Rotation thimble

A thimble and integrated technology, which is applied to woodworking lathes, wood processing equipment, manufacturing tools, etc., can solve the problems of workpiece rotation vibration, seam top cracking, and unsatisfactory results, and achieve the effect of convenient replacement and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

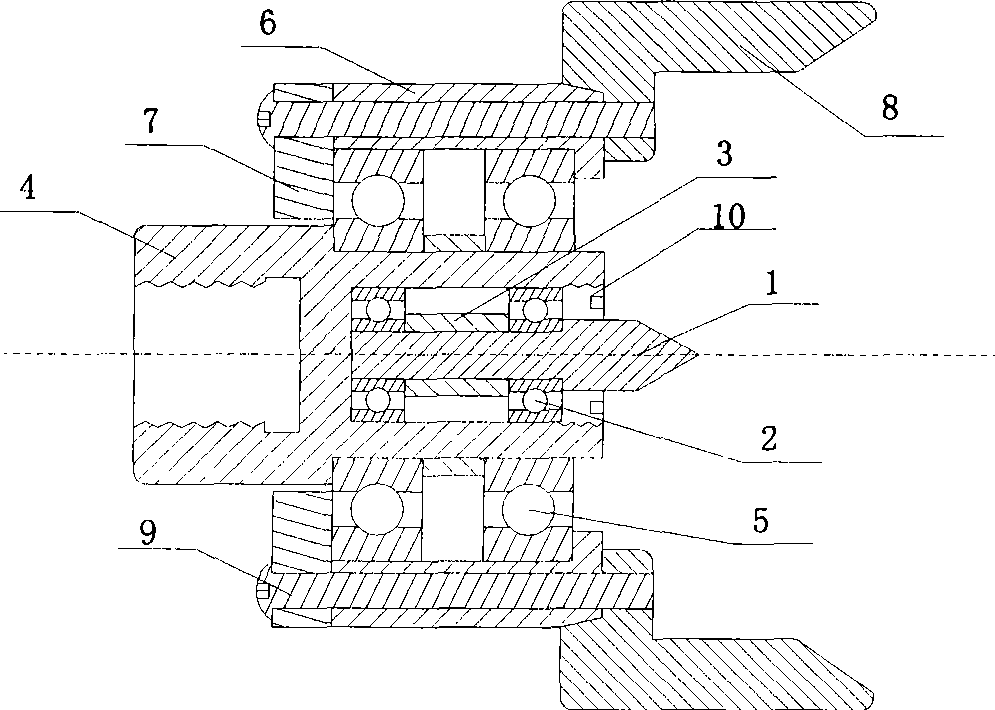

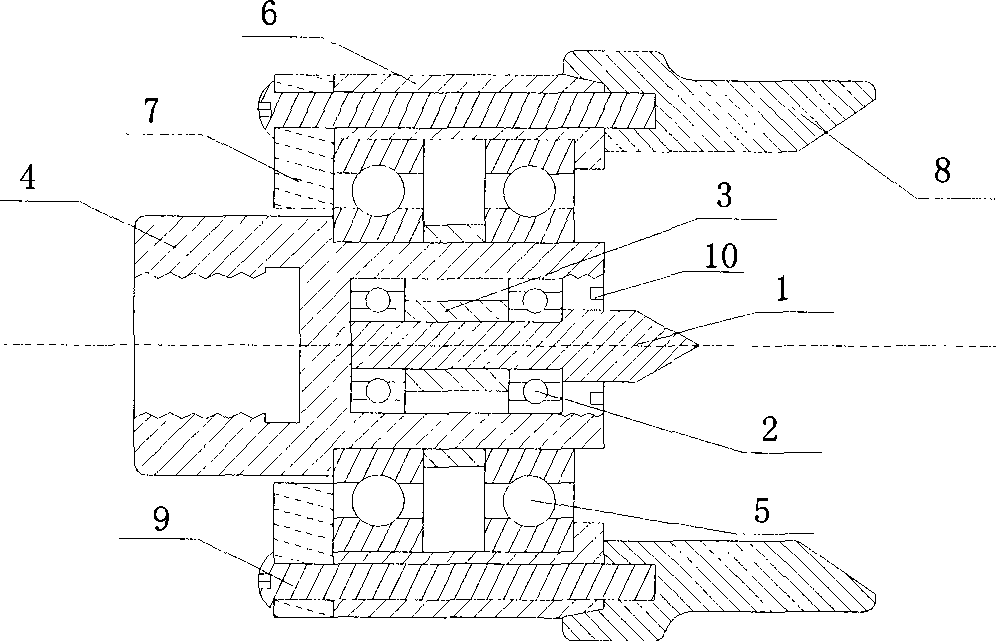

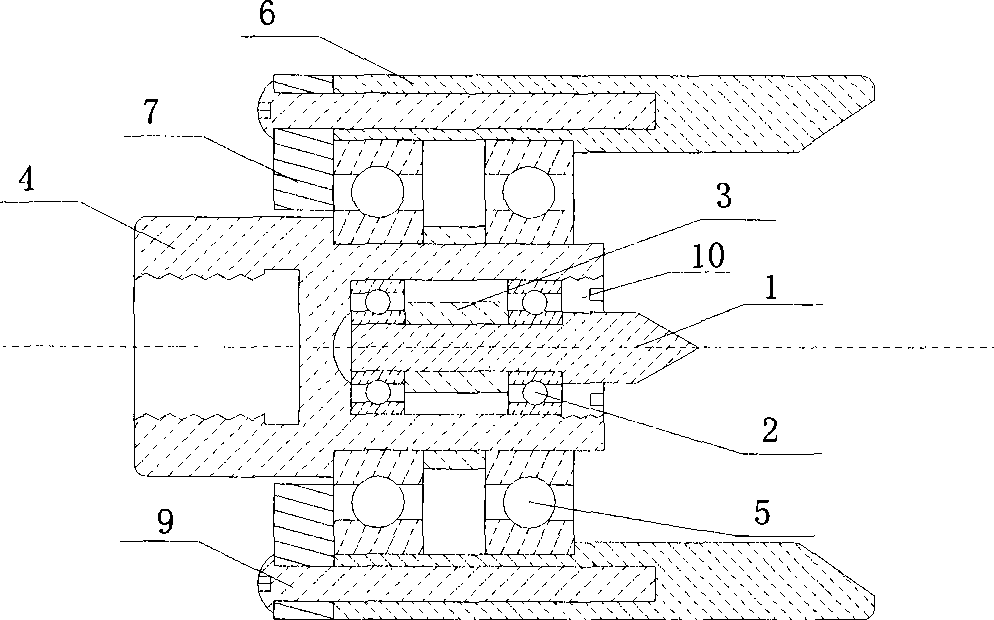

[0017] Implementation case: such as figure 1 As shown, a rotary thimble. At least two sets of first bearings 2 are arranged on the shaft including one end of the center thimble 1 , and an inner sleeve 3 for controlling the distance between the bearings is arranged between the first bearings 2 . The first bearing 2 is arranged at one end of the middle sleeve 4, and the other end of the middle sleeve 4 is provided with an internal thread. The middle sleeve 4 is provided with the first bearing 2 and one end of the center thimble 1 is provided with a middle sleeve dust cover 10 . At least two sets of second bearings 5 are arranged on the outer shaft body of the middle sleeve 4 . A first casing 6 is arranged outside the second bearing 5 . One end of the second bearing 5 in the first jacket 6 is provided with a jacket dust cover 7, the other end of the first jacket 6 is provided with a second jacket 8, and the tip of the center thimble 1 is shorter than that of the bell mouth o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com