High-capacity copper-clad steel composite optical cable for fusion of three nets and production method thereof

A technology of triple play and composite optical cable, which is applied in cable, communication cable, cable/conductor manufacturing, etc. It can solve the problems of low temperature resistance, poor corrosion resistance, short-circuit overheating, etc., and achieve high temperature resistance, long service life and short process flow , the effect of high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

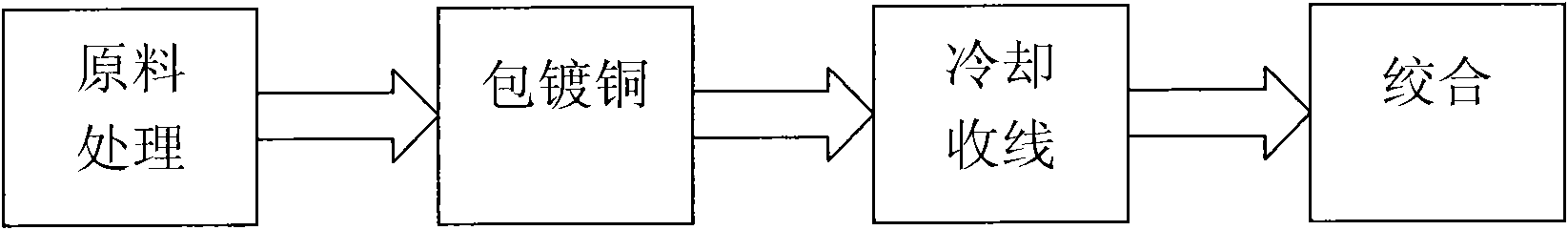

Method used

Image

Examples

Embodiment Construction

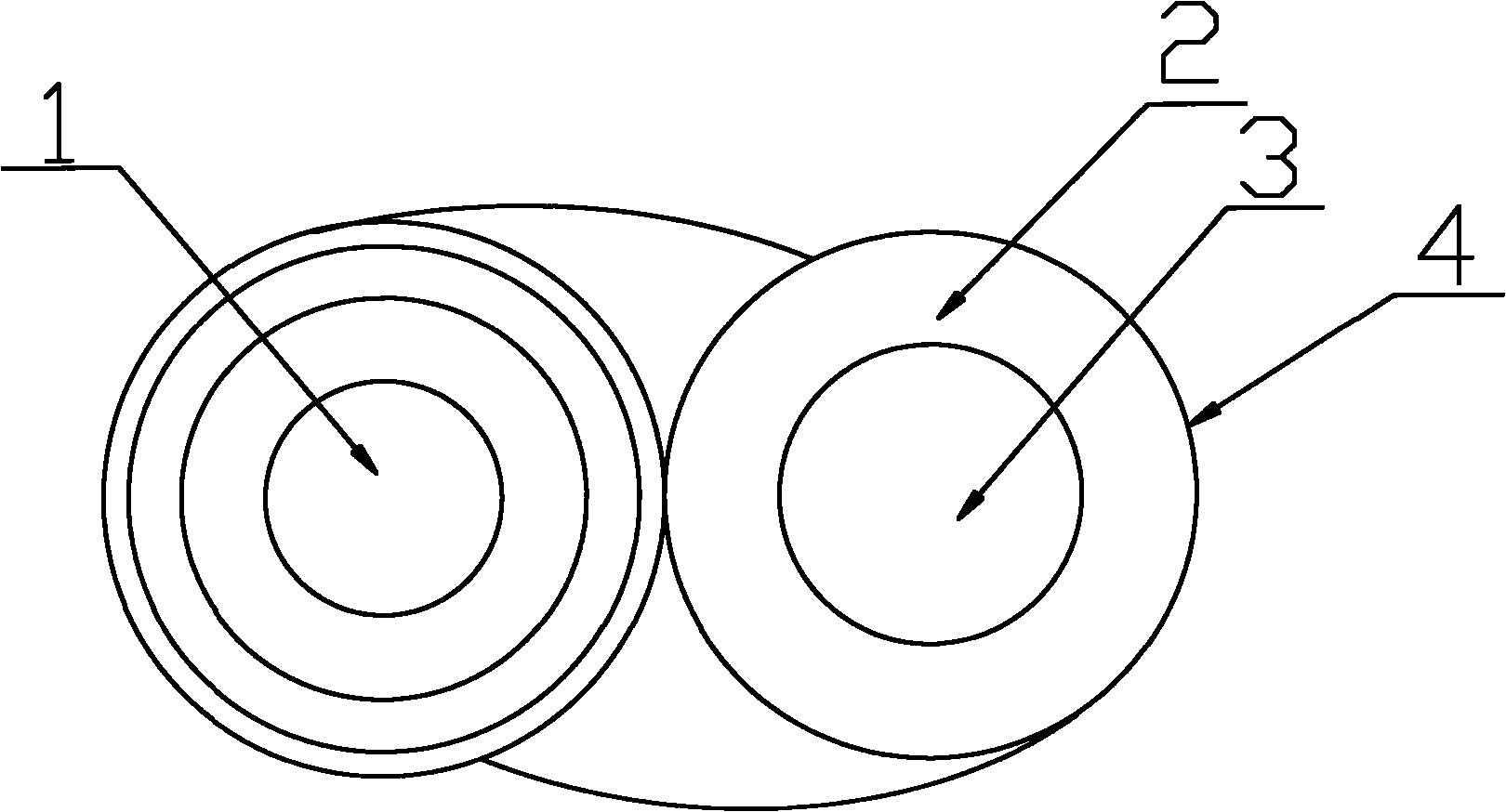

[0016] As shown in Figure 1, a large-capacity copper-clad steel composite optical cable for triple play, comprising an optical fiber tube 1 and a copper-clad steel wire 4, is characterized in that: the optical fiber tube 1 and the copper-clad steel wire 4 are twisted into a center Reinforcement core, the outer layer of the central reinforcement core is stranded by copper-clad steel wire 4 to form a conductive matrix, and the copper-clad steel wire 4 is composed of a hot-dipped copper layer 2 coated on a high-carbon steel core 3 .

[0017] This kind of composite optical cable is not limited by the safety distance to the ground and the crossover, it can truly realize the perfect integration of power transmission and optical fiber communication, improve the level of power grid automation and dispatch communication, and is a telecommunication network, computer network, and cable TV network through technological transformation. Provide comprehensive multimedia communication service...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com