Automatic device before hoisting of wind turbine main shaft flange

A technology of automation device and wind power spindle, applied in the direction of conveyor control device, transportation and packaging, roller table, etc., can solve the problems of high cost of large-scale driving, increase of production cost, high risk, etc., achieve low noise, less error-prone, Excellent safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

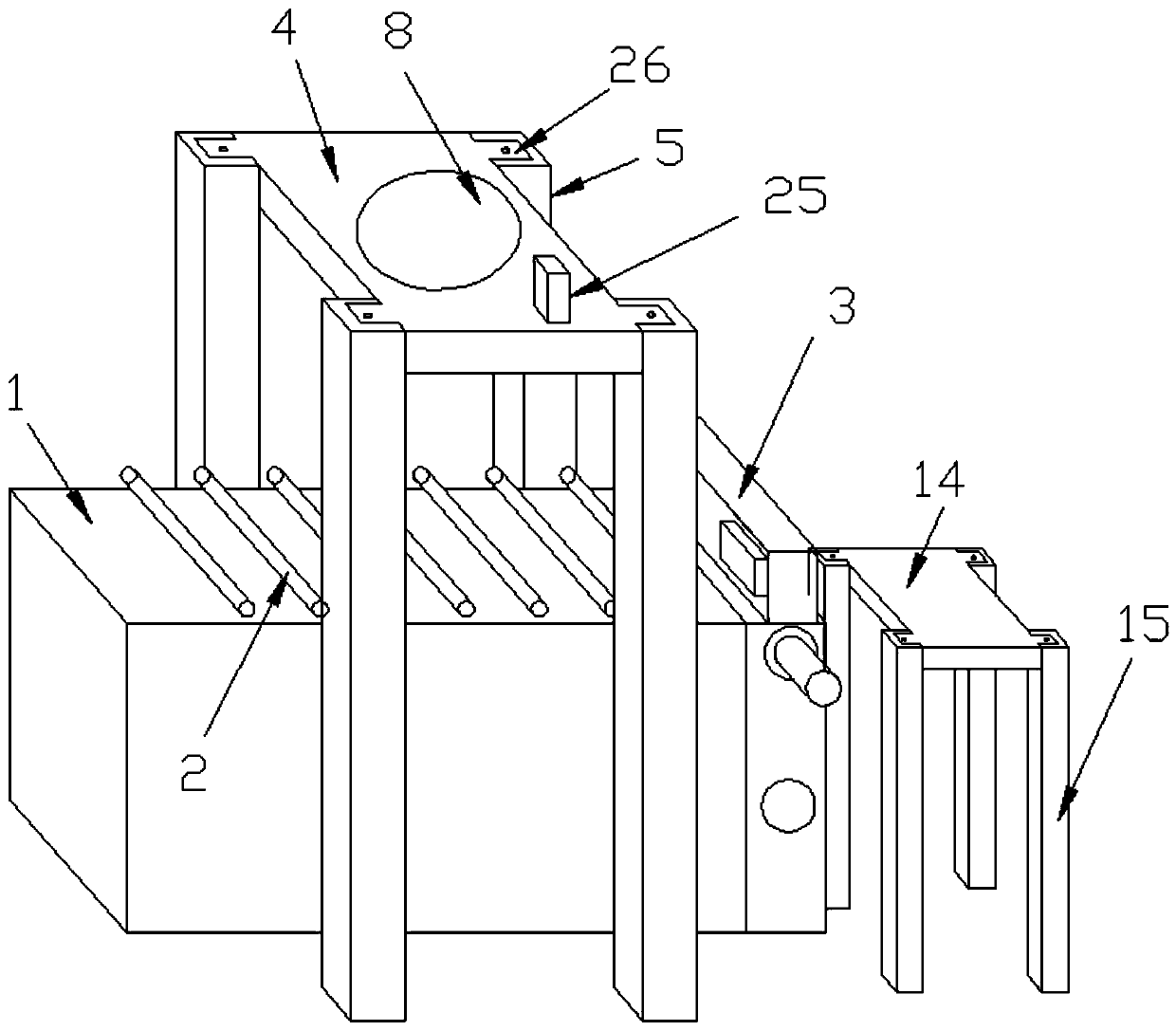

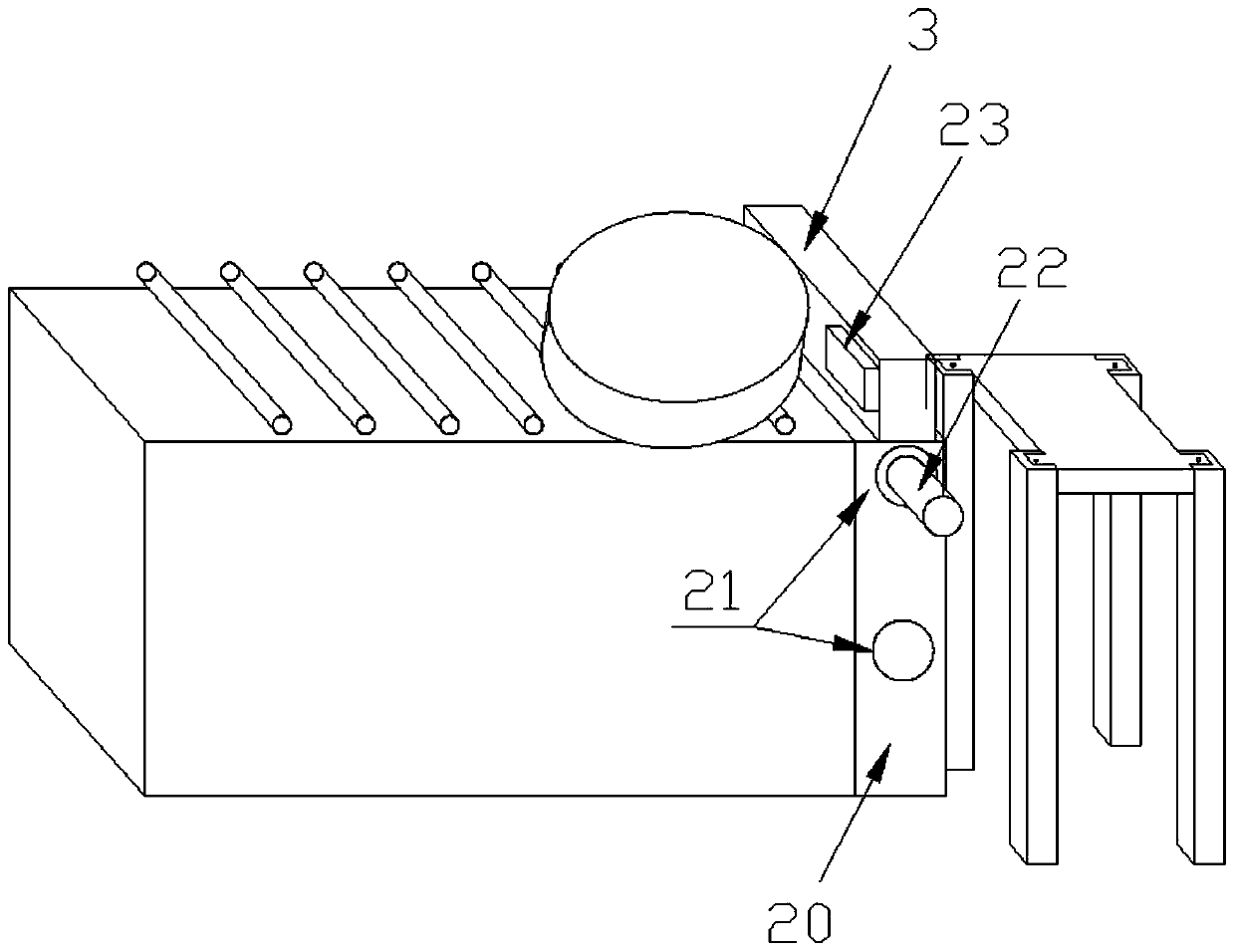

[0028] like Figure 1 to Figure 8 as shown ( figure 1 Flange and sleeve not shown, Figure 5 , Figure 7 , Figure 8Only one sleeve is shown, and the sleeve on the right side is not shown in the figure), the present invention is an automatic device for wind power main shaft flange hoisting, including a frame 1, and a flange is provided on the working surface of the frame 1 The conveying device 2, one end of the conveying direction of the frame 1 is provided with a limit baffle 3 that can slide up and down, and the height of the limit baffle 3 does not exceed the height of the flange; it also includes an orifice plate 4 arranged above the frame 1 The hole plate 4 is slidably arranged on the hole frame 5, and the hole frame 5 is provided with a first lifting screw 6 for driving the hole plate 4 to slide up and down and a first motor 7 for driving the first lifting screw 6 to rotate. , the orifice plate 4 is fixedly provided with a slider 26 adapted to the first lifting screw...

Embodiment 2

[0030] The difference from Embodiment 1 is that, as Figure 9 As shown, the lifting lead screw and the drive motor are also arranged under the limit baffle, so that all operations are fully mechanized, without manual labor, and realize full automation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com