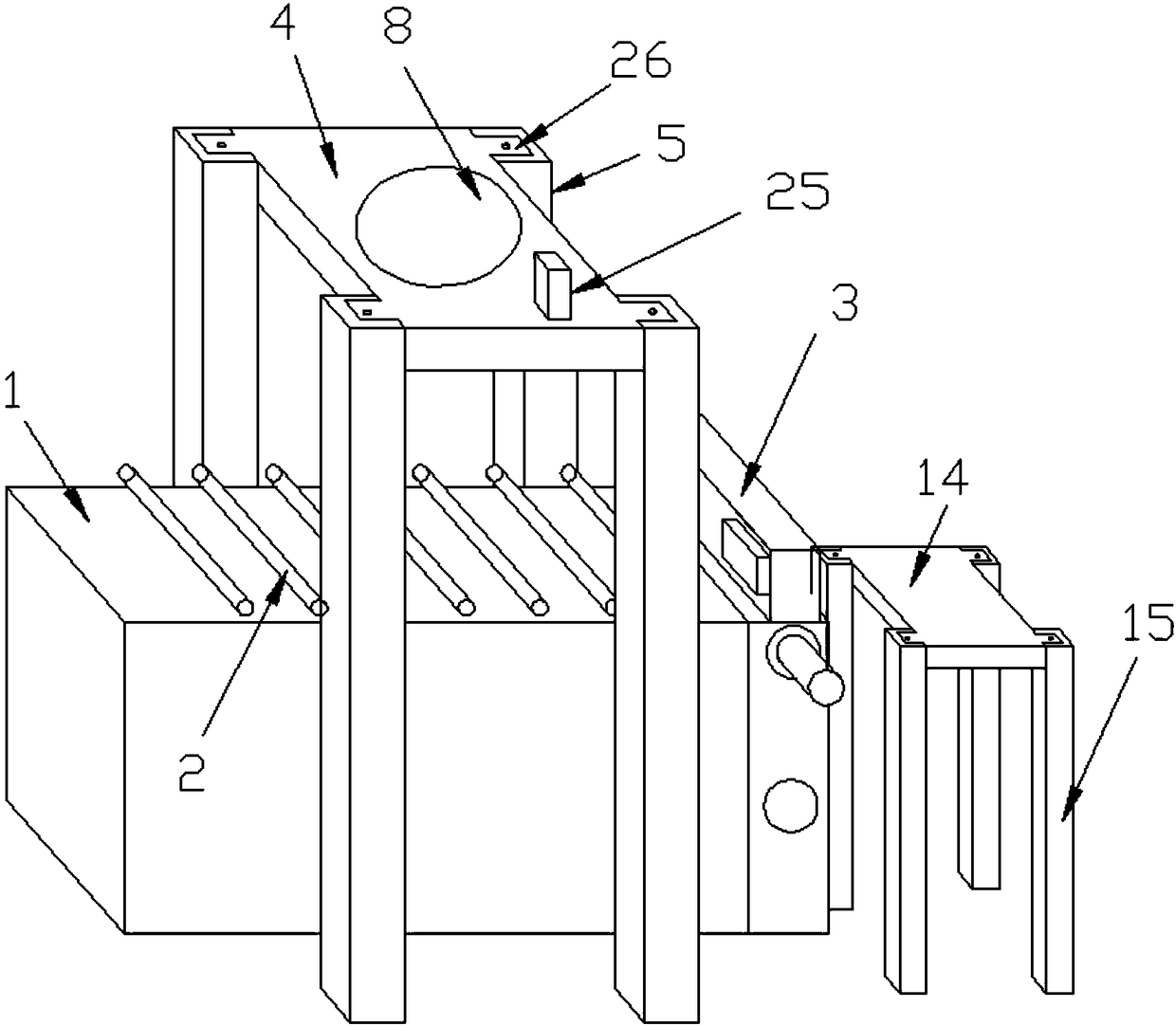

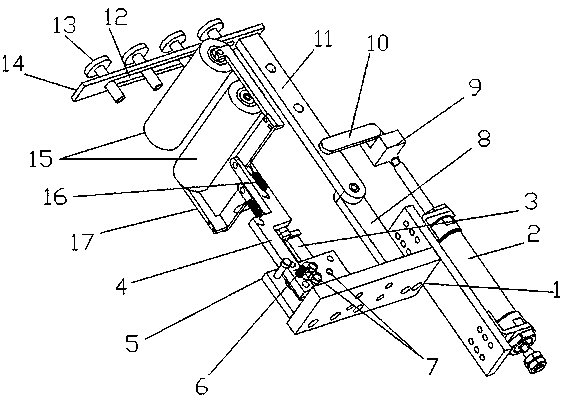

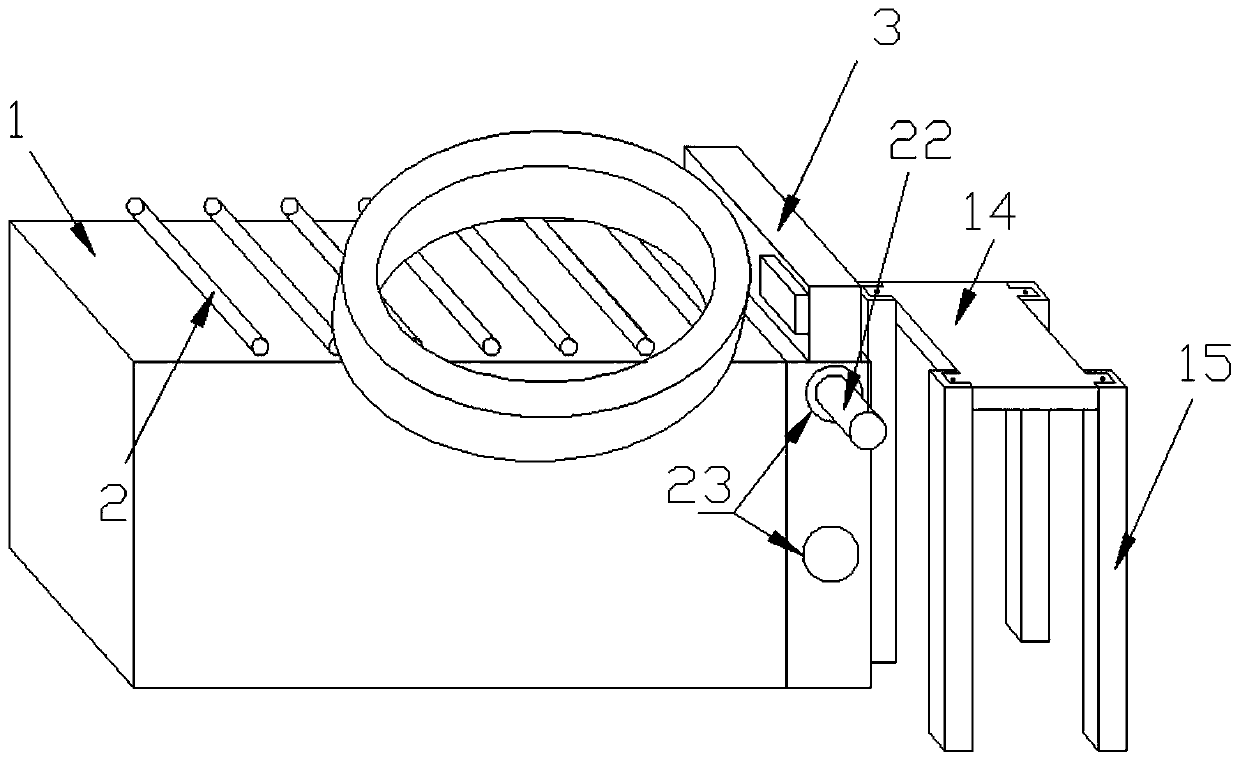

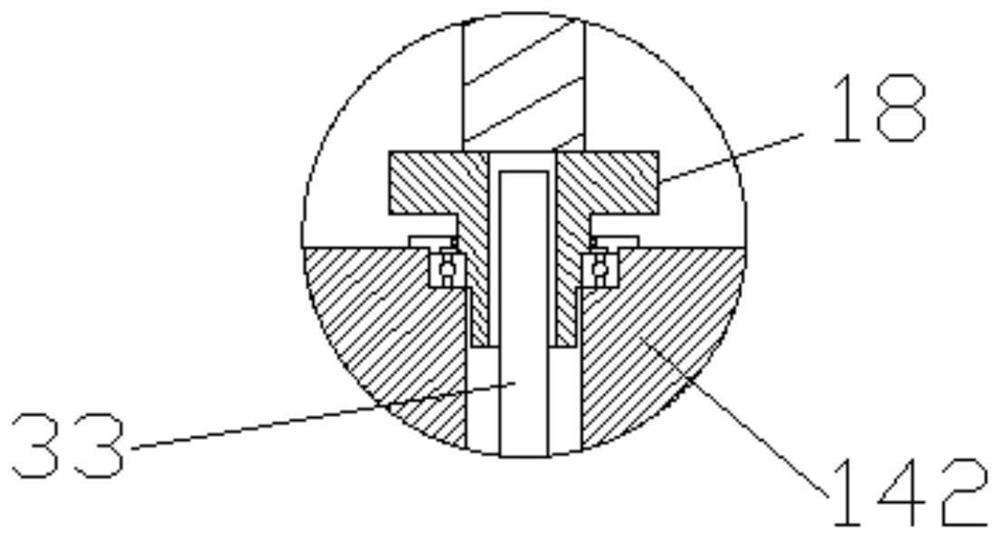

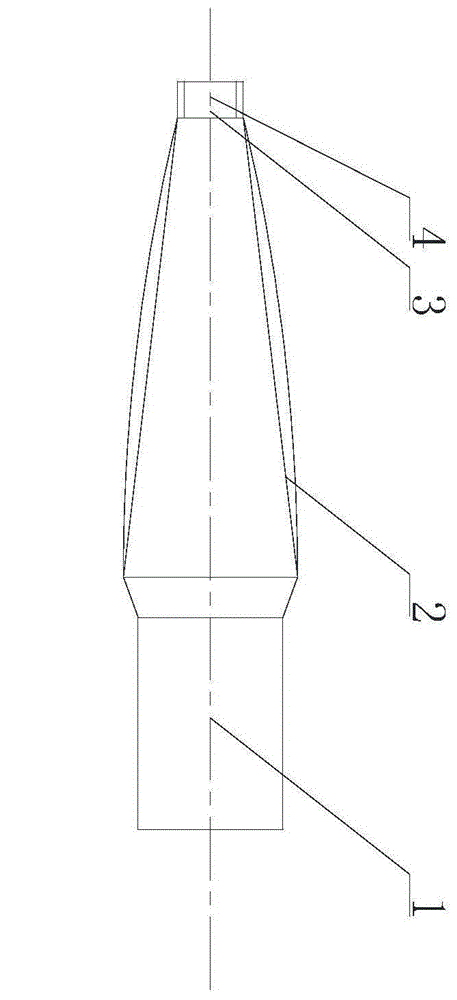

Tongs of brake cylinder cover grabbing device of wagon brake cylinder disassembling and assembling trolley

InactiveCN104442737AOperation mechanizationGripping headsVehicle servicing/repairingBrakeControl theory

The invention relates to tongs of a brake cylinder cover grabbing device of a wagon brake cylinder disassembling and assembling trolley. The tongs are composed of a supporting column 1, a supporting rod 2, an electromagnet groove 3 and an electromagnet 4. The tongs have the advantages that the brake cylinder cover can be easily grabbed through the electromagnet, and mechanical operation can be achieved without the need that workers enter a wagon chassis.

Owner:NINGXIA ZHONGYUAN TIANYU TECH

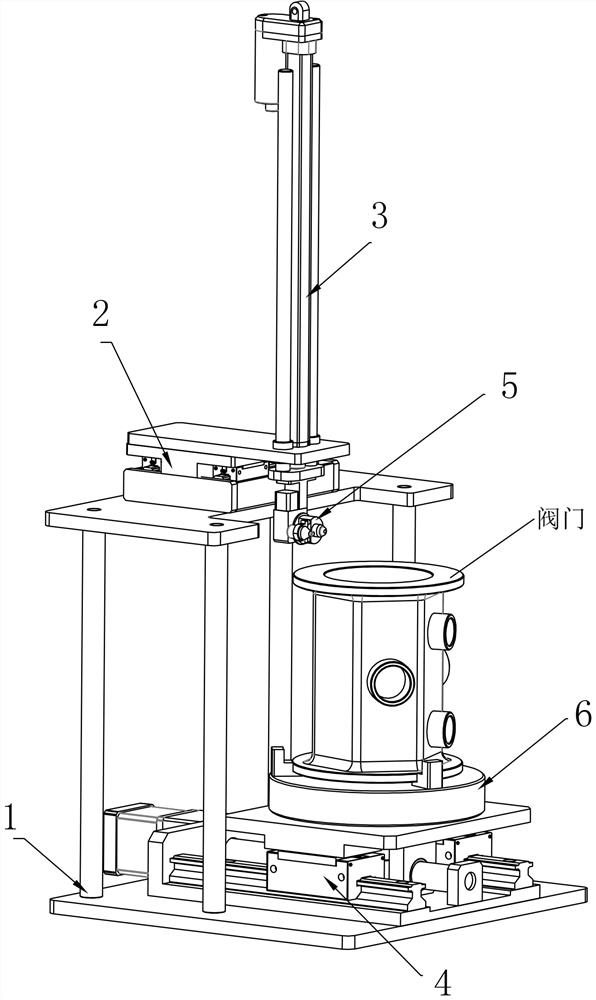

Non-contact laser chip removal robot

InactiveCN112296527ANot easy to damageReduce labor intensityLaser beam welding apparatusControl engineeringMachine

The invention discloses a non-contact laser chip removal robot. The robot comprises a machine table, a non-contact laser chip removal structure arranged at one end of the machine table, a conveying table arranged at the other end of the machine table, and a material moving mechanical arm arranged on the machine table and located between the non-contact laser chip removal structure and the conveying table; the non-contact laser chip removal structure comprises a rack, a first sliding table arranged at the top of the rack, a lifting mechanism arranged at the output end of the first sliding table, a second sliding table arranged at the bottom of the rack, a variable-diameter laser chip removal component arranged at the output end of the lifting mechanism and a rotary clamping mechanism arranged at the output end of the second sliding table; the rack is fixed to the machine table; and the movement direction of the first sliding table is perpendicular to the movement direction of the secondsliding table. According to the robot, mechanical operation is achieved, the removing efficiency is high, the labor intensity of operators is reduced, the production cost is reduced, contact with a valve is not required, and the valve is not prone to damage.

Owner:JINGMEN YIMEI IND DESIGN CO LTD

Automatic device before hoisting of wind turbine main shaft flange

ActiveCN108217054BReduce labor intensityReduce manual workConveyorsControl devices for conveyorsElectricityThrust bearing

The invention discloses an automation device for wind power spindle flanges before hoisting. The automation device comprises a frame, a conveying device, a limiting baffle, a hole aligning plate, a lifting screw rod, a first motor, a flange stacking and storing frame, a second lifting screw rod and a second motor, wherein the limiting baffle is not higher than the flange; the hole aligning plate is slidably arranged on the hole aligning frame; the lifting screw rod is arranged inside the hole aligning frame and is used for driving the hole aligning plate to slide downwards; the first motor isarranged inside the hole aligning frame and is used for driving the lifting screw rod to rotate; the hole aligning plate is connected with a disc-like rotating plate by virtue of a first thrust bearing; the rotating plate is fixedly connected with at least one pair of sleeves; the top wall of each sleeve is fixedly connected with a spring; each spring is fixedly connected with one hole aligning column which can slide inside the corresponding sleeve; each hole aligning column is rotationally connected with an idler wheel; the diameter of each hole aligning column is smaller than that of the corresponding idler wheel; the diameter of each sleeve is smaller than the hole diameter of each mounting hole in the wind power flange; the flange stacking and storing frame is used for stacking flangeplates; and the second lifting screw rod is used for driving the stacked flange plates to slide up and down. By using the automation device disclosed by the invention, manual operations for aligning the mounting holes before a plurality of flanges are hoisted are reduced, the labor intensity of a worker is alleviated, relatively high efficiency is achieved, and extremely good safety is realized.

Owner:JIANGYIN ZENKUNG FORGING CO LTD

Deburring device for frustum-shaped rubber workpiece

ActiveCN105328534BSolve instabilityImprove efficiencyEdge grinding machinesLeft directionRound table

The invention discloses a deburring device for a circular truncated cone shaped rubber workpiece. The deburring device comprises a machine frame, a grinding head, a swing arm, a sliding wedge block, a guide rail and a pushing rod driven by an air cylinder, wherein the grinding head, the swing arm, the sliding wedge block, the guide rail and the pushing rod are sequentially arranged on the machine frame from top to bottom; a through hole for swinging of the swing arm is formed in the left side of the machine frame, and the inner wall of the upper portion of the through hole is in sliding connection with a limiting pin; the middle of the swing arm is pivoted to the middle of the machine frame and further provided with an ejecting block abutting against the lower end of the limiting pin in a protruding mode; the gravity center of the swing arm is located on the lower left direction of the pivoting point, the lower end of the swing arm protrudes leftwards to form an abutting block abutting against the left side of the sliding wedge block, the pushing rod is arranged in the middle of the machine frame in a sliding mode; the sliding wedge block and the upper end of the pushing rod are positioned through pins and connected and fixed through screws, the left side of the sliding wedge block is wedge-shaped, the right side of the sliding wedge block is in sliding fit with a guide rail, and the guide rail and the right side of the machine frame are positioned and fixed through pins. According to the scheme, the deburring device for the circular truncated cone shaped rubber workpiece is simple in structure, easy to operate and high in safety, and the problem that when burs of the rubber workpiece are processed in the prior art, the rubber workpiece is not stable under the action of external force is solved.

Owner:安徽源茂橡塑科技有限公司

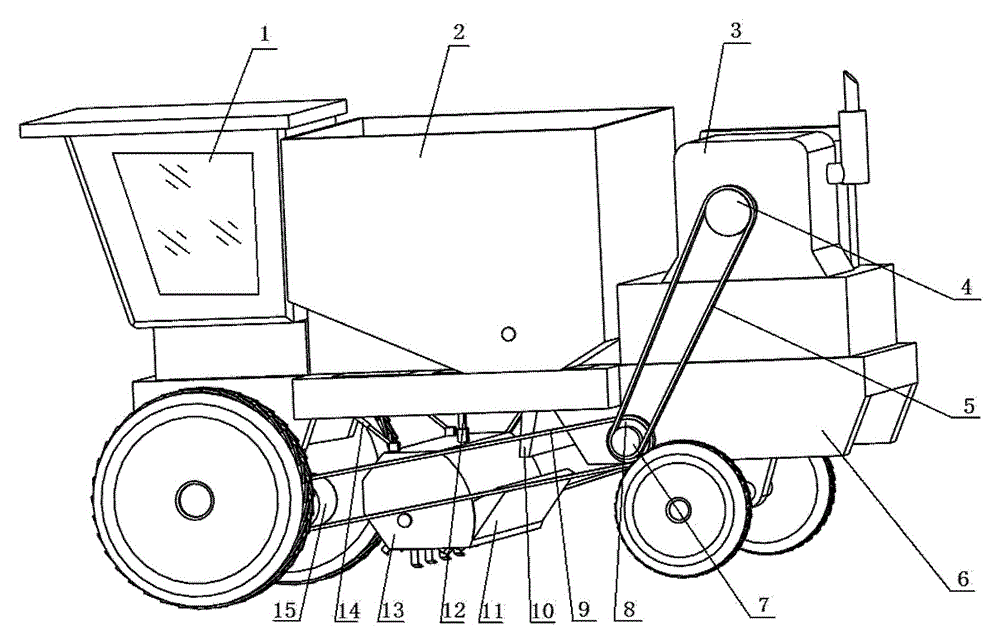

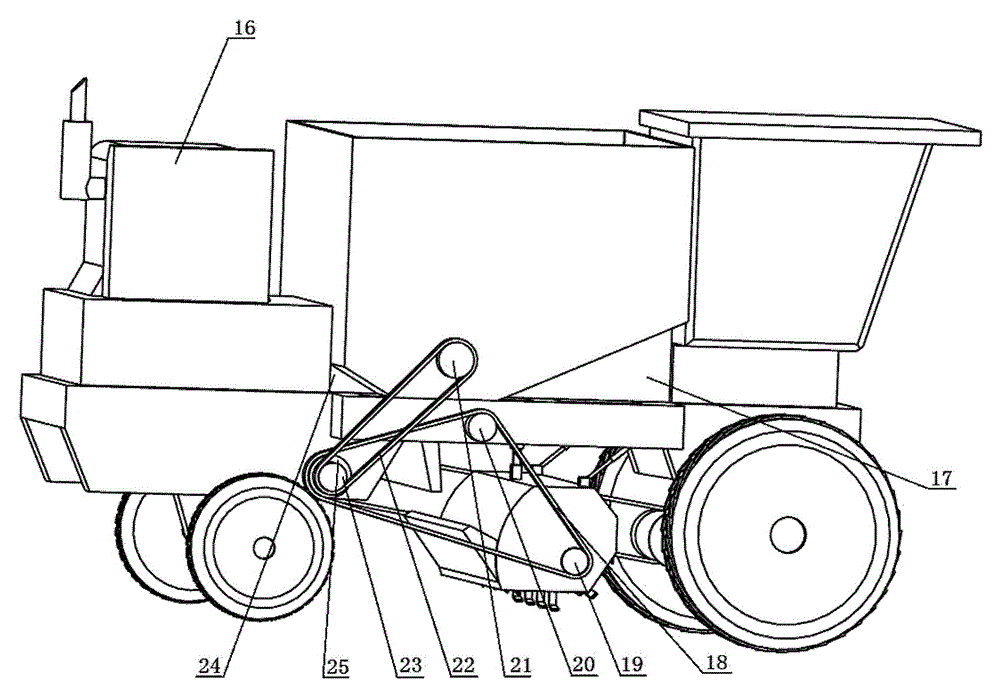

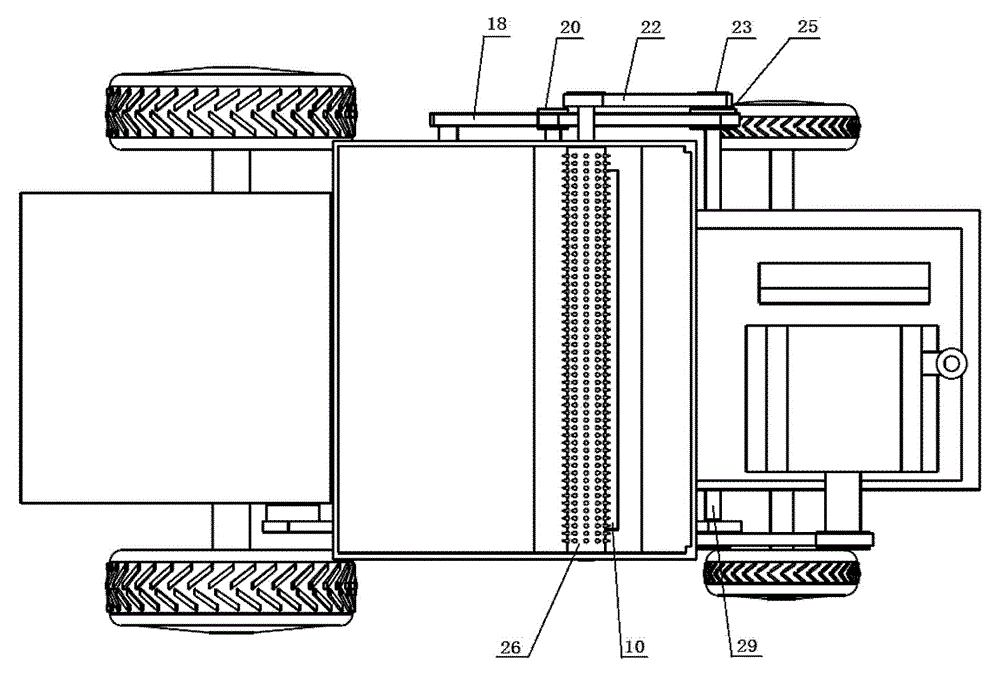

Self-propelled two-layer covering machine for straws of orchard

ActiveCN105052404AOperation mechanizationPromote the applicationCrop conditionersMowersMicro environmentWeed

The present invention provides a self-propelled two-layer covering machine for straws of an orchard, and relates to the field of orchard machinery. A straw tank is mounted on a frame of of the covering machine; the tank bottom of the straw tank is a V-shaped structure; a discharge roller is arranged above an opening in the bottom of the V-shaped structure; and a slot body of a straw discharge slot below the discharge roller is inclined forwards and downwards. An soil throwing machine is suspended on a position, below the outlet of the straw discharge slot, at the bottom in front of the covering machine; and after an soil throwing opening of the soil throwing machine is inclined upwards, the direction of the soil throwing opening is crossed with the direction of the outlet of the straw discharge slot. The soil throwing machine can move up and down under the action of a hydraulic lifting oil cylinder. The covering machine can cover the straws on the ground between roes of the orchard, and covers the straws with a thin layer of soil, is suitable for mechanical operation of covering the orchard or other farmland with straws so as to achieve effects of keeping soil moisture, saving water, preventing weeds from growing in oil, increasing soil organic matters, keeping warm against freezing of soil, and improving soil texture and micro environment of soil, and is especially applicable in dwarf apple orchards The self-propelled two-layer covering machine for straws of the orchard provided by the present invention can reduce cost of covering straws, can promote large-scale utilization of straws, and can achieve agricultural income increase and efficiency growth.

Owner:NORTHWEST A & F UNIV

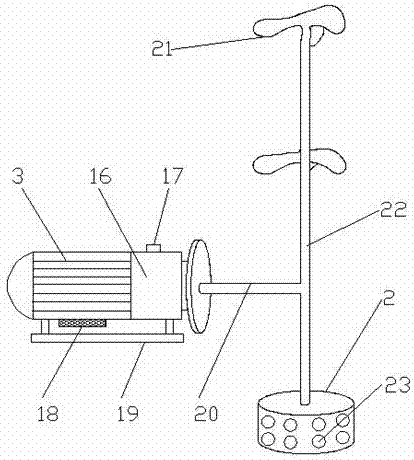

Rotary-nozzle agricultural irrigating barrel

InactiveCN107318604AIrrigate evenlyStir wellRotary stirring mixersTransportation and packagingImpellerAgricultural engineering

The invention discloses a rotary-nozzle agricultural irrigating barrel, comprising an irrigating barrel, a nozzle, a motor and a transverse bar; a barrel cover is arranged at the top of the irrigating barrel, the side of the irrigating barrel is provided with an observation window, the bottom of the observation window is provided with a water outlet, the nozzle is arranged at the bottom of the water outlet, support bars are arranged on two sides of the irrigating barrel, the motor is arranged on the left of the water outlet, travelling wheels are arranged at the bottoms of the support bars, the transverse bar is arranged on the right of the support bars, a vertical bar is arranged at the bottom of the transverse bar, a universal wheel is arranged at the bottom of the vertical bar, the handlebar is arranged on the right of the transverse bar, a speed control button is arranged on the left of the handlebar, and a switch key is arranged on the right of the handlebar. The rotary-nozzle agricultural irrigating barrel with the rotary nozzle allows a farmland to be effectively and evenly irrigated, a blade wheel arranged inside allows full stirring, and the rotary-nozzle agricultural irrigating barrel is convenient to use and popularize, reasonable in design and easy to implement.

Owner:陈聪

Unartificial material mechanical agitator for manufacturing industry

An unartificial material mechanical agitator for the manufacturing industry is characterized in that the unartificial material mechanical agitator comprises a driving cylinder, a drive wheel, a conveyor belt, a driven wheel, a rotating shaft, a mixer and agitating blades, wherein the rotating shaft is arranged inside the mixer; the agitating blades are disposed on the rotating shaft; and the rotating shaft is connected with a driving mechanism through a transmission mechanism. The unartificial material mechanical agitator for the manufacturing industry has advantages of low time consumption, uniform mixing, full stirring and high production efficiency; labor intensity of workers is reduced; and the unartificial material mechanical agitator satisfies modernized production and mechanization of manufacturing.

Owner:李君浩

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com