Non-contact laser chip removal robot

A non-contact, laser cutting technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of scratches on the hole wall and valve cavity, low removal efficiency, and high labor intensity for operators. The effect of reducing labor intensity, not easy to damage, and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

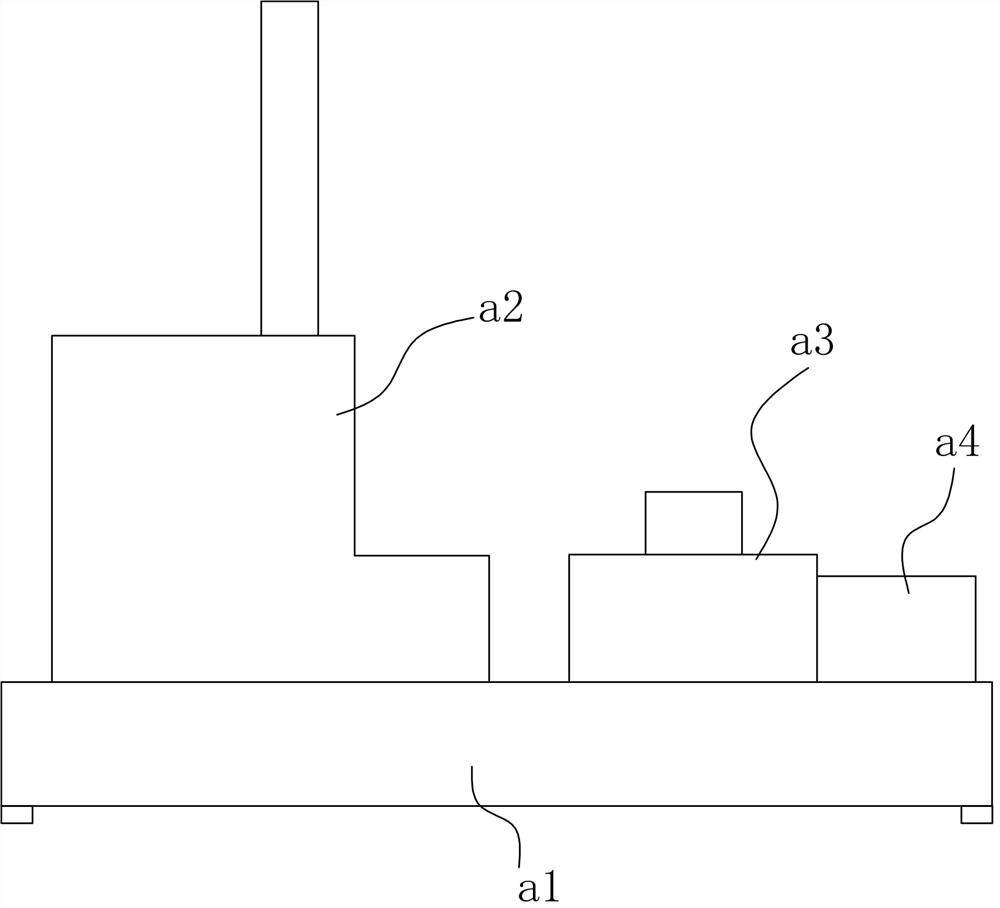

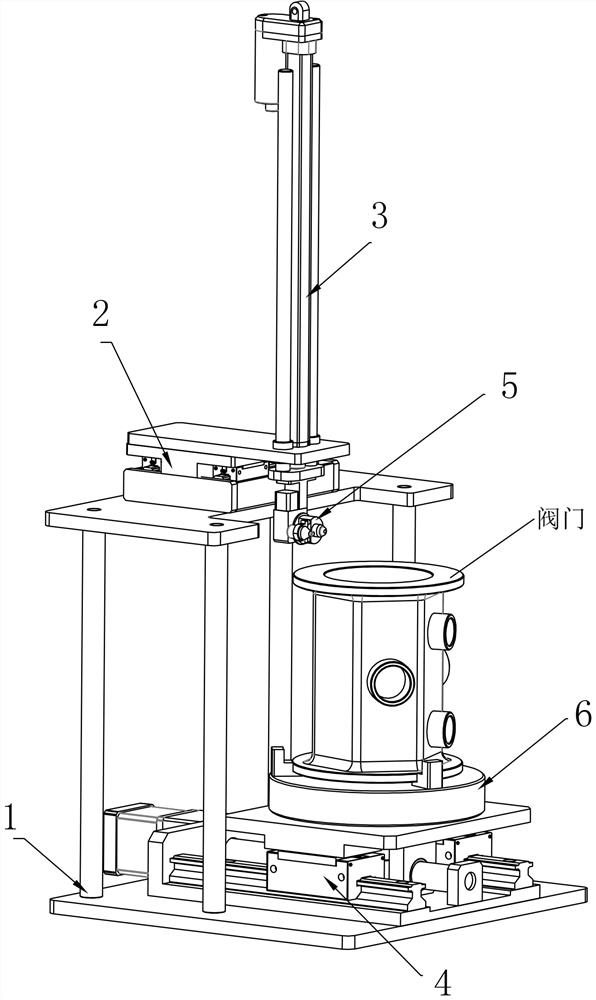

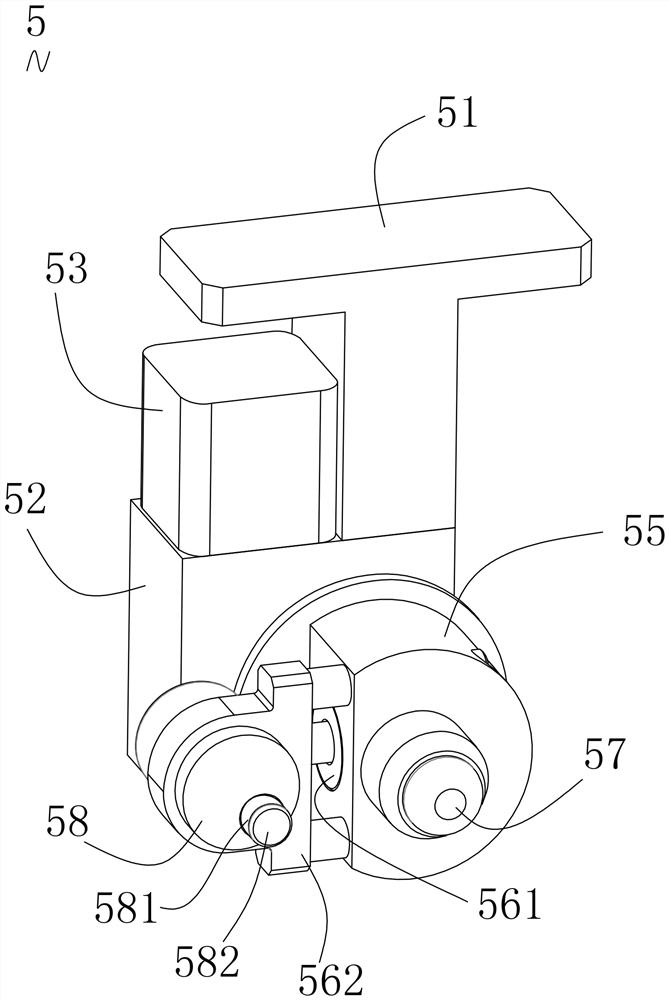

[0025] like Figure 1 to Figure 6 As shown, a non-contact laser chip removal robot described in this embodiment includes an organic table a1, a non-contact laser chip removal structure a2 provided on one end of the machine table a1, and a non-contact laser chip removal structure a2 provided on the other end of the machine table a1 The transfer table a4, and the material transfer robot a3 arranged on the machine table a1 and between the non-contact laser chip removal structure a2 and the transfer table a4.

[0026] In actual use, the transfer table a4 first moves the valves to be removed to the waiting area, and then the material transfer robot a3 transfers the valves in the waiting area on the transfer table a4 and places them on the non-contact laser chip r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com