Complete film coating machine for solar heat collection shuttle

A solar heat collection and coating technology, which is applied in the field of energy mining equipment manufacturing, can solve the problem of no heat collecting shuttle coating production equipment and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

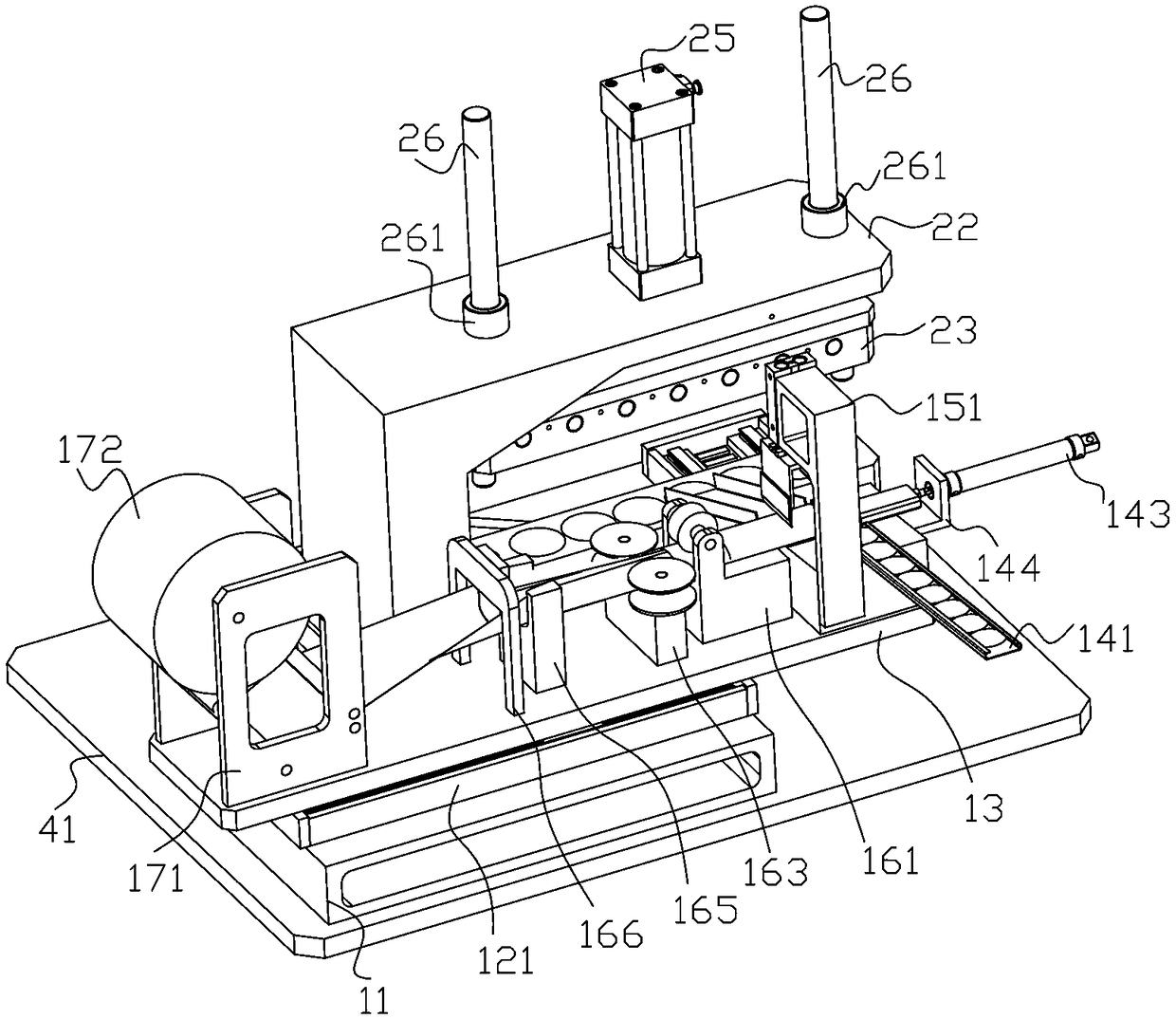

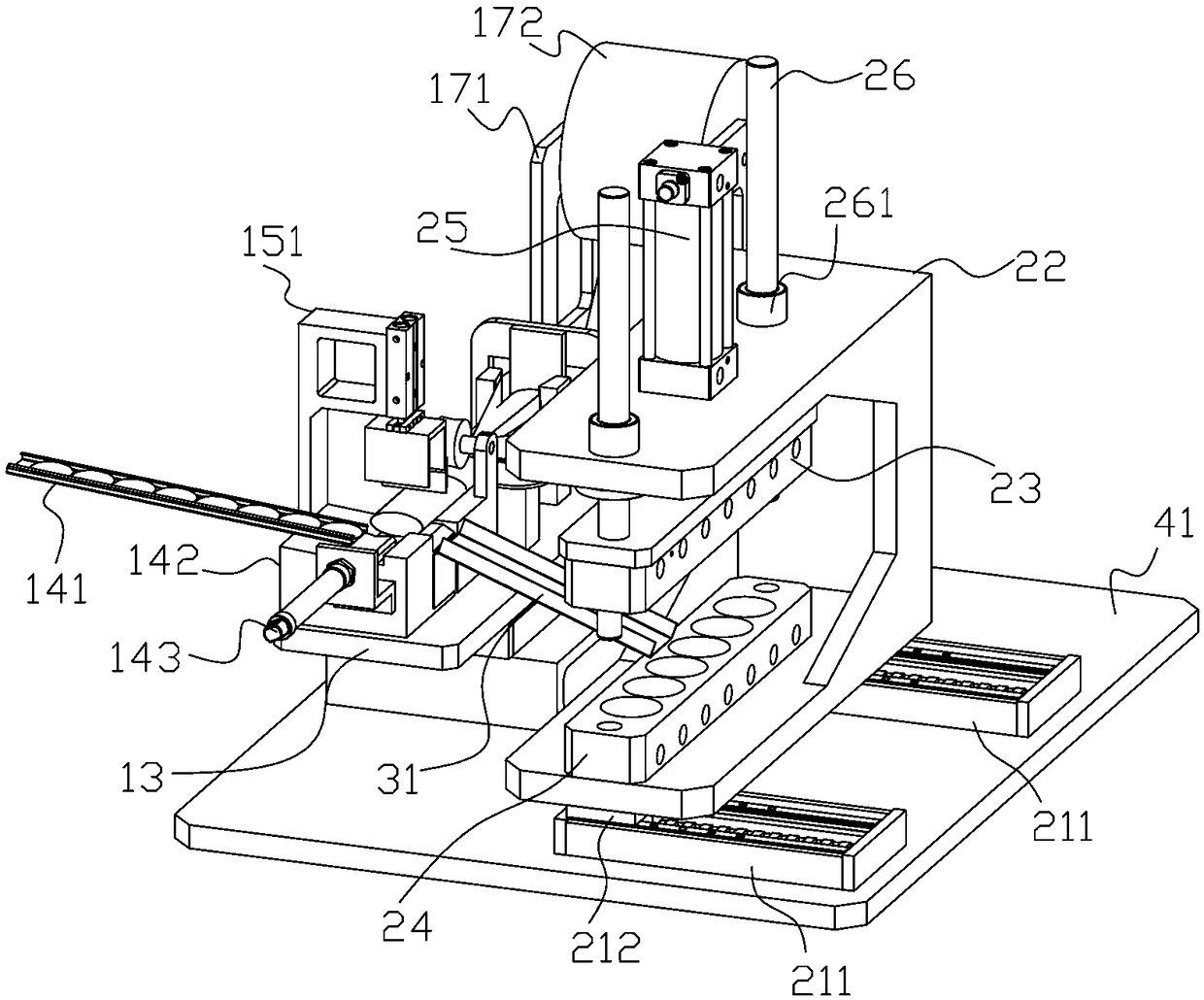

[0034] Such as Figure 1 to Figure 12 As shown, a solar thermal collector shuttle coating machine described in this embodiment includes a workbench a, a coating mechanism is provided on the workbench, and a recovery frame b is also provided on one side of the workbench .

[0035]The coating mechanism includes a feeding mechanism, and the feeding mechanism includes a backing plate 11 and a first linear motion device, and the first linear motion device is fixed on the backing plate 11, and the first linear motion device includes a first linear motion device A linear motor box 121 and a T-shaped first sliding plate 122, the first linear motor box 121 is provided with components for driving the first sliding plate 122 to reciprocate, the first linear motor box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com