A bolt surface oiling system

A bolt and thread connection technology, which is applied in the field of bolt surface oiling system, can solve problems such as inapplicability, and achieve the effects of reducing labor intensity, high efficiency, and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

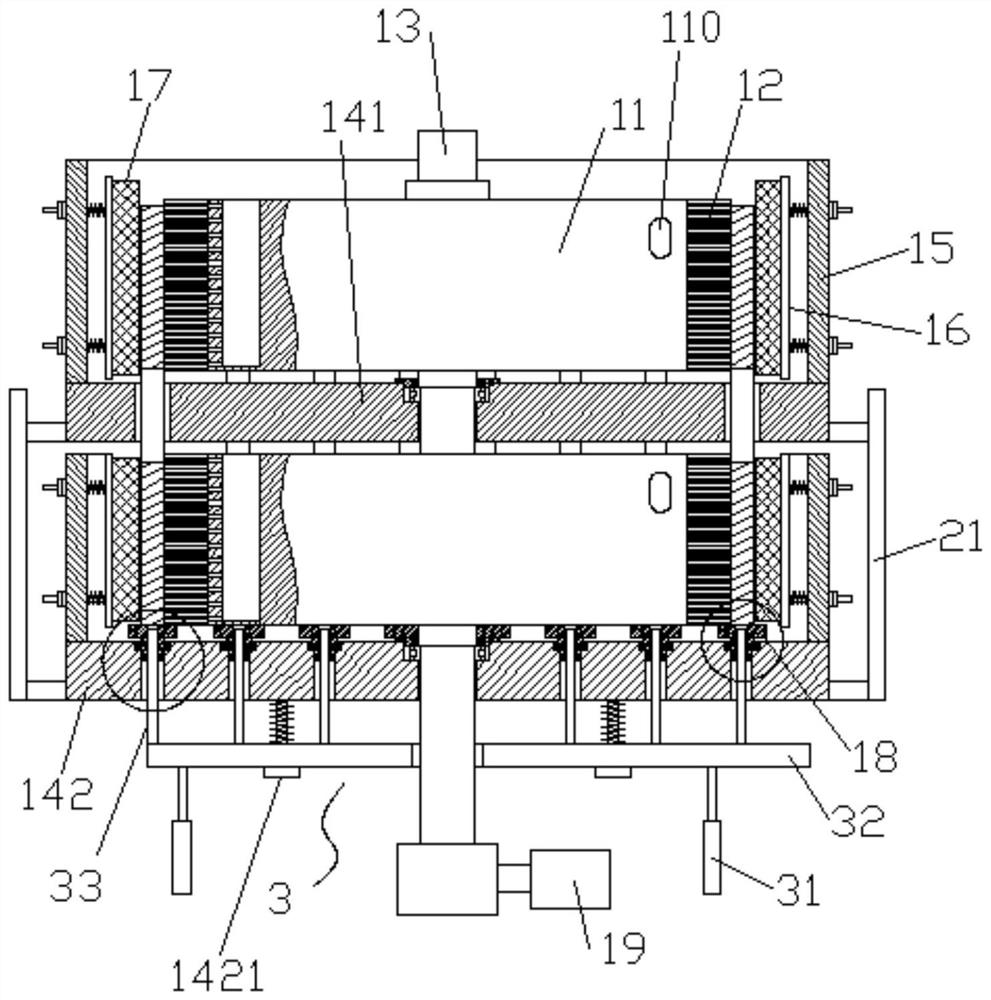

[0022] Such as Figure 1 to Figure 5 , the present invention is a bolt surface oiling system, the bolt involved in the present invention is a cylindrical structure, the two ends of the bolt are provided with a threaded connection surface, and the oiling system is used for one time on the two ends of a plurality of bolts on the threaded connection surface Apply grease.

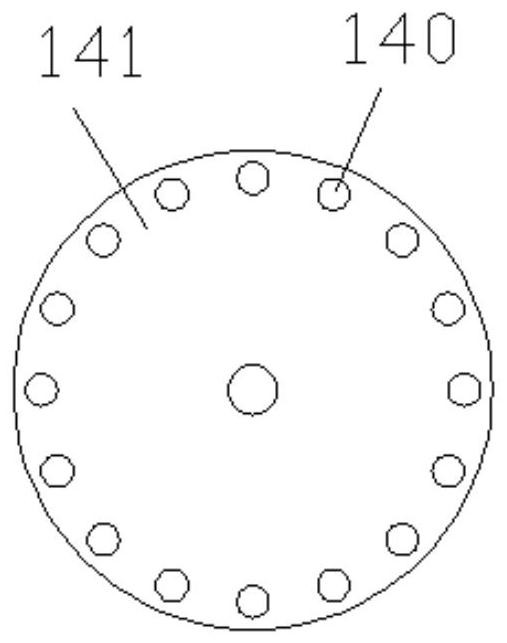

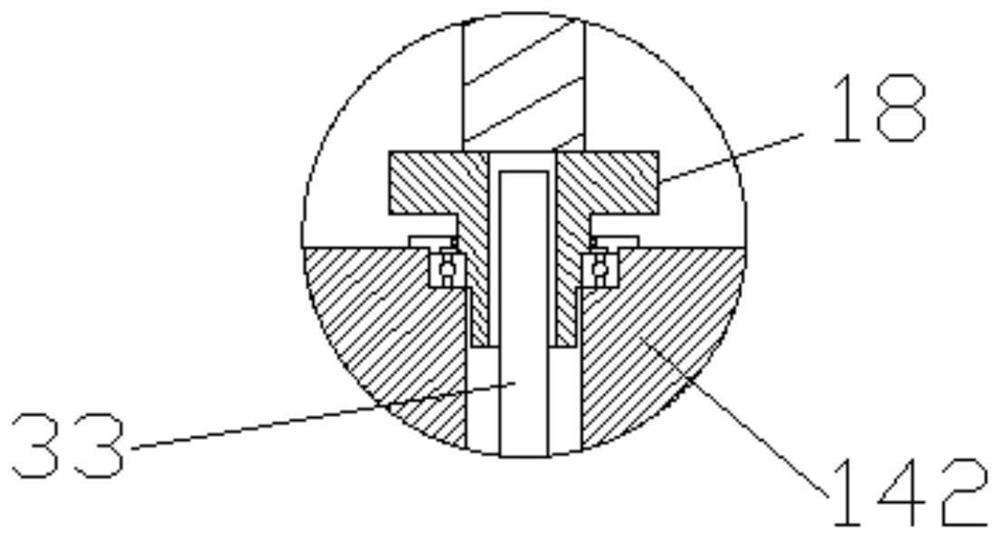

[0023] The oiling system of the present invention includes a drum 11, bristles 12, a rotating shaft 13, an upper mounting plate 141, a lower mounting plate 142, a tray 18, a motor 19, a fixed frame 21, a reducer and a discharge mechanism 3. The upper-level mounting plate 141 and the lower-level mounting plate 142 are spaced apart from each other and arranged parallel to each other, and the upper-level mounting plate 141 and the lower-level mounting plate 142 are fixedly connected by a fixed frame 21, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com