Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

139results about How to "No eccentricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

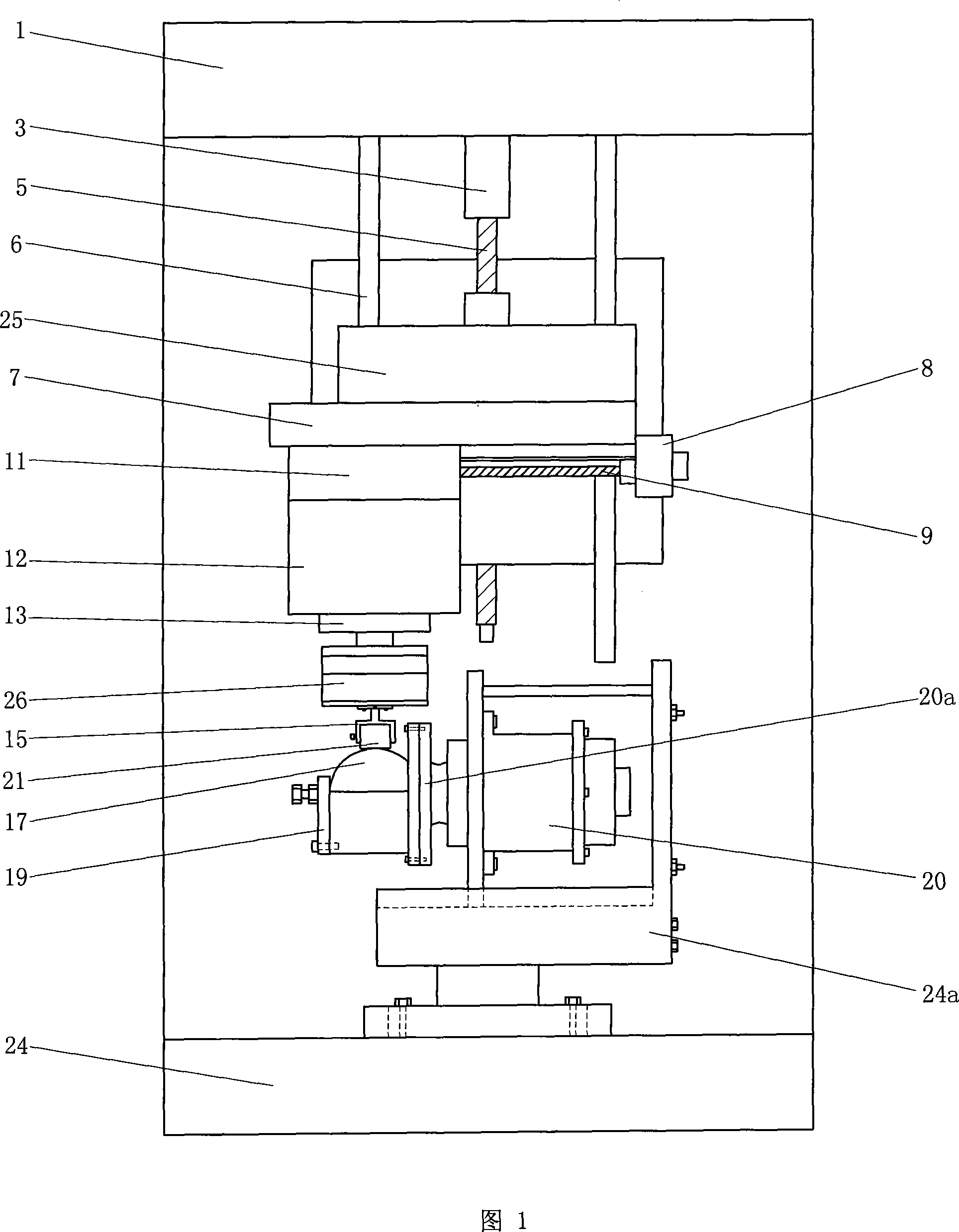

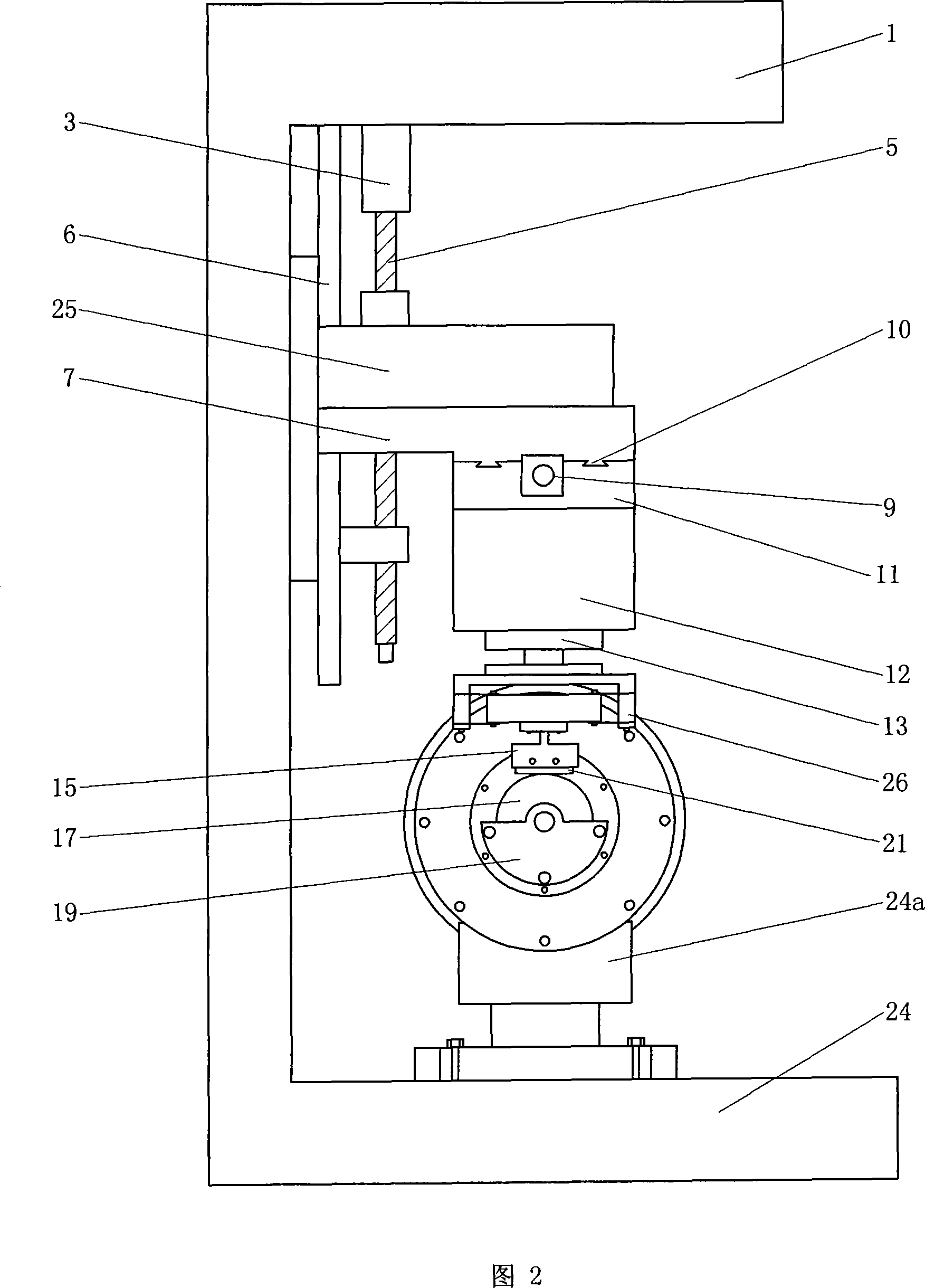

Rotary micromotion friction wear test method and device thereof

InactiveCN101226122AHigh degree of automationHigh precision of control and testingMachine part testingInvestigating abrasion/wear resistanceTorque sensorLow speed

The invention relates to a rotary inching friction abrasion test method and a relative device, wherein the method comprises clamping a plane upper sample on an upper clamp, fixing a lower clamp on the horizontal rotation shaft of a high-precision ultra-low speed rotation motor, clamping a spherical lower sample via a lower clamp, aligning the horizontal central line of the lower sample with the rotation shaft of the rotation motor, using a data acquisition and control system to control the up-and-down and left-and-right motions of the upper clamp to contact the upper and lower samples and apply a preset normal load, at the same time, using the data acquisition and control system to control the rotation motor to reciprocally rotate the lower clamp and lower sample at preset rotation argument, rotation speed and times, to realize the rotary inching friction between the upper and lower samples, using a six-dimension force / torque sensor to test and feed the friction force to the data acquisition and control system to be analyzed to obtain a friction force-angle displacement curvature. The inventive method can simply realize small angle rotary inching friction abrasion of material, with high automatic degree, high control and test accuracy and better test data reappearance.

Owner:SOUTHWEST JIAOTONG UNIV

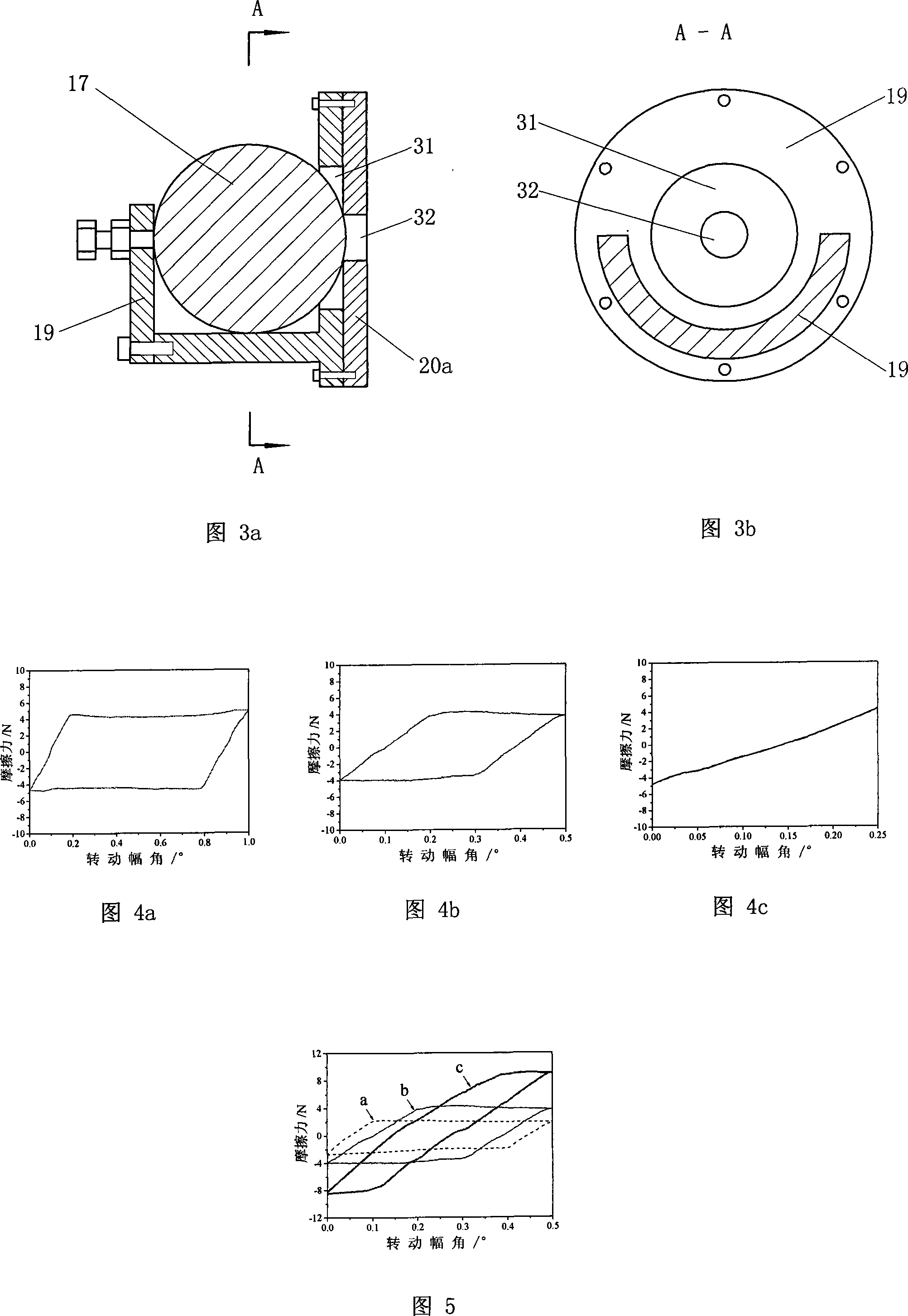

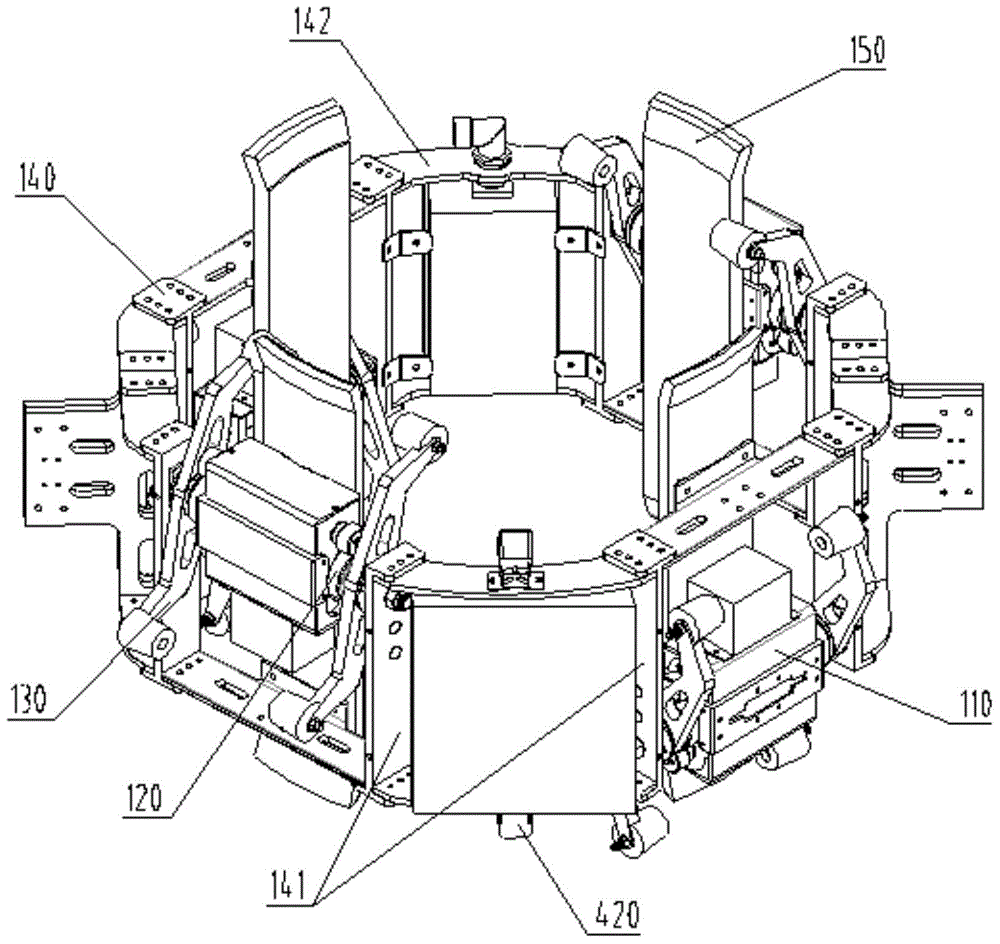

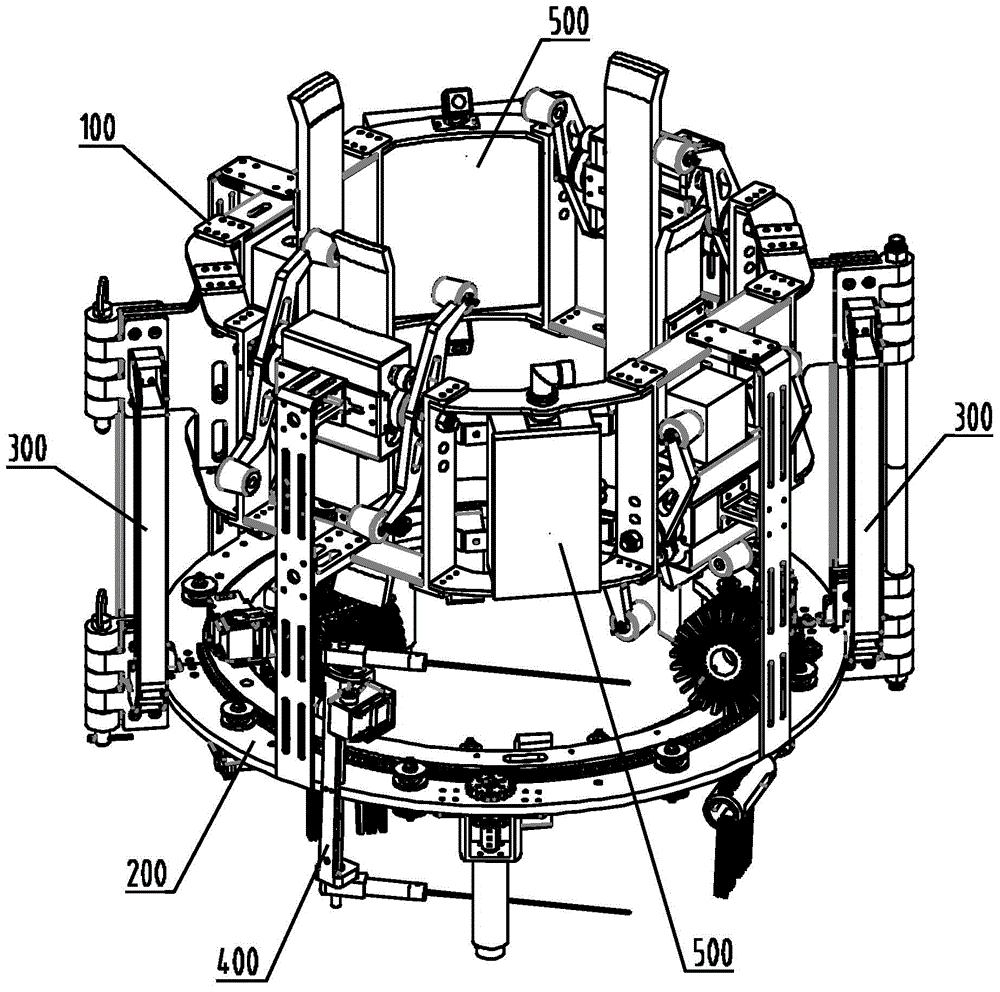

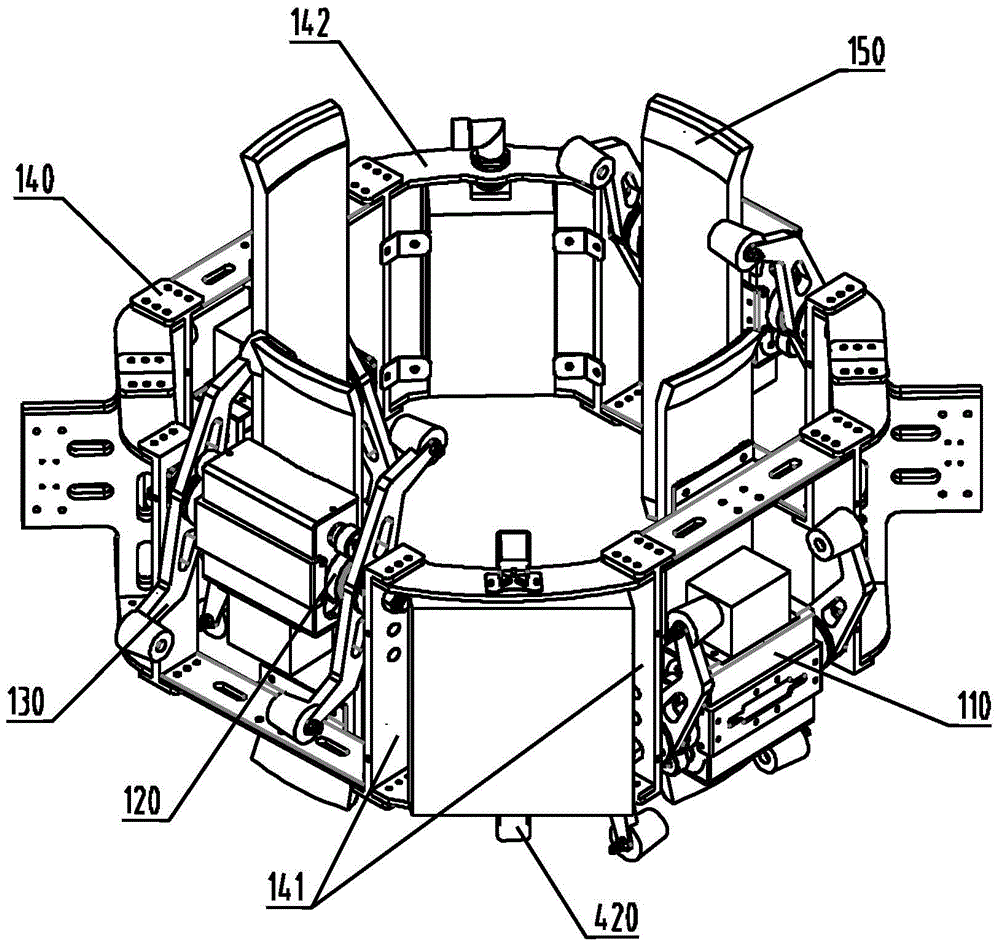

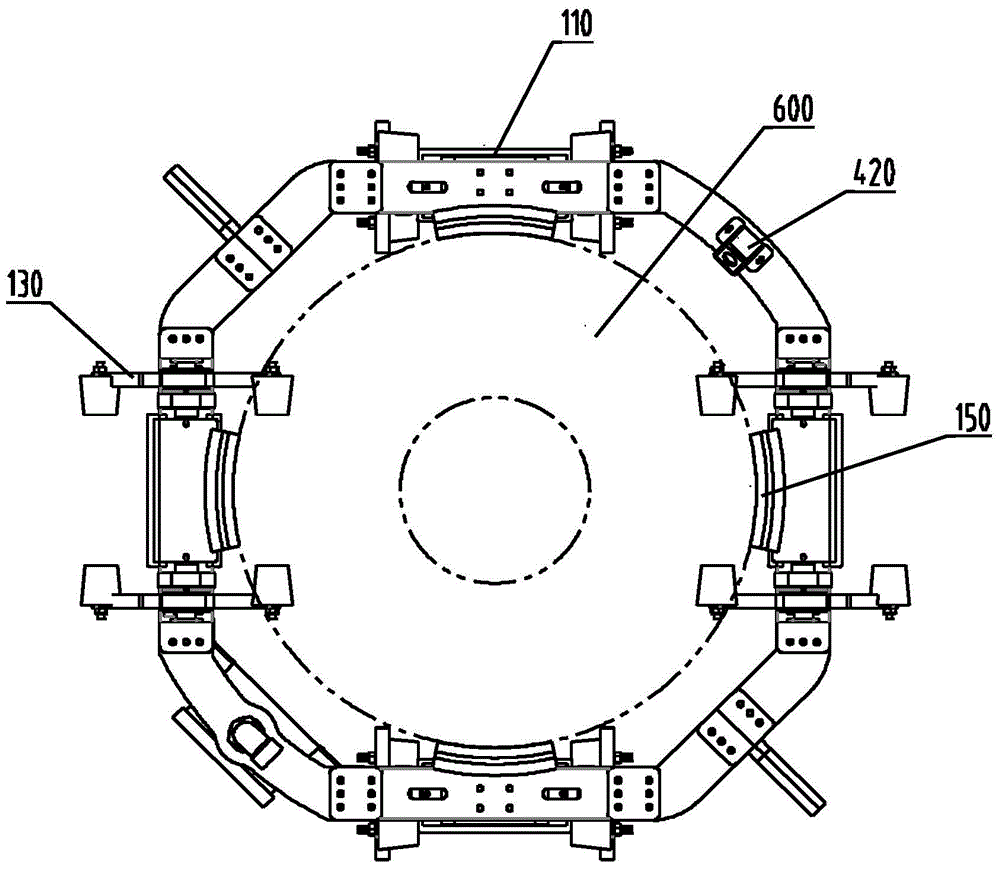

Insulator cleaning robot

ActiveCN104438164ARun smoothlyReduce wearElectrical testingCleaning using toolsMoving speedDisc diameter

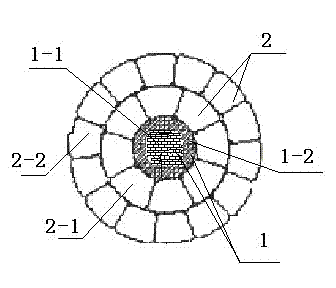

The invention discloses an insulator cleaning robot. The insulator cleaning robot comprises a crawling mechanism, a cleaning mechanism, a locking mechanism, a detection mechanism and a battery control system, wherein the crawling mechanism is of a closed circumferential structure, surrounds an insulator string and drives a robot body to continuously move along the insulator string; the cleaning mechanism is of a closed circumferential structure and surrounds the insulator string; the locking mechanism is evenly arranged on the crawling mechanism, and the crawling mechanism is connected with the cleaning mechanism through the locking mechanism; the detection mechanism is arranged on one side of the locking mechanism, and the battery control system is installed on the crawling mechanism. The insulator cleaning robot is simple in structure; due to the overall symmetrical structure, the stability of the robot is good; as the continuous type movement mode is adopted, the movement speed is high, the cleaning mode is simple, the cleaning speed is high, abrasion to coatings of insulators is small, locking is reliable, an adjustment mechanism can be suitable for insulator strings different in structural height and disc diameter, and electrification insulator string cleaning operation and insulator sheet quality detection can be carried out.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

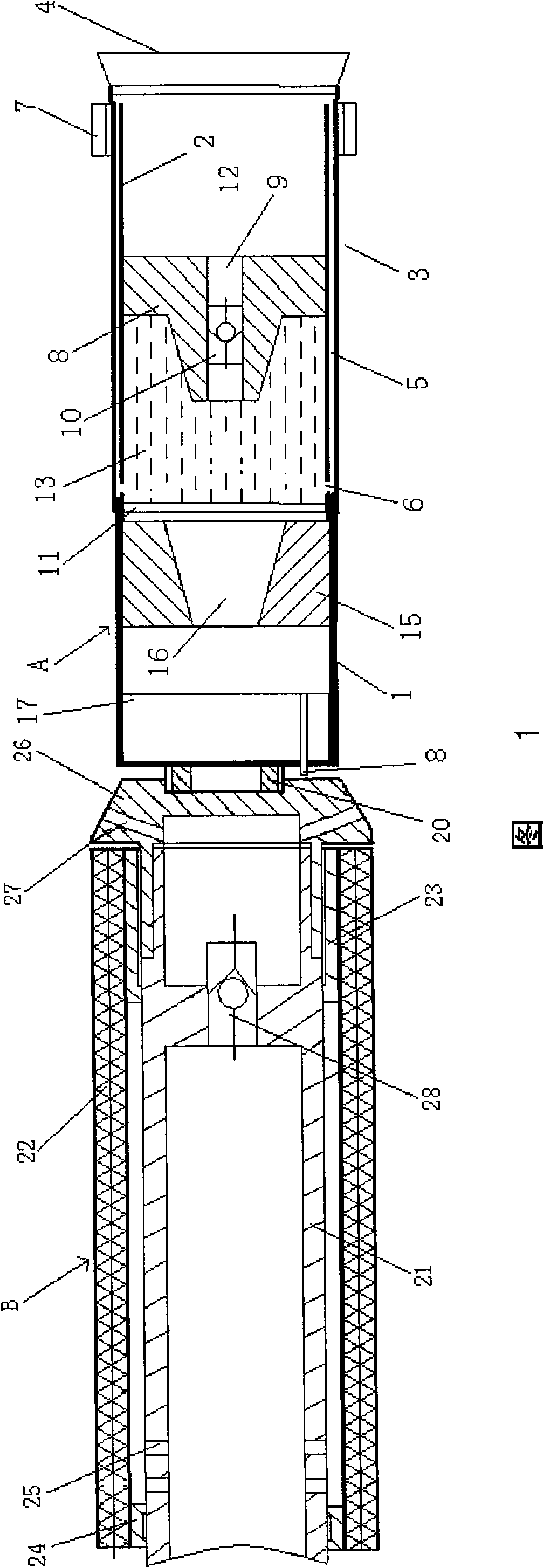

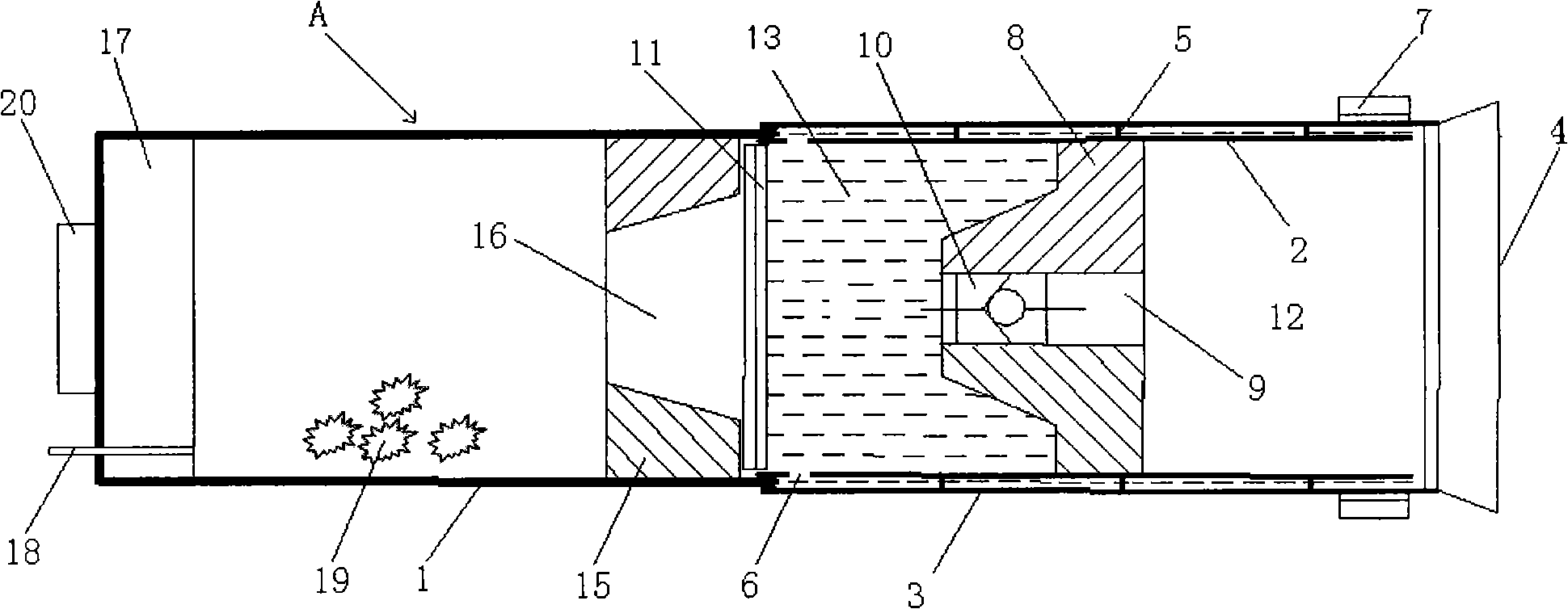

Self sealed self decompressed coal seam sampling method and apparatus

InactiveCN101308062APrevent leakagePrevent escapeWithdrawing sample devicesBorehole/well accessoriesThermodynamicsMechanical engineering

The invention relates to a self-sealing and self-decompressing coal seam sampling method and a device thereof, which comprises the steps as follows: (1) a sampler is arranged ready; (2) when a sampling drilling bit drills into a coal seam, a coal sample goes into the front end of a piston of a sampler and repeatedly extrudes the piston to squeeze the sealing liquid through a liquid outlet of an inner tube of the sampler into a gap between the inner tube and an outer tube of the sampler, the coal sample is penetrated, enwrapped and solidified through the gap between the sampling drilling bit and the inner tube to form the front end sealing of the coal sample; (3) when the piston crushes a brittle baffle inside the sampler, coal sampling is completed, and the gas borne by the coal sample automatically butts against the piston to continue to move backwards until an unidirectional valve of the piston is opened for pressure relief, and the gas which enters a vacuum tube of the sampler is absorbed by the absorbing material in the vacuum tube; and (4) when the absorption is completed, the coal sample and the absorbing material are taken out, and the conventional gas content measurement and calculation are conducted. The coal seam sampling method and the device can be widely used in sampling processes for various coal gas content measurements.

Owner:NORTH CHINA INST OF SCI & TECH

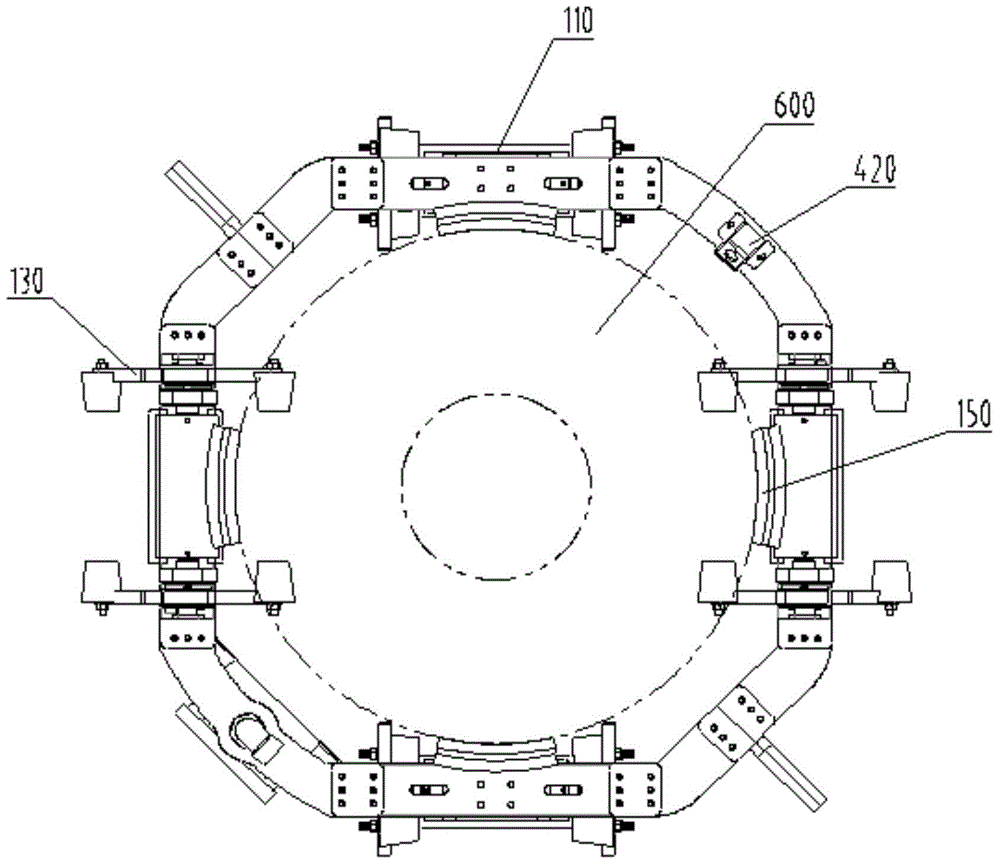

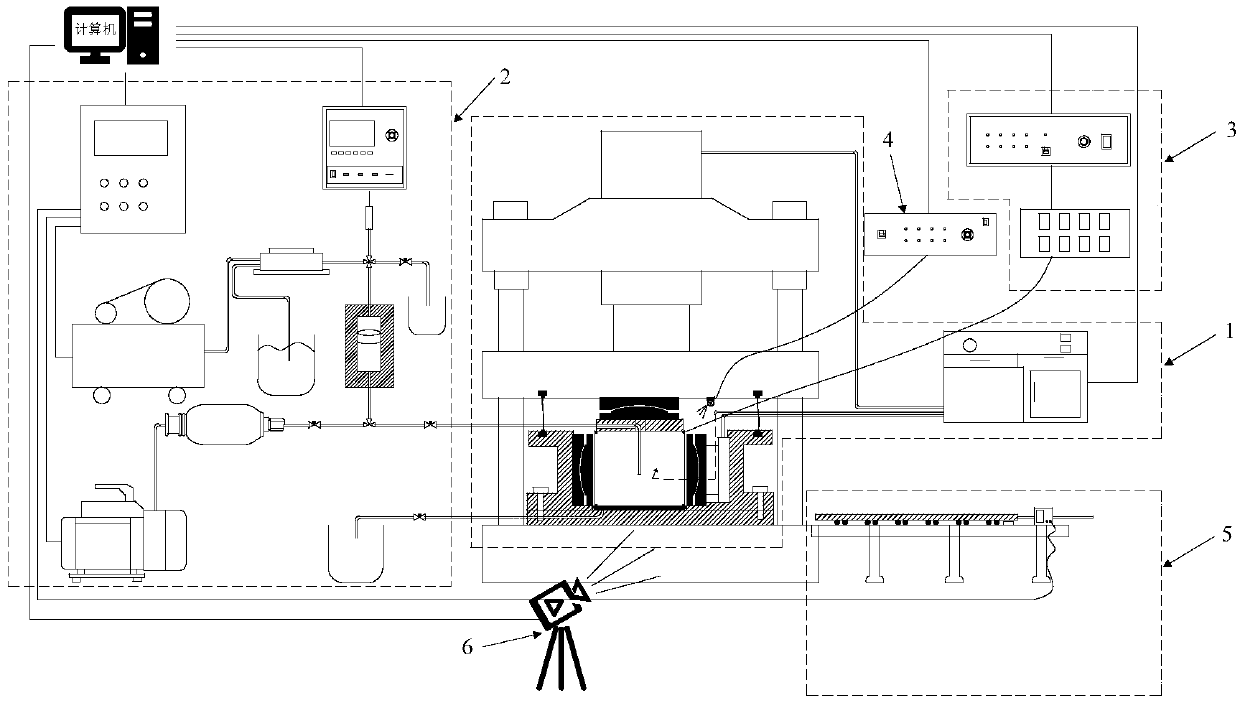

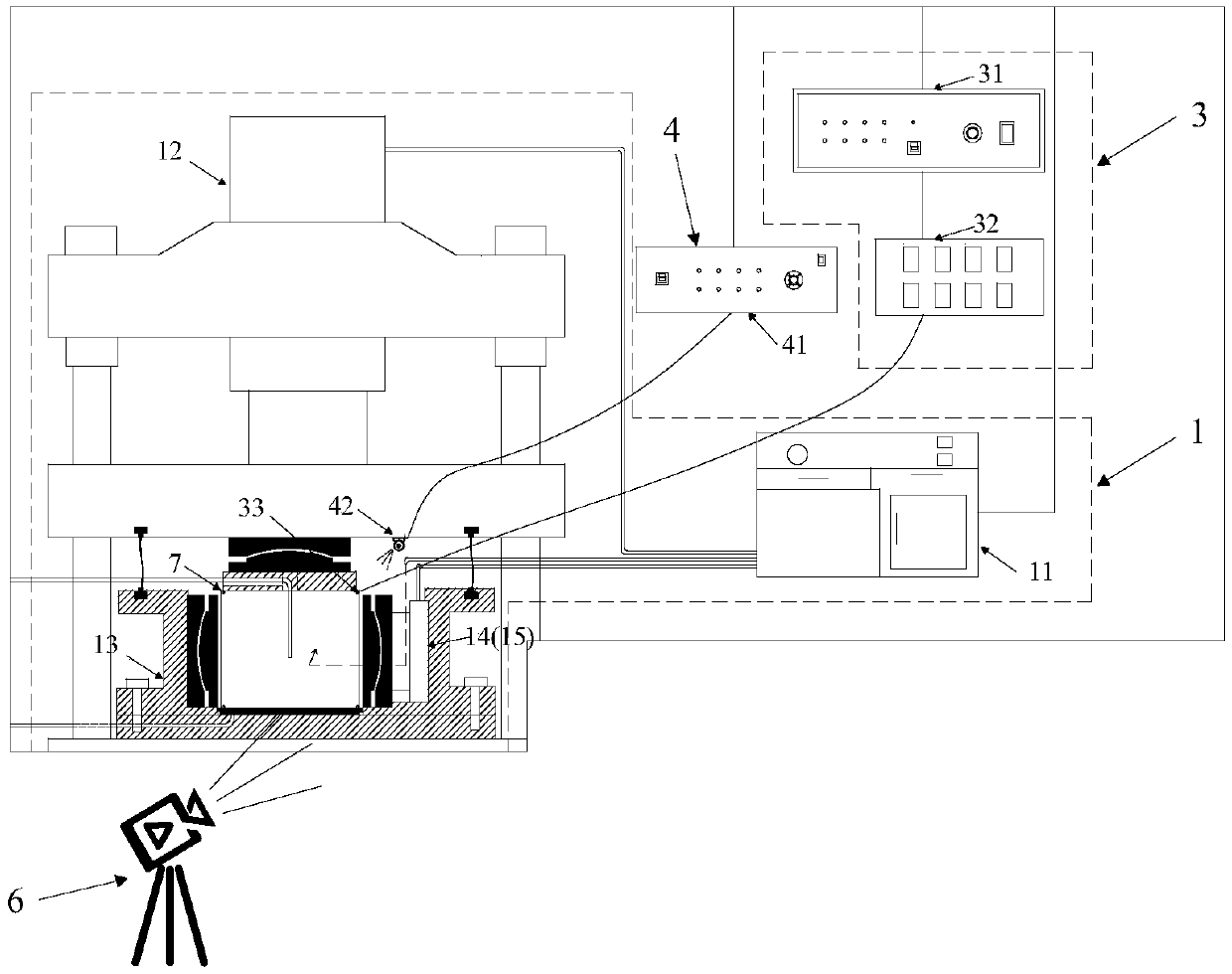

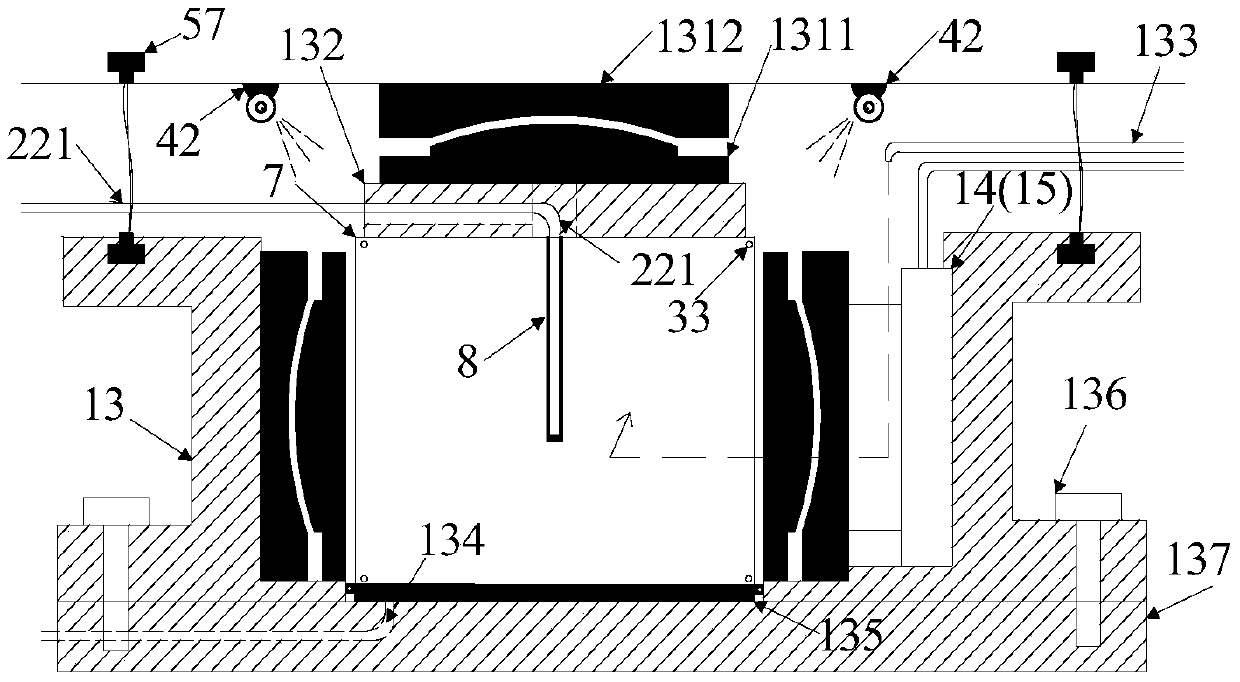

Large-size true triaxial hydraulic fracturing simulation test device and test method

PendingCN109540688ADoes not affect accuracyImprove reliabilityMaterial strength using tensile/compressive forcesTest sampleAcoustic emission

The invention discloses a large-size true triaxial hydraulic fracturing simulation test device and a test method. The test device comprises a large-size true triaxial loading module, a hydraulic servopumping module, an acoustic emission positioning module, an infrared monitoring module, a sample loading and unloading module and a computer, wherein a loading plate is formed by combining an inner plate and an outer plate which are matched with each other through a spherical surface. The test method comprises the following steps of manufacturing and loading a test sample, and performing hydraulic fracturing simulation test, sample unloading, data processing and analysis and the like. The device and the method for a hydraulic fracturing simulation test of shale have the following advantages that the accuracy of a test result is not influenced by the sample processing size and the parallelism deviation, so that the requirements for the sample size processing precision are reduced, and thetest reliability is improved; a loading condition of the shale in a triaxial loading chamber in a test process can be monitored in real time; the fracturing conditions of the multi-size samples can bemet; and a high-speed camera is matched for a uniaxial hydraulic fracturing simulation test, the dynamic expansion rule of hydraulic cracks can be observed directly, and multiple purposes of one machine can be realized.

Owner:LIAONING TECHNICAL UNIVERSITY

Insulator cleaning robot system

ActiveCN104438165AGuaranteed uptimeMove fastCleaning using toolsApparatus for overhead lines/cablesRobotic systemsLocking mechanism

The invention discloses an insulator cleaning robot system. The insulator cleaning robot system comprises a crawling mechanism, a cleaning mechanism, a locking mechanism, a detection mechanism and a battery control system, wherein the crawling mechanism is of a closed circumferential structure, surrounds an insulator string and drives a robot body to continuously move along the insulator string; the cleaning mechanism is of a closed circumferential structure and surrounds the insulator string; the locking mechanism is evenly arranged on the crawling mechanism, and the crawling mechanism is connected with the cleaning mechanism through the locking mechanism; the detection mechanism is arranged on one side of the locking mechanism, and the battery control system is installed on the crawling mechanism. The insulator cleaning robot system is simple in structure; due to the overall symmetrical structure, the stability of the robot is good; as the continuous type movement mode is adopted, the movement speed is high, the cleaning mode is simple, the cleaning speed is high, abrasion to coatings of insulators is small, locking is reliable, an adjustment mechanism can be suitable for insulator strings different in structural height and disc diameter, and electrification insulator string cleaning operation and insulator sheet quality detection can be carried out.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

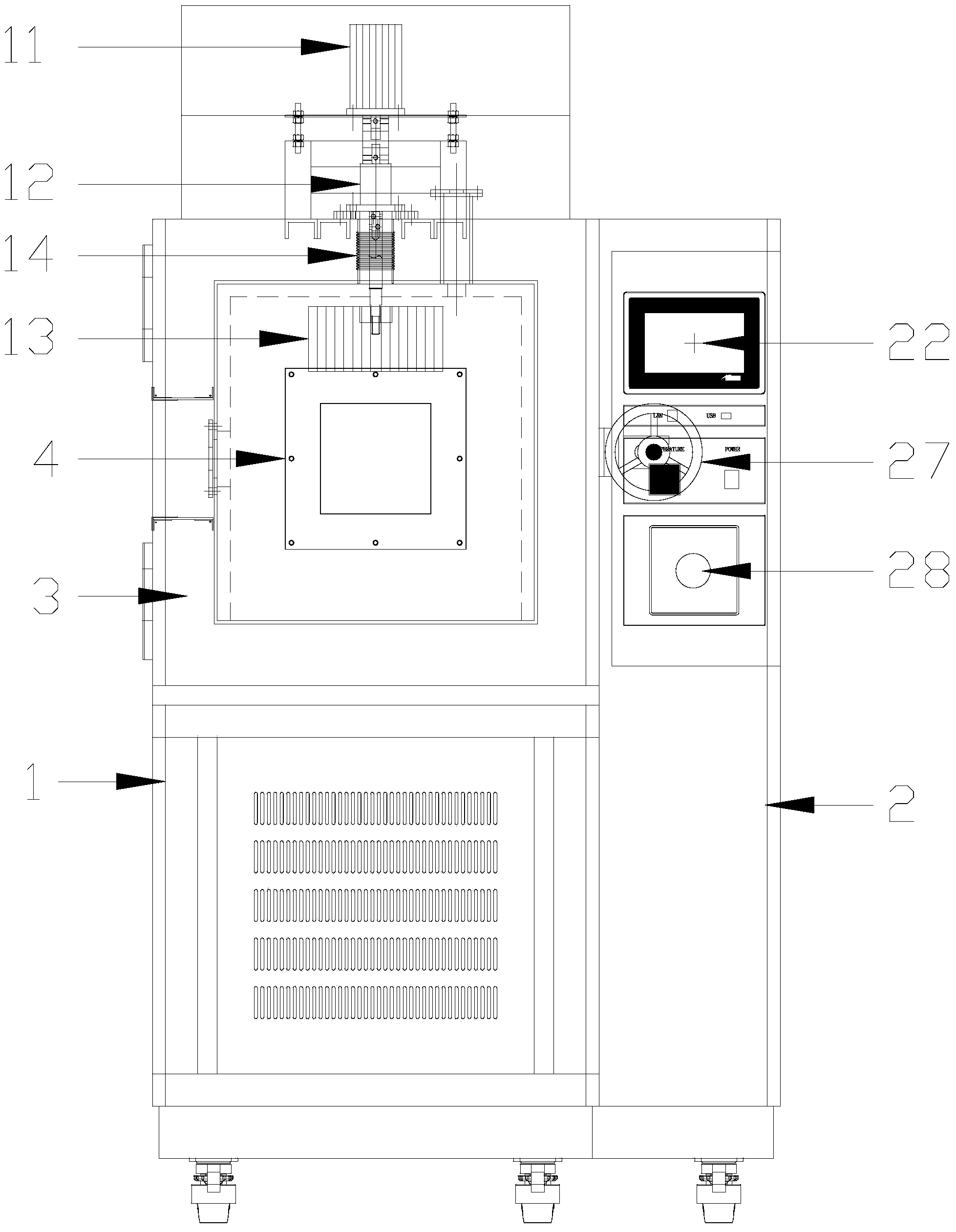

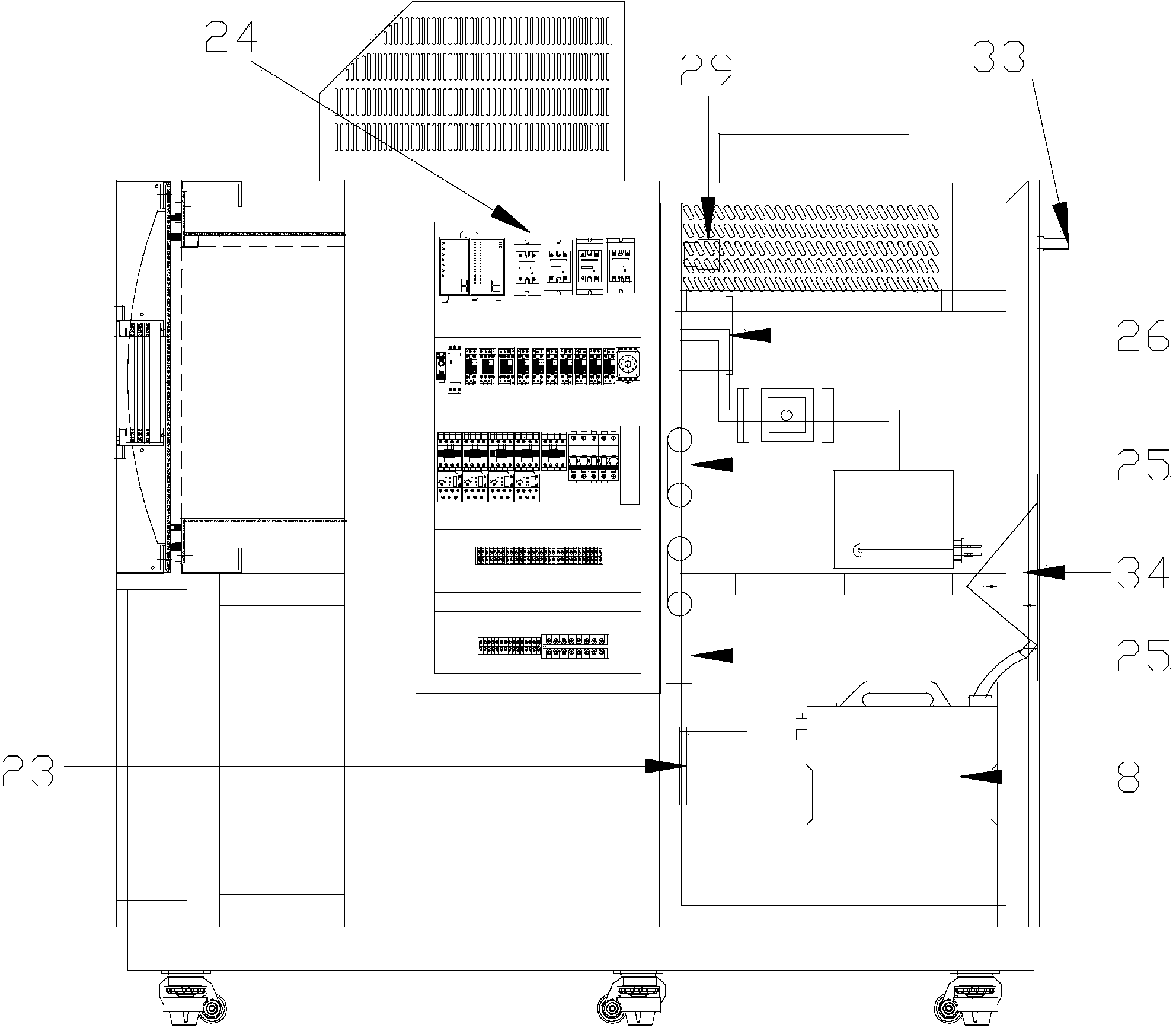

High low temperature damp and hot low gas pressure test box

The invention relates to the technical field of environmental testing instruments, in particular to a high low temperature damp and hot low gas pressure test box. The high low temperature damp and hot low gas pressure test box comprises a box body, a heating system, a refrigerating system, a vacuum system, an electrical cabinet and an electrical system, wherein a box door is arranged at the front end face of the box body, and an observing window is arranged on the box door; the box door is connected with the box body in a sealing manner; the heating system and a vacuum chamber are arranged at the upper part in the box body, and a sample stand is mounted in the vacuum chamber; the heating system, the refrigerating system and the vacuum system are respectively connected with the electrical system through a circuit. The high low temperature damp and hot low gas pressure test box also comprises a humidifying system, and the humidifying system is arranged outside the vacuum chamber in the box body and is communicated with the interior of the vacuum chamber through a pipeline. An electric valve is arranged on the pipeline, and the humidifying system and the electric valve are respectively connected with the electrical system through a circuit. Compared with the prior art, the high low temperature damp and hot low gas pressure test box integrates humidity, high low temperature and low gas pressure, and the function of the test box can be furthest performed, so that the test box can simulate a complicated real test environment, and the test accuracy of tested products is improved.

Owner:SHANGHAI LINPIN INSTR

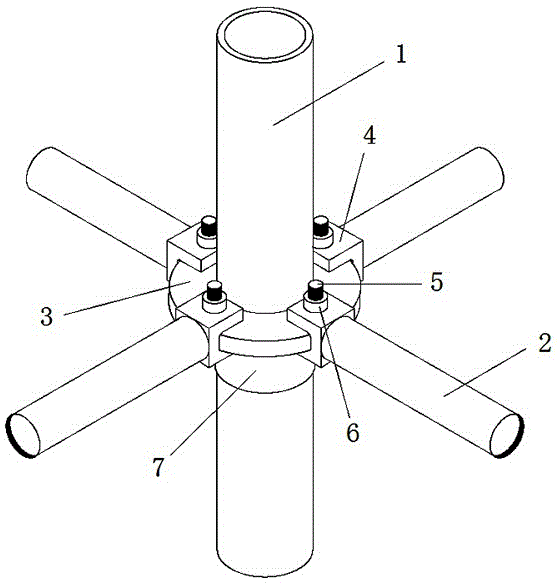

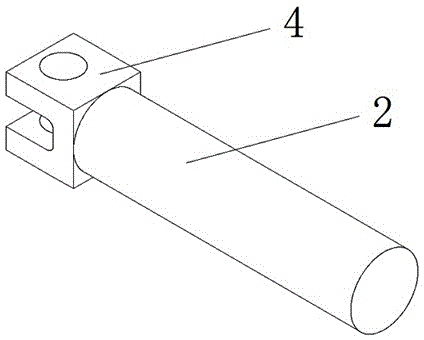

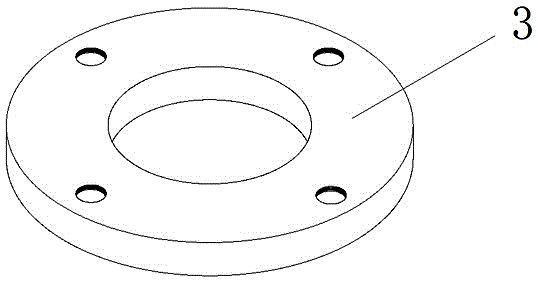

Rapid scaffold connecting device and construction method thereof

InactiveCN106401166AImprove stabilityQuick installation and removalScaffold connectionsEngineeringFast speed

The invention relates to a rapid scaffold connecting device and a construction method thereof. The rapid scaffold connecting device comprises a stand column which is sleeved with a ring disc connected with the ends of a plurality of transverse rods, U-shaped ends clamped to the ring disc are fixedly connected to the ends of the transverse rods, and the U-shaped ends and the ring disc are fixedly connected through bolts A and nuts A; and the stand column is further sleeved with a positioning ring buckle located below the ring disc to limit gliding of the ring disc. The rapid scaffold connecting device is large in rigidity, high transverse rod transmitting loads can be borne, the eccentricity effect is avoided during stressing, the stress performance is good, safety is high, and the overall stability of a scaffold is greatly improved; and rapid mounting and demounting of the scaffold can be achieved, the construction speed is high, and needed manpower is less.

Owner:FUZHOU UNIV

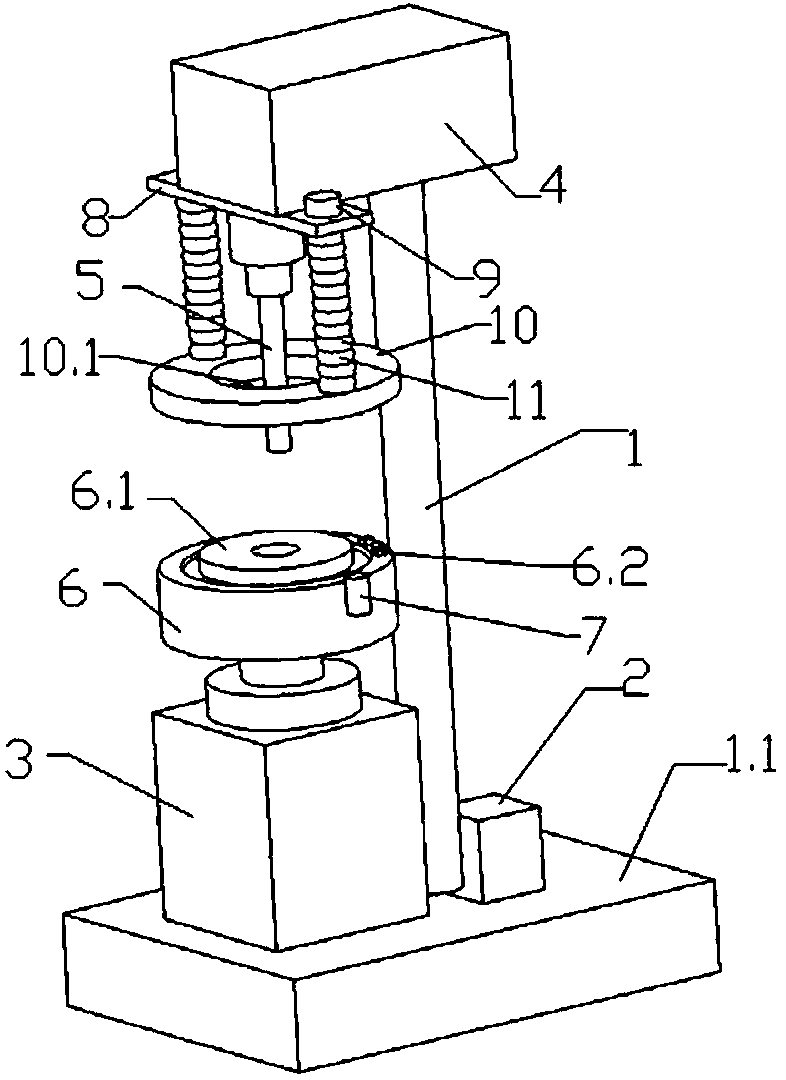

Automatic reaming machine

InactiveCN104070234ANo wasteAvoid compromising reaming qualityFeeding apparatusReaming devicesInductorEngineering

The invention discloses an automatic reaming machine. The automatic reaming machine comprises a rack (1), a controller (2), a cylinder (3) and a motor (4), wherein a reamer (5) is installed on a motor output shaft; a location seat (6) is installed on a cylinder piston rod; a location boss (6.1) is formed on the location seat (6); a limit block (6.2) is further arranged on the location seat (6); an inductor (7) used for inducting an aluminium freezing motor shell, and clamped and located on the location seat (6) is further installed on the location seat (6); the cylinder piston rod, the location seat (6), the motor output shaft and the reamer (5) are coaxially arranged; the cylinder (3), the motor (4) and the inductor (7) are electrically connected with the controller (2). The automatic reaming machine is high in automation degree, fast in reaming speed, high in efficiency, high in reaming quality, and relatively low in cost.

Owner:NINGBO LIONBALL VENTILATOR

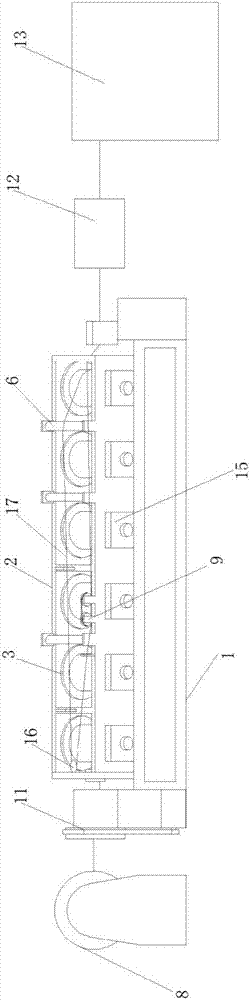

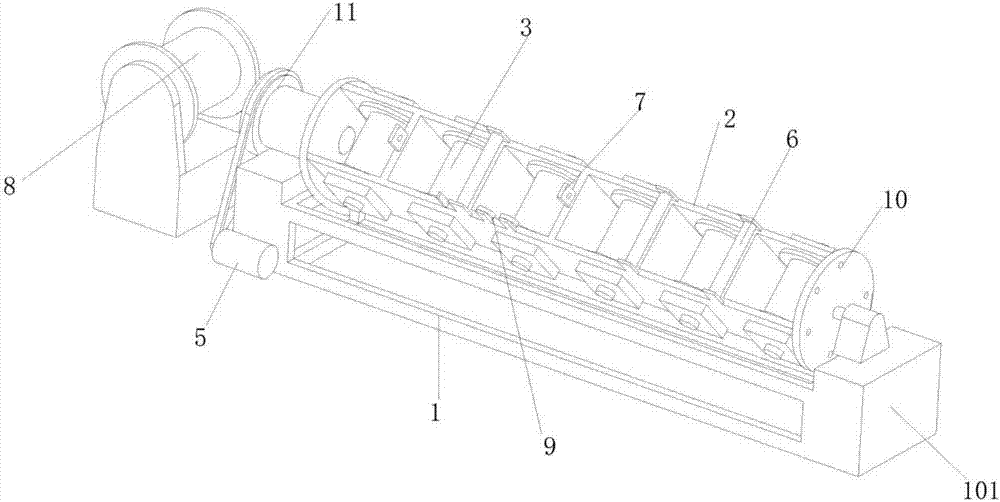

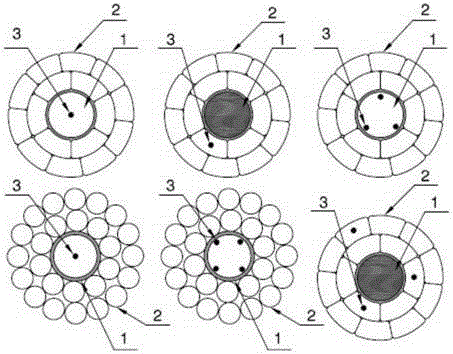

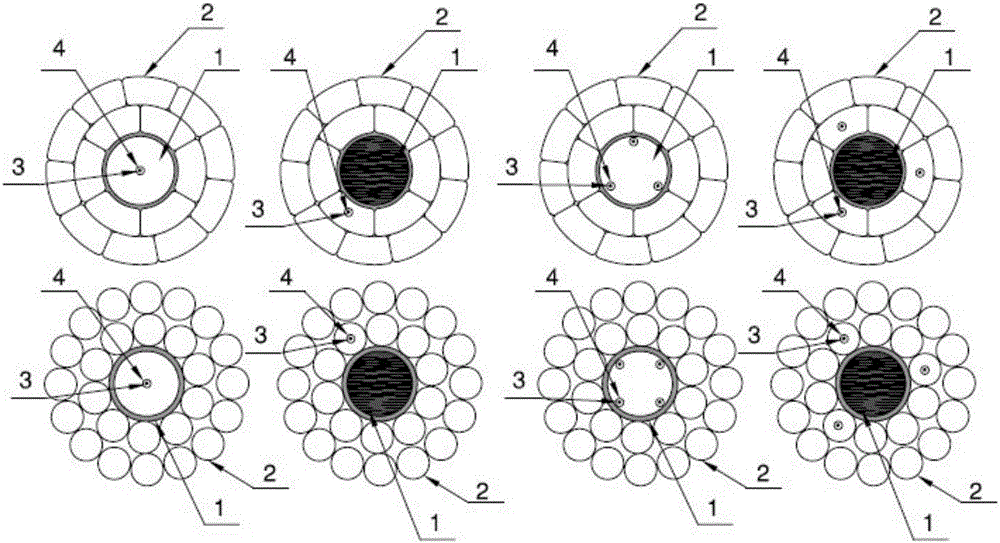

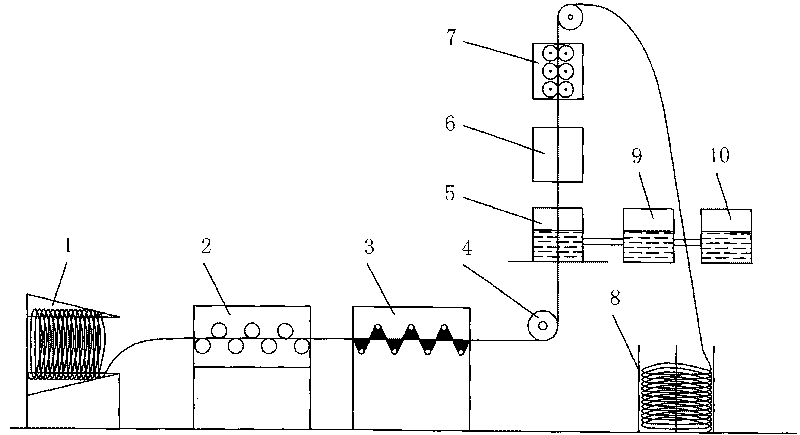

Concentric high-speed stranding machine

PendingCN107039128AReduce resistanceTo achieve twist and actionCable/conductor manufactureStructural engineeringMachine

The invention discloses a concentric high-speed stranding machine, which comprises a rack and a stranding system arranged on the rack. The concentric high-speed stranding machine also comprises a traction machine and a take-up machine, which are used for carrying out traction and take-up and rolling on the stranded cables in sequence. The concentric high-speed stranding machine is characterized in that the stranding system comprises a bracket rotatably connected with the rack through bearing pedestals at the two ends; the bracket is uniformly equipped with a plurality of paying-off wheels in the same line direction; the paying-off wheels can rotate automatically and can also rotate synchronously with the bracket; and one side surface, opposite to an end frame, at the tail end of the bracket is uniformly provided with cable outlets. The provided concentric high-speed stranding machine is unique in structure; in the stranding machine, the bracket drives the paying-off wheels to rotate together, and the paying-off wheels are arranged uniformly in the same line direction, so that the bracket is smaller in overall structure; and therefore, the stranding machine is small in space occupation, fast in stranding speed and low in energy consumption.

Owner:邵现明

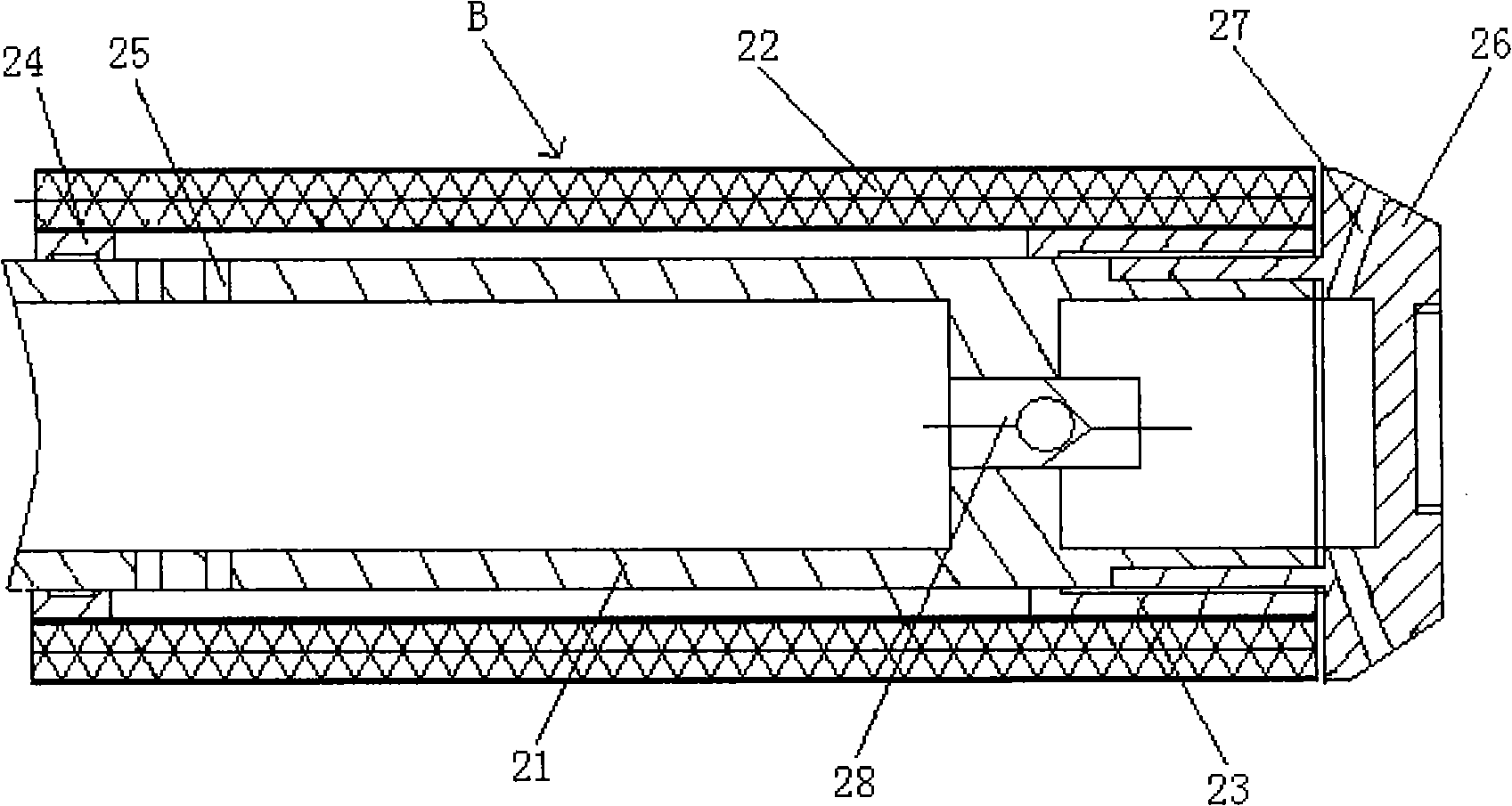

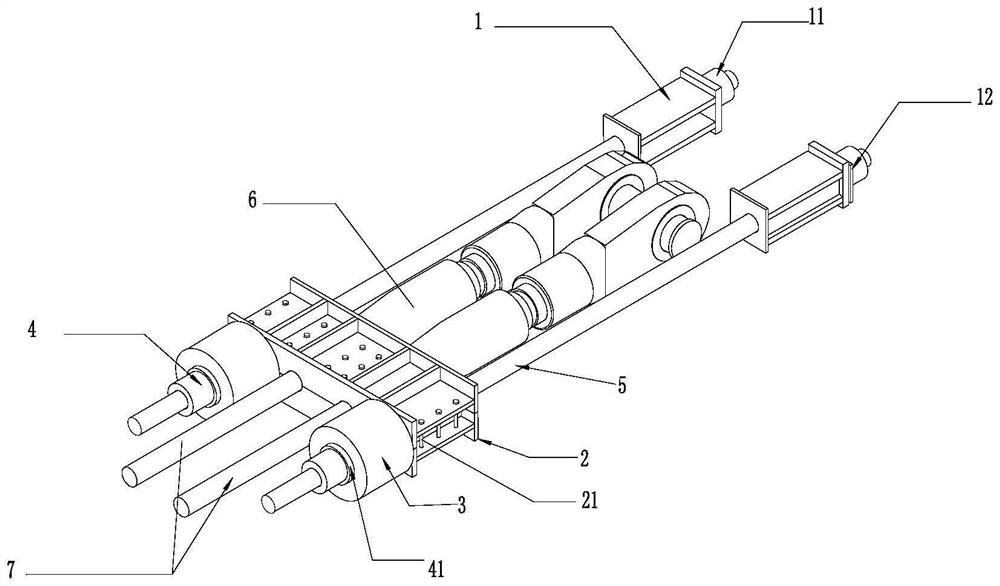

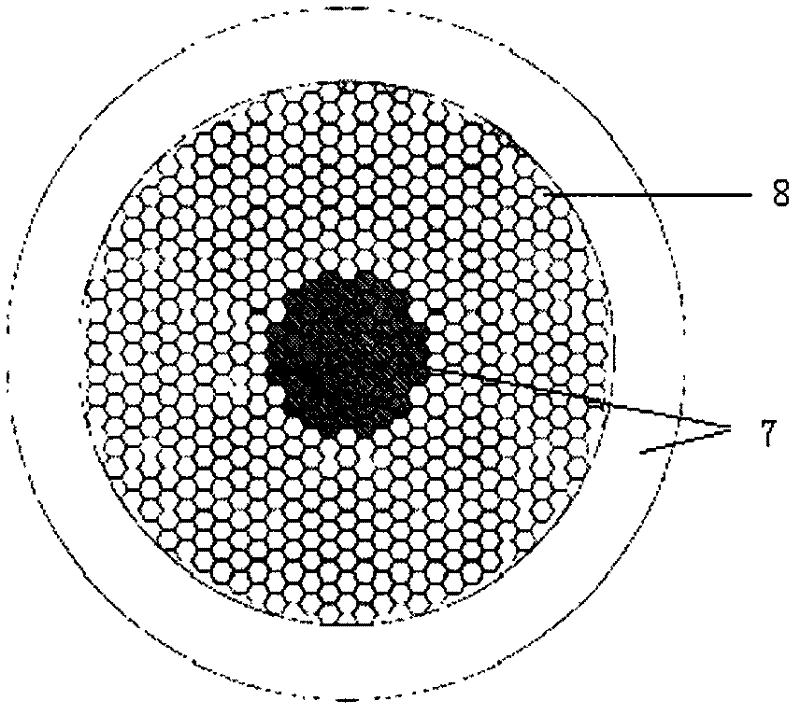

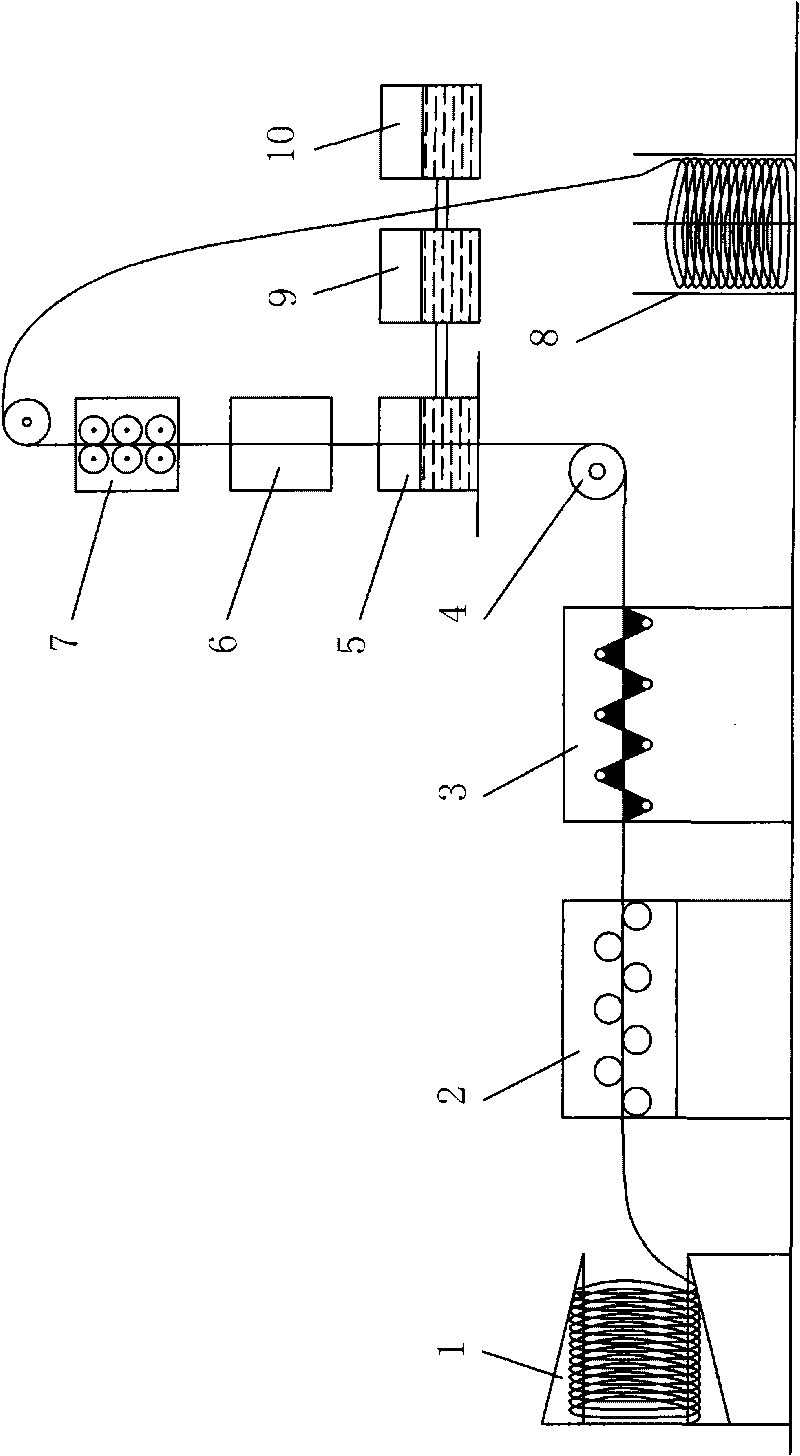

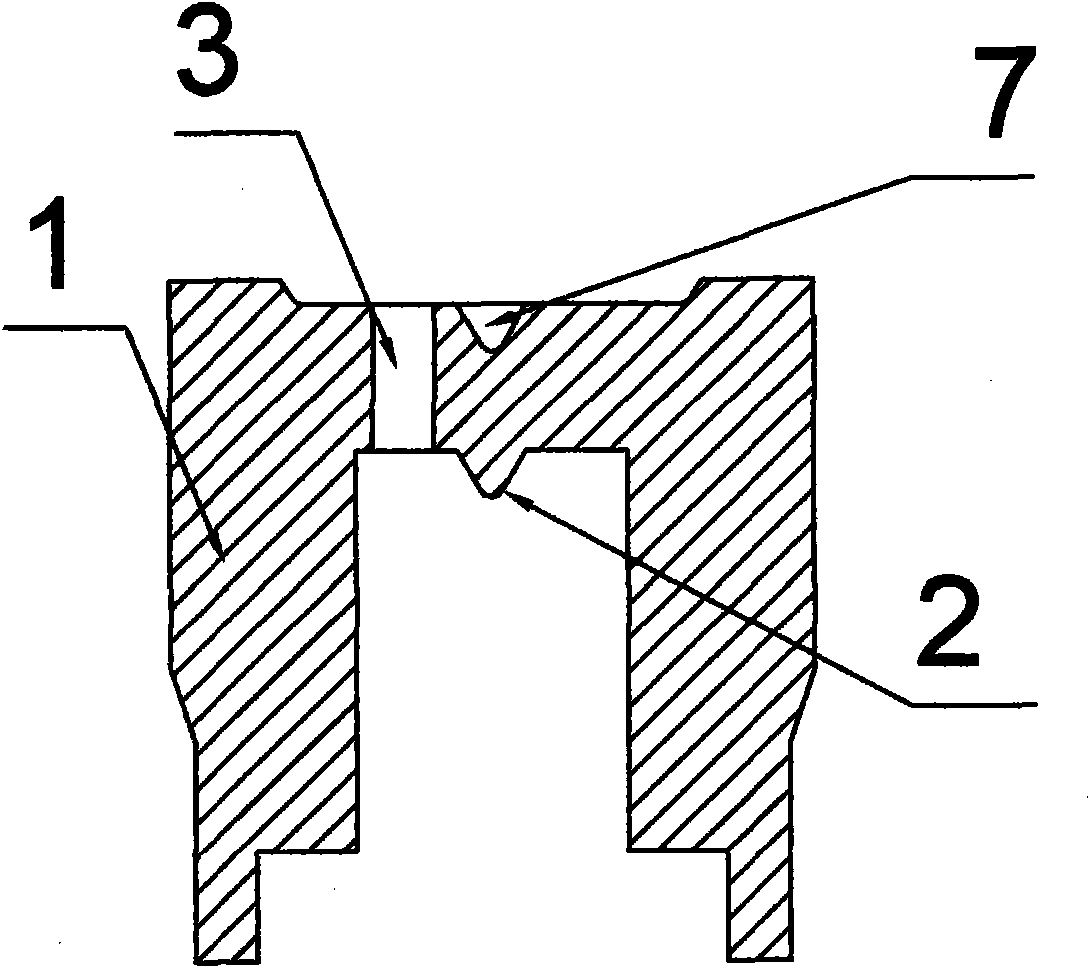

Carbon fiber composite material cable and preparation method of cable core thereof

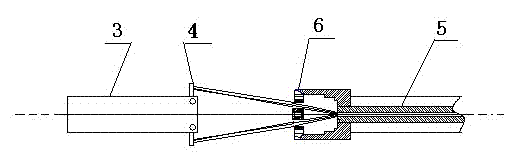

ActiveCN102810346AImprove straightnessGuaranteed tensionNon-insulated conductorsPower cablesFiberGlass fiber

The invention discloses a carbon fiber composite material cable and a preparation method of a cable core of the carbon fiber composite material cable. The preparation method comprises the following steps: testing and adjusting the tensile forces of carbon fibers and glass fibers; dewatering; pulling the carbon fibers into a procuring die (3) by infiltrating adhesive in a constant temperature adhesive groove; operating the glass fibers to pass through a rectangular splitting plate (4); pulling the carbon fibers into a curing die (5); feeding the glass fibers through a planar guide plate (6), and then puling into the curing die (5) so as to wrap the surrounding parts of the carbon fibers with the glass fibers, thus obtaining the carbon fiber composite material cable core. The method provided by the invention has high operability and relatively high production efficiency, can saves large amount of manpower and materials, and has low cost of production; and the carbon fiber composite material cable core prepared by the method has relatively high linearity, high roundness, no eccentricity, no bending, and high consistency in color; and as the detecting results shown, the carbon fiber composite material cable core has the advantages of high temperature resistance, lower energy consumption, long service life, no eccentricity, and good performance.

Owner:ZHONGFU CARBON FIBER CORE CABLE TECH

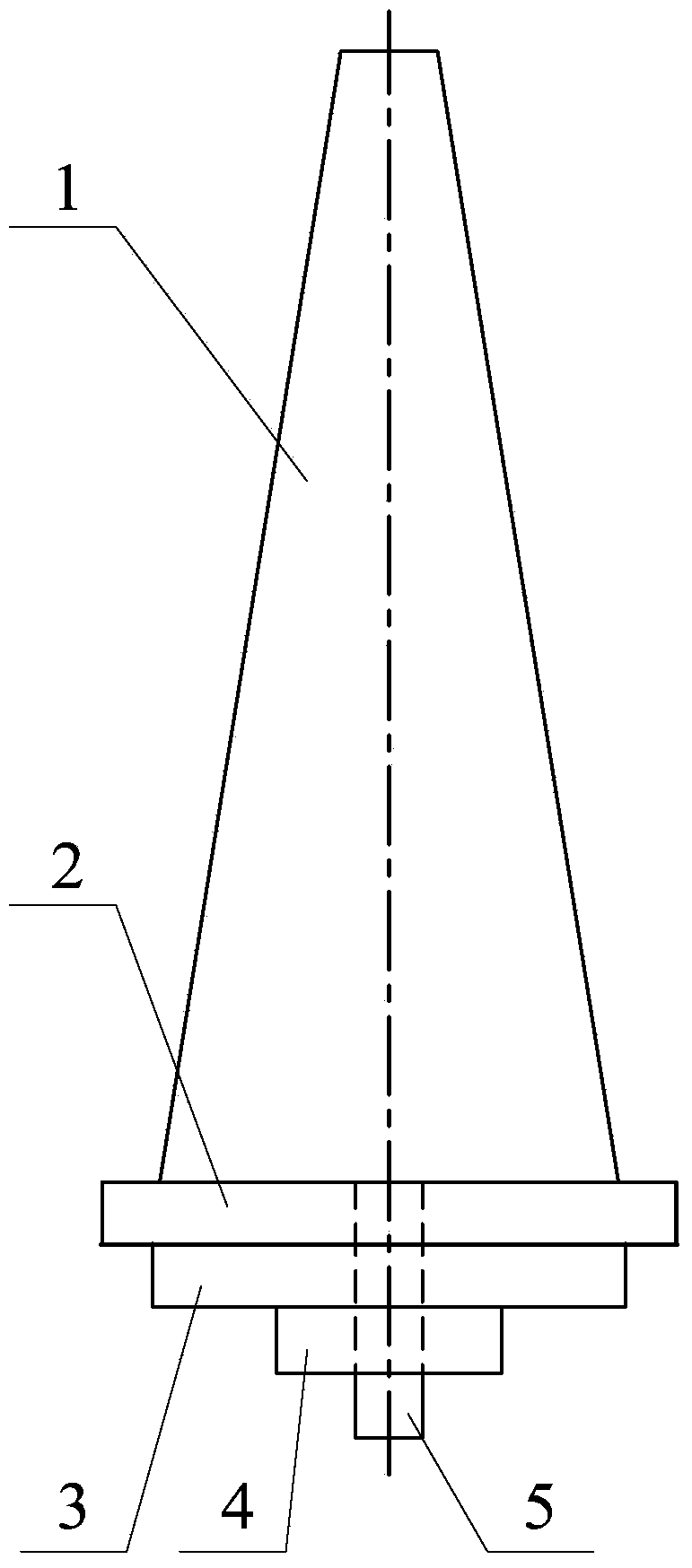

Positioning centering system and method for true three-axis Hopkinson pressure bar and positioning method

ActiveCN109668775APrecise positioningQuick alignmentMaterial strength using single impulsive forceMeasuring instrumentEngineering

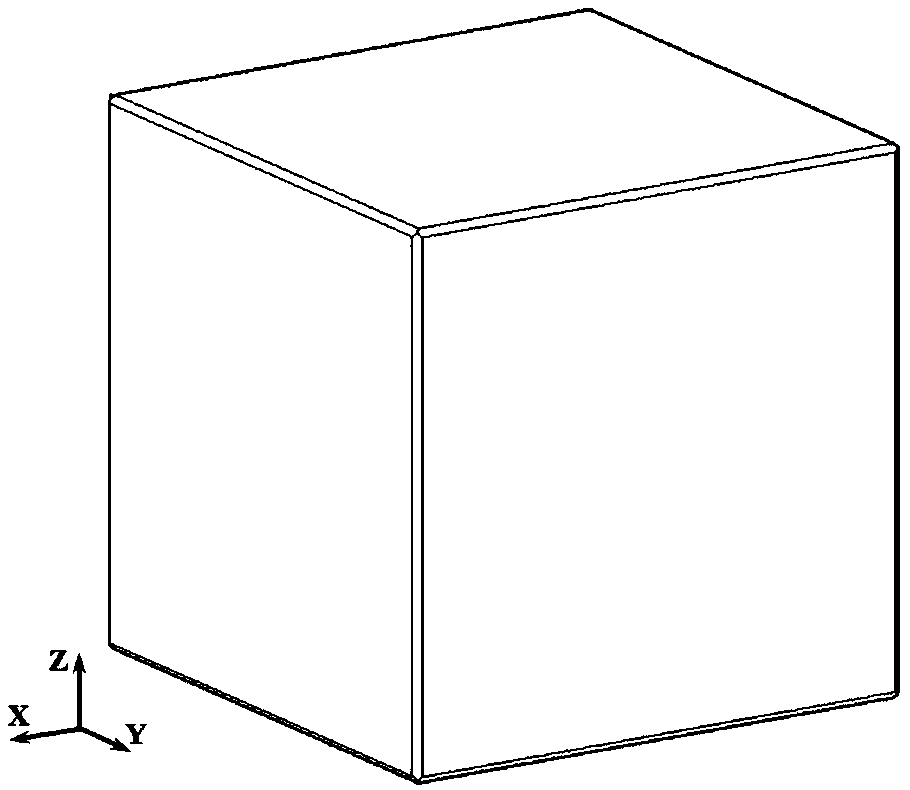

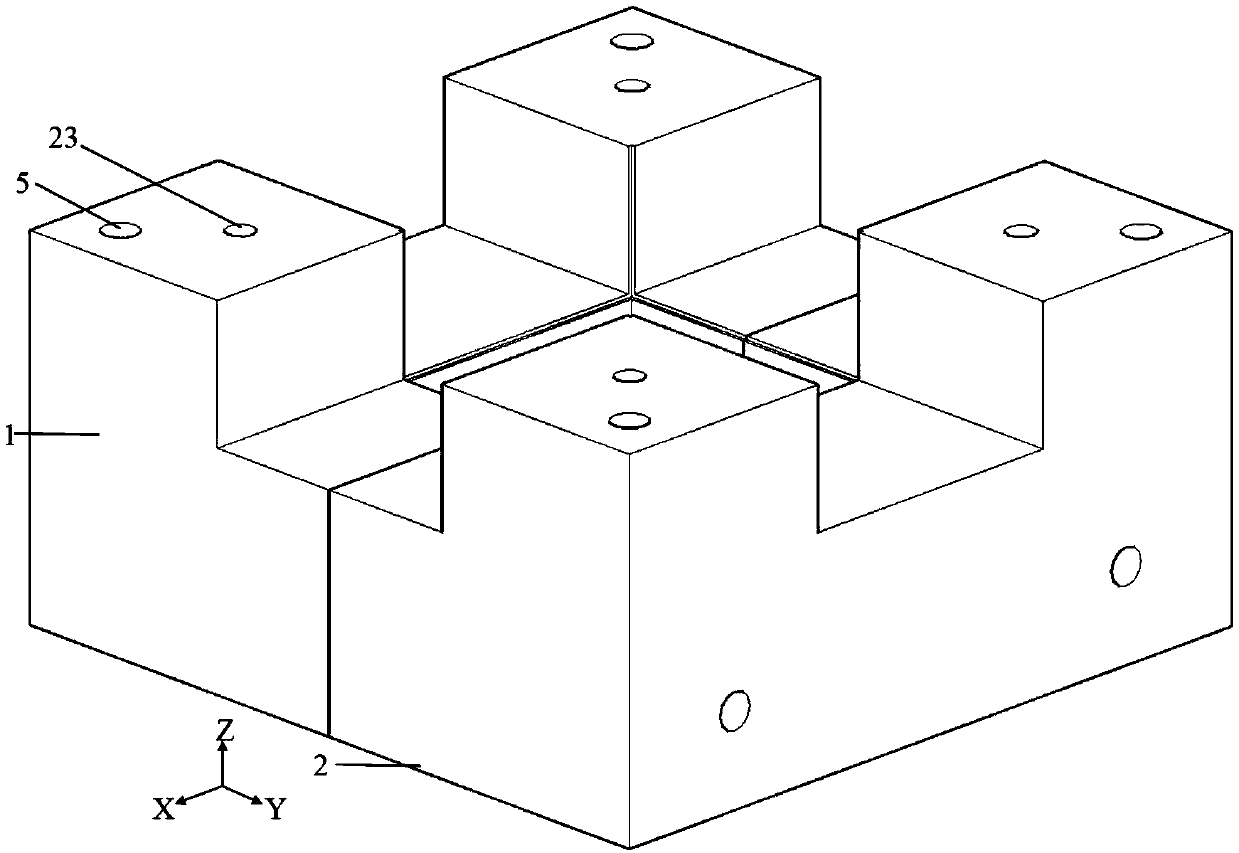

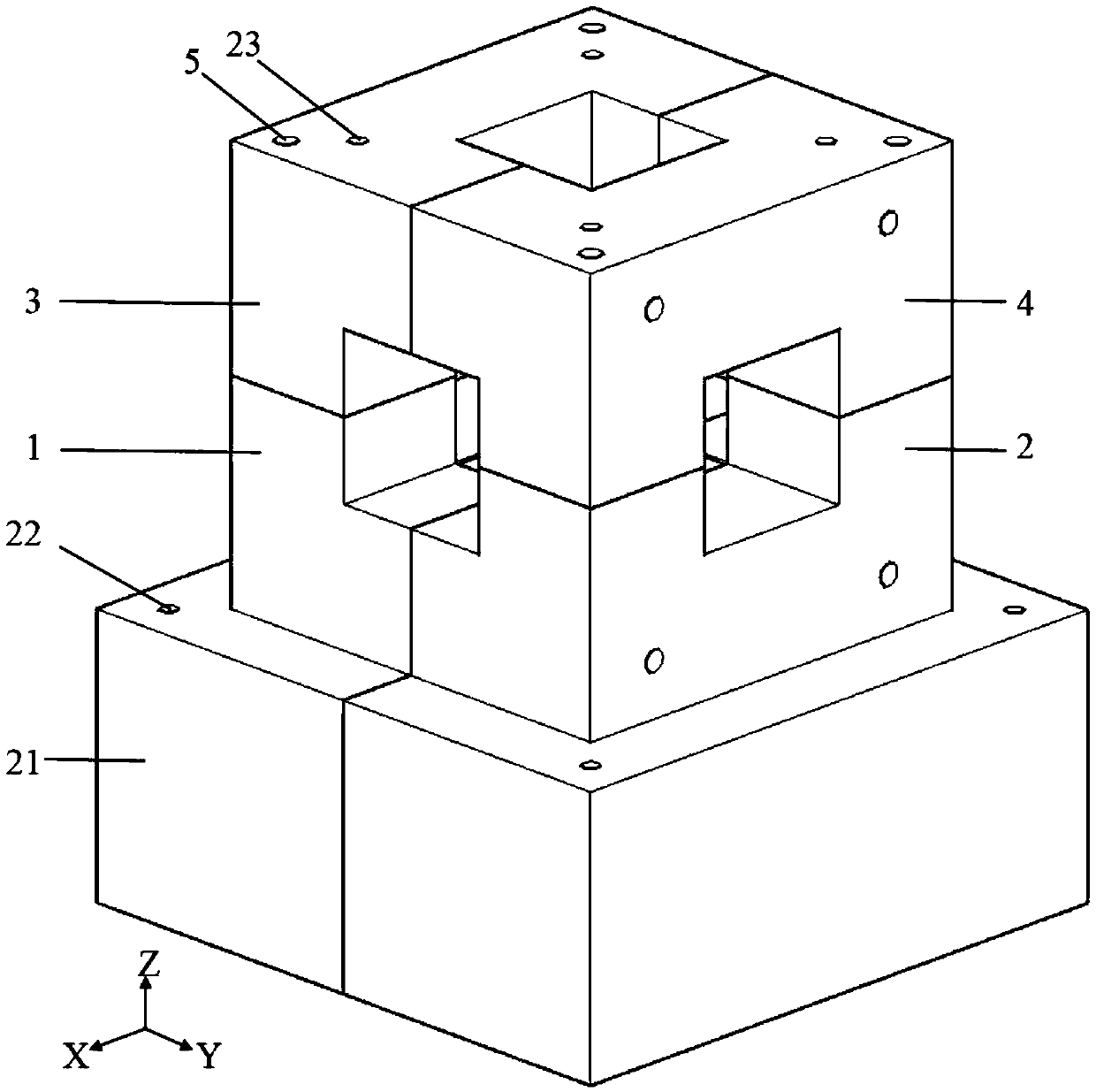

The invention provides a positioning centering system and method for a true three-axis Hopkinson pressure bar. A positioning guiding centering box is a cube, and square holes are reserved on the six surfaces of the positioning guiding centering box, and the sizes of the square holes in the six surfaces are the same as the size of a square rod of a Hopkinson rod; the size of an inner cavity of thepositioning guiding centering box is the same as the size of a cubic sample, and the positioning guiding centering box is designed to be symmetrical four parts. The method comprises the steps that step 1, the positioning guiding centering box is assembled, step 2, the positioning guiding centering box is immediately placed in the center position of a central cube square box, and step 3, the three-axis six-direction pressure bar is quickly and precisely aligned with assisting of an infrared laser measuring instrument. Through structural design of the positioning guiding device box and the tubesquare box, the quick and precise positioning centering mounting of test materials such as rock and concrete can be ensured. According to the positioning centering method for the true three-axis Hopkinson pressure bar, quick alignment of the three-axis six-direction pressure bar can be ensured through an infrared laser measuring instrument auxiliary mounting system.

Owner:SHENZHEN UNIV

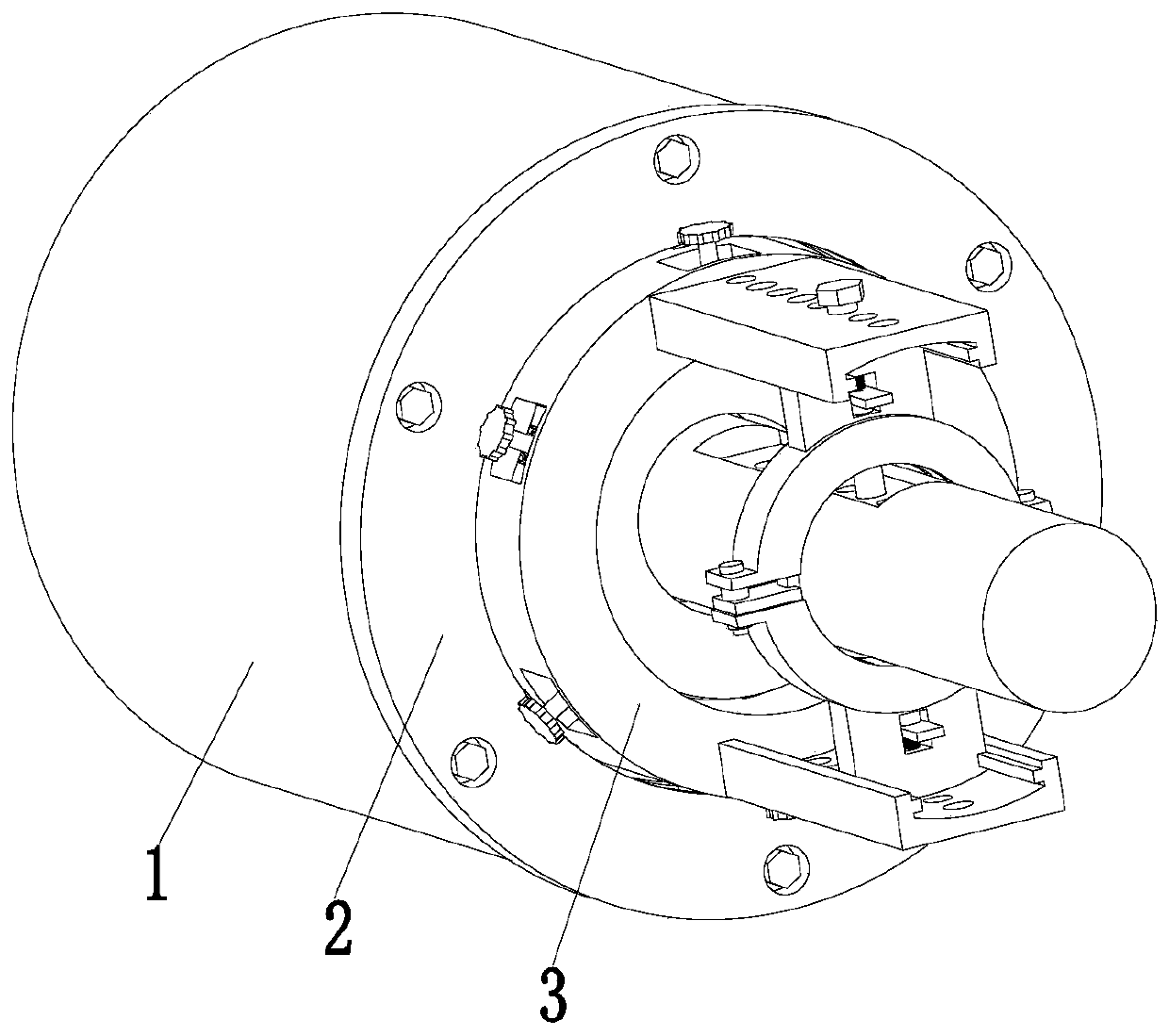

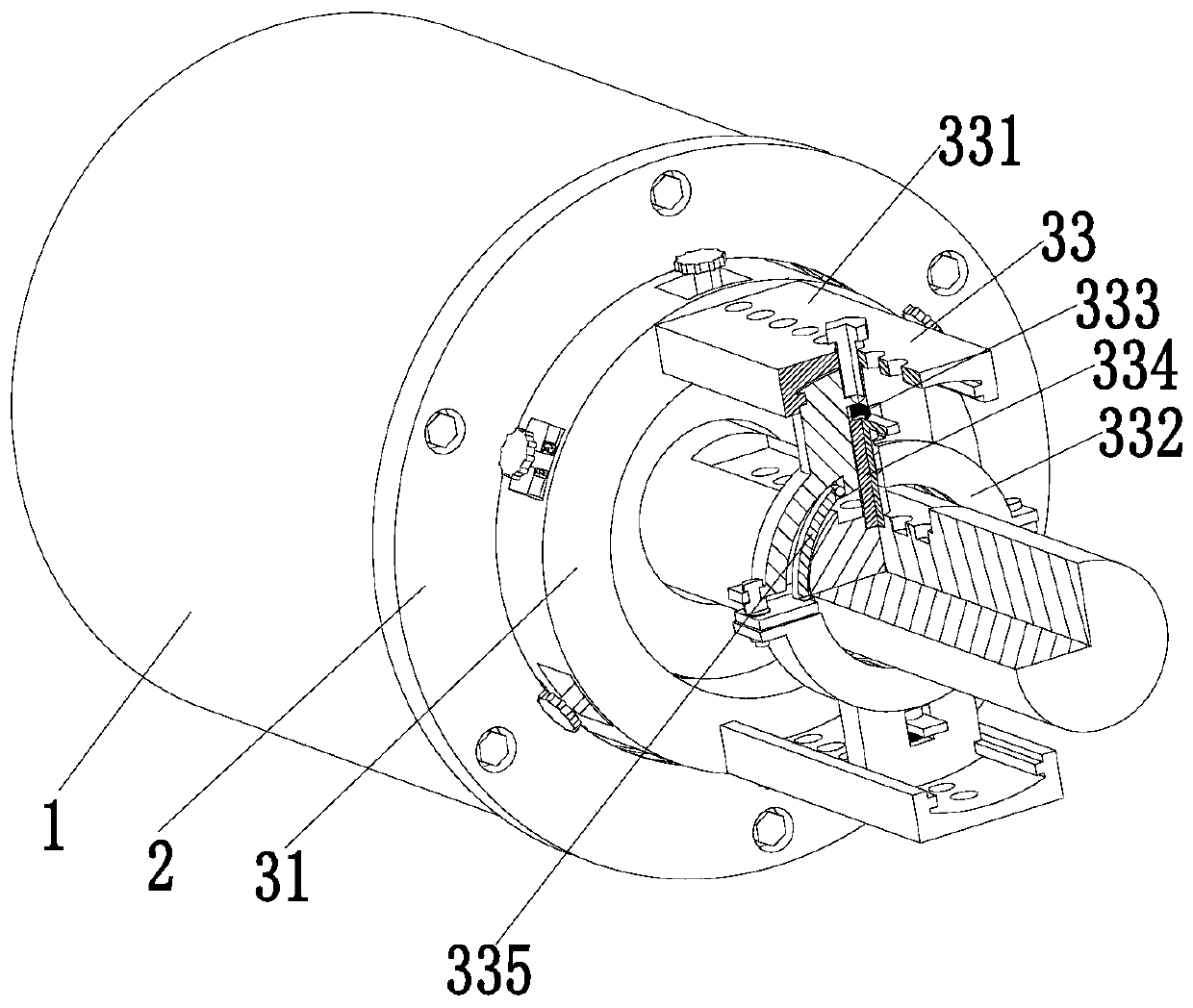

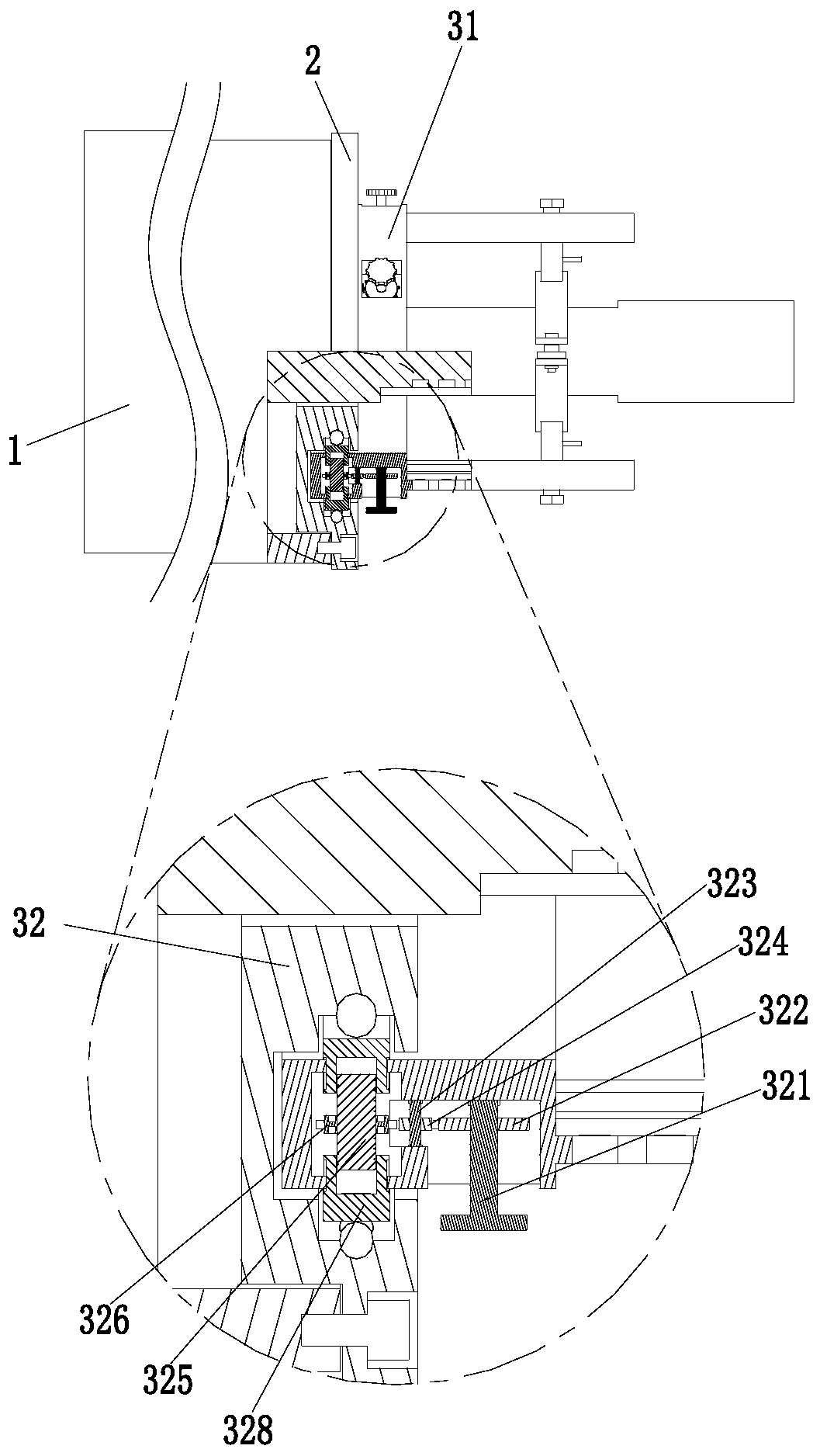

Stepping motor capable of preventing eccentric operation

The invention provides a stepping motor capable of preventing eccentric operation. The stepping motor comprises a stepping motor main body, a cover plate and a balancing device, and can solve the problems that the existing stepping motor is easy to generate resonance when being incorrectly controlled, and is difficult to operate to a higher rotating speed and obtain a larger torque; when an outputshaft of the stepping motor bears a carrier with a certain weight and is driven to rotate, the stepping motor often needs to be started and stopped in the working process; in order to solve the problems that the output shaft is difficult to keep balanced when bearing an object, and the output shaft eccentricity of a carrier borne by the output shaft is caused in the rotating process, so that theoutput shaft cannot operate better, the stepping motor can keep a stable function in the moving process of the stepping motor; the stepping motor has the advantages that stability of the stepping motor in the moving process can be kept, resonance of the stepping motor is reduced; and meanwhile the stepping motor guarantees that the output shaft cannot be eccentric when the output shaft bears objects of different weights.

Owner:ZHEJIANG JEAMO MOTOR

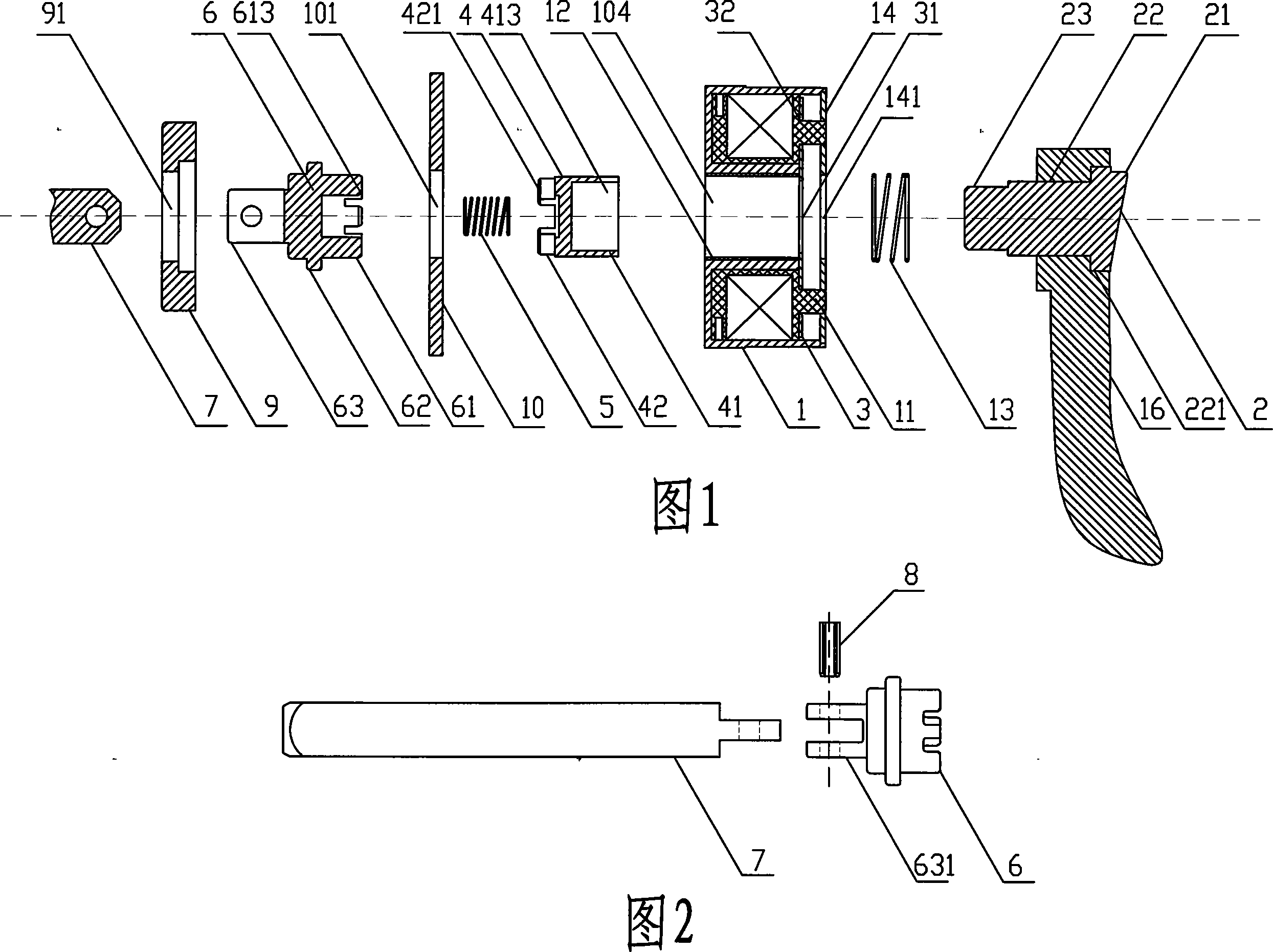

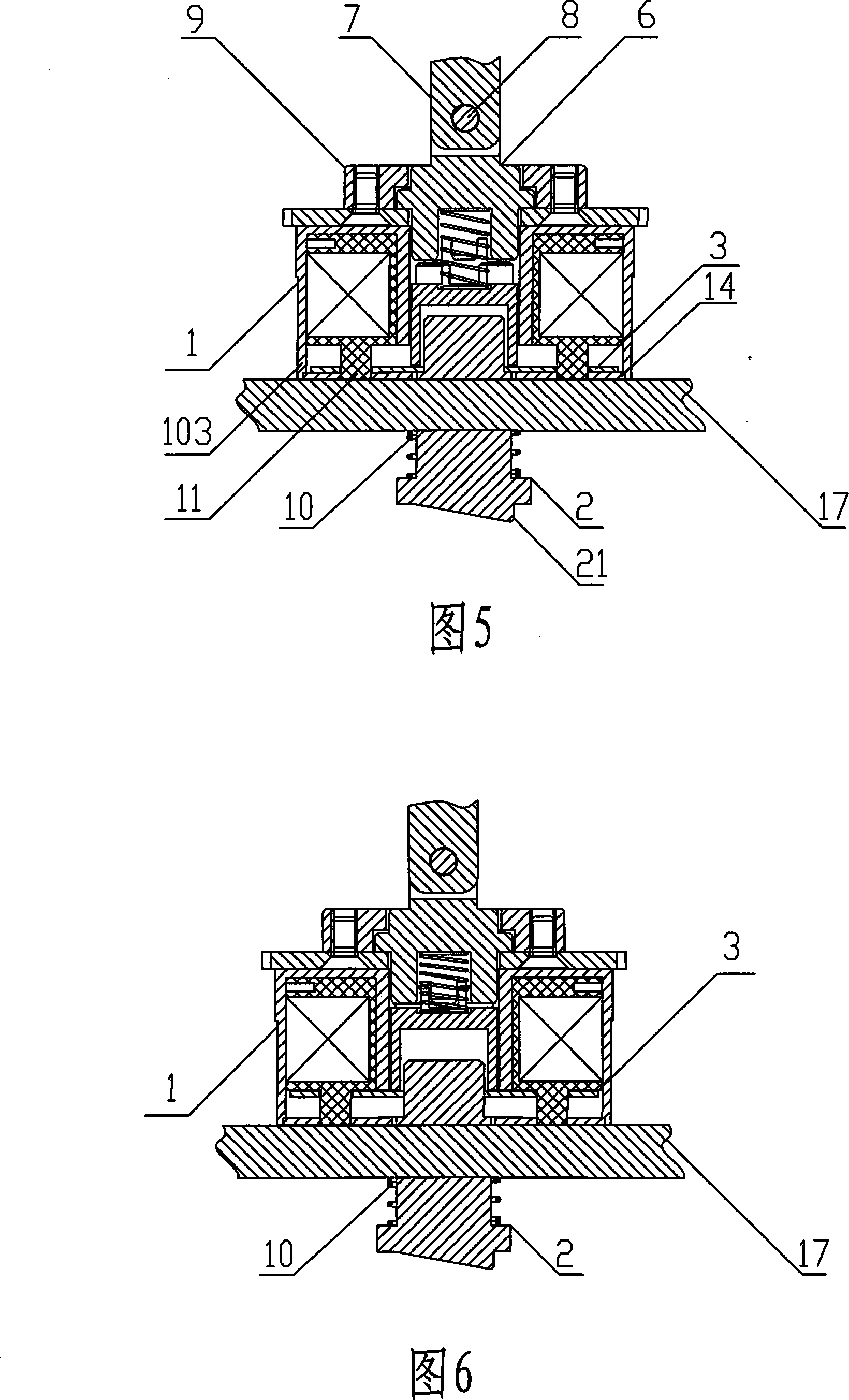

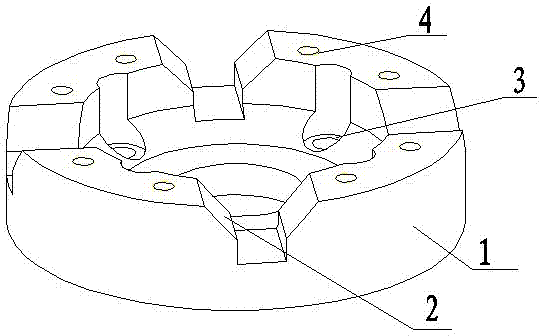

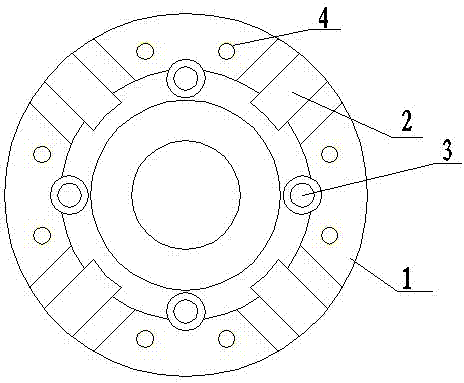

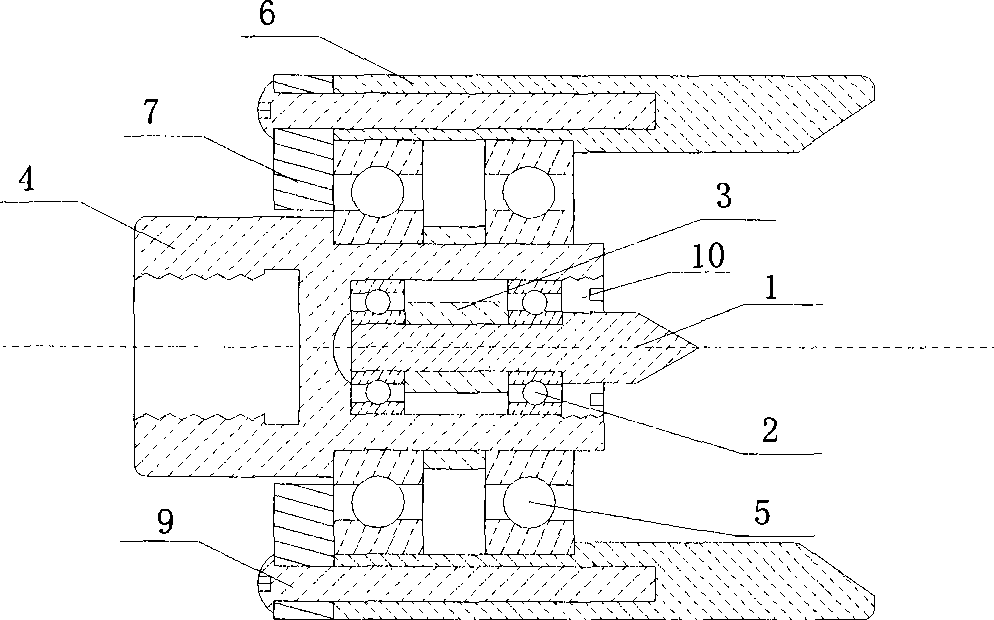

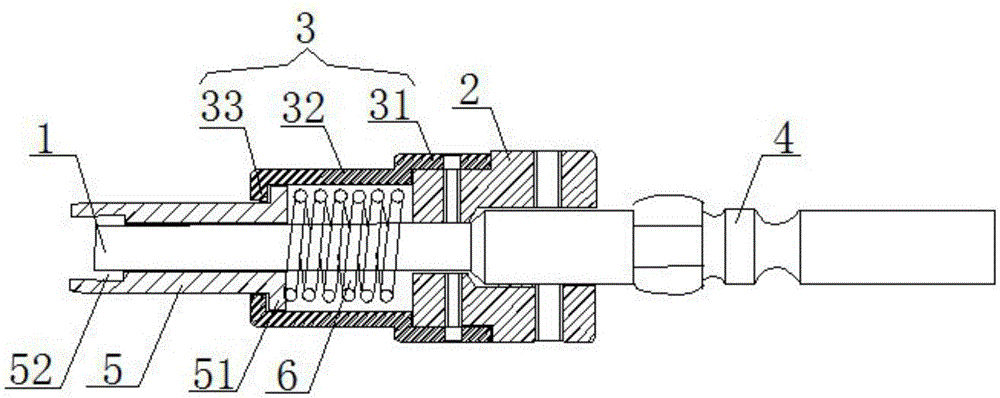

Clutch mechanism of electromagnetic lock

InactiveCN101182741AHave a positive effectHigh concentricityNon-mechanical controlsMagnetically actuated clutchesLocking mechanismElectromagnetic lock

The clutch mechanism of the electromagnetic lock consists of an electromagnet assembly, a push piece connected in sequence, a push piece return spring, a movable piece, a transmission piece, a transmission piece return spring, a square bar linkage block, and a square bar. A sliding shaft and a stopper are arranged on the top end surface of the electromagnet assembly, and the stopper is fixedly connected with the sliding shaft; the movable piece is slidably sleeved on the sliding shaft; the head of the transmission part is provided with a first blind hole cavity; the pushing part The protruding part of the main body passes through the central hole of the movable piece and fits into the first blind hole cavity of the transmission part, and the square rod linkage block is movably connected with the square rod, which facilitates the replacement and folding of the square rod. The clutch mechanism is mainly used in a dual-purpose electromagnetic lock that can be opened and closed mechanically and controlled by an electric circuit.

Owner:GUANGDONG ARCHIE HARDWARE

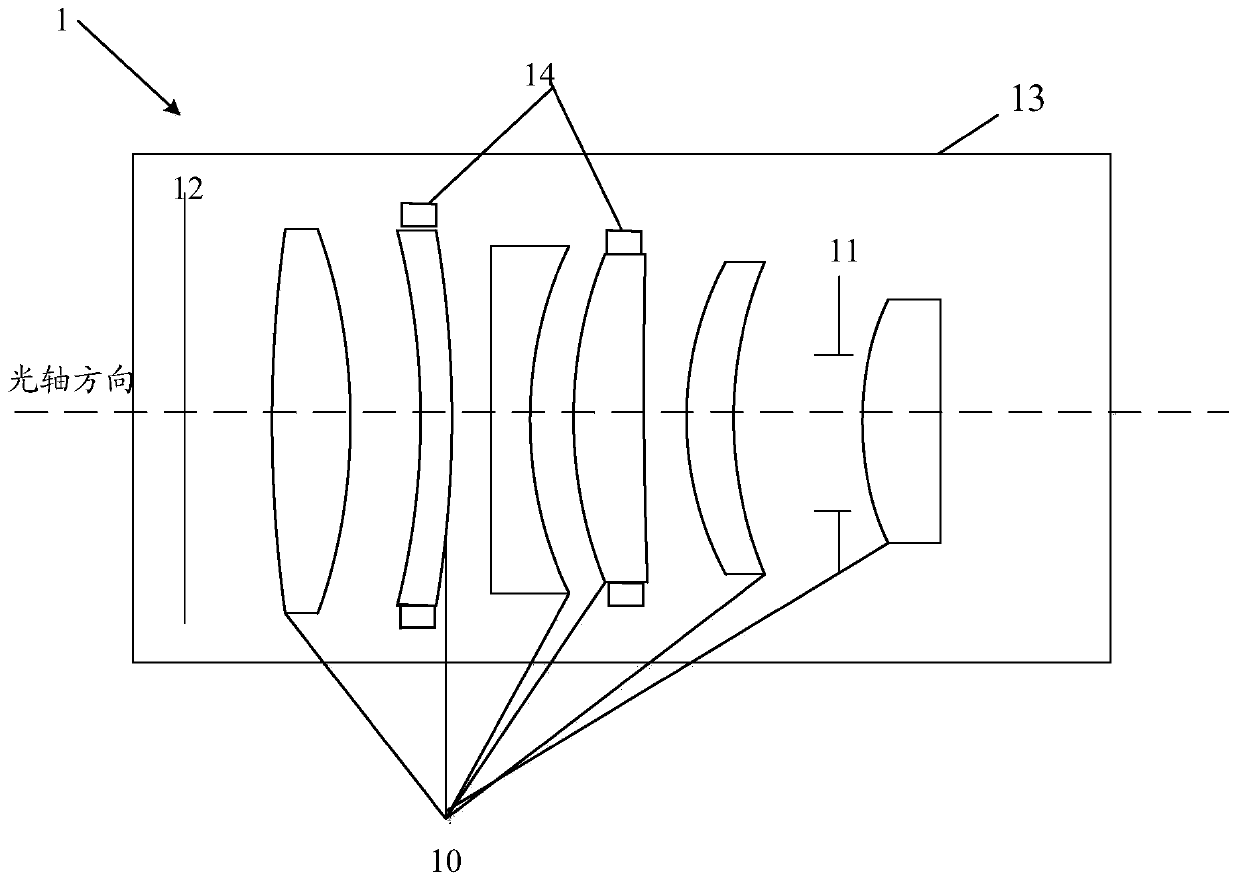

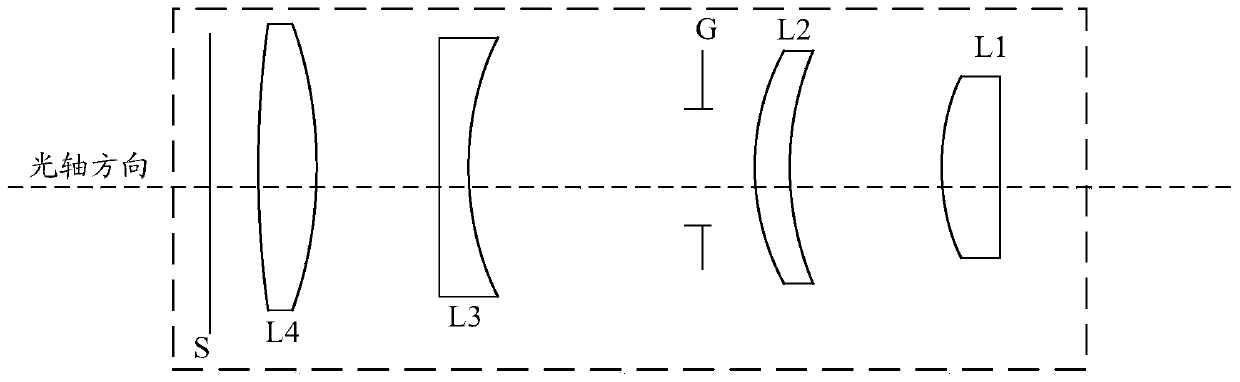

Zoom lens, zoom method, terminal and computer readable storage medium

The embodiments of the invention provide a zoom lens, a zoom method, a terminal and a computer readable storage medium. The zoom lens includes n lenses; the n lenses are successively arranged in an optical axis direction; n is a positive integer greater than or equal to 2; an aperture is arranged parallel to the n lenses in an optical axis direction; the aperture is arranged at the tail end of theoptical axis and parallel to the n lenses to form an image plane; the n lenses include m variable curvature lenses and n-m aspherical lenses; the top end and bottom end of each variable curvature lens of the m variable curvature lenses are provided with driving parts; m is a positive integer greater than 1 and less than n; by changing the power of the driving parts corresponding to the m variablecurvature lenses, the radiuses of curvature of the m variable curvature lenses are changed, and an incident angle is obtained; and after receiving incident light corresponding to an object space, under the action of a beam of light of the aperture, and through the n lenses, the incident light is reflected to the image plane to be an image at an incident angle.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

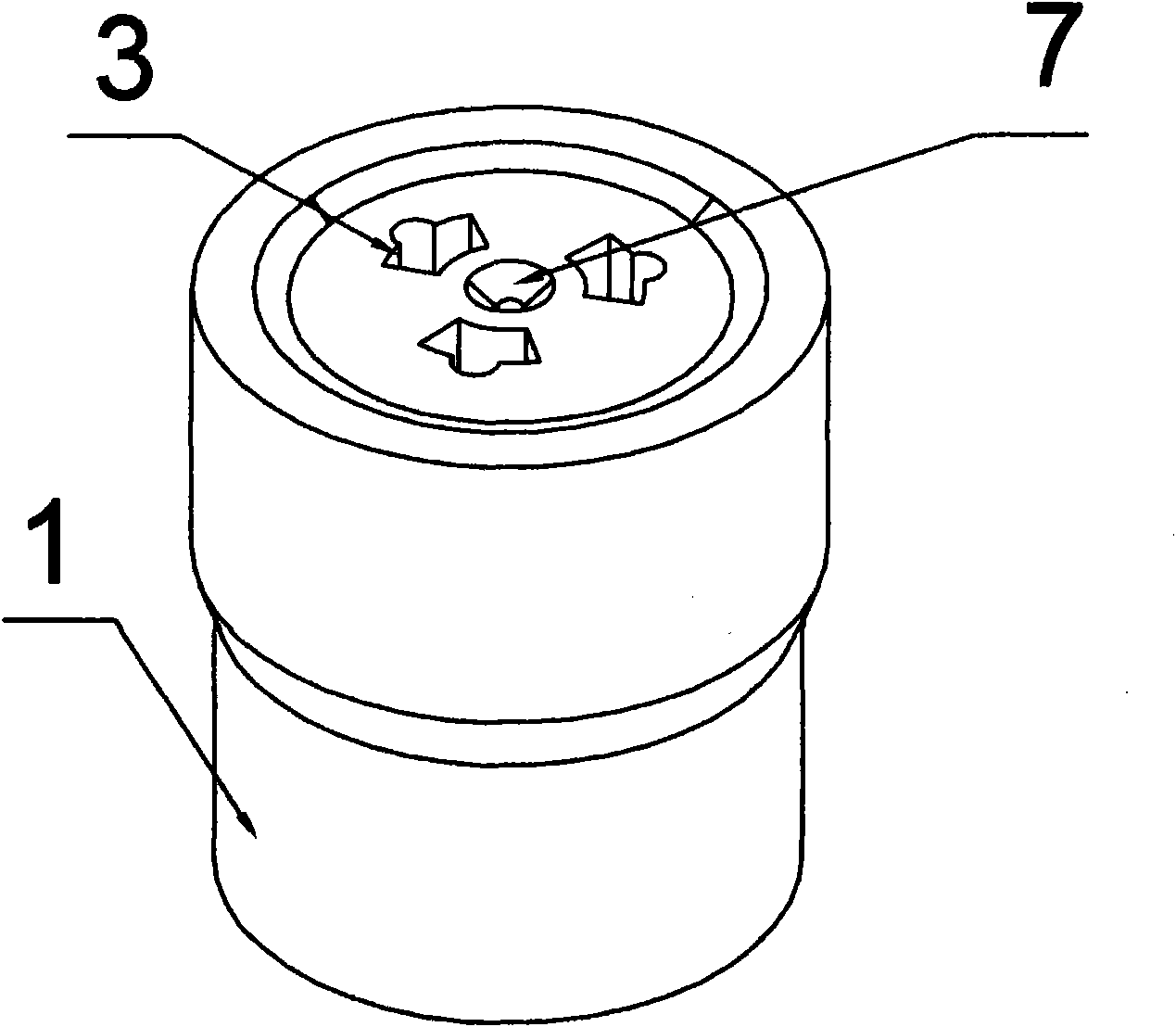

Cross axle processing clamp

InactiveCN102873570AGuaranteed accuracyGuaranteed service lifePositioning apparatusMetal-working holdersCounterboreBiomedical engineering

The invention discloses a cross axle processing clamp. The cross axle processing clamp comprises a clamp body (1), wherein the clamp body (1) is cylindrical; a screw hole (4) is formed in the upper surface of the clamp body (1); four V-shaped grooves (2) are symmetrically arranged on the clamp body (1) in the crossed direction; and a counterbore (3) is formed in the inner side of the clamp body (1). The processing clamp for cross axle turning solves the problem that the conventional cross axle rough lathing quality is difficult to control.

Owner:江国辉

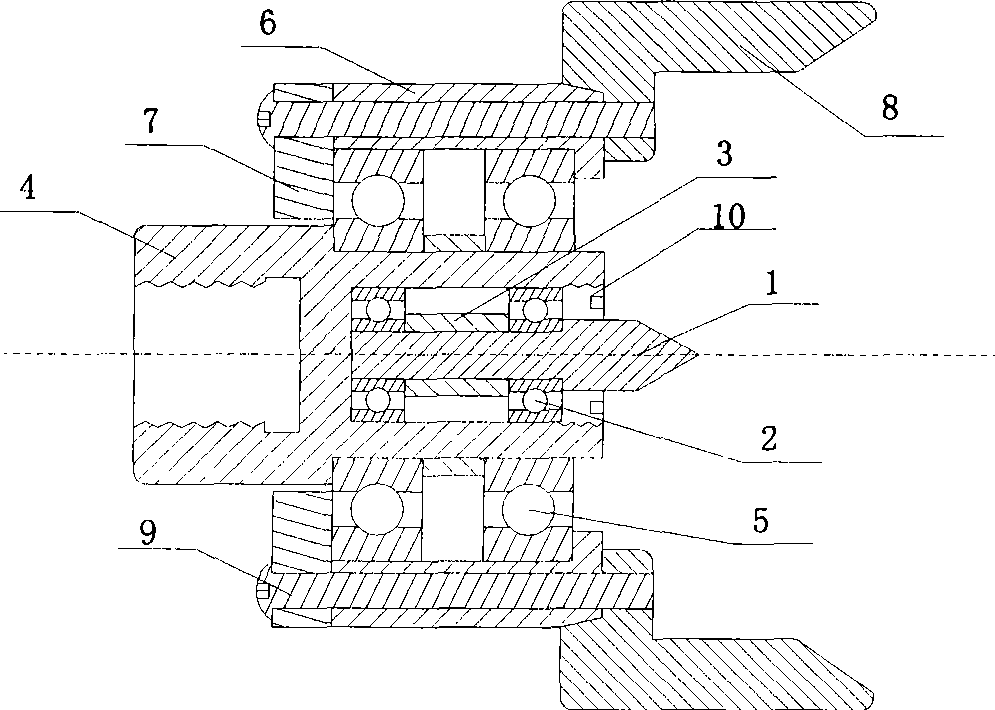

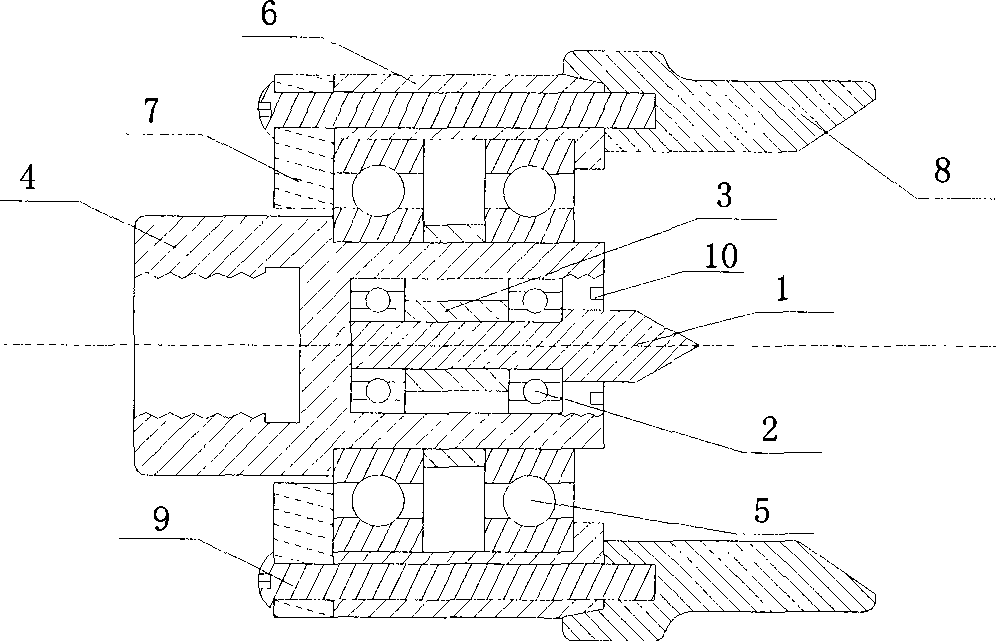

Rotation thimble

The invention discloses a rotation thimble which includes a center thimble, a middle bush and an out bush set on the center thimble. The rotation thimble has characteristics that: the rotation thimble is composed of the center thimble, a first bearing, a middle bush, a middle bush anti-dust cover, a second bearing, a first coat, a second coat, a first coat anti-dust cover and a fixing bolt; one end shaft body of the center thimble is equipped with two first bearings, one end of the center thimble and the first bearing are set in a cavity of one end of the middle bush, the shaft body on one end of the middle bush cavity is equipped with the second bearing, the middle bush is set on one end of the first coat, another end of the first coat is equipped with the second coat, one end of the second coat is equipped with a pipe socket. The rotation thimble has advantages that the rotation first coat and the second coat are added on the rotation thimble based on the prior rotation thimble; thesecond coat of the rotation thimble can noose one end of a processing workpiece tightly in process of the rotation thimble closing and tightening a wooden workpiece, then, the center thimble closing and tightening which can not occur workpiece eccentricity and increase the processing workpiece quality.

Owner:海门嘉濠建材贸易有限公司

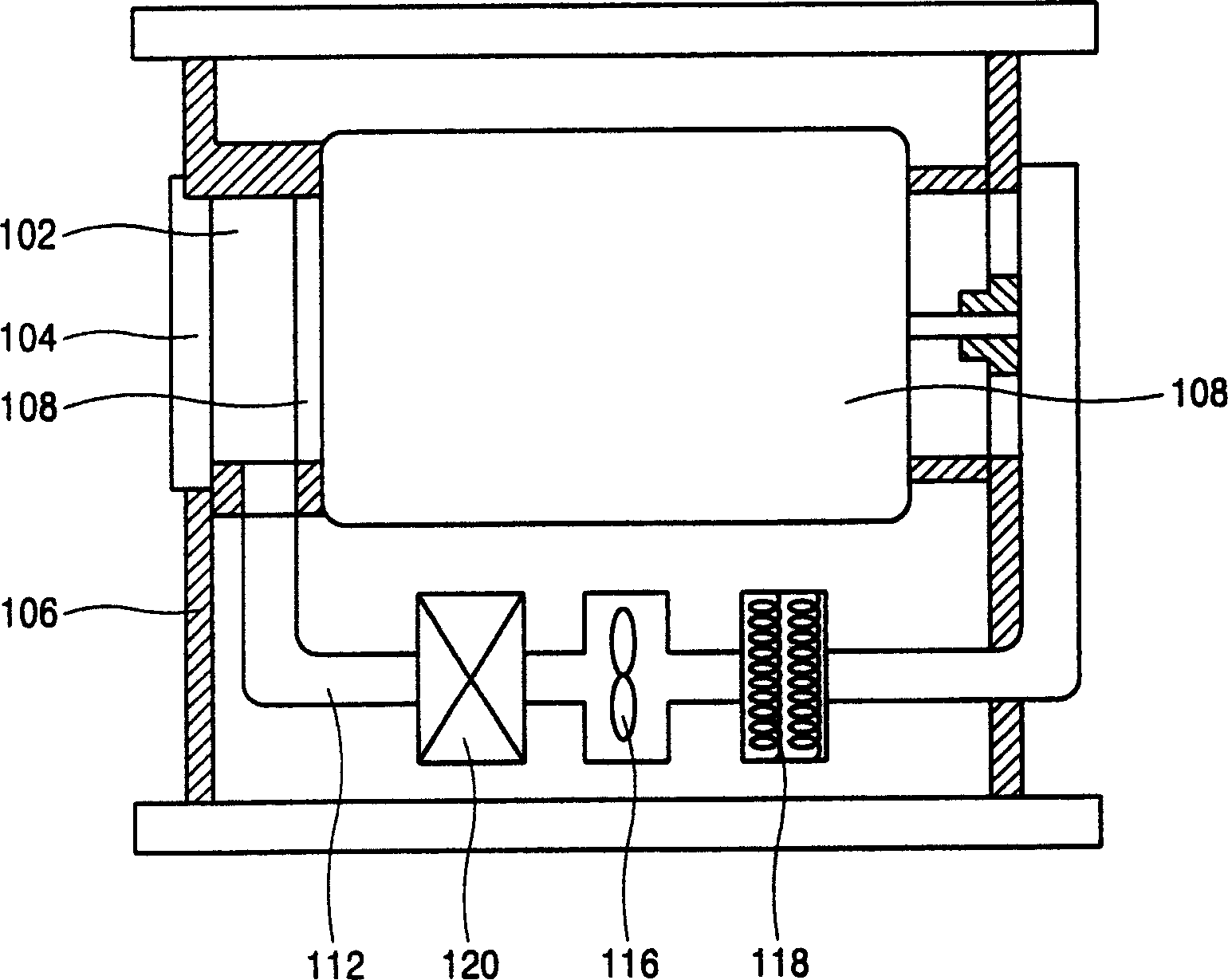

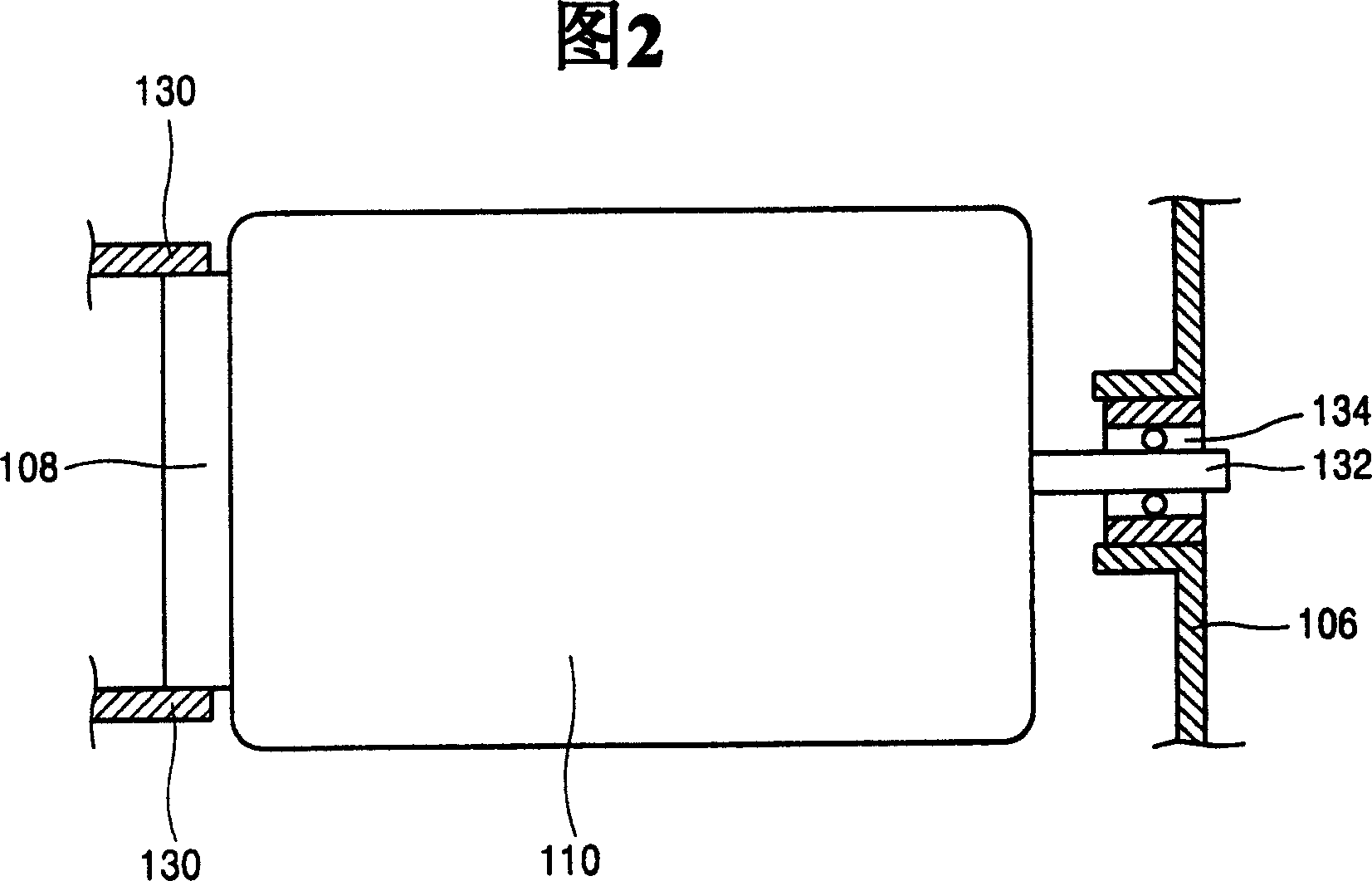

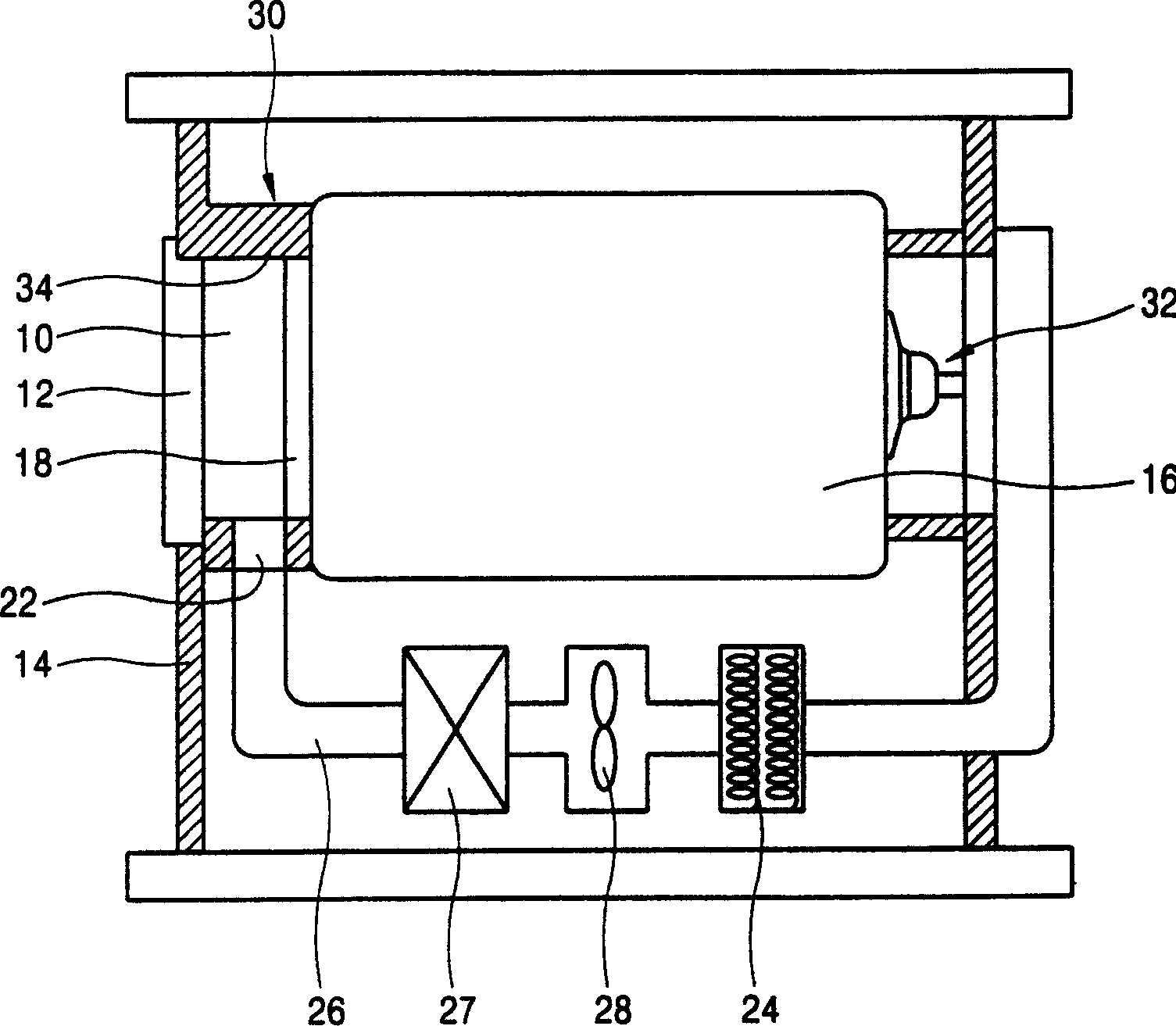

Hinge apparatus of drum for clothing dryer

InactiveCN1580378ASmooth rotationNo eccentricityOther washing machinesTextiles and paperEngineeringMechanical engineering

A hinge apparatus of a drum for a clothing drier includes a front hinge portion formed between a front of a case and a front of a drum, for rotatably supporting the front of the drum; and a rear hinge portion installed between a rear of the case and a rear of the drum, and for supporting the rear of the drum so as to swing in vertical and horizontal directions, so that the drum can be smoothly rotated without being eccentric even in case that the center of rotation of the front of the drum is different from that of the rear of the drum, and also noise and vibration generated when the drum is rotated can be minimized.

Owner:LG ELECTRONICS INC

Mould structure of slender tubular product

InactiveCN102328406AGuaranteed positioning accuracyOffset positioning errorSurface fittingMechanical engineering

The invention provides a mould structure of a slender tubular product, which is used for ensuring the reliability in locating a slender mould core of a back mould, preventing a manufactured product from being eccentric, ensuring that the wall thickness of the product is even, and further enabling the product to meet the technical requirements. The mould structure of the slender tubular product comprises a front mould, a back mould, a tube body excircle mould core, a slender mould core and a fixed shaft sleeve, wherein a cavity among the front mould, the back mould, the tube body excircle mould core and the slender mould core is a diccavity; the fixed shaft sleeve is sleeved on the excircle surface at the middle-lower part of the slender mould core; and the bottom of the slender mould core is tightly fixed on a fixed plate. The mould structure of the slender tubular product is characterized in that a gap between the fixed shaft sleeve and the slender mould core is internally provided with a steel ball liner in a filling manner, the steel ball liner is sleeved on the excircle surface of the slender mould core, and the outer surface of the steel ball liner is attached to the inner circle surface of the fixed shaft sleeve.

Owner:VANGUARD TECH WUXI

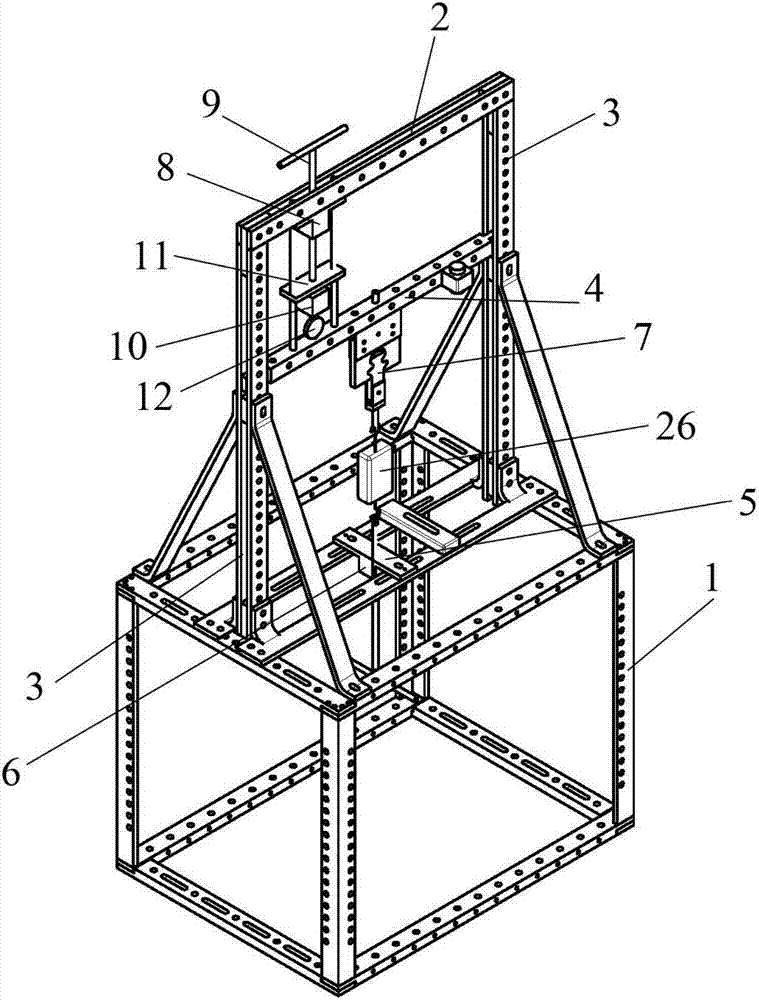

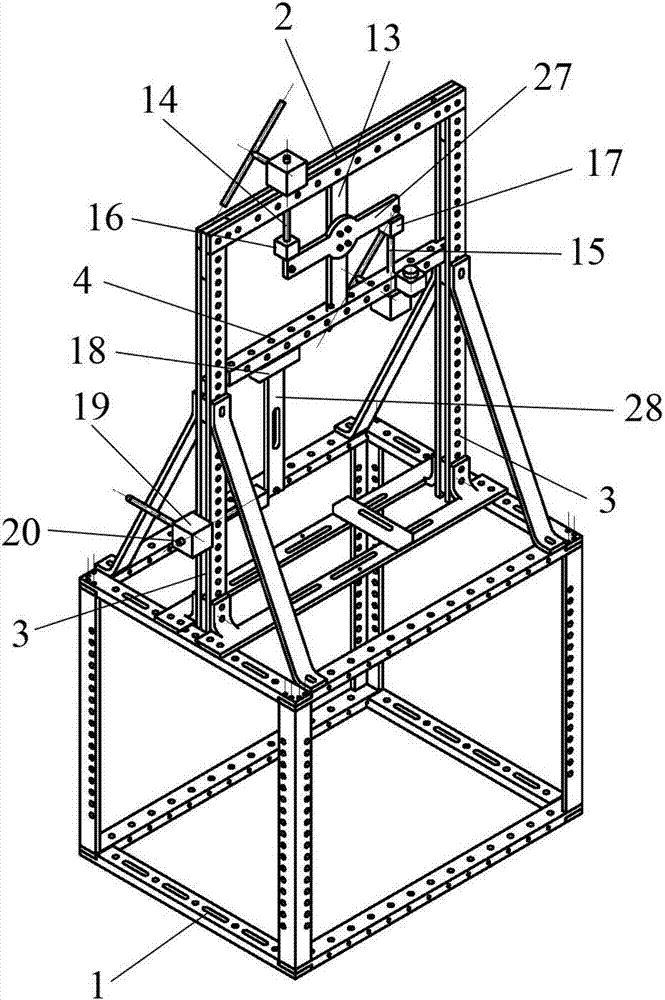

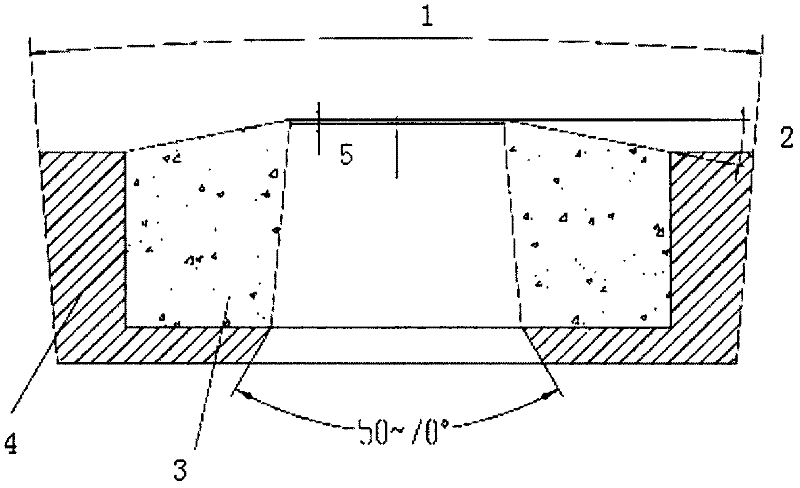

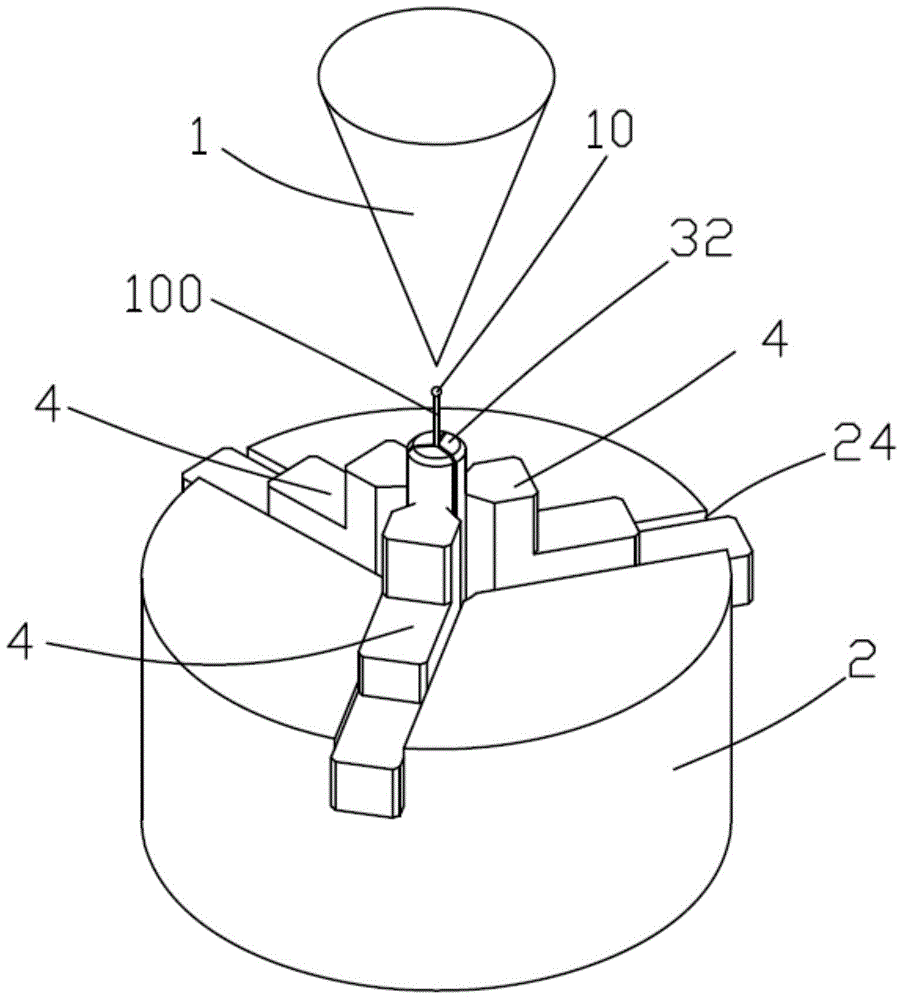

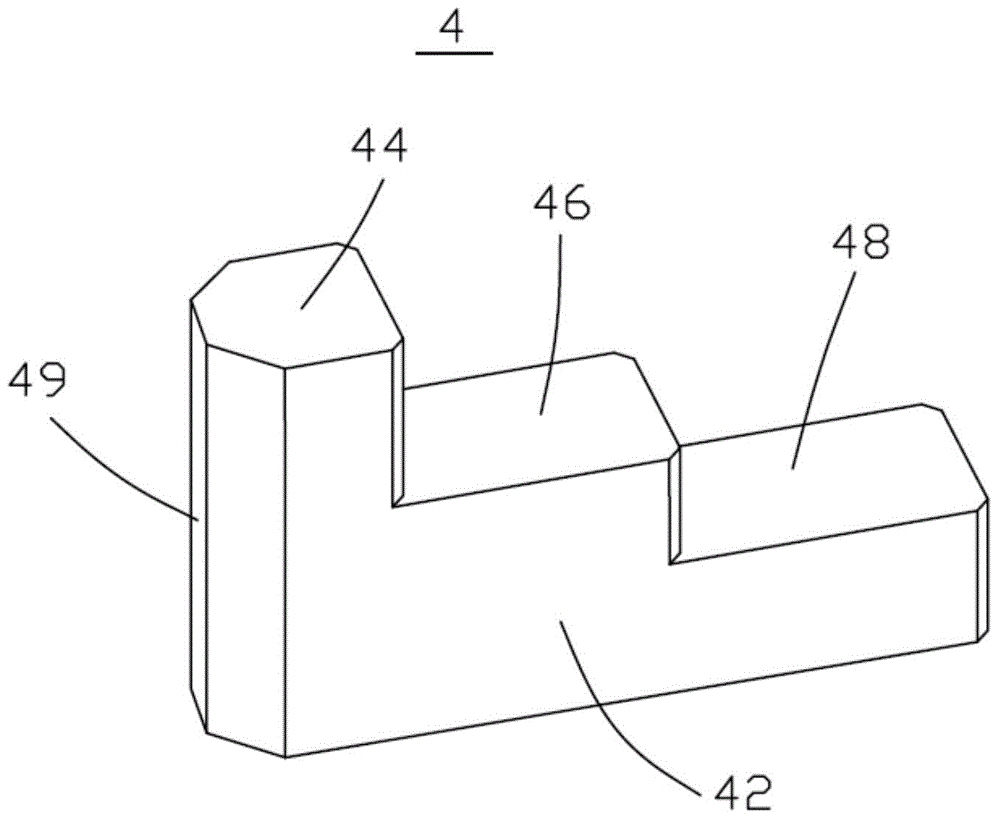

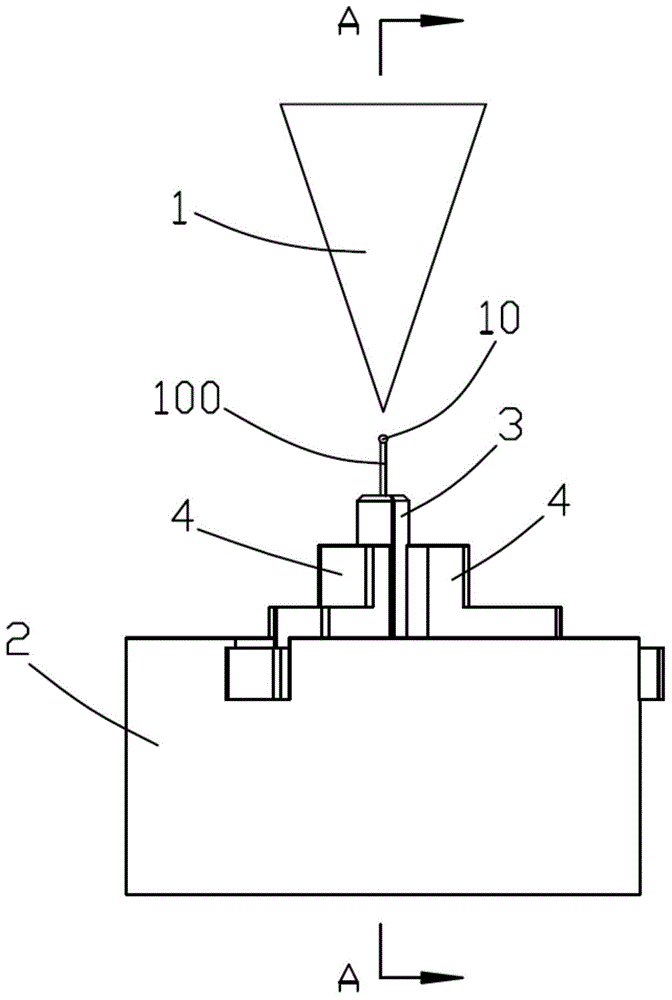

A photosensitive resin model loading device

ActiveCN107101874ANo eccentricityNo partial loadMaterial strength using tensile/compressive forcesEngineeringForce sensor

A photosensitive resin model loading device is provided. The device includes a basic unit, a tensile loading unit, a pressure loading unit and a calibrating unit. The basic unit includes a pedestal, a frame and a supporting bar. The frame includes a top cross beam and two vertical arms. The two vertical arms are vertically fixed to the pedestal. The top cross beam is fixedly and horizontally connected to the two vertical arms. The supporting bar is horizontally disposed between the two vertical arms. The tensile loading unit is disposed between the supporting bar and the pedestal in a detachable manner, and includes a connector, a tensile loading base, a tensile screw and a tensile force sensor. The pressure loading unit is disposed between the supporting bar and the top cross beam in a detachable manner, and includes a pressure loading base, a pressurizing screw, a pressurizing force sensor and a limiting plate. The calibrating unit is disposed on the basic unit and is used for measuring levelness and perpendicularity changes of the basic unit.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

Construction method of ultra-large-span double-high-vanadium-cable curved surface beam string

PendingCN113431186AReliable structureSolid foundationExtraordinary structuresBuilding material handlingStructural systemStructural rigidity

The invention provides a construction method of an ultra-large-span double-high-vanadium-cable curved surface beam string. The construction method comprises the steps that simulation analysis and checking calculation are conducted on the construction process before construction, and the beam string is segmented and sectioned through the BIM technology, and model selection is conducted on hoisting equipment; the beam string is machined in a factory and then transported to the site in a spare part mode to be spliced, and thus transportation is convenient; and a corresponding supporting jig frame is arranged, a large-tonnage crane is arranged to conduct high-altitude segmented hoisting on the beam string, construction simulation calculation is conducted on the tensioning process before double-high-vanadium-cable tensioning construction, synchronous monitoring is conducted during construction, and thus tensioning force in the whole tensioning process is controlled. The situation that the structural rigidity of a beam string structural system is weak before prestressed steel cable tensioning construction is solved, and through synchronous tensioning of double high vanadium cables, the problems that stress secondary distribution in the prestressed cable tensioning process, structural deformation caused by prestressed cable tensioning construction and the influence on the mounting quality are prevented.

Owner:中建五局第三建设有限公司

Telescopic screwdriver head

InactiveCN105538213ANo eccentricityImprove assembly and installation efficiencySpannersWrenchesArchitectural engineering

Owner:WUHAN WEILIKE TECH

Method for performing surface peeling processing to superconducting composite bar

The invention relates to a method for performing surface peeling processing to superconducting composite bar, which is characterized in that extruded bars are straightened on a linear broaching machine before peeling so as to ensure no eccentricity in the follow-up surface peeling process. A hard alloy peeling mould is adopted, the shape of the hard alloy peeling mould is a tapered structure and matched with a tapered hole of a broaching machine mould base, thereby guaranteeing concentricity in the peeling process, controlling cutting edge angles to be in a range of 10-15 degrees and controlling cutting edge length to be in a range of 1-3mm. The peeling amount for each time is controlled in a range of 0.1-0.5mm, thereby preventing overlarge peeling thickness from blocking a peeling mould inlet copper sheet and scratching the bar surface. Simultaneously, when matrix materials and superconducting materials in the superconducting composite bars are required to be adjusted according to design requirements of superconducting composite conductors, the purpose can be achieved by implementing the method.

Owner:西部超导材料科技股份有限公司

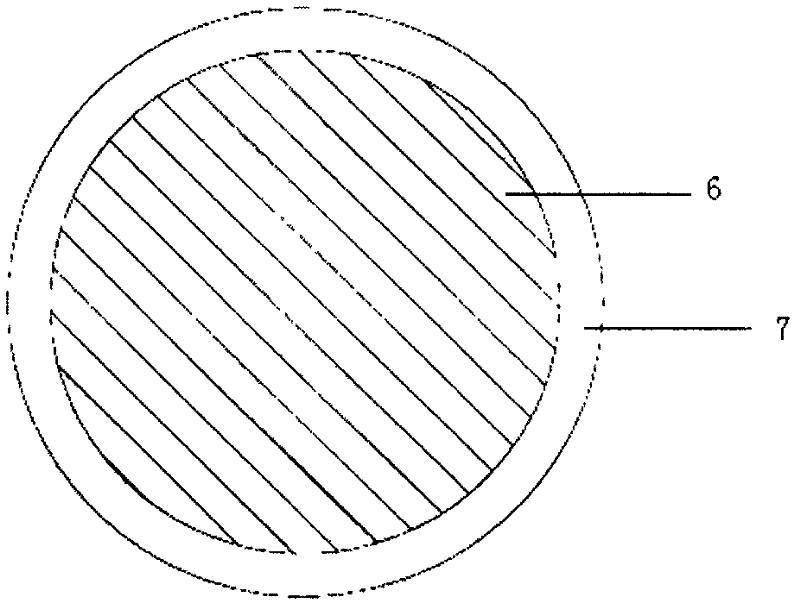

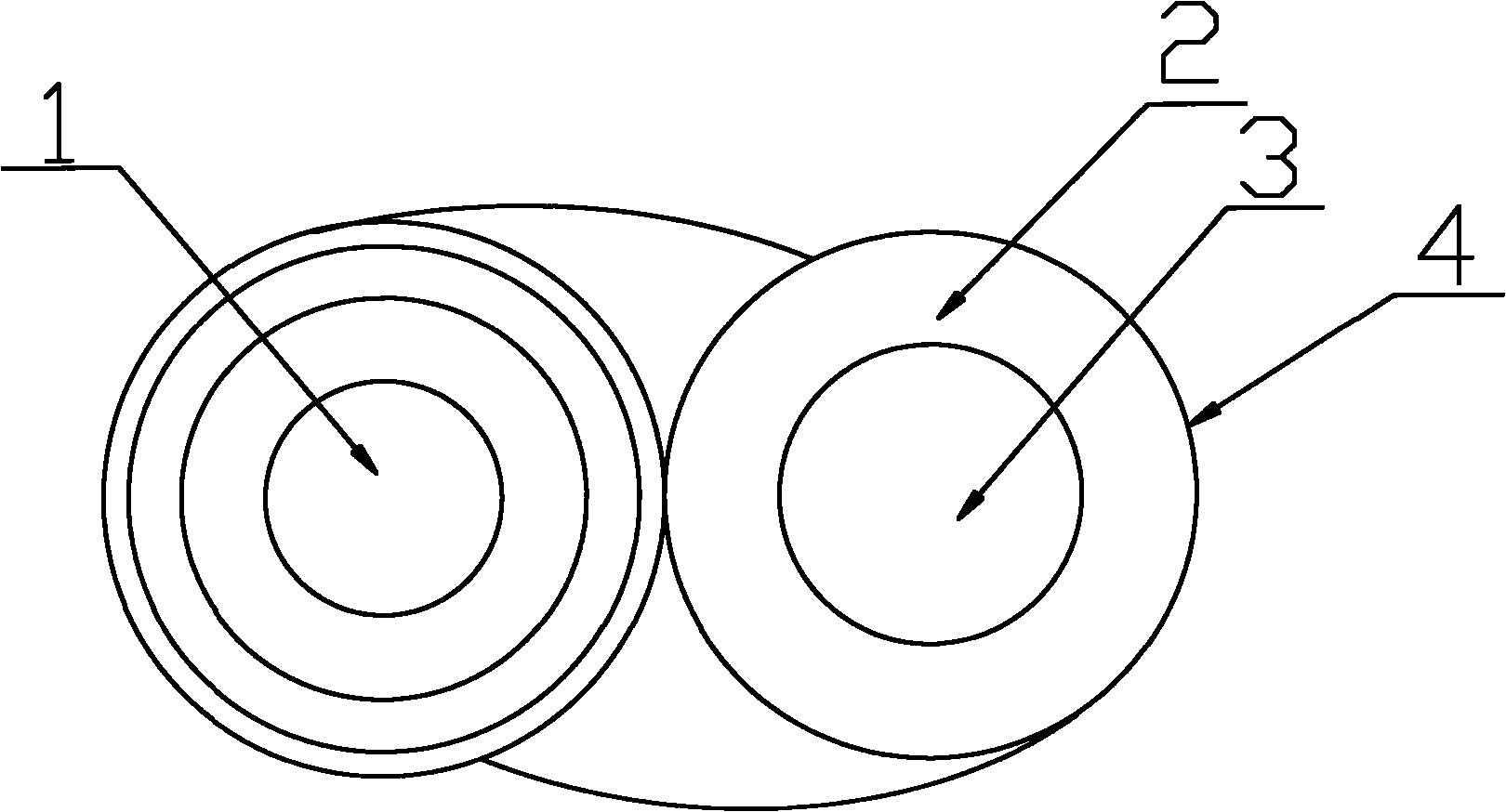

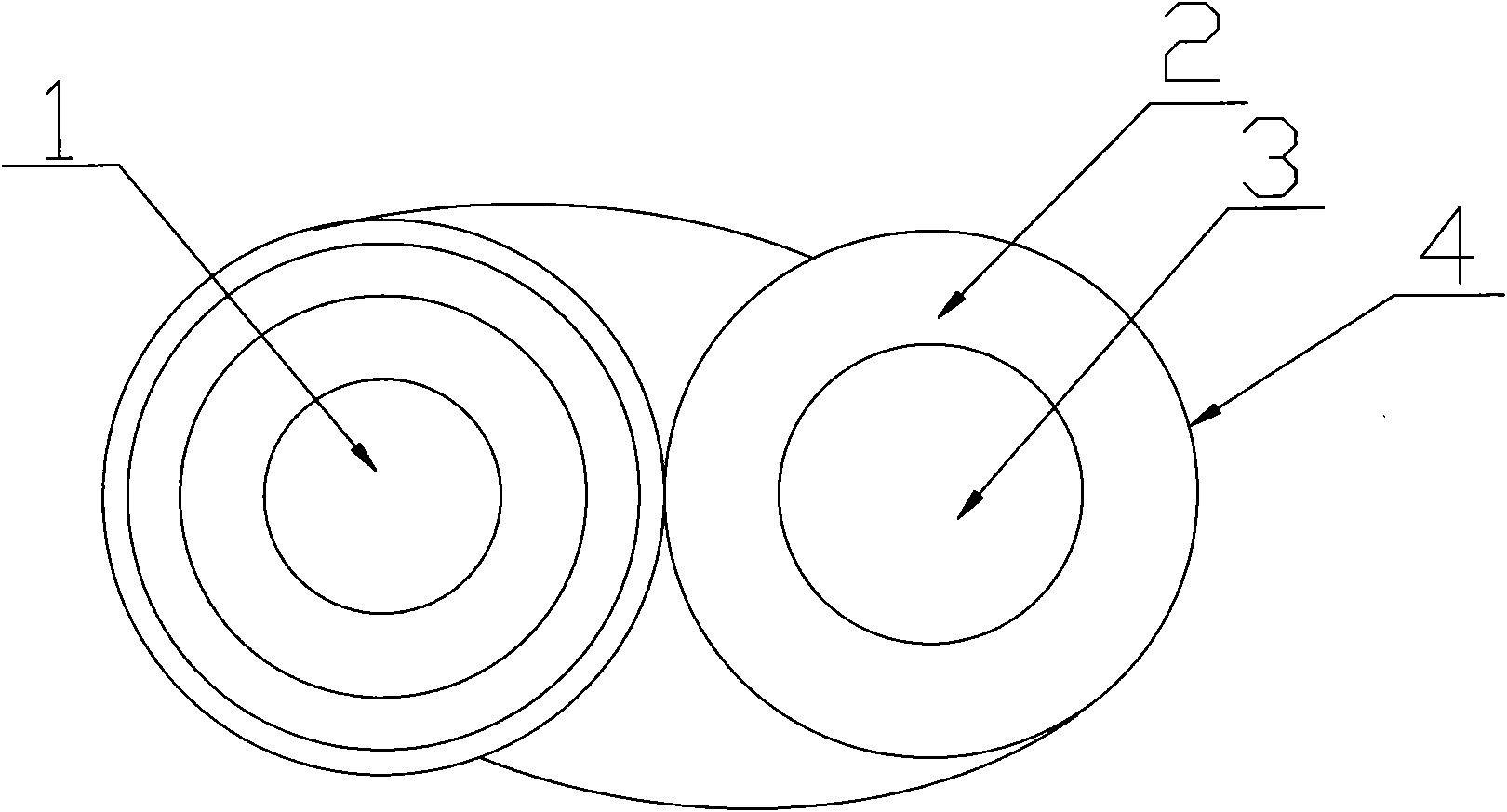

Intelligent composite material core wire and preparation method thereof

ActiveCN105825945AReasonable structural designHigh temperature resistantNon-insulated conductorsPower cables including optical transmission elementsCarrying capacityAging resistance

The invention discloses an intelligent composite material core wire and a preparation method thereof. The intelligent composite material core wire includes a composite material core (1) and single conductor wires (2) stranded at the periphery of the composite material core (1), wherein the composite material core (1) or the single conductor wires (2) are internally provided with optical fibers (3) or optical fiber protection pipes (4) for communication or monitoring; and the optical fibers (3) are arranged in the optical fiber protection pipes (4). The preparation method of the intelligent composite material core wire includes the steps of preparing the composite material core and stranding the single conductor wires (2) at the periphery of the composite material core (1). The preparation method of the intelligent composite material core wire has the advantages of being high in operability, being higher in production efficiency, being able to save a lot of manpower and material resources, and being low in production cost; the prepared composite material core has the advantages of being high in linearity and roundness, having no bending, being high in color consistency, being high in intensity, being long in the service life, having no eccentricity, and being high in aging resistance; and the prepared intelligent composite material core wire has the advantages of being higher in the wire compactness and filling rate, being resistant to high temperature, being high in current-carrying capacity and being small in sag.

Owner:ZHONGFU CARBON FIBER CORE CABLE TECH

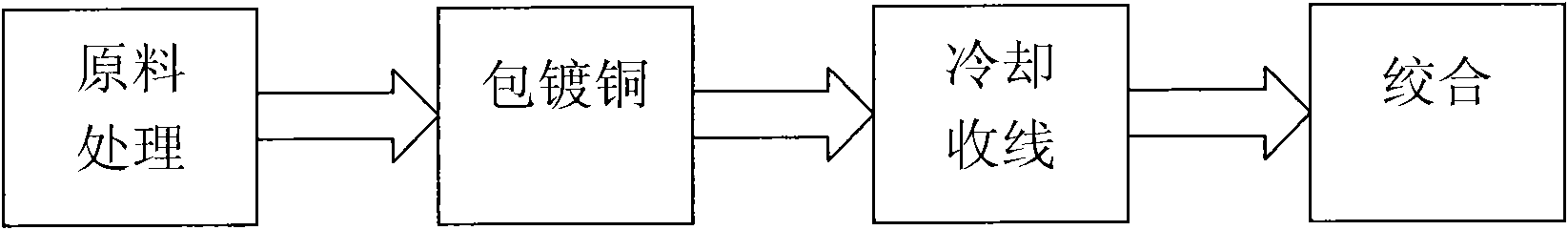

High-capacity copper-clad steel composite optical cable for fusion of three nets and production method thereof

InactiveCN101814342AReduce pollutionNo eccentricityNon-insulated conductorsCommunication cablesHigh carbonCooling chamber

Owner:ZHANGJIAGANG CITY YONGJIN CABLE

Yarn cone base

The invention discloses a yarn cone base. The yarn cone base comprises a yarn cone inner core, a yarn cone chassis, a rhombus regulating frame and a yarn cone locating part, wherein the yarn cone inner core comprises a first inner core and a second inner core which are used for supporting and fixing a yarn cone, and regulating rods are arranged inside the first inner core and the second inner core; the yarn cone chassis is provided with a first groove hole and a second groove hole which are distributed in a perpendicular intersecting mode, and the two regulating rods can slide in a reciprocating mode in the first groove hole; the included angel between every two adjacent rigid edges of the rhombus regulating frame is adjustable, and two opposite angle points of the rhombus regulating frame are connected with the two regulating rods respectively; the yarn cone locating part is used for fixing the relative positions of the yarn cone inner core and the yarn cone chassis. According to the scheme, stepless regulation of the outer diameter of the yarn cone inner core is achieved by adopting the rhombus regulating frame, so that the first inner core and the second inner core move by the same distance in a facing or opposite mode in a regulating process, and eccentricity can not occur. In addition, the yarn cone can be supported tightly so that radial shaking of the yarn cone can not be caused. Therefore, yarn cones with different diameters can be fixed, and yarns are more stable in an unwinding process.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST

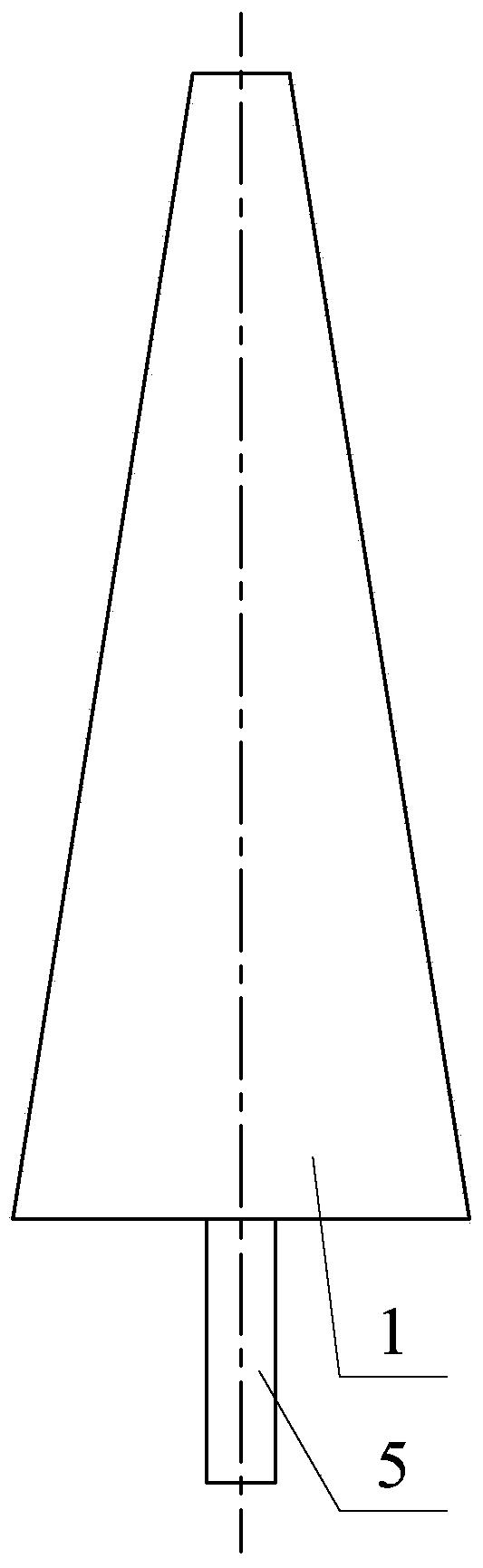

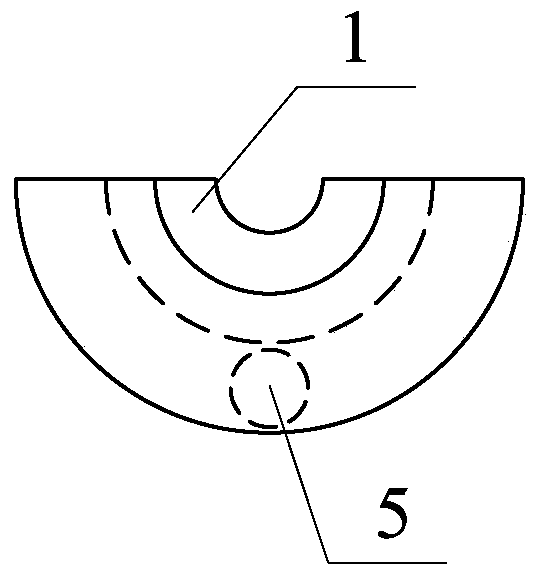

Laser welding device and method for melting ball on filament end face

ActiveCN104690424AImprove welding effectNo eccentricityWelding/cutting auxillary devicesAuxillary welding devicesHeat-affected zoneEngineering

The invention provides a laser welding device and method for a melting ball on a filament end face, wherein the device comprises a laser used for producing a laser beam, a circular truncated cone, a clamping piece used for clamping and fixing a filament, and a plurality of fixing blocks, wherein the clamping piece is vertically fixed in the center of the circular truncated cone, the plurality of fixing blocks are evenly distributed around the axis of the filament, are fixed on the circular truncated cone, and are abutted against the clamping piece, and the laser beam and the filament are coaxially arranged. The laser welding device and method guarantee that the melting ball is not eccentric when welded at the end part of a wire, the welding heat affected zone is small, no oxidation occurs after the welding, and the welding effect of the filament end face is effectively improved.

Owner:HANS LASER TECH IND GRP CO LTD

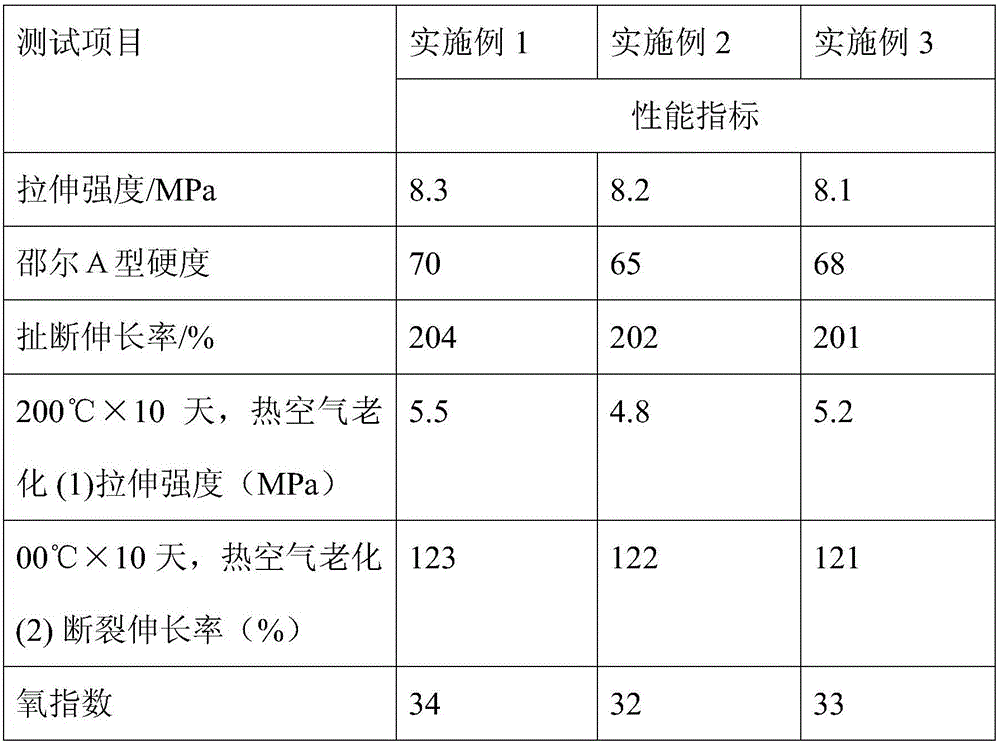

Fire-proof material for power cable

InactiveCN105885424AIntegrity guaranteedPrevent infiltrationRubber insulatorsInsulated cablesInsulation layerFumed silica

The invention discloses a fire-proof material for a power cable. The material is prepared from, by weight, 80-120 parts of silicon rubber, 40-50 parts of glass fibers, 15-30 parts of fumed silica treated with D4, 10-20 parts of fumed silica, 30-50 parts of mica, 15-25 parts of quartz powder, 3-5 parts of rutile titanium dioxide, 6-8 parts of coupling agent, 1-3 parts of dual vulcanizing agent 25, 3-5 parts of hydroxyl silicone oil, 4-8 parts of fire retardant and 3-5 parts of heat stabilizer. The fire-proof material has the performance identical to that of a common polymer at normal temperature, the material is the ceramization product has certain strength and can bear certain impact force, the completeness of the product can be kept, meanwhile, excellent machining performance is achieved, particles are even in size, therefore, the discharging amount is stable in the extruding process, it is ensured that an extruding insulation layer is even in thickness, and no decentration is generated.

Owner:ANHUI TIANYUAN CABLE

Vertical hot-dipping copper-clad high carbon steel wire machine

InactiveCN101760718ANo pollution in the processShort processHot-dipping/immersion processesProduction rateHigh carbon

A vertical hot-dipping copper-clad high carbon steel wire machine comprises a payoff rack, the high carbon steel wire sequentially threads through a straightener, a surface treating machine, a work furnace and a cooling chamber, and returns to a take-up rack via a traction wheel; the steel wire machine is characterized in that the steel wire machine also comprises the traction wheel for driving the high carbon steel wire to be upward vertically; the vertical hot-dipping copper-clad high carbon steel wire machine has small volume, low pollution, high productivity, short process and stable electrical conductivity; the produced copper-clad steel wires have consistent copper layer thickness and stable electrical conductivity, also overcome the defects of poor adhesive force and easy oxidation.

Owner:张家港市汇金电力材料有限公司

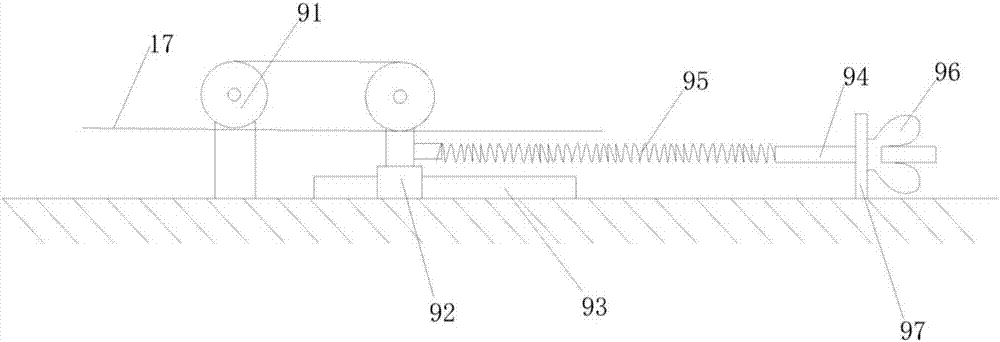

Chain tension automatic adjusting device of scraper conveyer

InactiveCN105059835AHigh adjustment accuracyReduce maintenance frequencyConveyorsLiquid pressureSprocket

A chain tension automatic adjusting device of a scraper conveyer comprises an adjusting hydraulic cylinder, a hydraulic stabilizing mechanism, a liquid inlet pipe connector, a liquid return pipe connector and a shutdown locking button. The adjusting hydraulic cylinder comprises a right cavity, a telescopic rod and a left cavity. The telescopic rod is connected with a chain wheel of the scraper conveyer. The chain wheel of the scraper conveyer is controlled to move leftwards and rightwards through stretching and retracting of the telescopic rod, so that a chain of the scraper conveyer is tensioned or loosened, and the tension of the chain is adjusted. The hydraulic stabilizing mechanism is connected with the right cavity of the adjusting hydraulic cylinder, the liquid inlet pipe connector and the liquid return pipe connector. Liquid is injected into or discharged from the right cavity through the liquid inlet pipe connector or the liquid return pipe connector, so that liquid pressure in the right cavity is kept in a set range, and accordingly the telescopic rod is controlled to stretch and retract. The chain tension automatic adjusting device can guarantee that the chain of the scraper conveyer always runs at optimal tension, the service life of the chain of the scraper conveyer is effectively prolonged, maintenance frequency is reduced, and maintenance strength is reduced. Besides, production efficiency of a fully-mechanized mining face is effectively improved.

Owner:TIANDI SCI & TECH CO LTD

Counterweight metal for exhaust valve of pressure cooker, special mould and manufacturing method

The invention relates to a counterweight metal for an exhaust valve of a pressure cooker, which comprises a counterweight metal body and a lug boss. Vent holes are reserved on the top wall of the counterweight metal body. The lug boss is positioned in the center of the top inner wall of the counterweight metal body and integrated with the counterweight metal body. A special mould for manufacturing the counterweight metal for the exhaust valve of the pressure cooker comprises an upper die, a middle die and a lower die. A method for manufacturing the counterweight metal for the exhaust valve of the pressure cooker comprises the following steps of: a, blanking, namely, arranging the lower die in a molding die cavity of the middle die, and loading a metal powder raw material into the molding die cavity; b, pressing, namely, performing downward stamping and pressure maintaining from the top by using the upper die to pressing-mold the metal powder raw material; c, die opening, namely, causing the upper die to return to a high original position; d, de-molding, namely, upwards ejecting a pressing-molded work piece out from the bottom by using the lower die; e, sintering; f, polishing; and g, vapor oxidation treatment. The exhaust valve adopting the counterweight metal body with the structure has stable performance and high sealing performance.

Owner:李文升

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com