Method for performing surface peeling processing to superconducting composite bar

A composite rod and peeling technology, which is applied in the field of surface peeling processing, can solve the problems of difficulty in controlling the uniformity of corrosion thickness, inability to obtain engineering practicality, and affecting volume ratio, etc. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

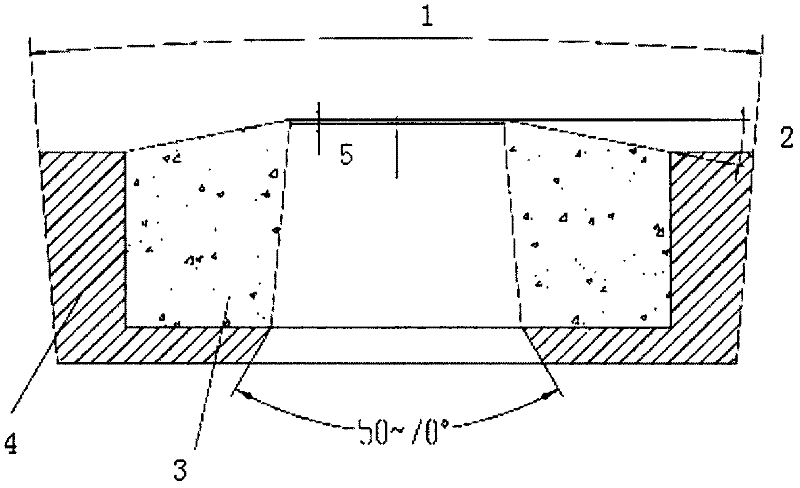

Embodiment 1

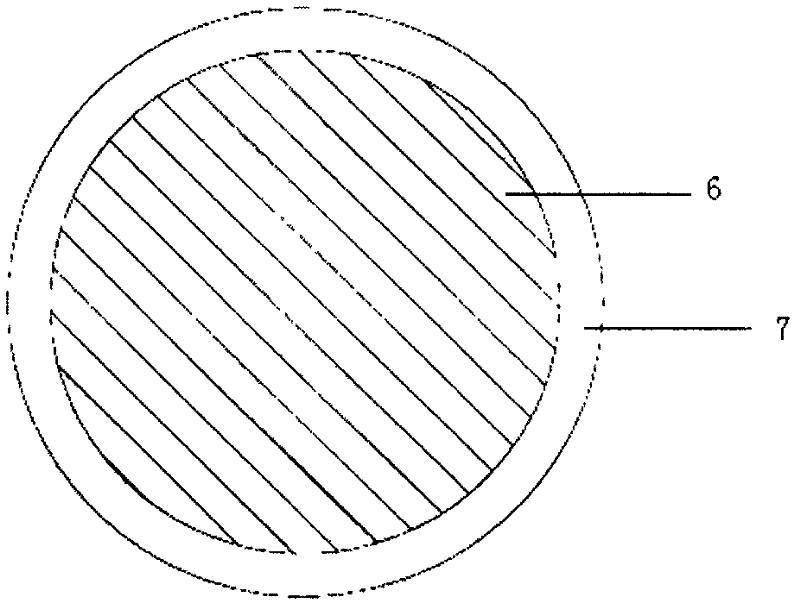

[0028] The extruded NbTi / Cu single-core composite rod has a diameter of Φ58mm and a length of 6m. The outer matrix material is oxygen-free copper with a thickness of 4.5mm. The cross-section is as follows figure 2 shown. The length of the pure copper upper and lower covers of the ingot is cut off before stretching, and the length is 5.5m. On a broaching machine, a Φ51.97mm round hole die is used for linear stretching and processing once. The stretching speed is 10m / min, and the die size is 51.97±0.05mm. , The bending degree of the bar is less than 2 / 1000. After stretching, a Φ51.18mm peeling die is used for peeling and stretching. The cutting edge angle of the peeling die is 10-15 degrees, and the peeling speed is 9m / min. After peeling, the diameter of the bar is 51.18±0.05mm, and the surface of the bar is smooth. There is no oxide layer or inclusions, which achieves the purpose of surface cleaning and will not cause any impact on the core NbTi alloy.

Embodiment 2

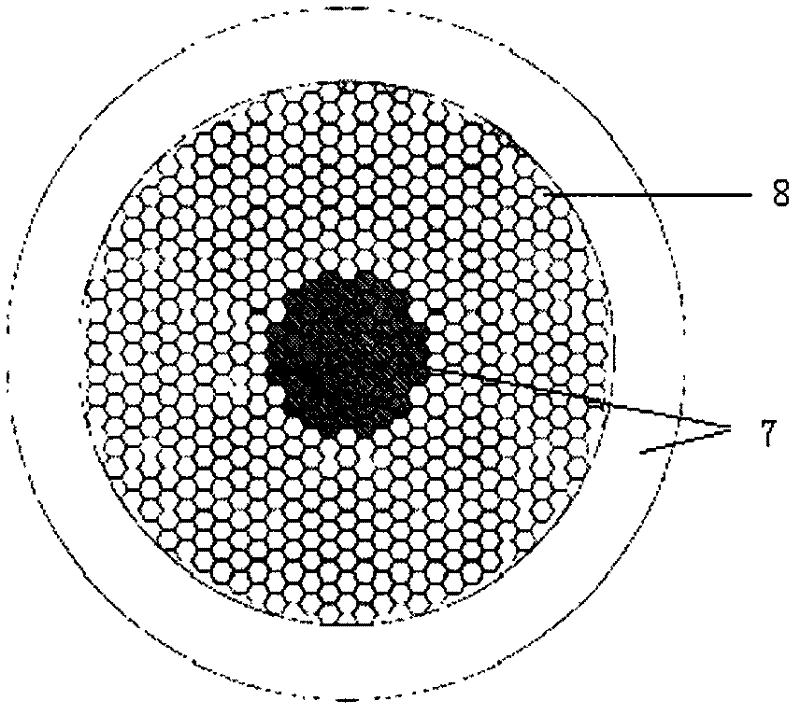

[0030] The extruded NbTi / Cu multi-core composite rod has a diameter of Φ70mm and a length of 15m. The outer matrix material is oxygen-free copper with a thickness of 6mm. The cross-section is as follows image 3 shown. The length of the pure copper upper and lower covers of the ingot is cut off before stretching, and the length is 13.5m. On the broaching machine, Φ63.8mm and Φ58.18mm circular hole dies are used for linear stretching twice, and the stretching speed is 9m / min. The final die size is 58.18±0.05mm, and the bending degree of the bar is less than 2 / 1000. After stretching, Φ57.74mm and Φ57.30mm peeling dies are used for peeling and stretching respectively. The cutting edge angle of the peeling die is 10-15 degrees, the peeling speed is 9m / min, and the diameter of the bar after peeling is Φ57.30±0.05 mm, the surface of the bar is not smooth, without oxide layer or inclusions, which achieves the purpose of surface cleaning and will not cause any impact on the internal ...

Embodiment 3

[0032] The assembled and processed SnTi / Nb / Cu multi-core subcomponent composite rod has a diameter of Φ50mm and a length of 2m. The outer matrix material is oxygen-free copper with a thickness of 4mm. The cross-section is as follows image 3 As shown (the subcomponent is stretched and processed to a certain shape and size, and is used to assemble the final blank for the production of Nb3Sn superconducting wire). Use 20-25% pass processing rate on the broaching machine, stretching speed 6-15m / min, straight-line stretching to Φ41.60±0.05mm, bar bending less than 2 / 1000, and then use Φ41.55mm peeling die Peel the skin once, and the stretching speed of the skin is 12m / min. Continue stretching one time to process to Φ37.2mm, and then use Φ36.8mm peeling die for peeling and stretching. The peeling speed is 12m / min. After peeling, the diameter of the bar is Φ36.8±0.05mm, and the surface of the bar is smooth. The size of the head and the tail is uniform, and the purpose of adjusting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com