Optical fiber cutting device

A cutting device and optical fiber technology, which is applied in the coupling of optical waveguides and other directions, can solve the problems of inability to cut large-diameter optical fibers, poor quality of the end face, and uneven end face, so as to improve the cutting efficiency of the optical fiber, avoid the limitation of the size of the optical fiber, and the operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

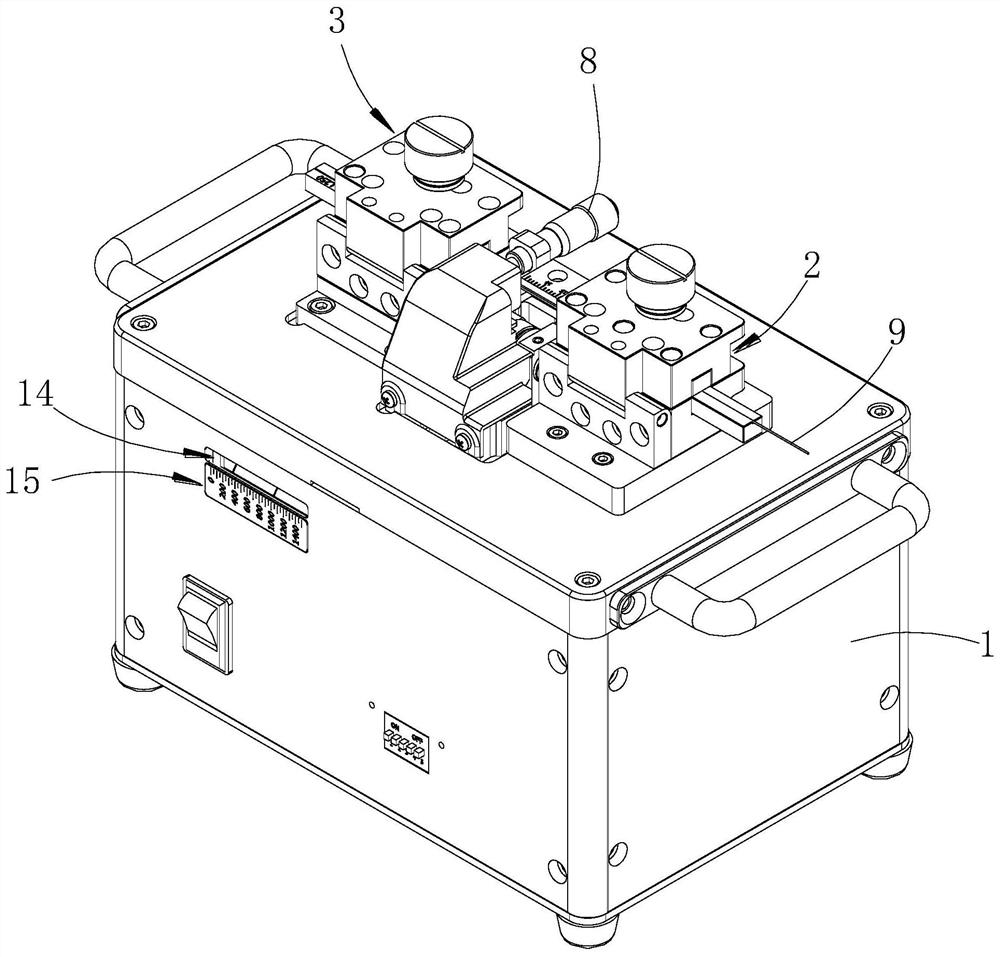

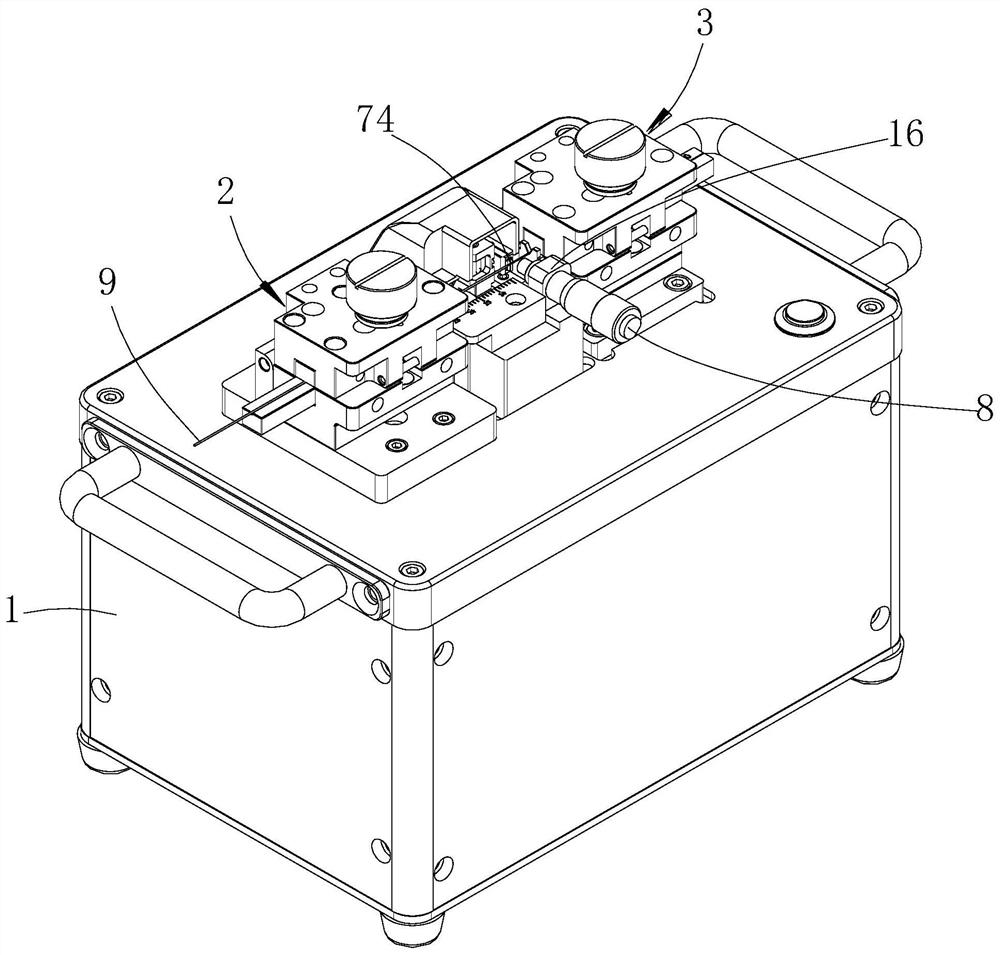

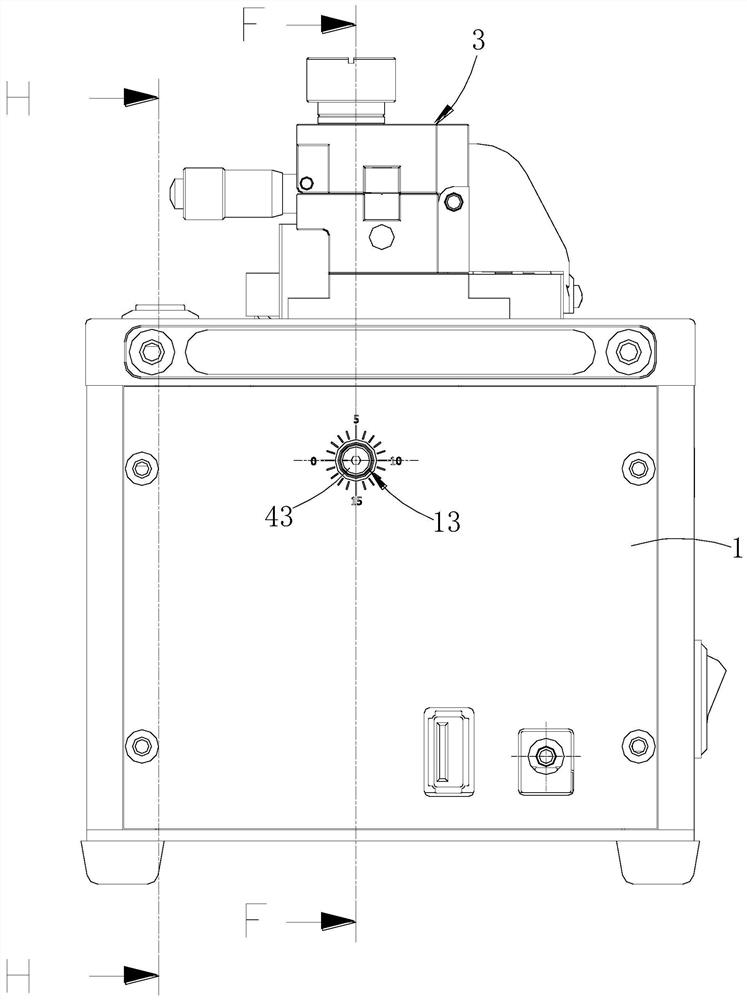

[0027] Such as Figures 1 to 8 shown

[0028] The optical fiber cutting device includes a box body 1, a pre-tensioning assembly, an ultrasonic cutting assembly, a cutting knife 74, a reset assembly, two sets of sliding assemblies and two sets of clamping mechanisms.

[0029] The box body 1 is generally in the shape of a cuboid, and the inside of the box body 1 is provided with a cavity 11. Two sets of clamping mechanisms are located on the upper side of the box body 1, and the two sets of clamping mechanisms are located on the left and right sides of the upper end surface of the box body 1. Tightening mechanism is the first clamping mechanism 2 and the second clamping mechanism 3, and the structure of the first clamping mechanism 2 and the second clamping mechanism 3 is identical;

[0030] Take the first clamping mechanism 2 as an example to introduce its structure in detail. The first clamping mechanism 2 is fixed on the right side of the upper end surface of the box body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com