Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Long design life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

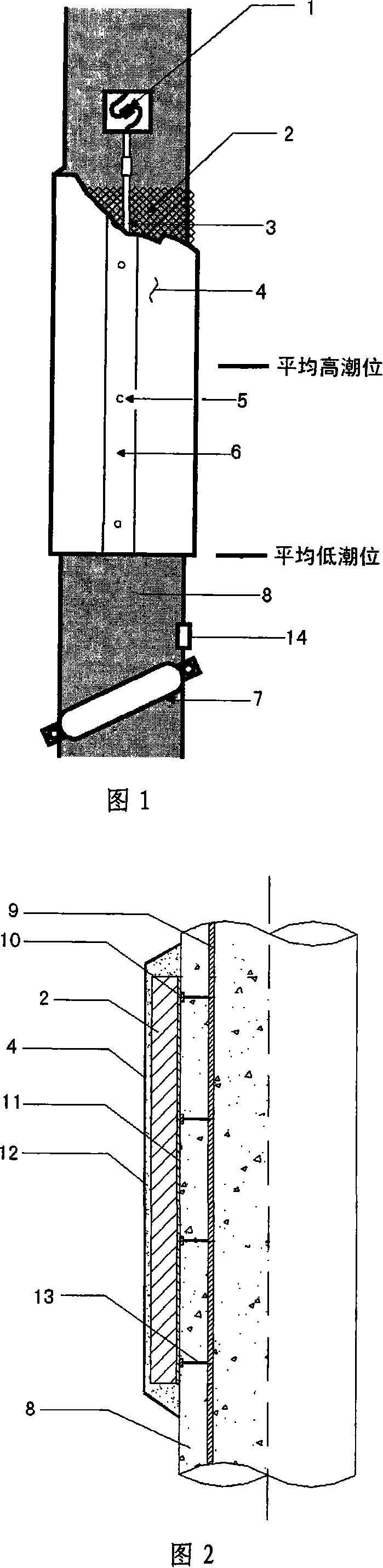

Anodic sacrifice protection method of steel reinforced concrete bridge pier

InactiveCN101109087AEasy to installImprove protectionBridge structural detailsRebarElectrically conductive

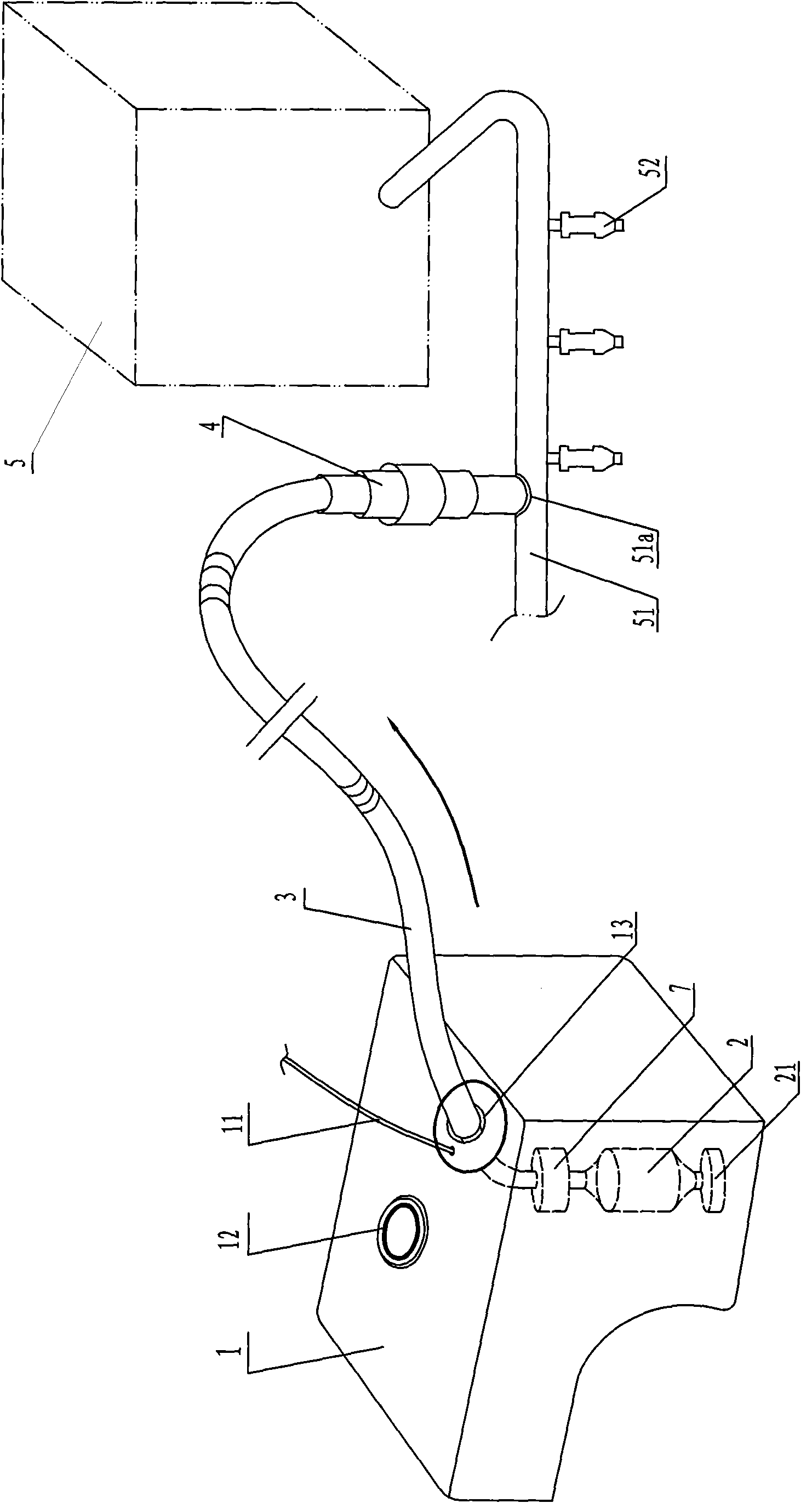

The utility model relates to an abandon-anode-protection method in the technical field of anti-corrosion for metals in reinforced concrete structures in marine environment, in particular to an abandon-anode-protection method for reinforced concrete in an area with tide difference and wave splashing. The main structure includes a terminal box, an extended anode, an electric connecting wire, a composite sheath, a metallic fastener, a sheath-connecting slot, an under-water abandon anode, a reinforced concrete bridge pier, rebars, fixing parts, extended-anode connector, electrically conductive cement mortar filler, conductive connectors and under-water fixers. The rebars in the concrete are fixedly connected with the conductive connectors at one end of the abandon anode; the electrically conductive cement mortar filler fixes the extended anode on the surface to be protected; the under-water abandon anode is fixed by steel strip or angle steel, and is electrically connected with the rebars in the concrete. The abandon-anode-protection method for reinforced concrete in an area with tide difference and wave splashing is characterized by no maintenance, easy installation, is helpful for after-stage replacing and re-protection, and will not influence the service life or operation of the reinforced concrete structures.

Owner:SUNRUI MARINE ENVIRONMENT ENG

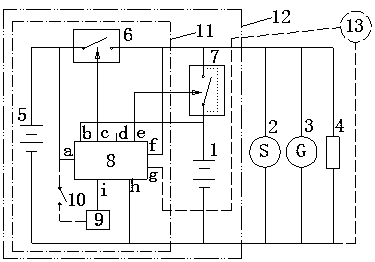

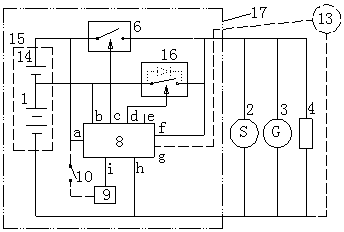

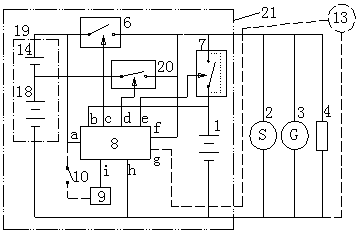

Vehicle-mounted Combined Battery Intelligent Power Supply System and Power Supply Method

ActiveCN108116350AReduce utilizationExtended service lifeElectric powerElectric/fluid circuitStart timeElectrical battery

The invention discloses a vehicle-mounted combined battery intelligent power supply system and a power supply method. The combined battery, such as a double-battery parallel power supply device (12),a double-battery series power supply device (17) or a multi-battery series-parallel power supply device (21), is used for upgrading the traditional automobile storage battery; the intelligent power supply method, namely, the control unit (8), controls each of the battery switches in accordance with an engine state, such as shut down, start up and operation, and each battery voltage, to provide therequired electric power, the main contents include: providing a power supply similar to the conventional storage battery when the engine is stopped, and the battery leakage protection is provided asneeded; providing a higher starting voltage than a conventional storage battery to shorten the starting time when the engine is started; when the engine is in operation, a supplementary supply voltagewhich is not lower than a certain preset voltage is provided, so that the phenomenon of insufficient power supply influencing the stable operation of the engine won't occur in the electric appliancesystem.

Owner:卢浩义

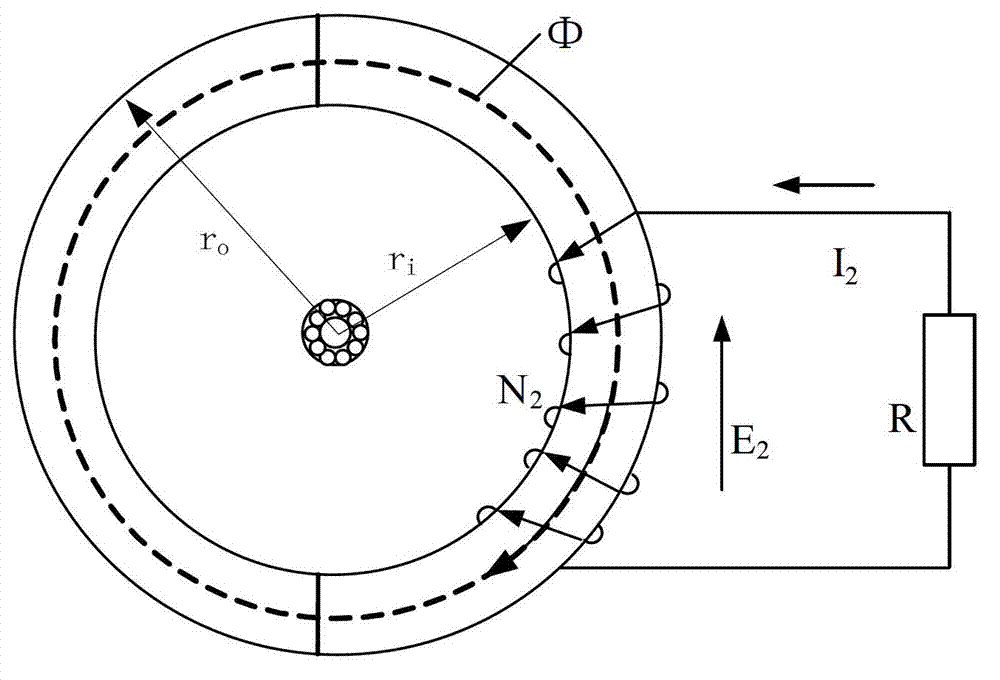

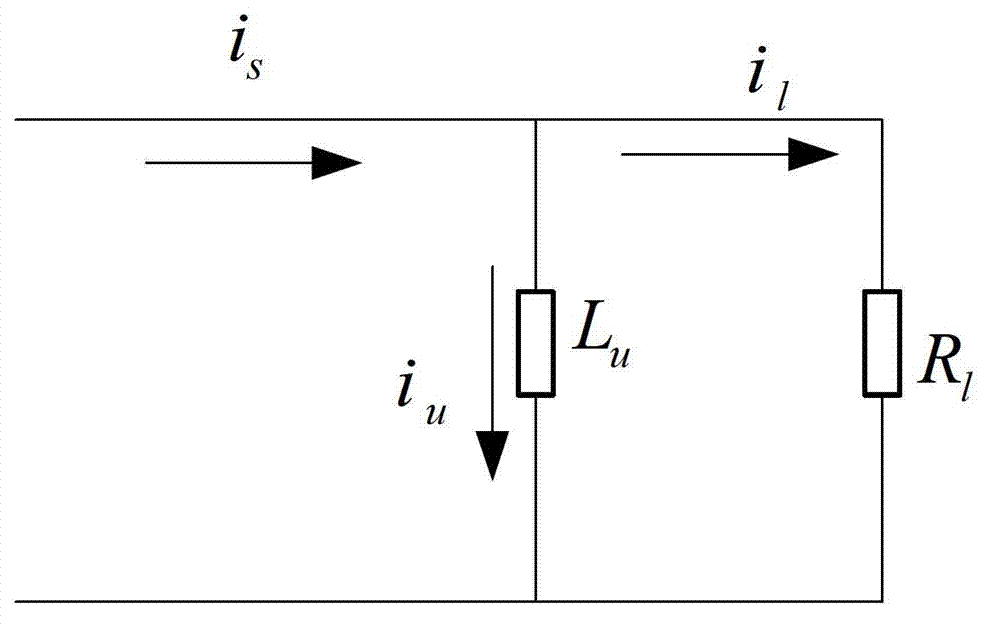

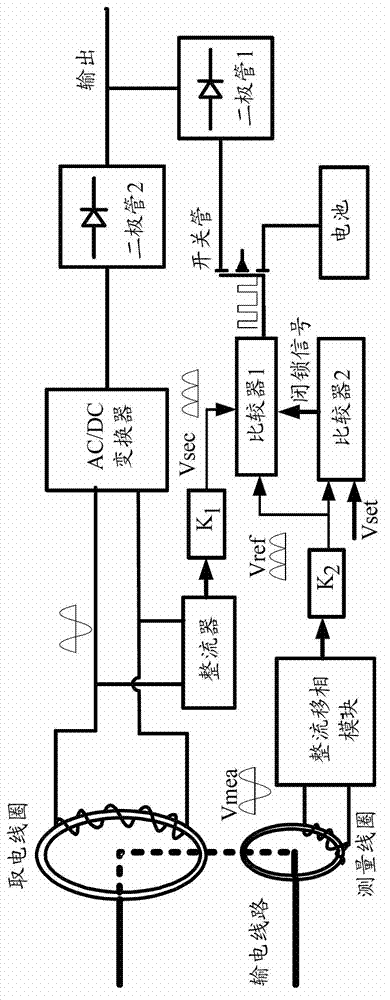

Maximum power tracking system and method of power transmission line induction power supply source

InactiveCN102957219ALong design lifeAdjustable output voltageElectromagnetic wave systemElectric variable regulationPhase shiftedElectricity

The invention provides a maximum power tracking system and a maximum power tracking method of a power transmission line induction power supply source. The method comprises the following steps of: detecting output voltage of a power supply coil and rectifying and amplifying the output voltage to obtain first output voltage; detecting output voltage of a measuring coil and performing rectification, amplification and phase-shift processing on the output voltage to obtain a reference voltage; outputting a drive control signal according to a comparison result of the two voltages; and switching on or off a switch tube by using the drive control signal to correspondingly select a battery or the power supply coil for supplying power for a load. By using the system and the method, the output voltage of the power supply coil can be adjusted by changing the duty ratio size of a gate drive signal of the switch tube to track the reference voltage all the time, thereby dynamically adjusting the output power of the power supply coil. In addition, when the power supply source and a backup battery are used for simultaneously supplying power, the time for supplying power for the load by the battery can be shortened to the greatest extent since the power supply coil works at the maximum power point for the most of time, so that the design life of the entire power supply source is prolonged.

Owner:国网山东省电力公司聊城供电公司 +2

Steel reinforced concrete sacrificial anode cathodic protection devices in atmospheric environment and method thereof

The invention relates to a protection device for sacrificial anodes and sacrificial cathodes in reinforced concrete structures in the atmospheric environment; wherein, the reticular sacrificial anodes are electrically connected with steel bars in concrete to form a protection system for the sacrificial anodes and sacrificial cathodes; the protection device is characterized in that the sacrificial anode is embedded in active mortar which is laid on the surface of the reinforced concrete; the sacrificial anode adopts pure zinc or zinc alloy; the active mortar consists of Portland cement, aggregates, water, synthetic fibers and active additives, and the water-cement ratio is 0.35 to 0.55:1 and the cement-sand ratio is 0.3 to 0.6:1; the active additives are lithium bromide or lithium nitrate with the mixing amount of 0.05 to 0.50g / cm <3>; the synthetic fibers are selected from polypropylene fiber, polyethylene fiber, cellulose and / or glass fiber with the mixing amount of 0.05 to 0.5 percent; the protection device also comprises a protection method; the protection device saves human and material resource and has low price and service life as long as 20 years; the active mortar does not shrink or crack and is lower in resistivity, high in intensity and stable in the open circuit potential of the sacrificial anode.

Owner:NANJING HYDRAULIC RES INST THE MINISTRY OF WATER RESOURCES THE MINIST

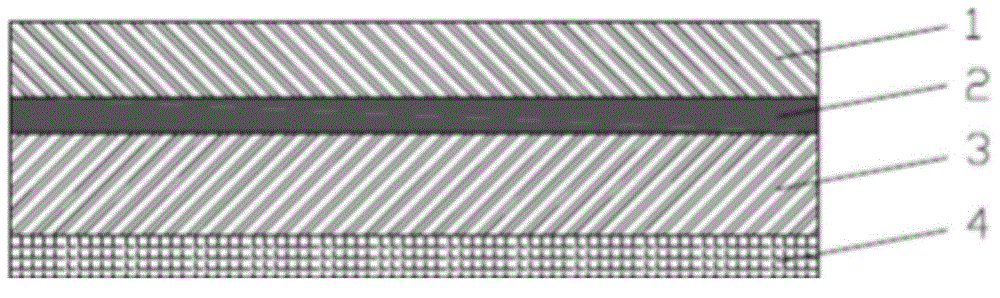

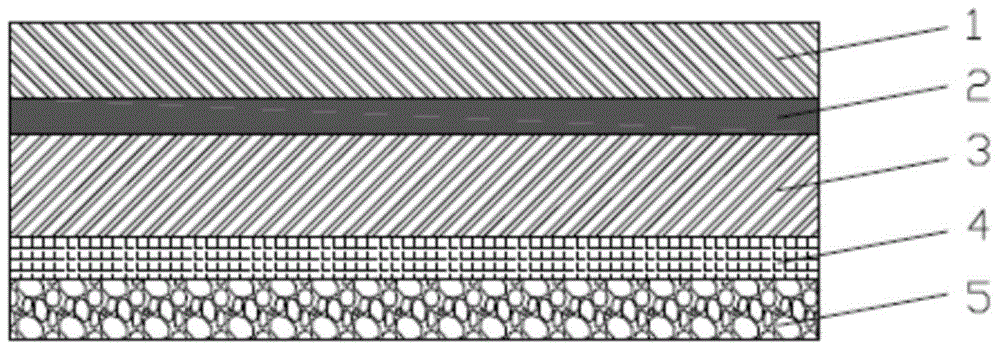

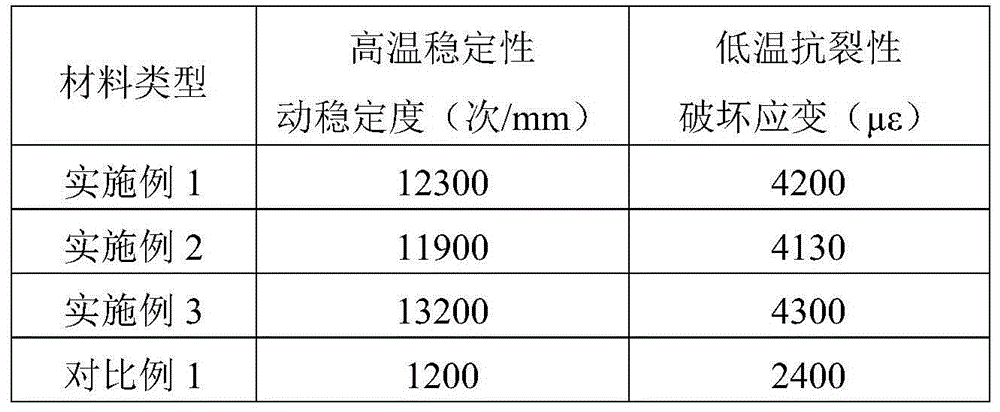

Durable tunnel paving structure

InactiveCN104863032AGood flexibilityImprove waterproof performanceIn situ pavingsClimate change adaptationRoad surfaceFire safety

The invention discloses a durable tunnel paving structure, which sequentially comprises a rubber asphalt gravel sealing layer, a pouring-type semi-flexible mixture paving lower layer, a modified emulsified asphalt bonding layer and a high-modulus warm mixing flame-retardant asphalt mixture paving upper layer from bottom to top. The durable tunnel paving structure provided by the invention has the advantages that the anti-track capability and anti-crack performance of the pavement are obviously enhanced; the durability is greatly improved; the anti-slip function of the paving surface is ensured; the problem of potential fire safety hazards of asphalt pavement is solved; the asphalt pavement construction temperature is lowered; energy sources are saved; emission is reduced; the construction simplicity is improved; only the surface maintenance and repair are needed in daily life; the integral repeated repair is avoided; and the investment is reduced in the whole life cycle.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

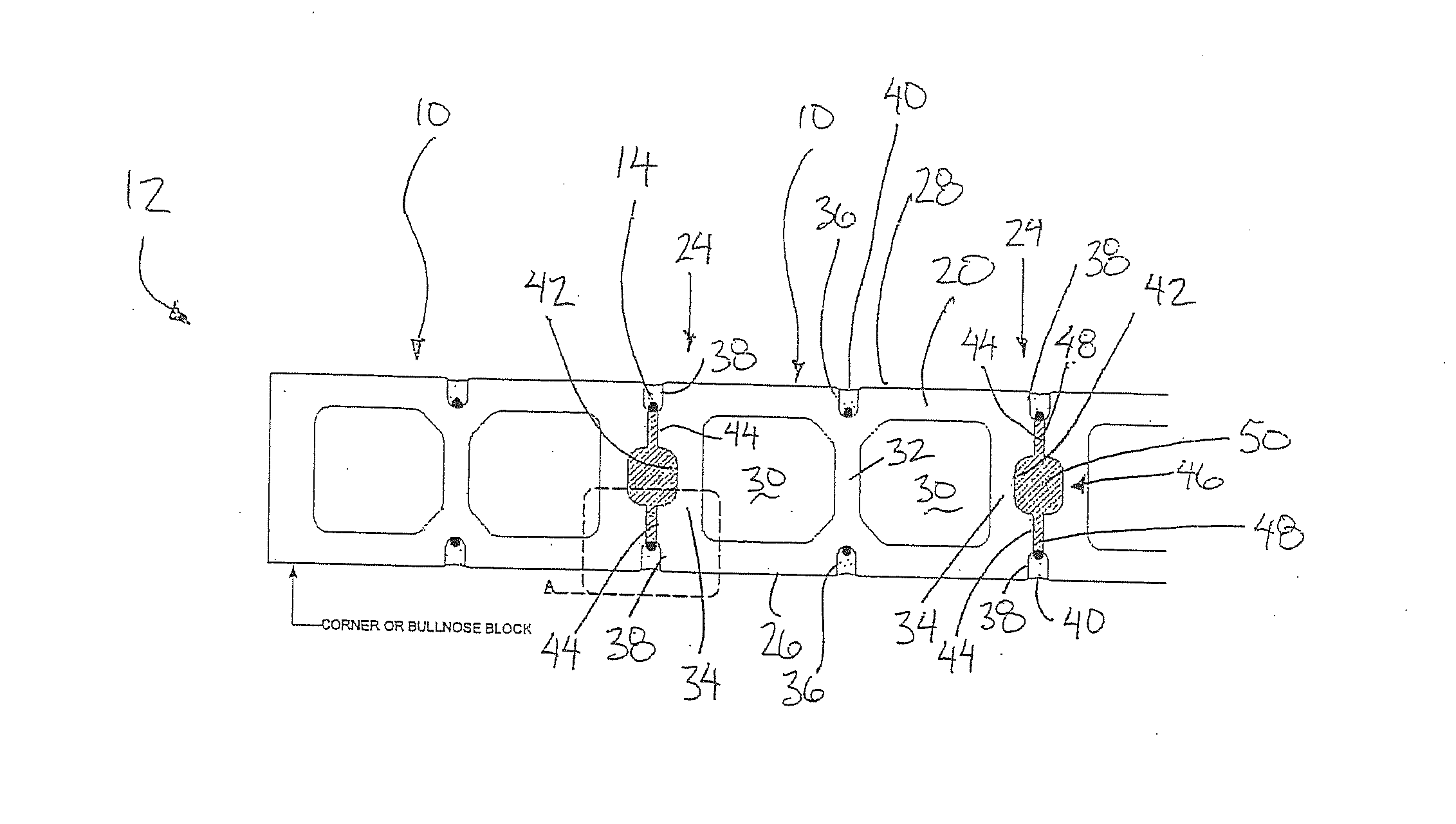

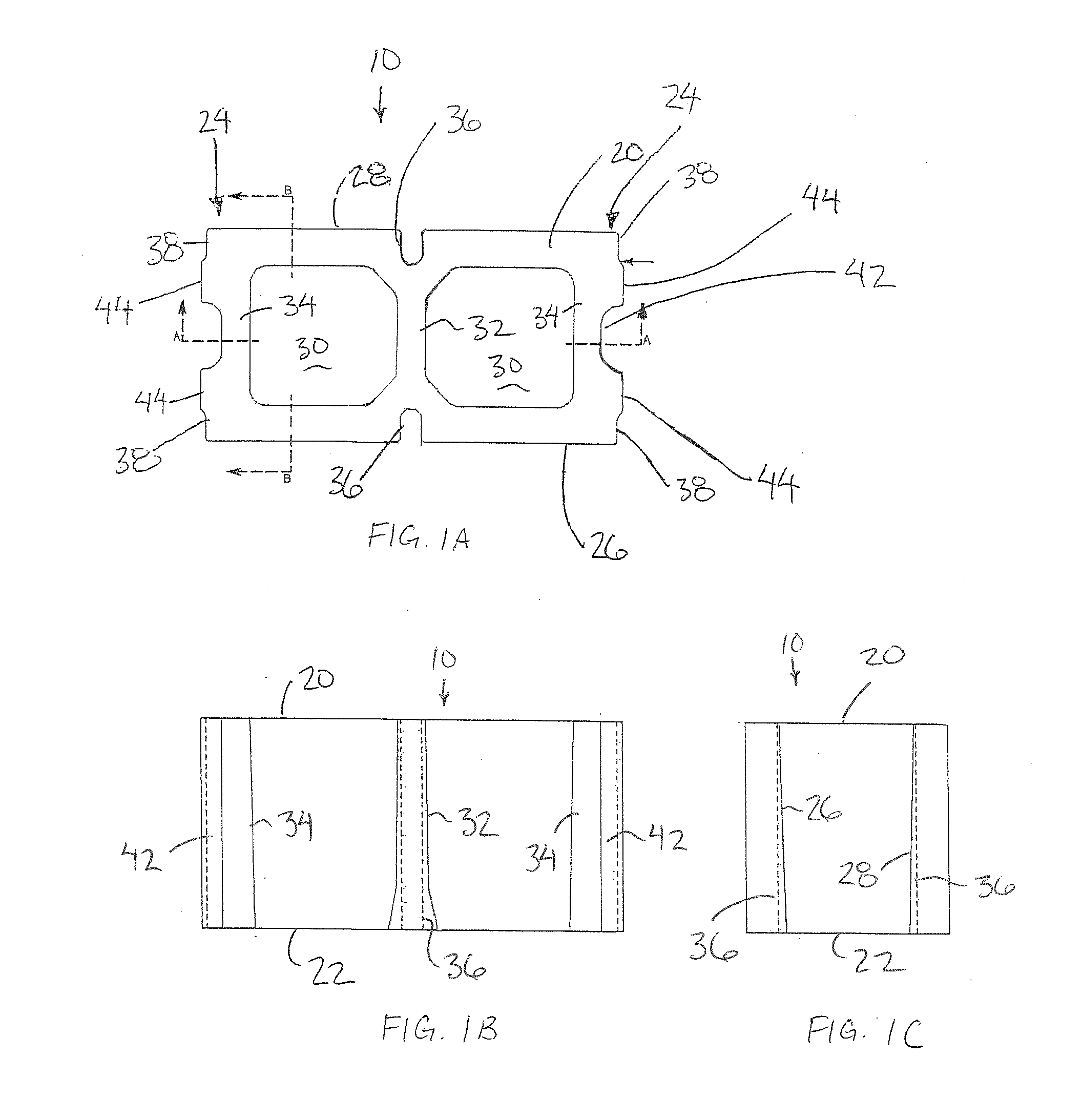

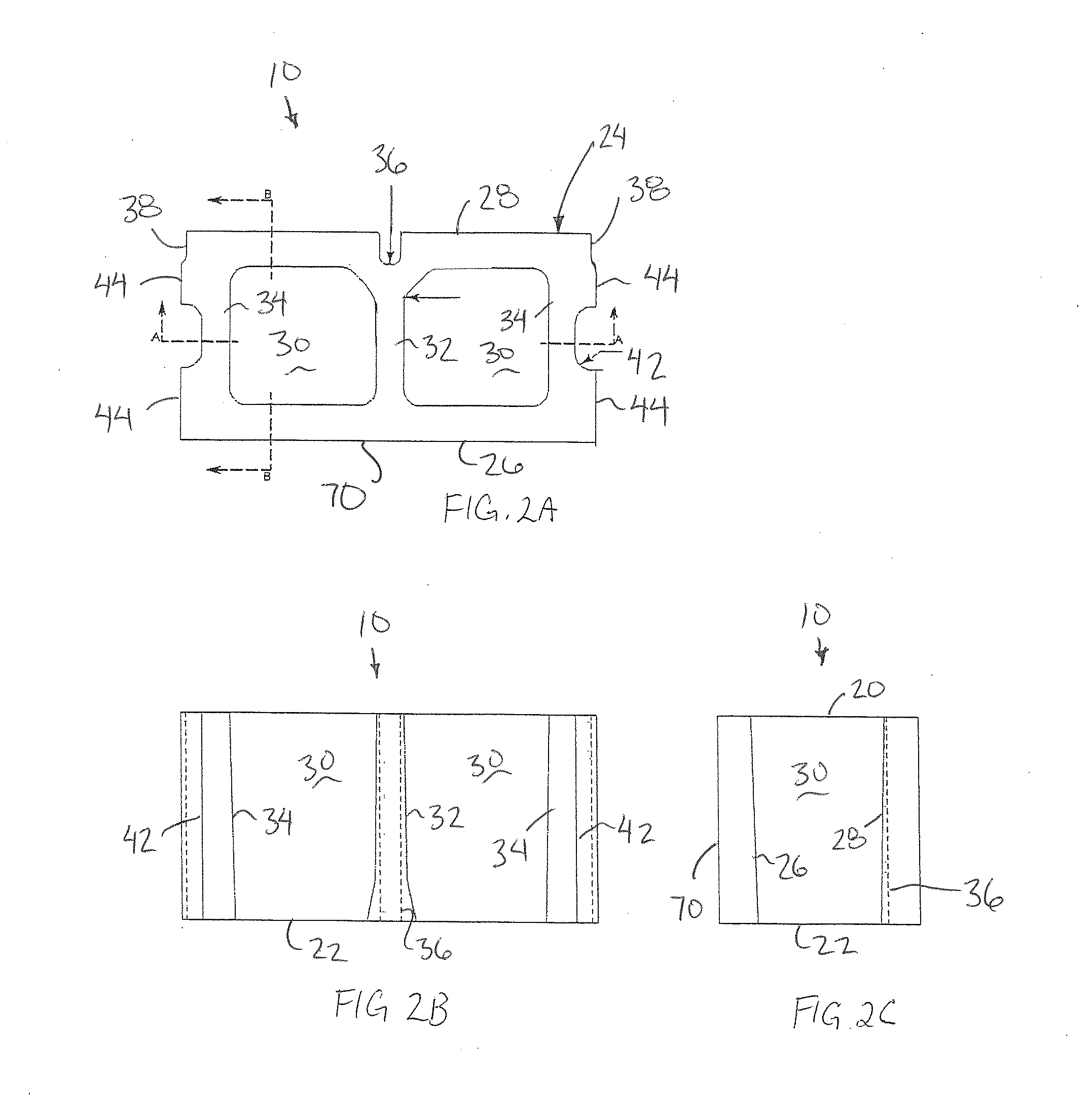

Surface Reinforced Concrete Masonry Units

A masonry wall is formed of masonry block units abutted with one another in series within stacked rows. Each masonry block unit is a concrete body having two opposing exterior side walls defining respective portions of the assembly masonry wall. Vertical reinforcement channels are formed in the exterior side walls of each masonry block unit so as to be open laterally to the exterior. The reinforcement channels align with corresponding channels in the masonry block units in adjacent stacked rows to receive elongate reinforcement members, for example rebar, inserted laterally therein from the exterior surface of the assembly masonry wall. A bonding material can then be recessed laterally into the reinforcement channels so as to bond the reinforcement members to the masonry assembly.

Owner:UNIVERSITY OF MANITOBA

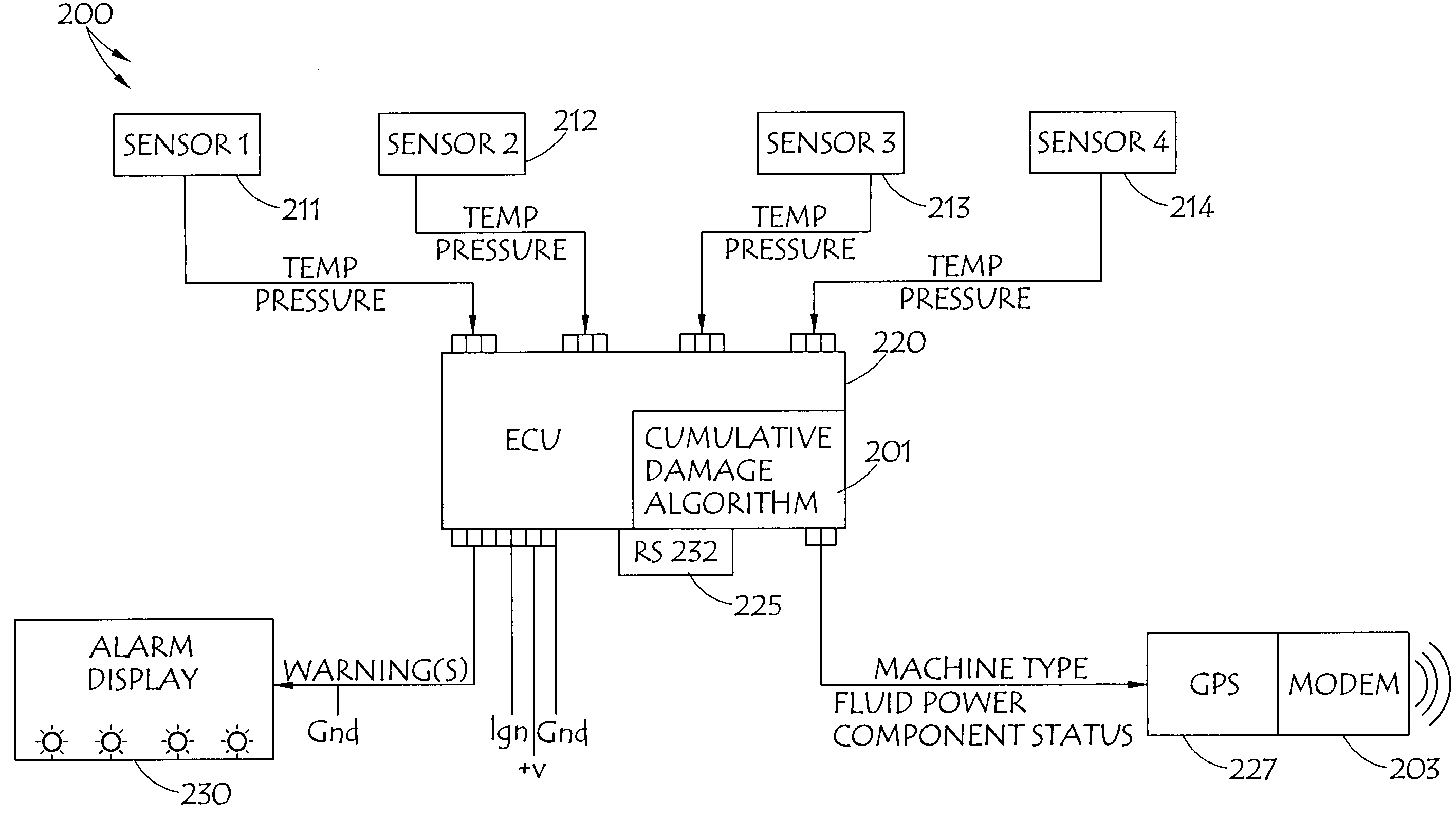

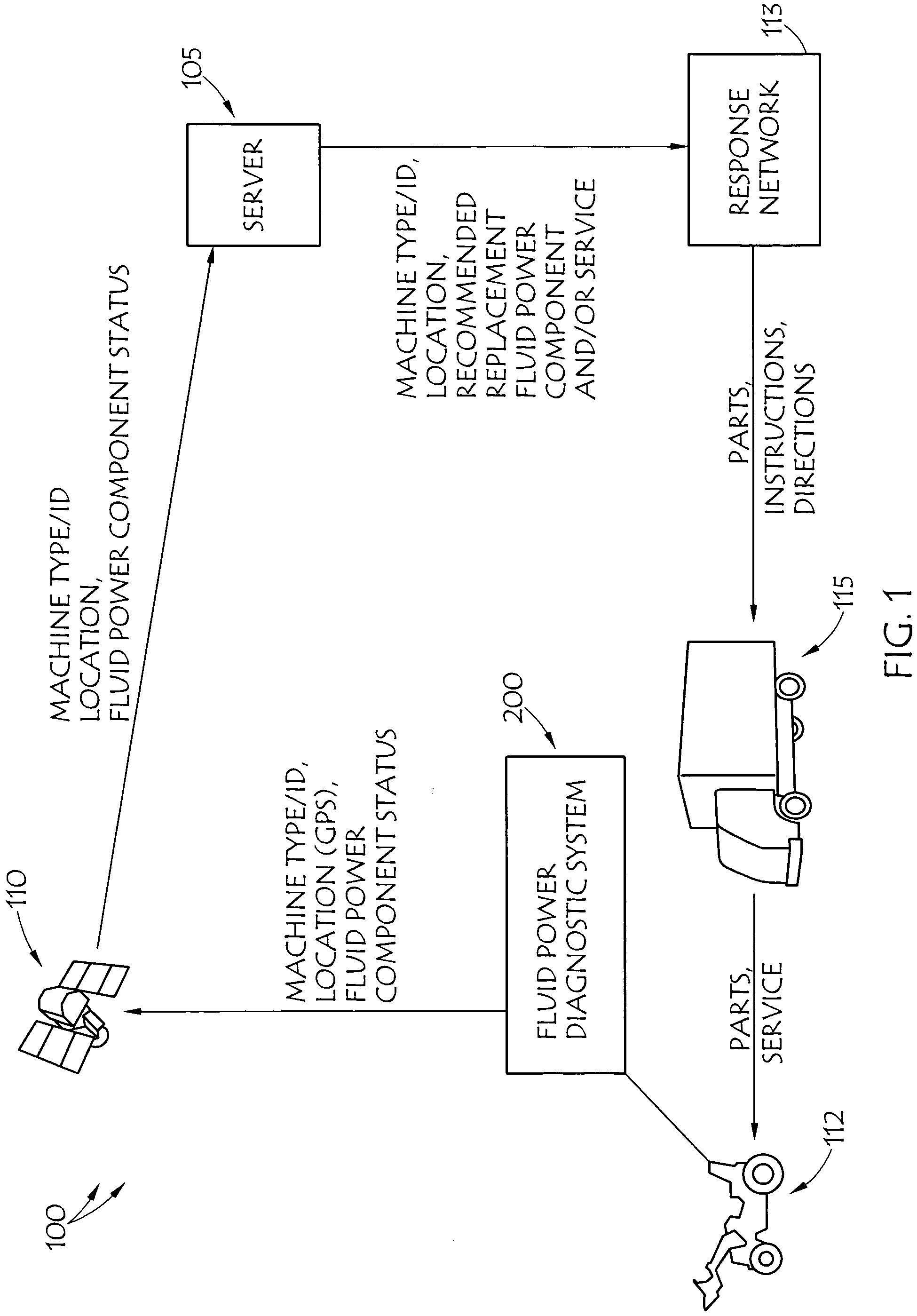

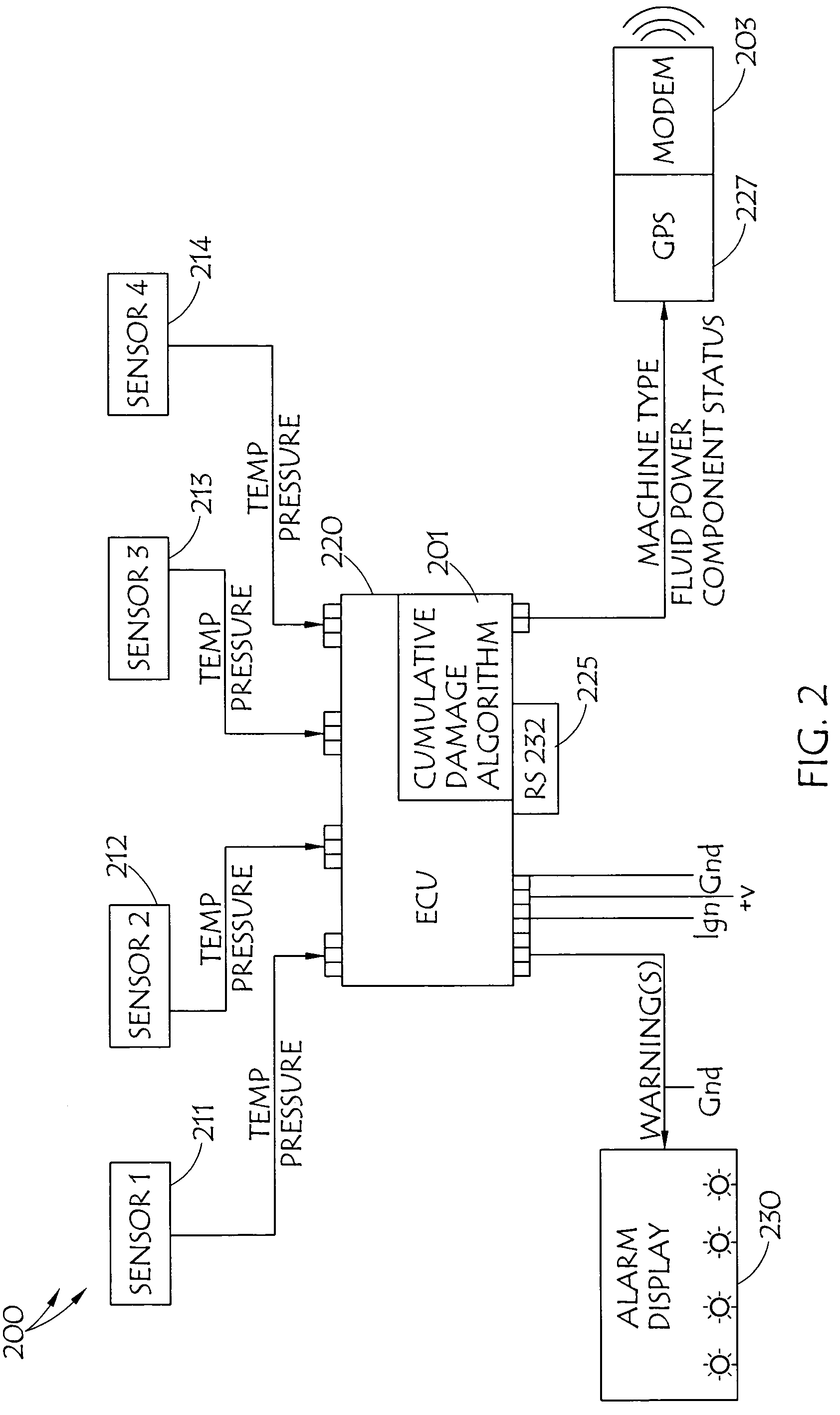

Diagnostic and response systems and methods for fluid power systems

InactiveUS20100106461A1Expand coverageNew revenue streamProgramme controlTesting/monitoring control systemsRapid response systemAnalysis center

Diagnostic and response systems and methods for a fluid power system acquire data from pressure and temperature sensors disposed in the fluid power system, analyze the data in a failure algorithm to build a history of cumulative damage to hoses in the fluid power system, communicates an indication of potential imminent hose failure to a central location when a level of the cumulative damage indicates imminent failure of a hose, analyze the information at the central location to determine an appropriate response, and transmit information about the fluid power system, including location, and identification of the hose about to fail to a response unit. The response unit responds to the location and replaces the component prior to failure, or the communication might include information that the hose has failed, such that the response unit replaces the failed hose to return the fluid power system to normal operation.

Owner:THE GATES CORP

Process without opening cylinder for quickly removing carbon deposition of combustion chamber of engine

InactiveCN101666268AHelp break downLong design lifeMachines/enginesEngine componentsCombustion chamberFuel tank

The invention relates to a process without opening a cylinder for quickly removing carbon deposition of a combustion chamber of an engine. An agent-added gasoline tank with an embedded electric fuel pump is filled with the agent-added gasoline that is mixed by a fuel cleaning agent and a regular vehicular gasoline; the tail end of an oil outlet hose of the oil tank is connected with a quick joint;the quick joint is hermetically connected with an oil pressure detecting hole of a cleaned engine fuel main pipe; the cleaned engine is started and the electric fuel pump in the oil tank is started subsequently so that the crude gasoline and the agent-added gasoline are supplied to the engine simultaneously; when the engine stably runs at a special working condition, the supply of the crude gasoline is cut so that the oil is singly supplied by the agent-added gasoline; the openness of the choke is gradually enlarged till the large load working condition occurs; and when the engine does work by combustion, the deposition carbon in the combustion chamber is decomposed and is exhausted along with the exhaust gas after being combusted and gasified. Without opening the cylinder of the engine,the severely deposited carbon in the combustion chamber is quickly removed till the original working performance of the engine is recovered; and the parts of the engine are not damaged in the whole cleaning process.

Owner:SHANGHAI UNIV OF ENG SCI +1

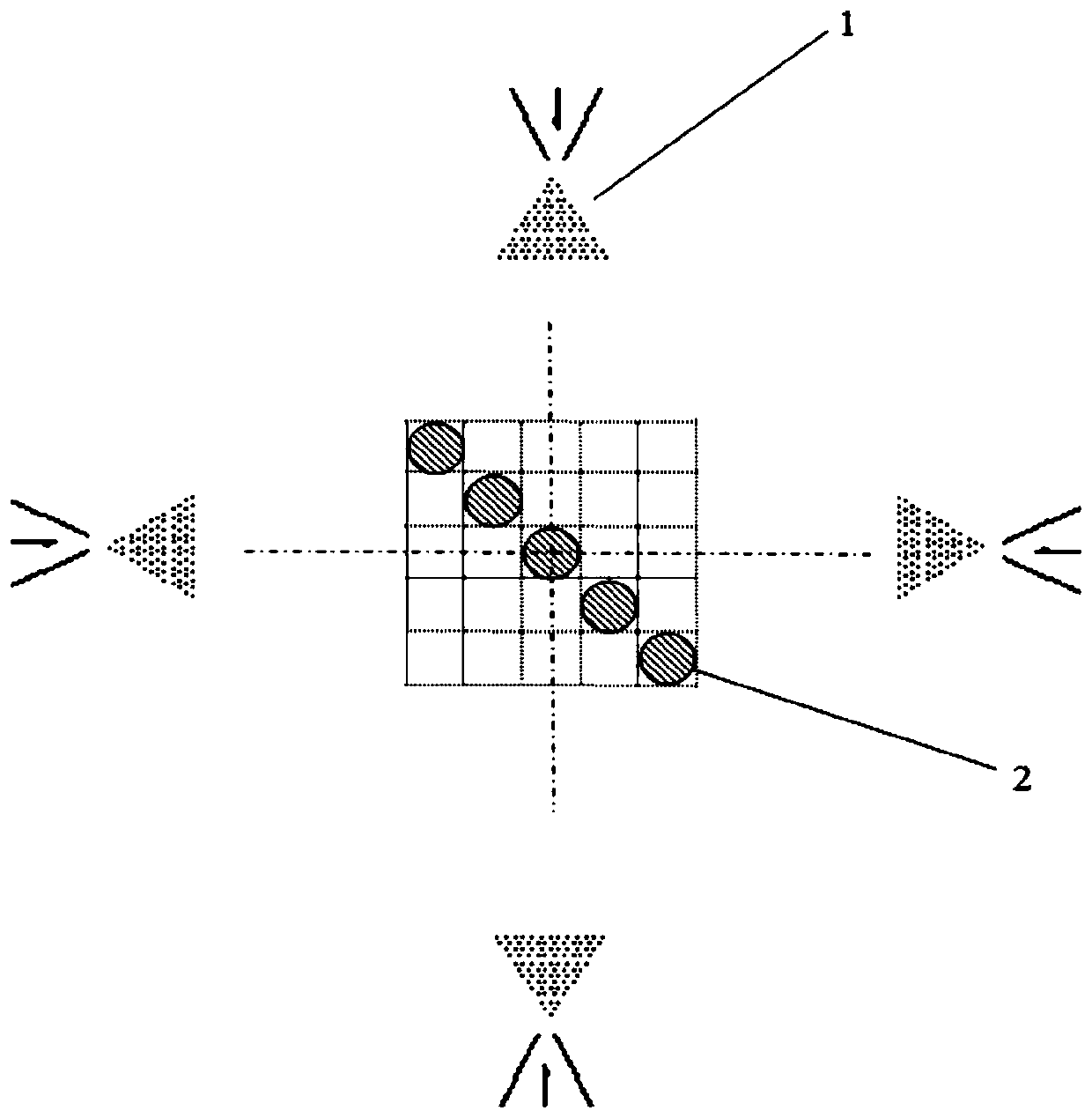

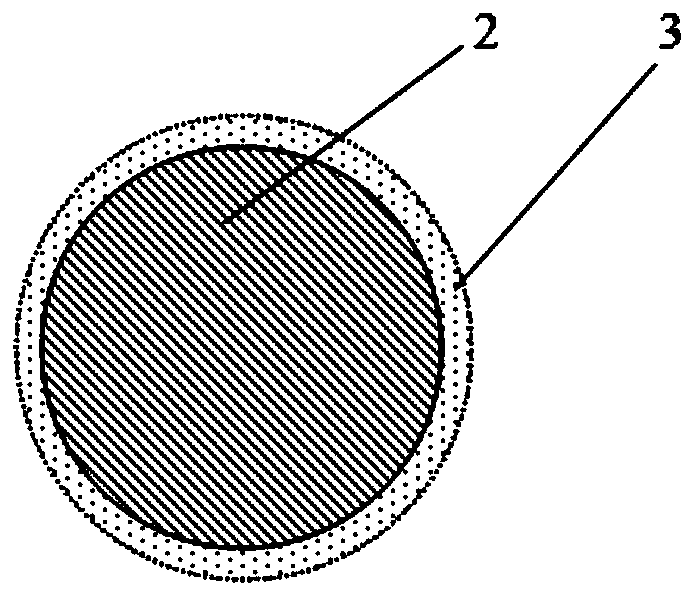

Hot spraying rare earth aluminum alloy coating steel bar

ActiveCN110923616AImprove surface conditionImprove hardnessMolten spray coatingRebarBonding strength

The invention discloses a hot spraying rare earth aluminum alloy coating steel bar. A hot spraying manner is adopted, and the hot spraying rare earth aluminum alloy coating steel bar is prepared by spraying a rare earth aluminum alloy wire to the surface of a steel bar base body through mechanical rust removal, hot spraying, after treatment and other steps, wherein Si, Li, Ti, B, Mn, rare earth metal and the like can improve hardness, plasticity, tenacity, shielding performance and cathode protection capability of an aluminum alloy and a clad layer. A double-component waterborne polyurethane sealing agent and a finishing coat are adopted for treatment, cleanliness and environment friendliness are achieved, surface drying is rapid, and compatible bonding with concrete is easier due to the surface of the hot spraying rare earth aluminum alloy coating steel bar. According to the hot spraying rare earth aluminum alloy coating steel bar, the common technical problems that according to a current epoxy coating steel bar and a zinc-aluminum clad layer steel bar, the relative bonding strength with concrete is greatly reduced, the steel bar anchoring length is increased by 25%, anti-corrosion durability is insufficient, and notch and damaged positions are hard to repair on the site are solved, and good application prospects are achieved.

Owner:XUZHOU ZHONGKUANG ANFENG ENG TECH

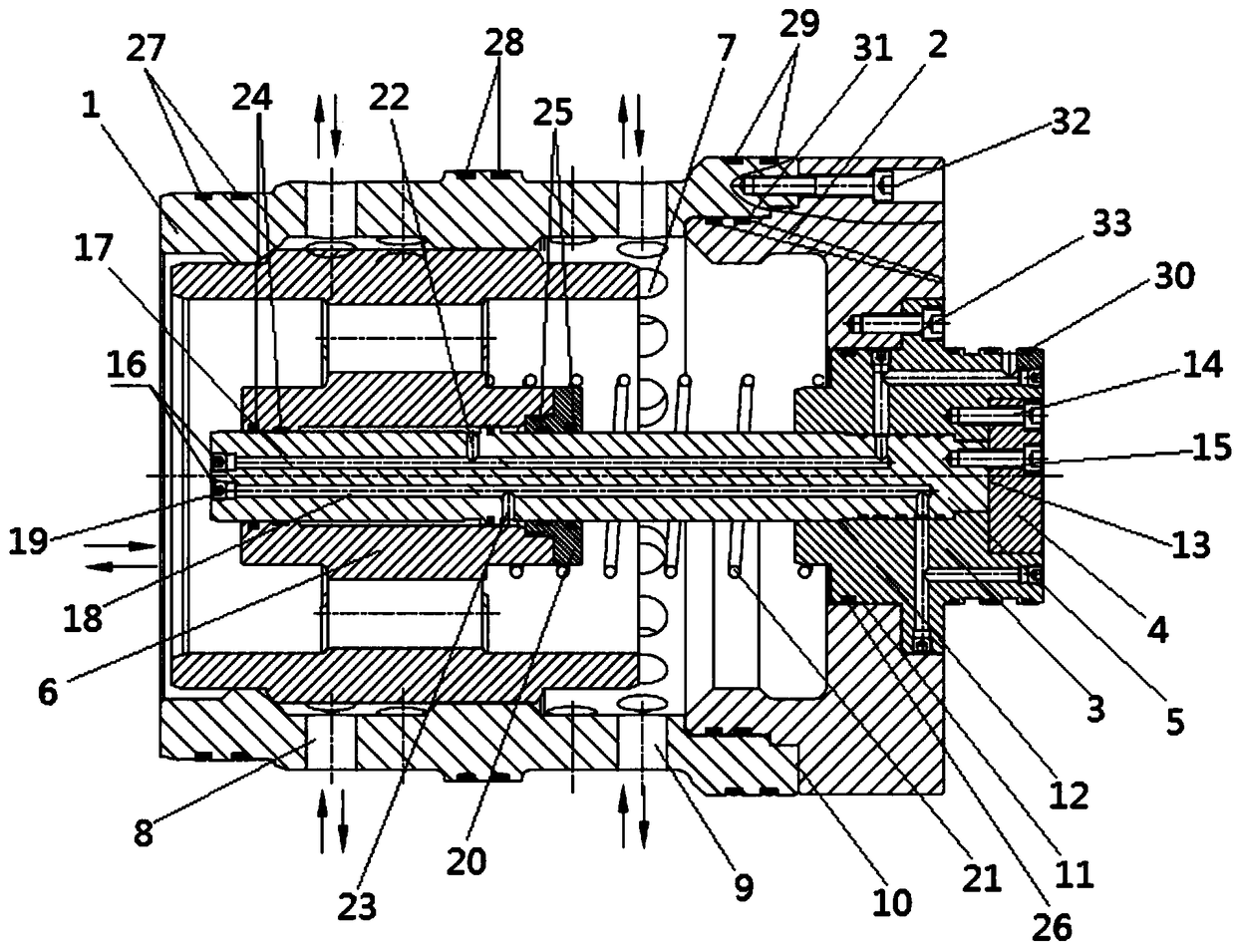

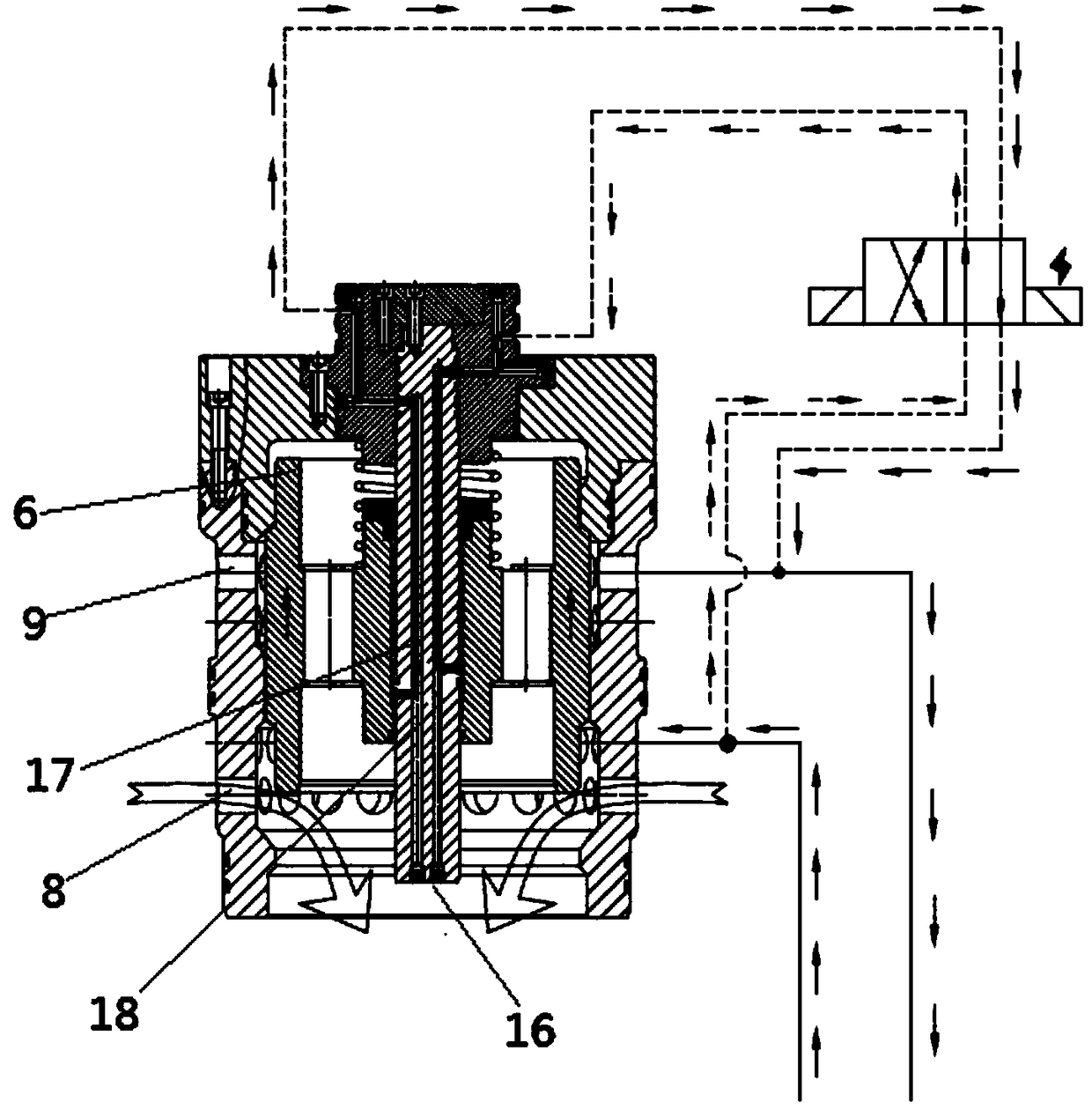

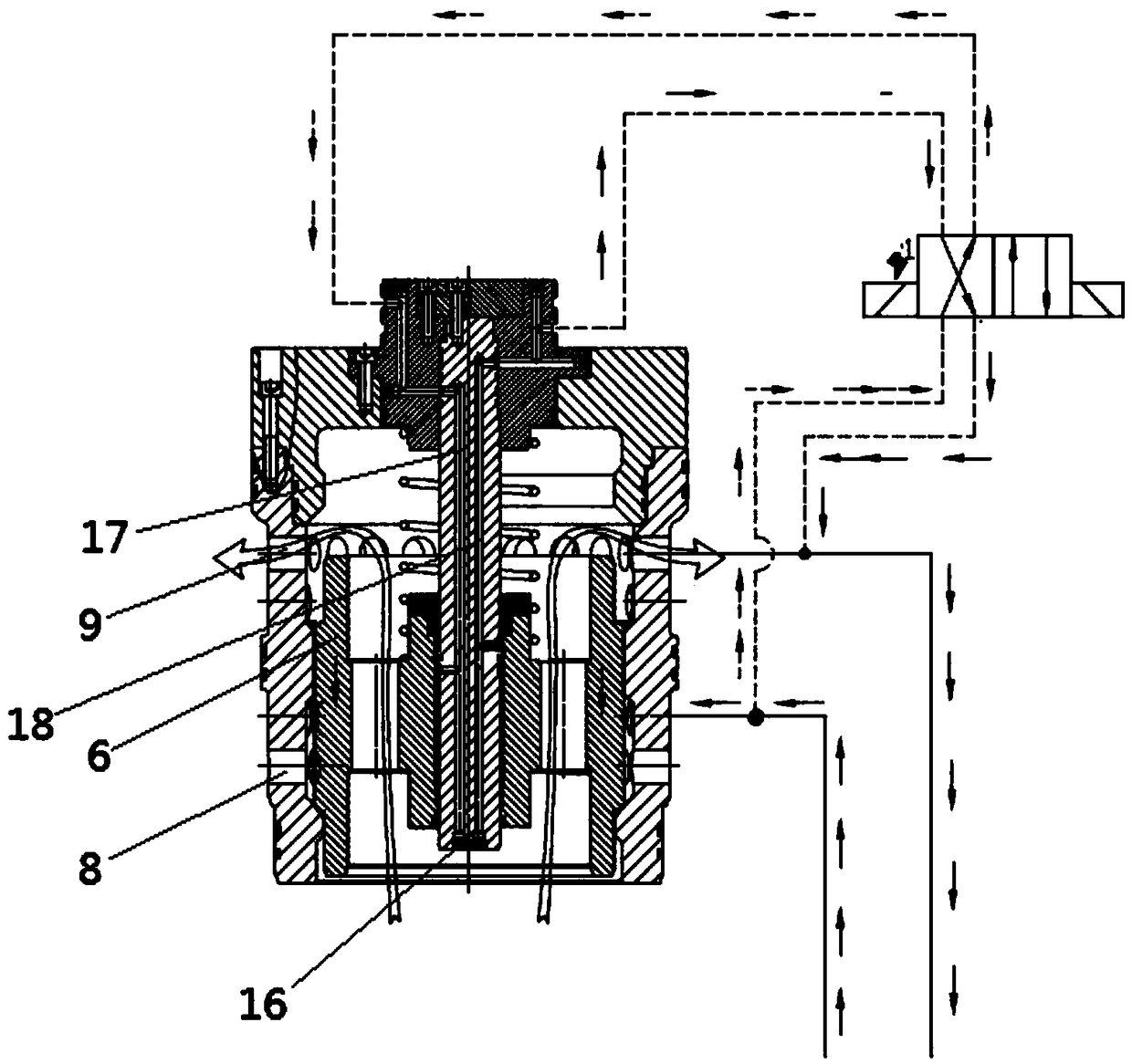

High-flow dynamic output control method of cartridge valve and cartridge valve

The invention discloses a high-flow dynamic output control method of a cartridge valve. The high-flow dynamic output control method of the cartridge valve comprises the steps that a DT2 oil path of acontrol solenoid valve is through while a DT1 oil path of the control solenoid valve is stopped, hydraulic oil inside a first oil conveying channel passes through the DT2 oil path to return to an oiltank so that a guide shaft can provide power for a valve element sleeving the guide shaft, and thus the valve element is driven to move upwards; the DT1 oil path of the control solenoid valve is through while the DT2 oil path of the control solenoid valve is stopped, hydraulic oil inside a second oil conveying channel passes through the DT1 oil path to return to the oil tank so that the guide shaft can provide supporting power for the valve element, and thus the valve element is driven to move downwards; a second oil outlet communicates with a third oil outlet, and hydraulic oil inside the third oil outlet is discharged out from the second oil outlet. The invention further provides the high-flow dynamic output cartridge valve for implementation of the method. By increasing the flow of thecartridge valve and improving flow stability, the requirements of providing sufficient power and stable control for large piling machines of 1000 tons or above.

Owner:GUANGDONG LIYUAN HYDRAULIC MACHINERY

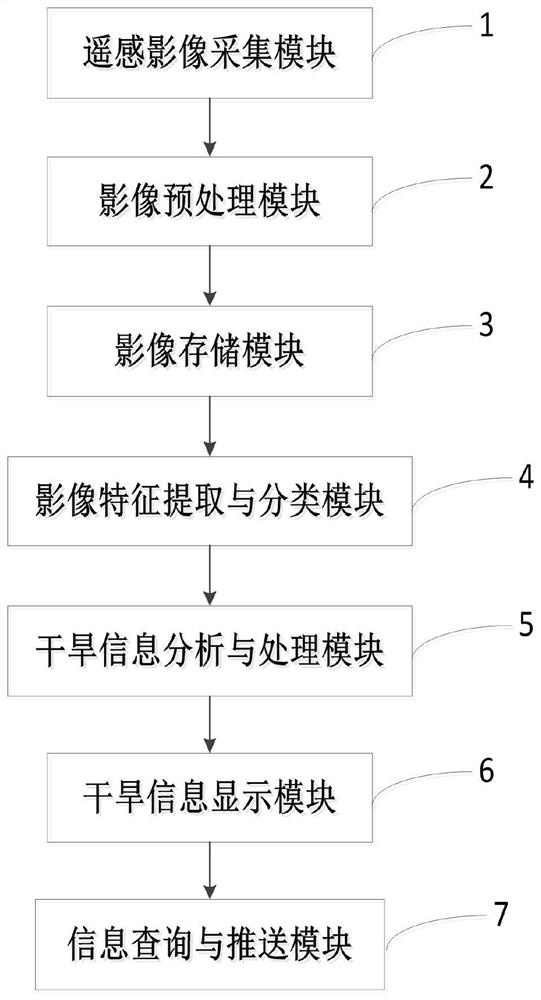

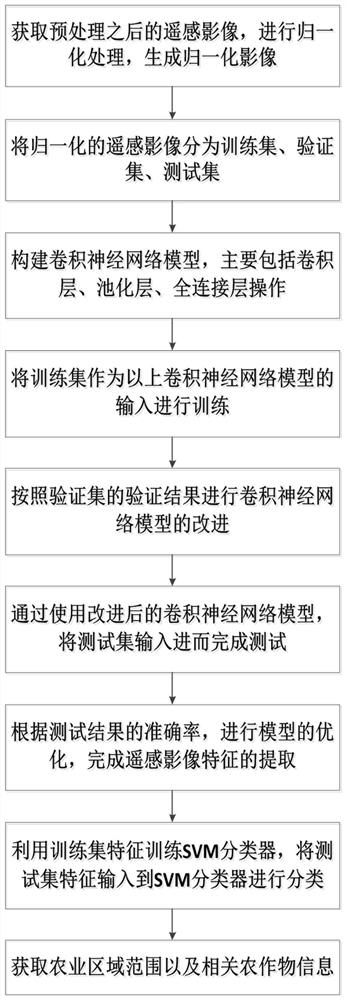

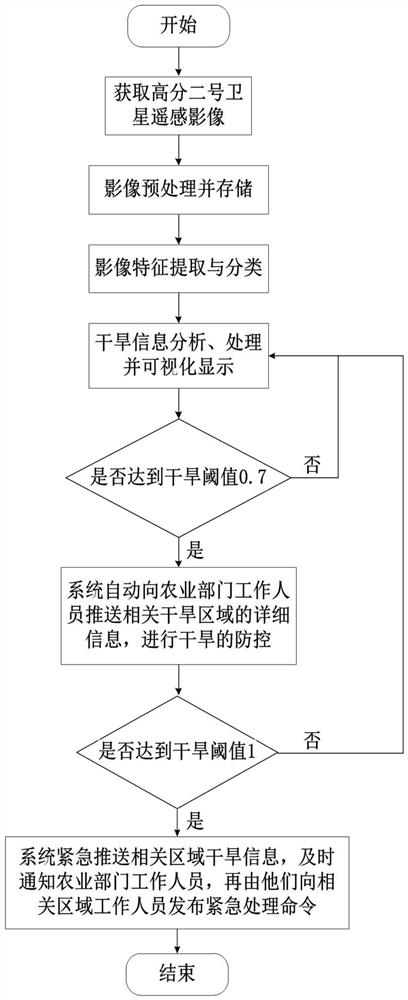

Agricultural drought monitoring system based on remote sensing image and convolutional neural network

InactiveCN111738175AImprove spatial resolutionHigh radiometric accuracyKernel methodsCharacter and pattern recognitionFeature extractionInformation visualization

The invention discloses an agricultural drought monitoring system based on a remote sensing image and a convolutional neural network. The system comprises a remote sensing image acquisition module, animage preprocessing module, an image storage module, an image feature extraction and classification module, a drought information analysis and processing module, a drought information display moduleand an information query and push module, which are are respectively responsible for high-resolution remote sensing image acquisition, remote sensing image preprocessing, remote sensing image storage,image feature extraction and classification, information analysis and processing, drought information visual display, and information query and pushing. According to the system, the convolutional neural network is adopted, the change problems of translation, rotation, scale zooming and other forms can be solved, and feature extraction is performed on the high-resolution satellite remote sensing image by using the powerful feature extraction capability of the convolutional neural network. The functions of drought information query, drought grading, drought information visual display, drought condition monitoring and prediction and the like can be achieved, and the requirement for agricultural drought monitoring under the current remote sensing image data growth background is met.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

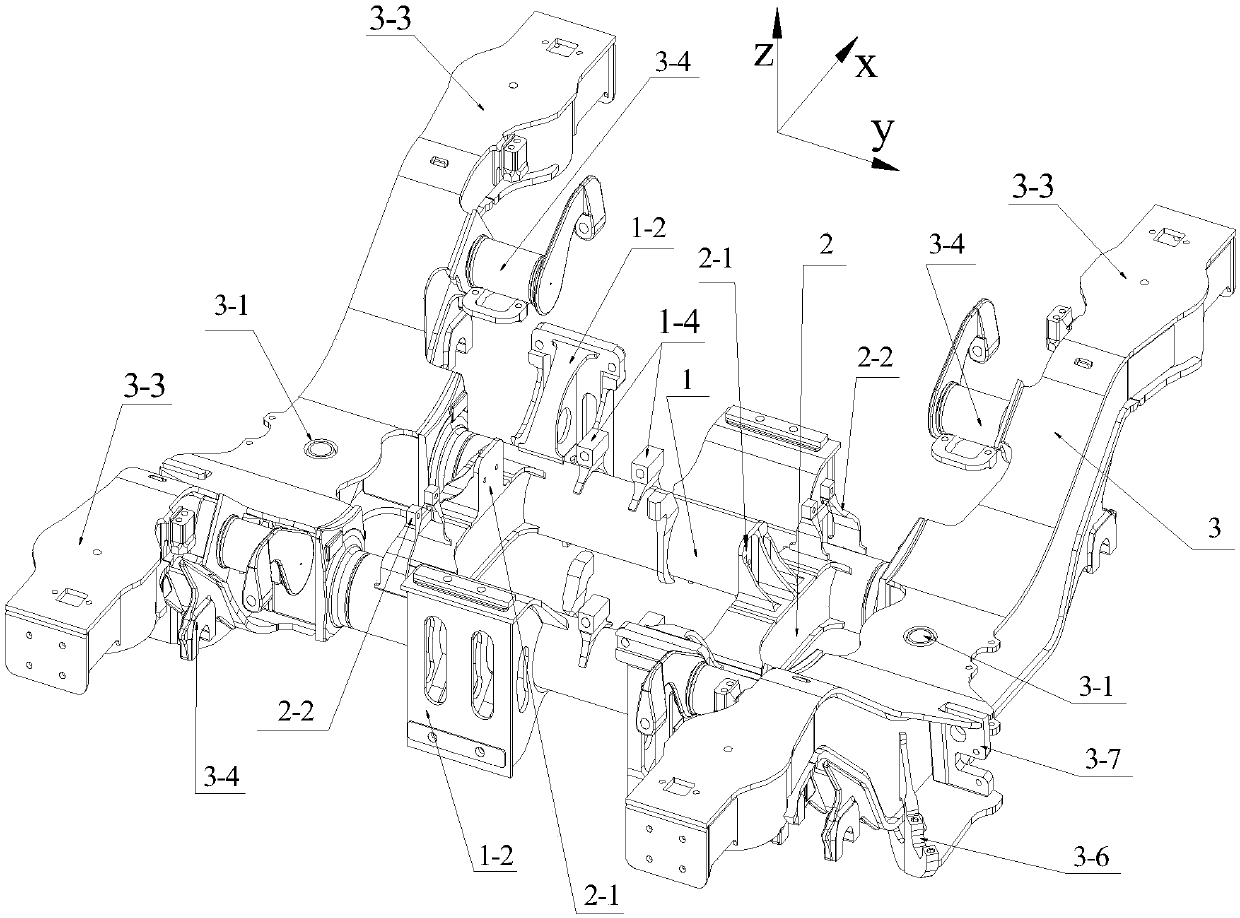

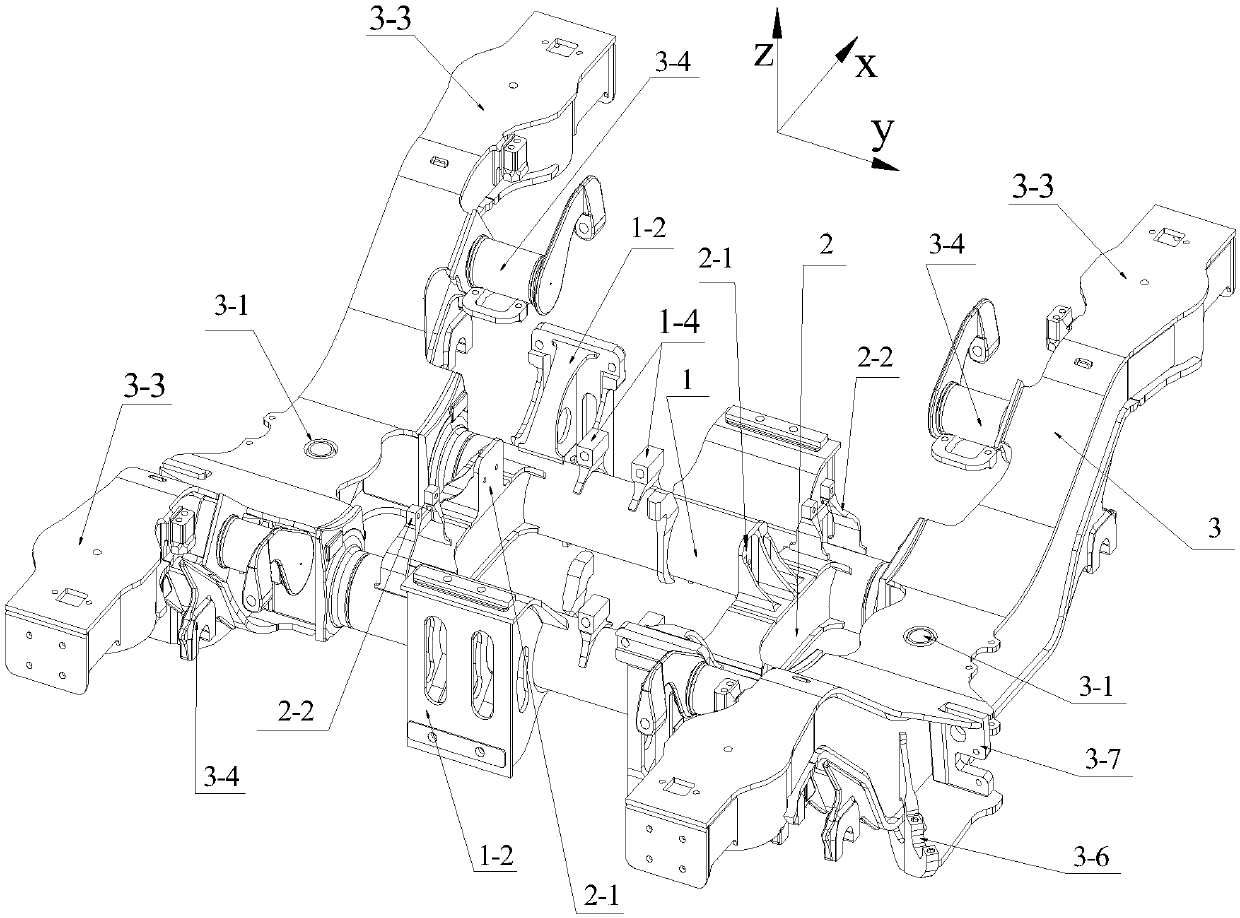

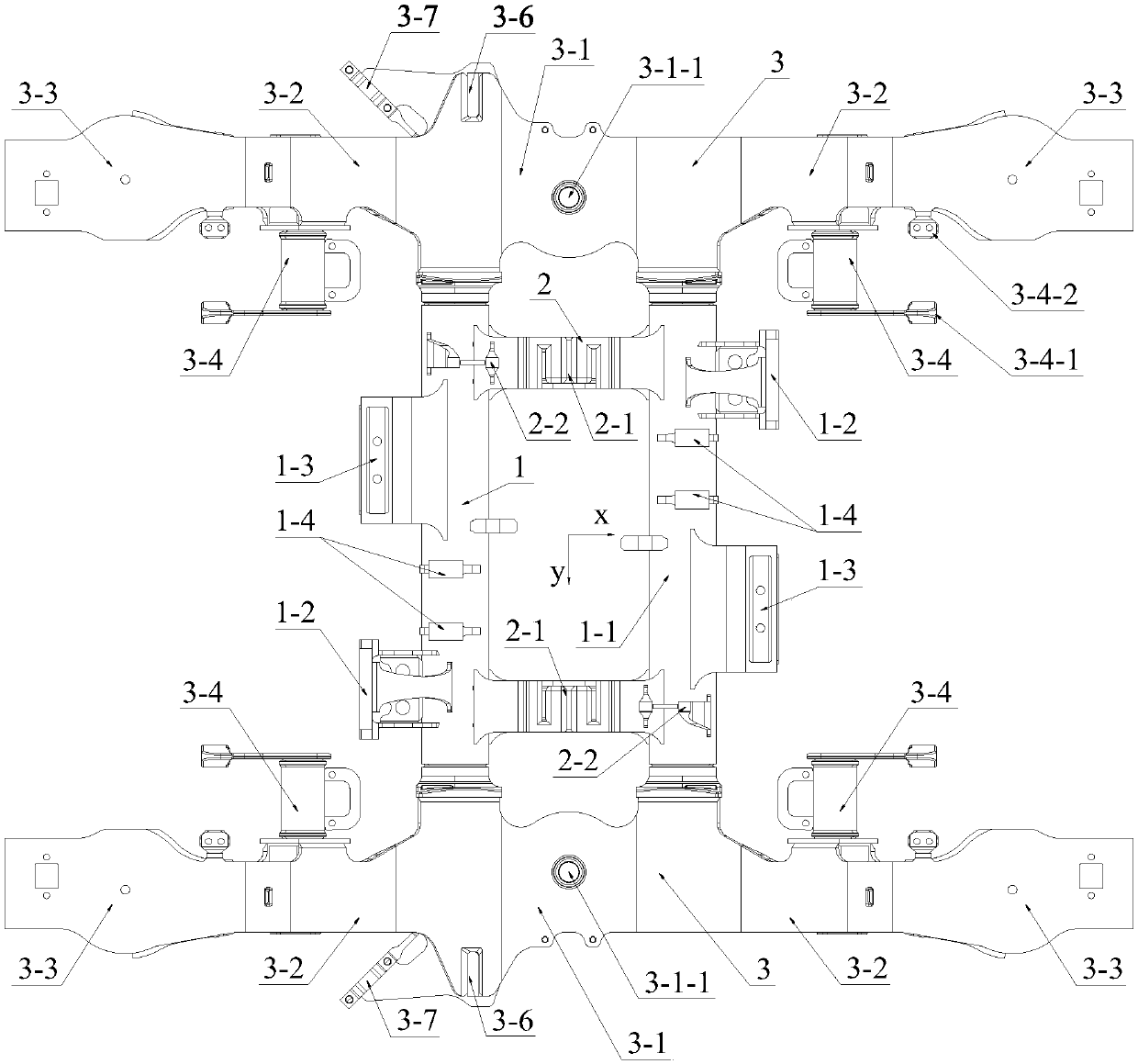

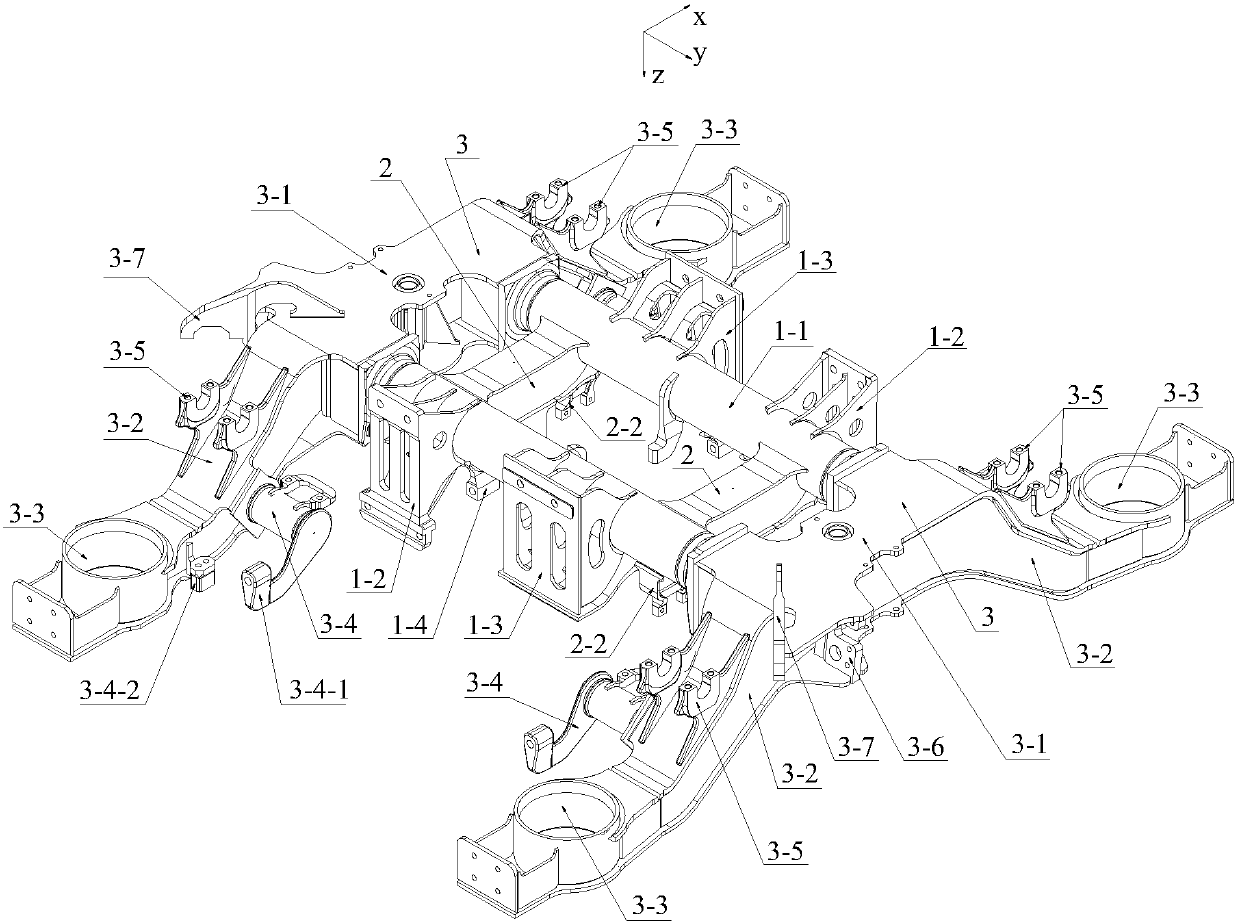

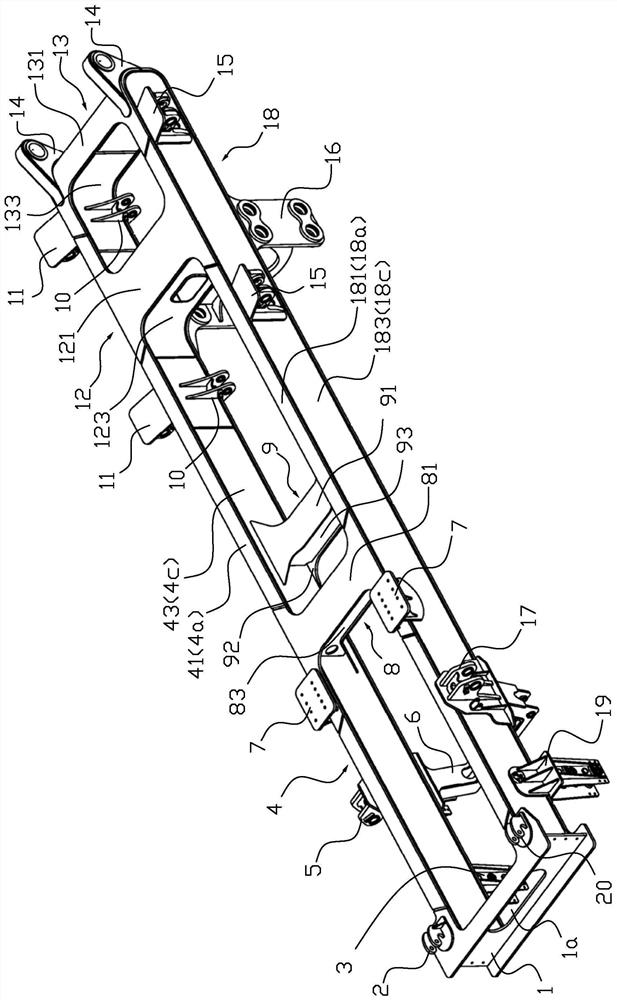

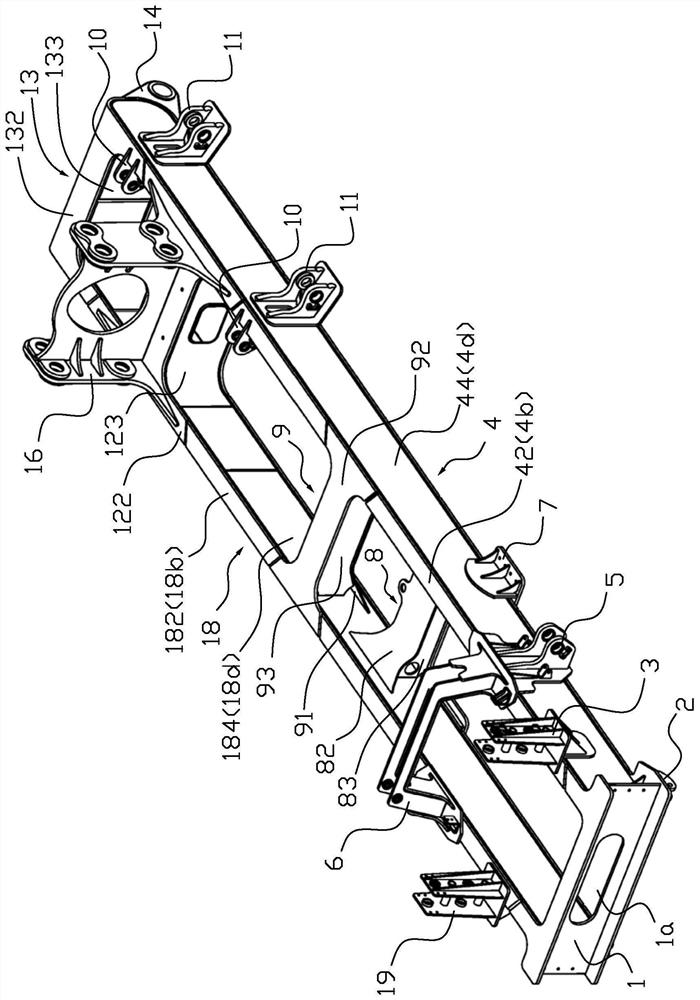

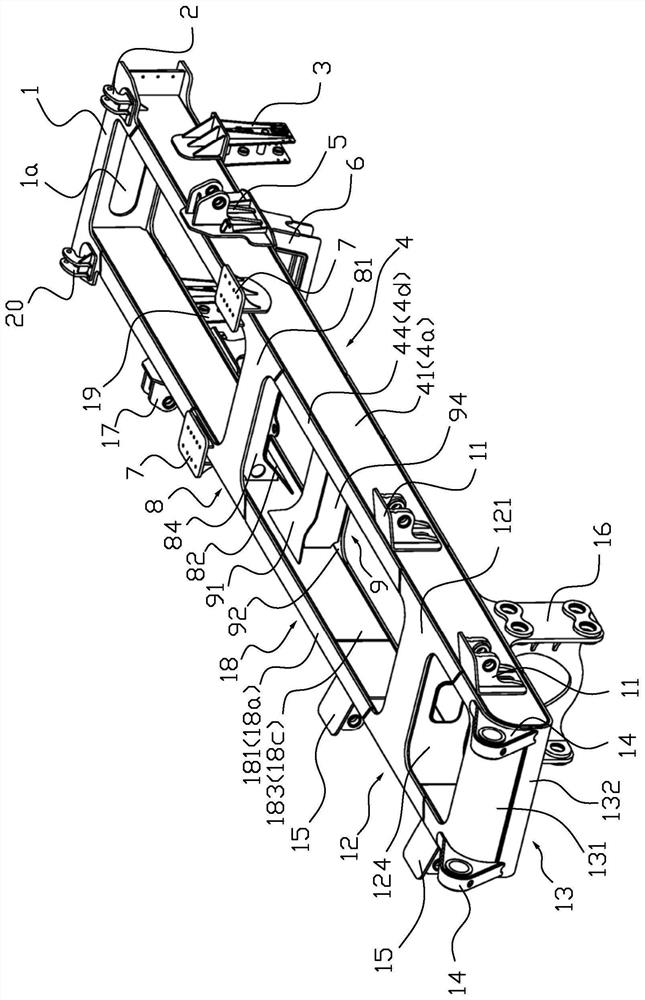

Compact bogie with built-in axle boxes for high-cold subway vehicles

ActiveCN107628049AReduce fixed wheelbaseSmall turning radiusRailway wheel guards/bumpersAxle-boxesTraction motorWheelbase

The invention discloses a compact bogie with built-in axle boxes for high-cold subway vehicles and belongs to the field of bogie devices for railway vehicles. The compact bogie with the built-in axleboxes for high-cold subway vehicles comprises two drive devices, two brake devices, two wheel set devices, a compact casting structure, a compact secondary suspension system and two wheel set built-inaxle box devices, wherein each wheel set device comprises an axle and wheels arranged at two ends of the axle symmetrically, each drive device comprises a traction motor and a gearbox, and each brakedevice comprises two wheel set brakes. The compact bogie with the built-in axle boxes for high-cold subway vehicles has the advantages that a bogie fixed wheel base is reduced substantially while structural strength is ensured, and yaw angle stiffness of wheel sets and distorsion stiffness of the bogie are both reduced effectively, so that a rotation radius of the bogie is decreased, the curve passage capacity thereof is improved to meet the anti-collision requirements of horizontal damping and curve bends completely, and the space occupied by a retainer of a previous horizontal buffer is saved; by the aid of a snow plow device and three-rail ice-snow scraper devices, the compact bogie is applicable to high-latitude extremely-cold regions.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

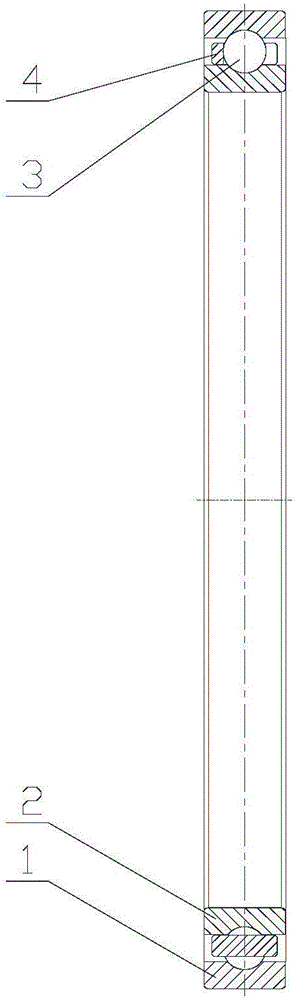

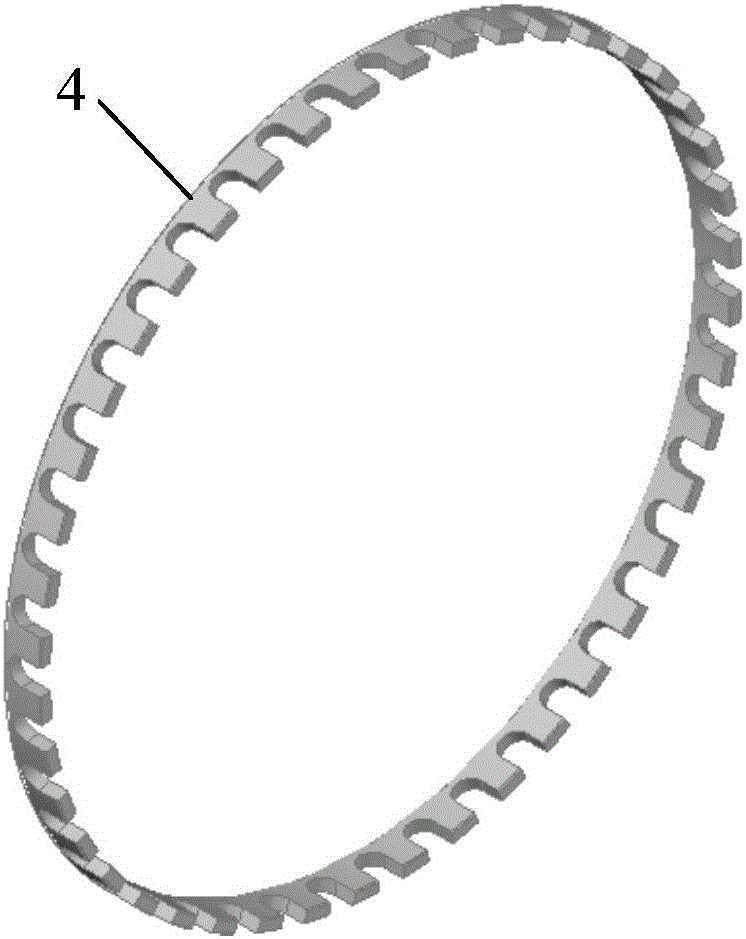

Machining method of large thin-wall bearing ring

The invention relates to a machining method of a large thin-wall bearing ring. The machining method comprises the steps that 1, pretreatment is carried out, wherein a bearing ring rough body is heated to 180-220 DEG C and kept at the temperature for 10-14 h; 2, the ring is subjected to heat treatment; 3, low-temperature cooling treatment is carried out, wherein the temperature is decreased to -65--75 DEG C and kept for 1.5-2.5 h; 4, rough grinding machining is carried out; 5, primary additional tempering is carried out, wherein the roughly-ground product is heated to 140-160 DEG C and kept at the temperature for 22-24 h; 6, semi-accurate machining is carried out; 7, secondary additional tempering is carried out, wherein the semi-accurate ground product is heated to 140-160 DEG C and kept at the temperature for 22-24 h; and 8, final grinding machining is carried out. By means of the machining method, the factors that before heat treatment, machining stress deformation is caused, quenching stress is too large, and stress cannot be completely released through one-time tempering are eliminated, the problem that large thin-wall bearing parts are large in heat treatment deformation is relieved, bearing size stability is improved, machining stress is sufficiently released, machining precision is improved, and therefore the surface quality and rotating precision of a bearing are improved.

Owner:LUOYANG BEARING RES INST CO LTD

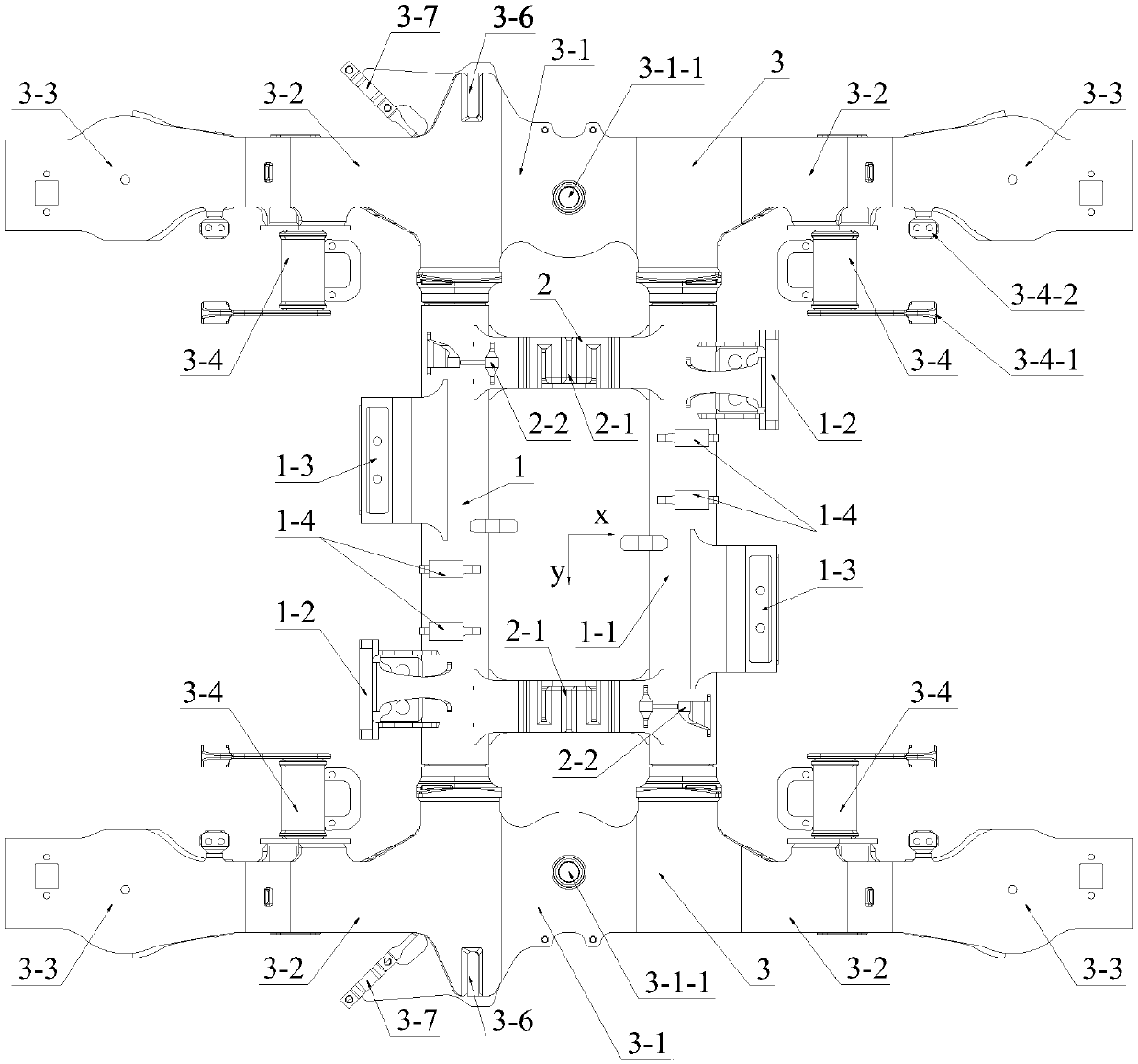

Compact type bogie with internally-arranged axle boxes for subway vehicle

ActiveCN107697091AReduce fixed wheelbaseSmall turning radiusBogiesBogie-underframe connectionsBogieGyration

The invention discloses a compact type bogie with internally-arranged axle boxes for a subway vehicle and belongs to the field of bogies for subway vehicles. The compact type bogie comprises two driving devices, two braking devices, two wheel pair devices, a compact type cast framework, a compact type secondary suspension system and two wheel pair internally-arranged type axle box devices. The wheel pair devices comprise axles and wheels symmetrically arranged at the two ends of the axles, the driving devices comprise traction motors and gear boxes, and each braking device comprises two wheelpair brakes. The fixed axle distance of the bogie is reduced substantially while structural strength is guaranteed, the yaw angle rigidity of wheel pairs and the warping rigidity of the bogie are reduced effectively, accordingly the gyration radius of the bogie is decreased, the small-radius curve passing capacity of the bogie is improved, the transverse damping requirement and the anti-collisionrequirement on a curve bend can be met completely, and the occupied space of an original transverse buffer stopping seat is saved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

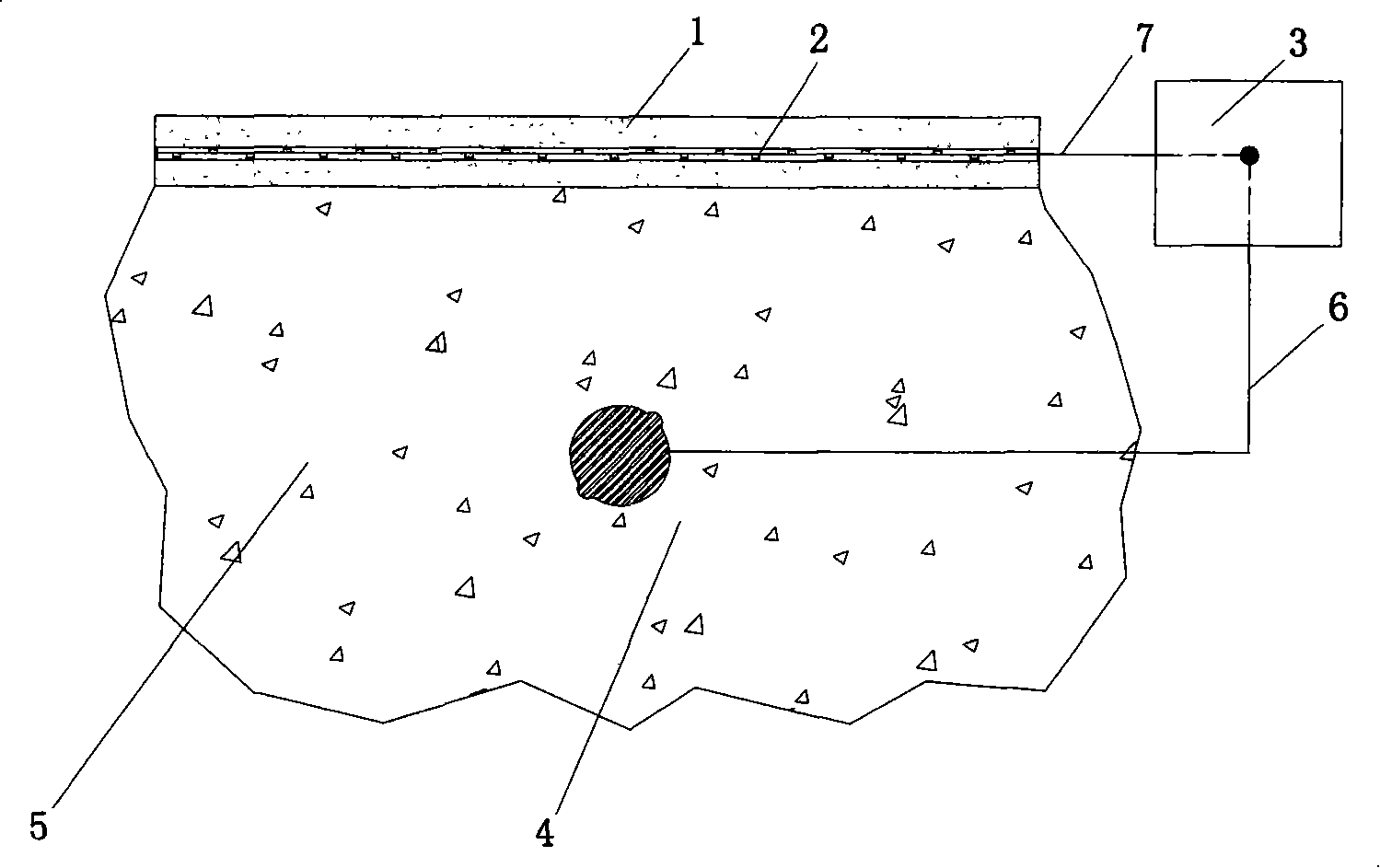

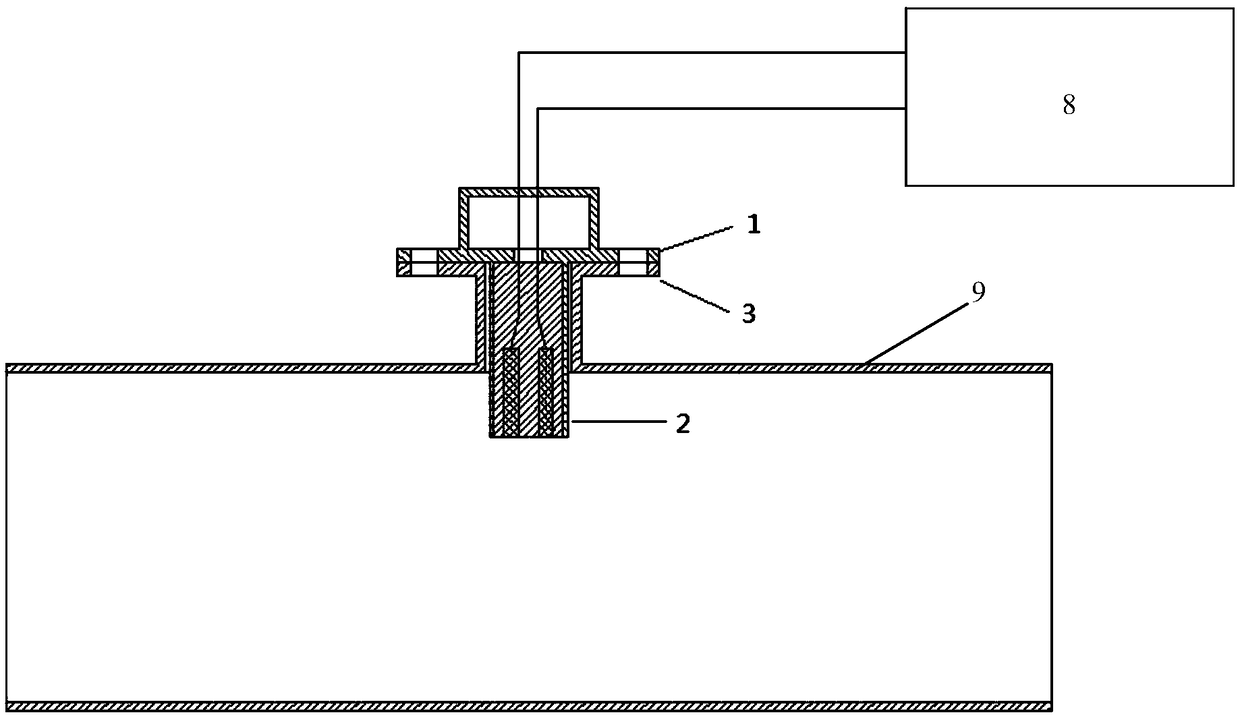

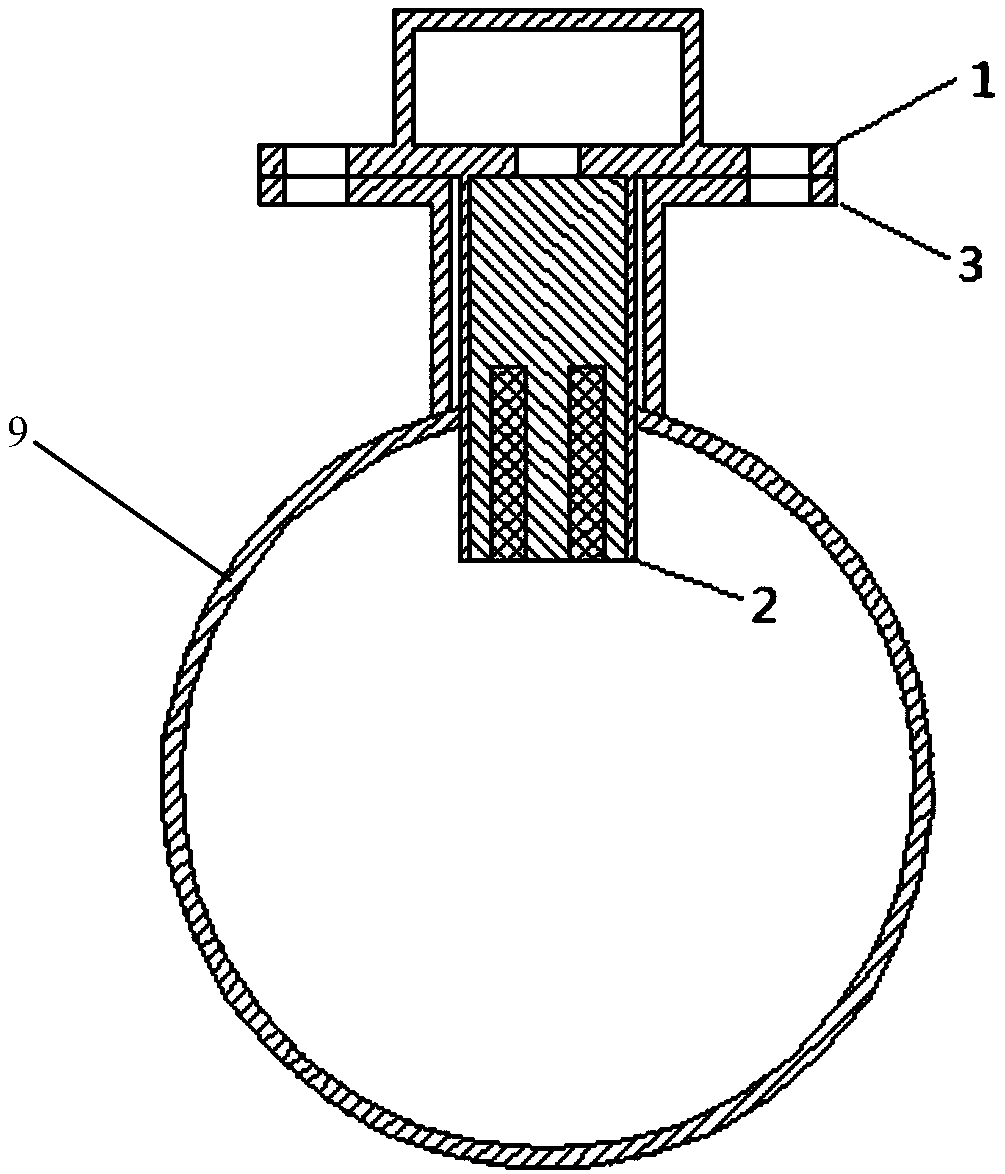

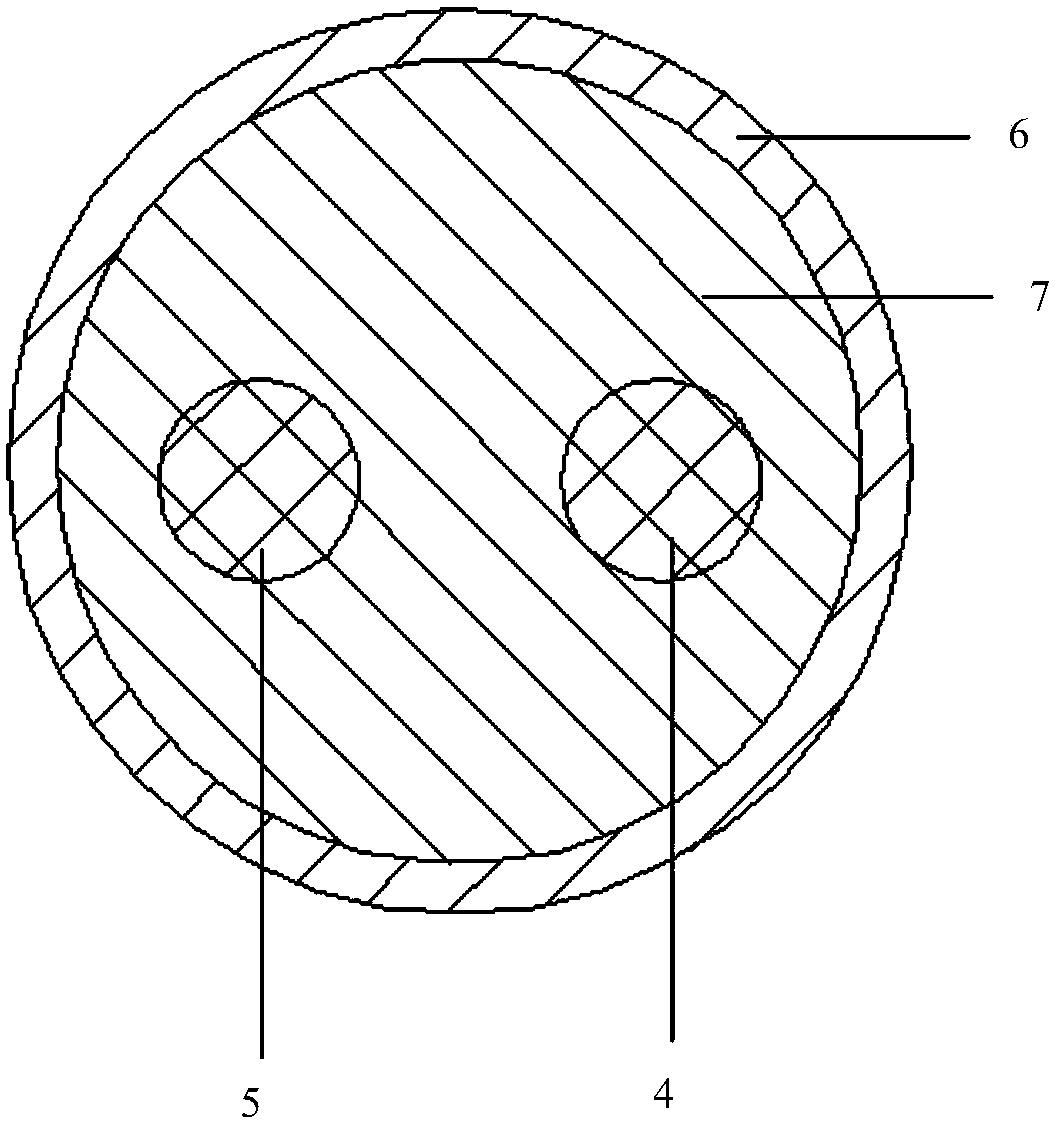

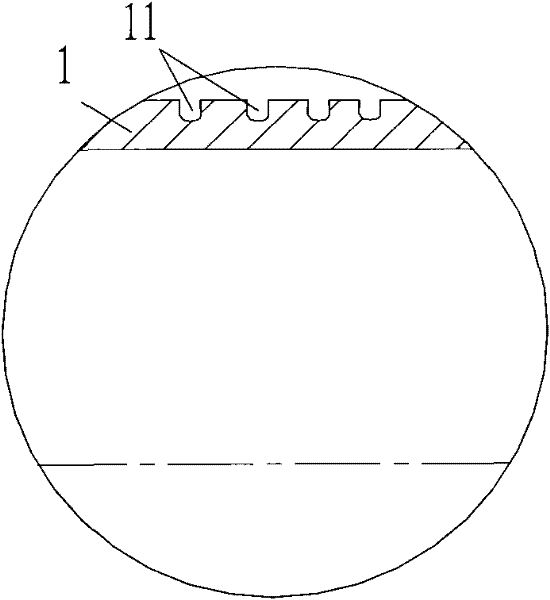

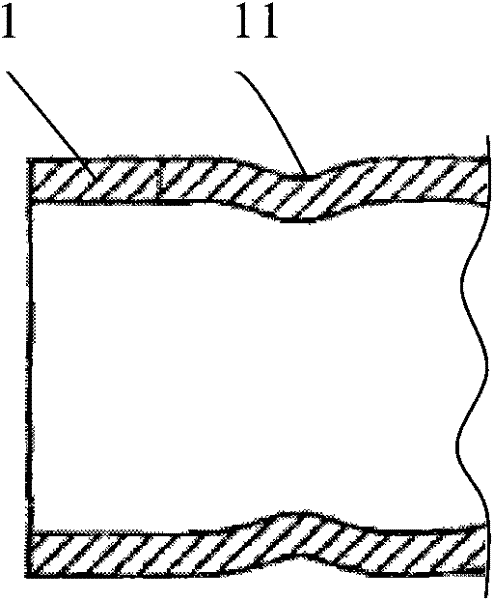

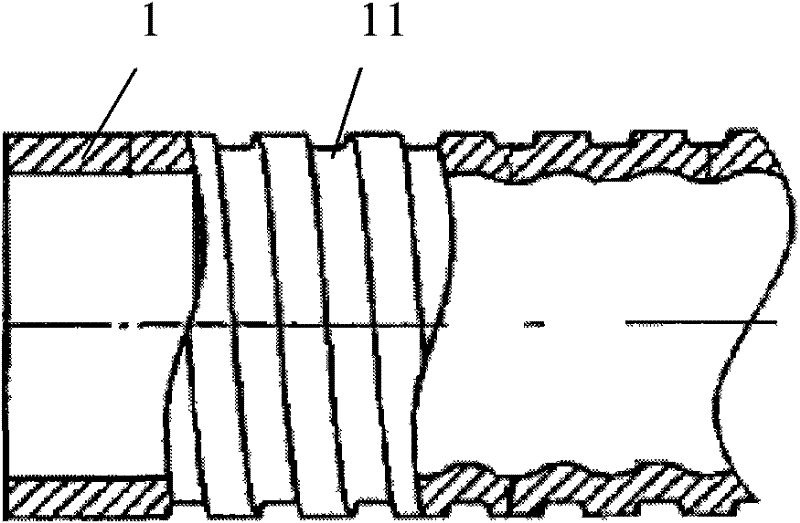

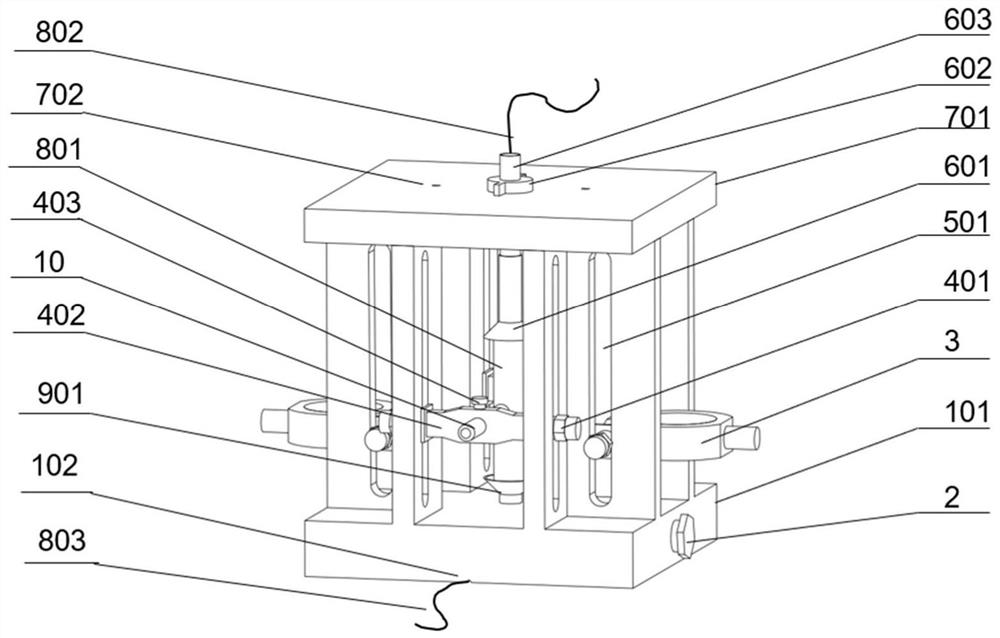

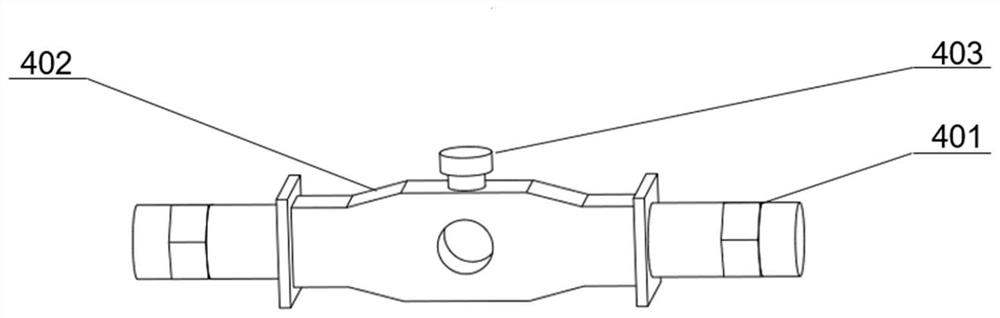

Device and method for measuring breakage rate of inner wall coating of pipeline

PendingCN109358094AEasy to installLong design lifeMaterial analysis by electric/magnetic meansPotentiostatEngineering

The invention belongs to the field of anticorrosion and antifouling, and relates to a device and a method for measuring the breakage rate of a coating inner wall of a pipeline, and is combined with acathode protection system for an impressed current. The device comprises a flange plate (1), an electrode probe (2), a flange base (3) welded on the pipeline, and a potentiostat (8). The flange plate(1), which carries the electrode probe (2), is connected and sealed to the flange base (3) through bolts. The electrode probe (2) is intended to obtain a current signal flowing through the device. Thecurrent is combined with the output current of the cathode protection system of the pipeline, so that the coating breakage rate of the inner wall of the pipeline can be calculated. According to the device and the method for measuring the breakage rate of the inner wall coating of the pipeline, the device can monitor online and measure the breakage condition of the coating on the inner wall of thepipeline where a cathode protection and anticorrosive system has been installed; and can measure the breakage rate of the inner and surface coating. The device is easy to install, does not need to replace, and can monitor online. The method is simple, and the calculation result is better matched with the actual situation.

Owner:青岛钢研纳克检测防护技术有限公司 +3

Paving method of durable tunnel pavement

InactiveCN104947564AGood flexibilityImprove waterproof performanceIn situ pavingsClimate change adaptationChipsealSand blasting

The invention discloses a paving method of a durable tunnel pavement. The paving method comprises the following steps: (1) carrying out sand blasting treatment on a cement concrete plate, spreading rubber asphalt and gravel on the surface of the cement concrete plate, and grinding to form a rubber asphalt and gravel seal coating; (2) grinding to form an asphalt mixture substrate on the rubber asphalt and gravel seal coating, pouring cement-based mortar, and naturally curing to form a poured semi-flexible paving lower layer; (3) spreading modified emulsified asphalt so as to form a modified emulsified asphalt layer; and (4) paving a fine-grain type asphalt mixture or a medium-grain type asphalt mixture to form a high-modulus warm mixing inflaming-retarding asphalt mixture paving upper layer. According to the invention, the paving method is strong in universality and simple in construction process, adopts a relatively conventional material, is strong in operability, and has good construction peaceability; with the whole paving structure, design service life can be obviously prolonged and can achieve 20-30 years, and good fireproofing, skid resistance, safety, as well as energy conservation and environment protection effects are achieved.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

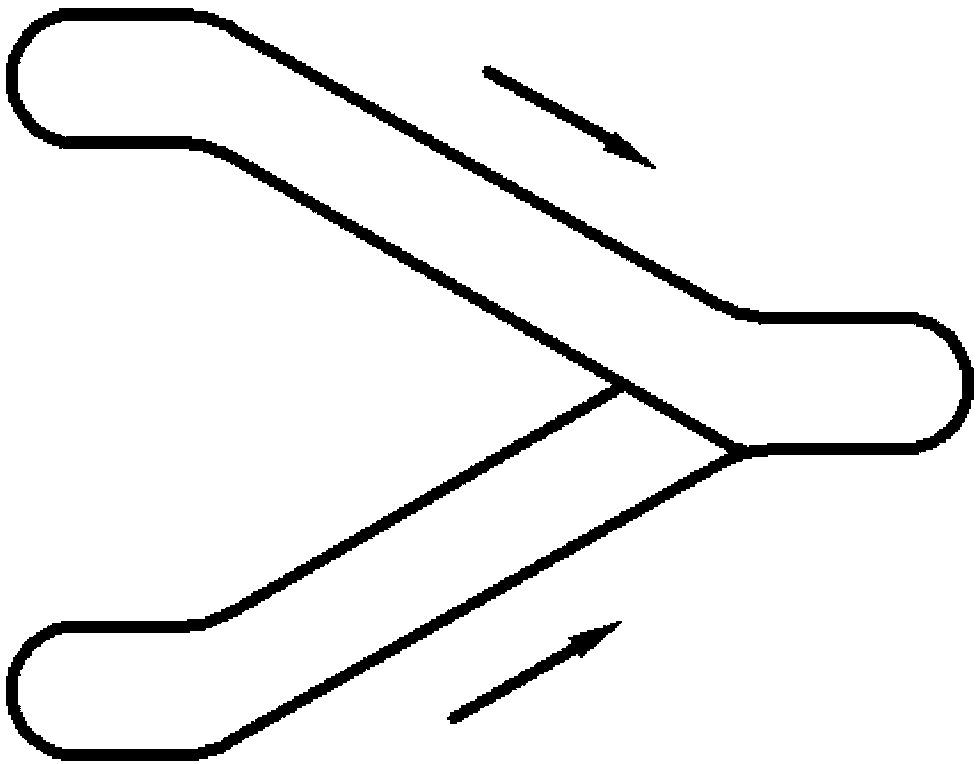

Escalator based on a potential energy transformation single drive mechanism

InactiveCN103359597ATo achieve the purpose of energy savingImprove reliabilityEscalatorsDrive shaftElectric machine

The invention discloses an escalator based on a potential energy transformation single drive mechanism. The single drive mechanism comprises an electric motor, a drive shaft, a downward driven sprocket and an upward driven sprocket, wherein a drive shaft drive sprocket is arranged at the middle part of the drive shaft, and is connected with a rotating shaft of the electric motor through a chain; a downward drive sprocket is arranged at one end of the drive shaft; an upward drive sprocket is arranged at the other end; the downward driven sprocket is connected with the downward drive sprocket through a downward chain; the upward driven sprocket is connected with the upward drive sprocket through an upward chain. Through the utilization of the fact that the gravitational potential energy of a downward passenger is transformed into the kinetic energy and the gravitational potential energy of an upward passenger, the running load of the electric motor is reduced, and the running cost of the escalator is lowered.

Owner:SOUTH CHINA UNIV OF TECH

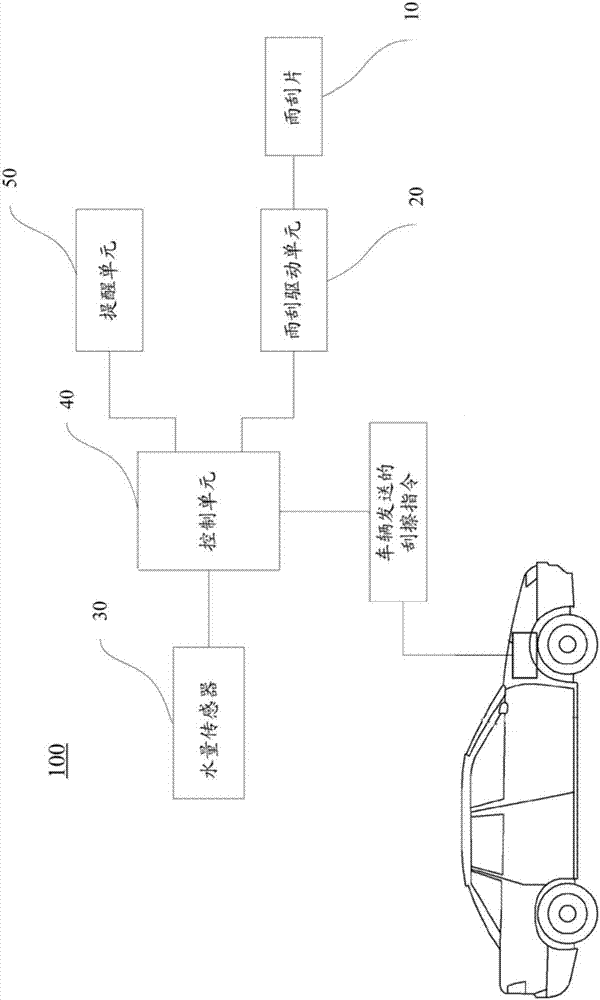

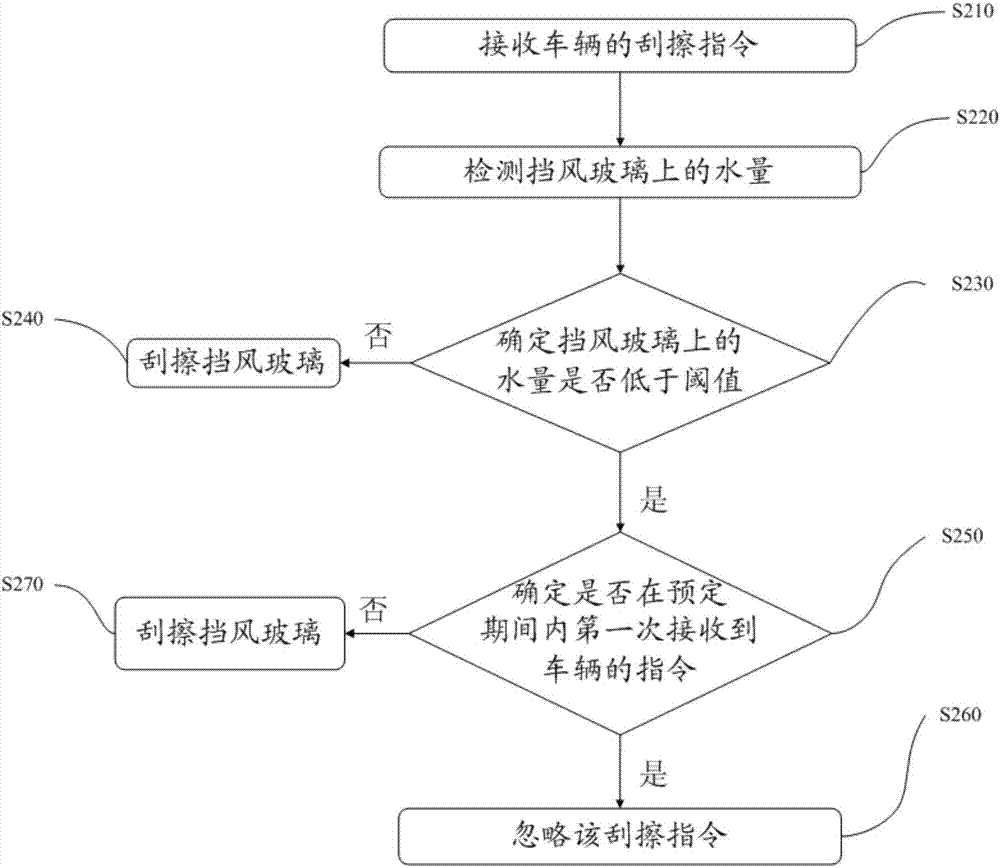

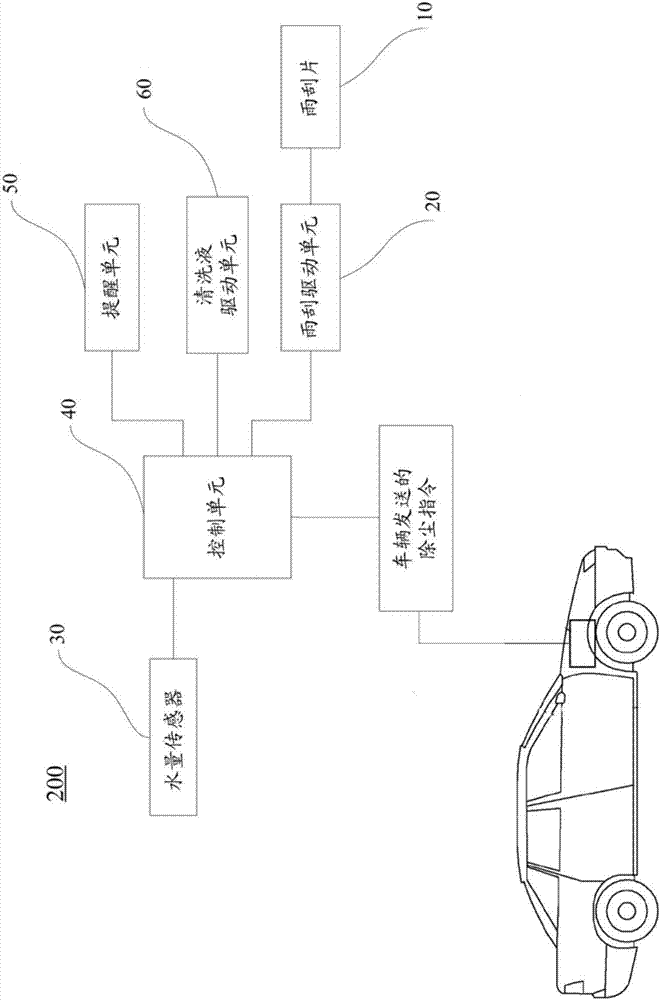

Windshield wiper system and vehicle with windshield wiper system

The invention discloses a windshield wiper system and a vehicle with the windshield wiper system. The windshield wiper system comprises at least one wiper blade, a wiper driving unit, a water amount sensor and a control unit; the wiper blades are used for wiping a windshield of the vehicle; the wiper driving unit is connected with the wiper blades and used for providing driving force for the wiperblades; the water amount sensor is used for detecting the amount of water on the windshield; the control unit is connected with the wiper driving unit and the water amount sensor, wherein under the conditions that the control unit receives a wiping instruction representing that a vehicle user intends to wipe the windshield for the first time within a predetermined period and the amount, detectedby the water amount sensor, of the water on the windshield is lower than a threshold value, the control unit is configured not to activate the wiper driving unit.

Owner:AUDI AG

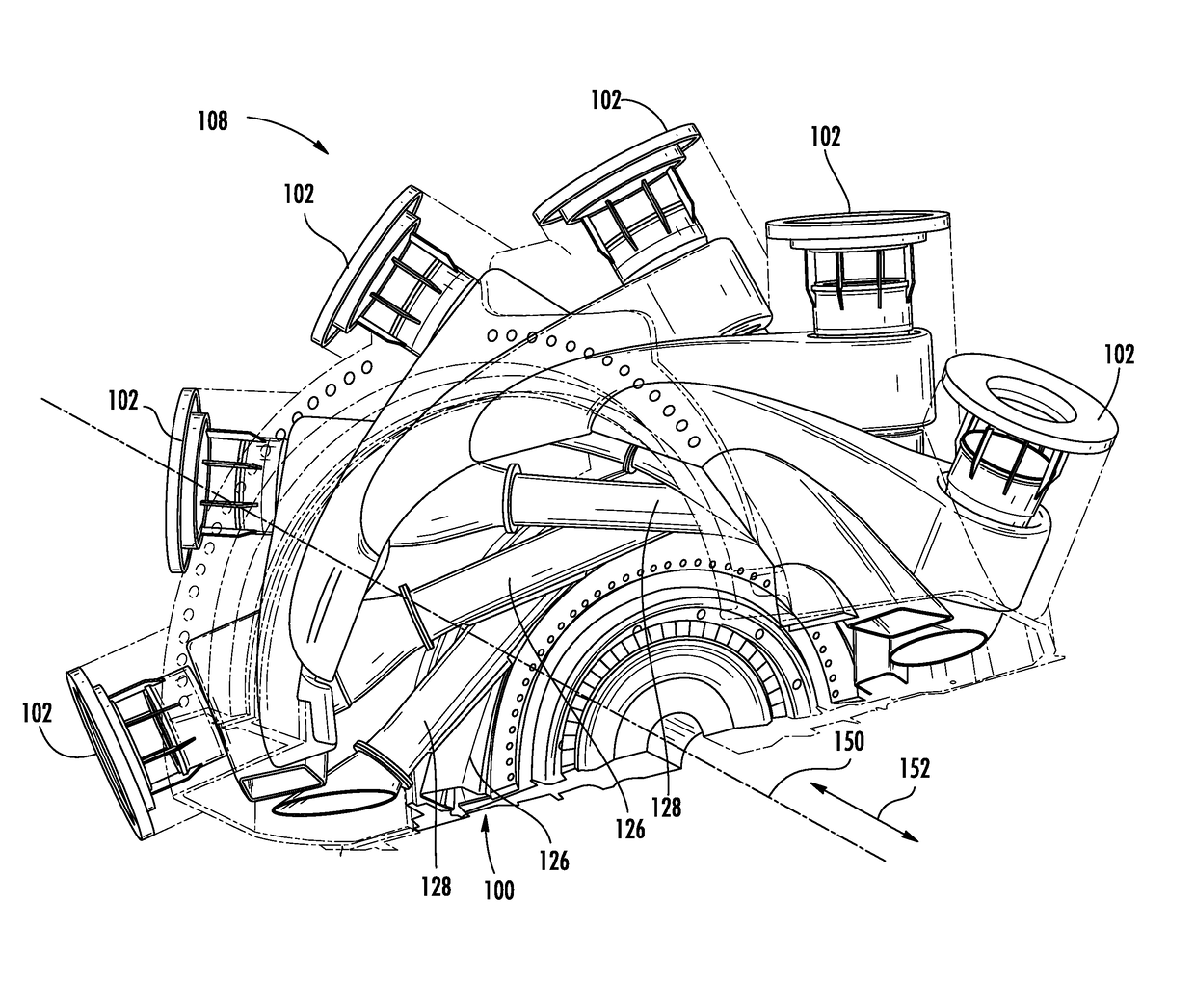

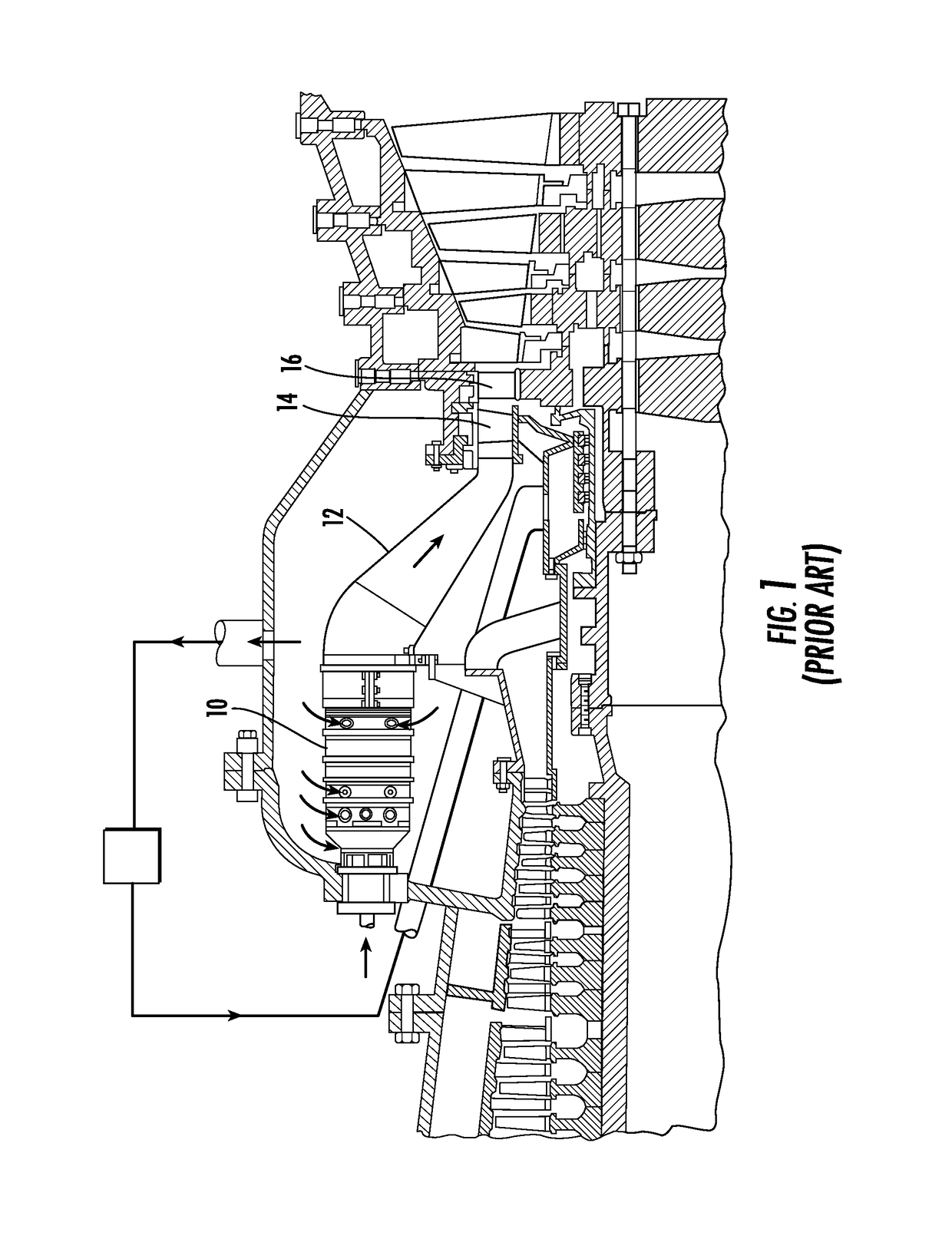

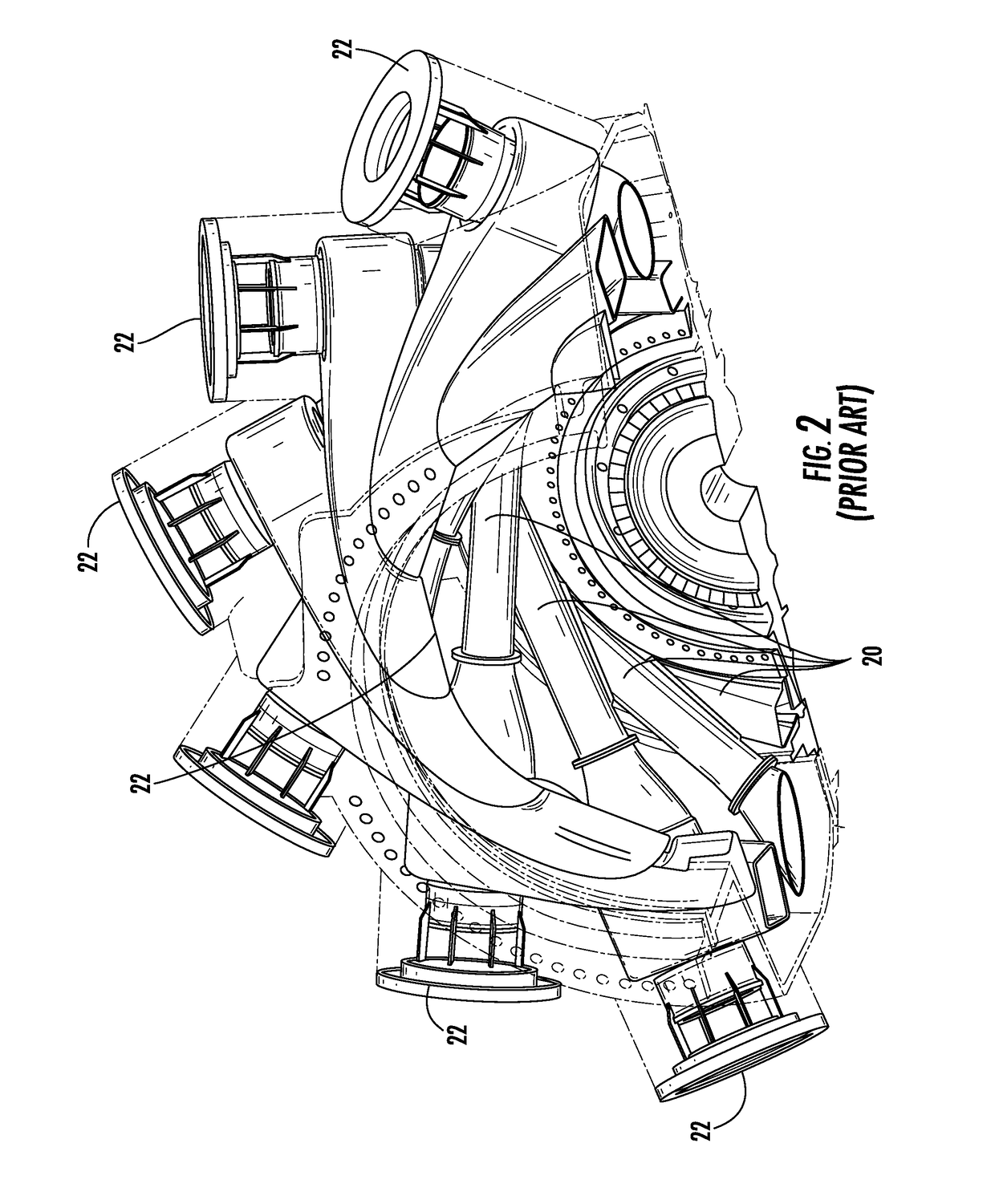

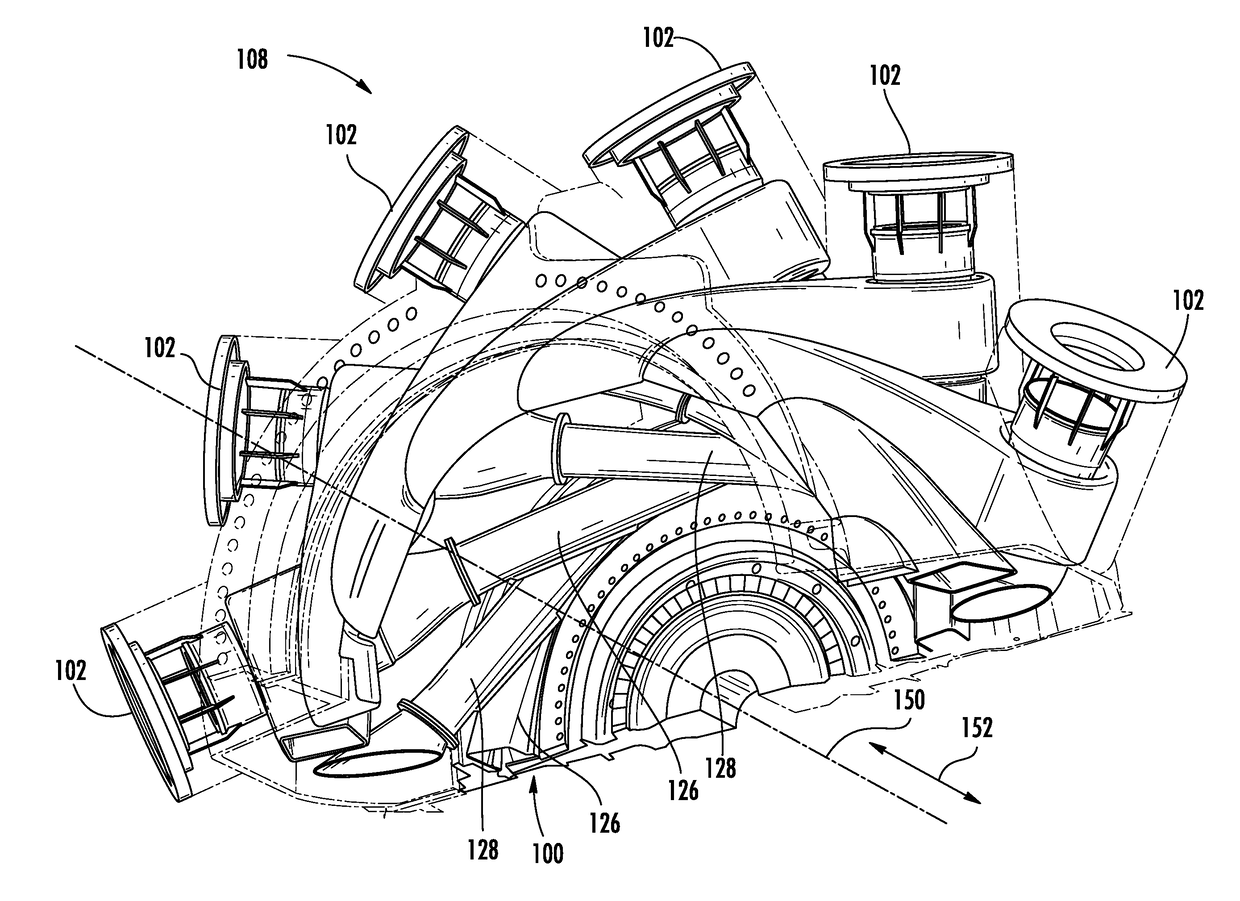

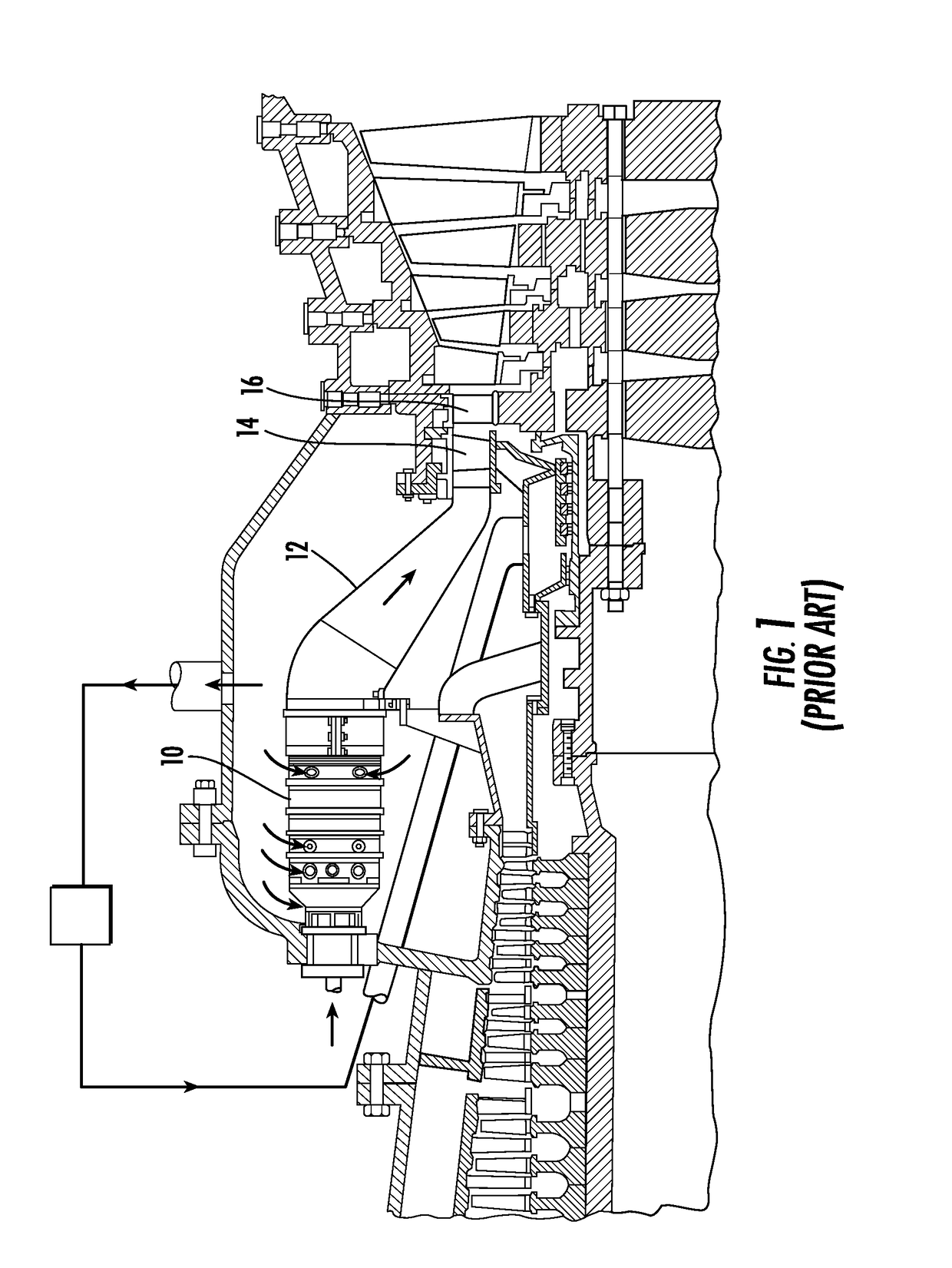

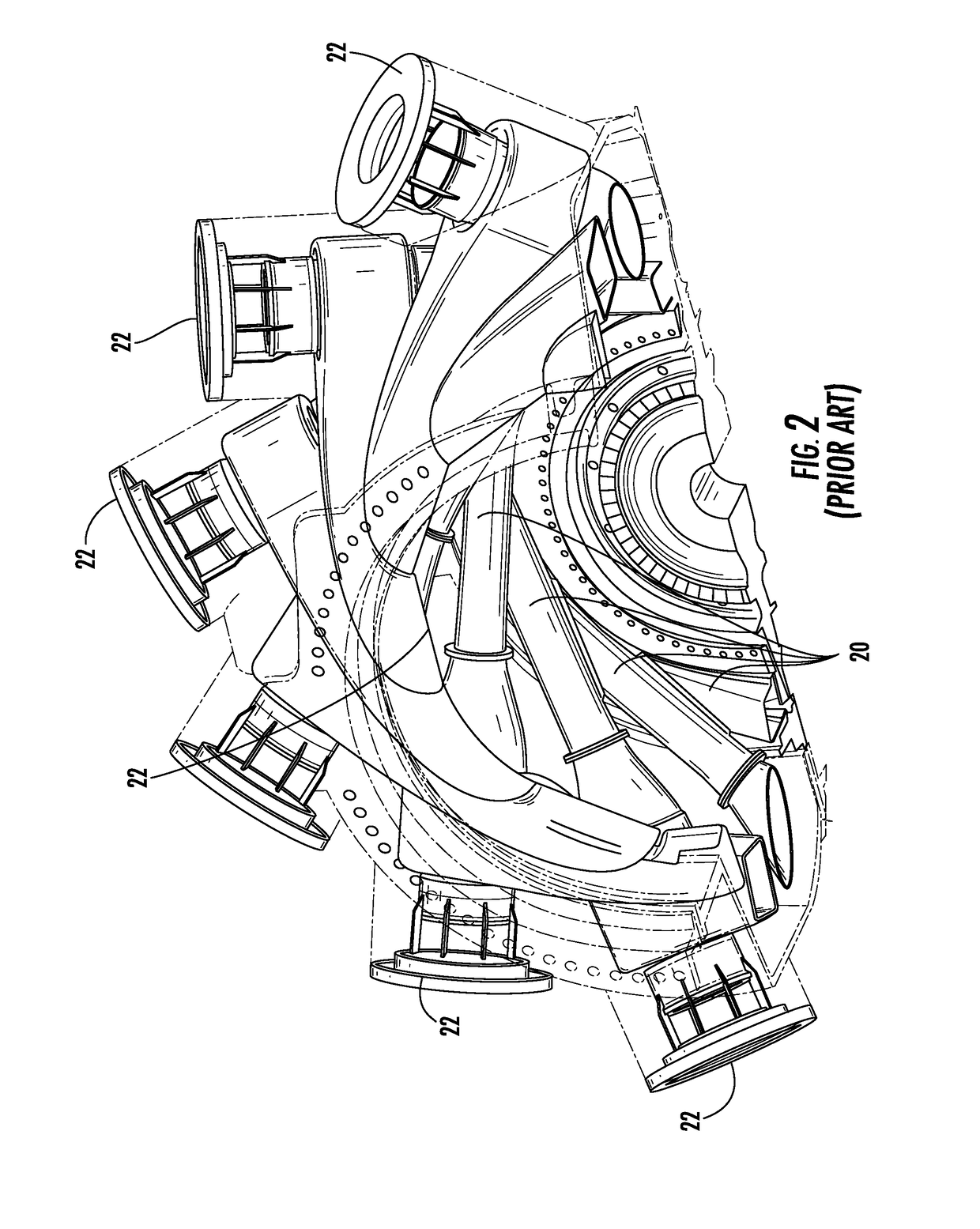

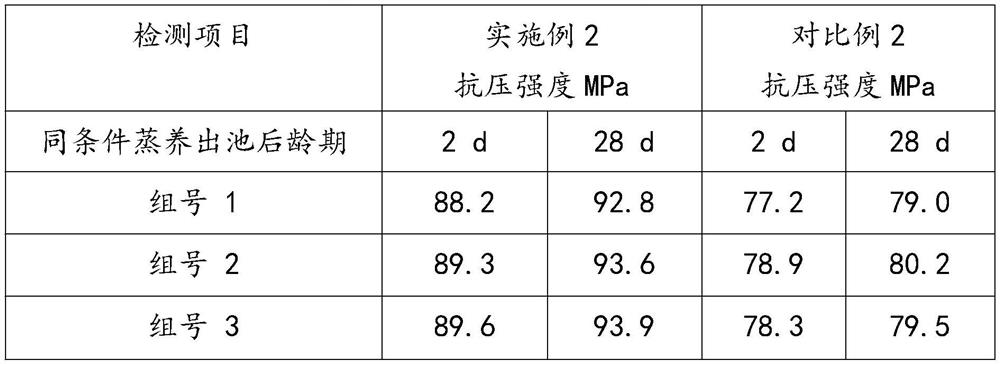

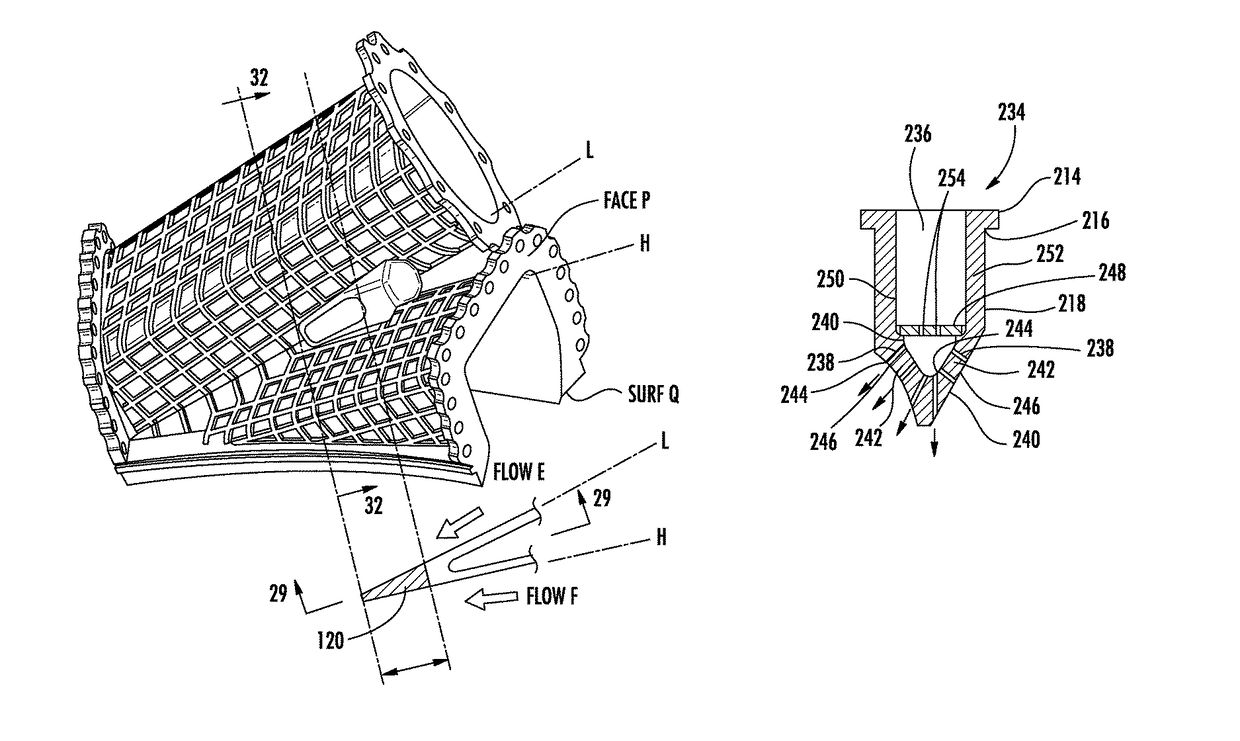

Converging flow joint insert system at an intersection between adjacent transitions extending between a combustor and a turbine assembly in a gas turbine engine

InactiveUS20170130595A1Eliminates stress formationProlong lifeContinuous combustion chamberEngine manufactureTrailing edgeCombustion chamber

A transition duct system (100) for routing a gas flow from a combustor (102) to the first stage (104) of a turbine section (106) in a combustion turbine engine (108), wherein the transition duct system (100) includes one or more converging flow joint inserts (120) forming a trailing edge (122) at an intersection (124) between adjacent transition ducts (126, 128) is disclosed. The transition duct system (100) may include a transition duct (126, 128) having an internal passage (130) extending between an inlet (132, 184) to an outlet (134, 186) and may expel gases into the first stage turbine (104) with a tangential component. The converging flow joint insert (120) may be contained within a converging flow joint insert receiver (136) and disconnected from the transition duct bodies (126, 128) by which the converging flow joint insert (120) is positioned. Being disconnected eliminates stress formation within the converging flow joint insert (120), thereby enhancing the life of the insert. The converging flow joint insert (120) may be removable such that the insert (120) can be replaced once worn beyond design limits.

Owner:SIEMENS ENERGY INC

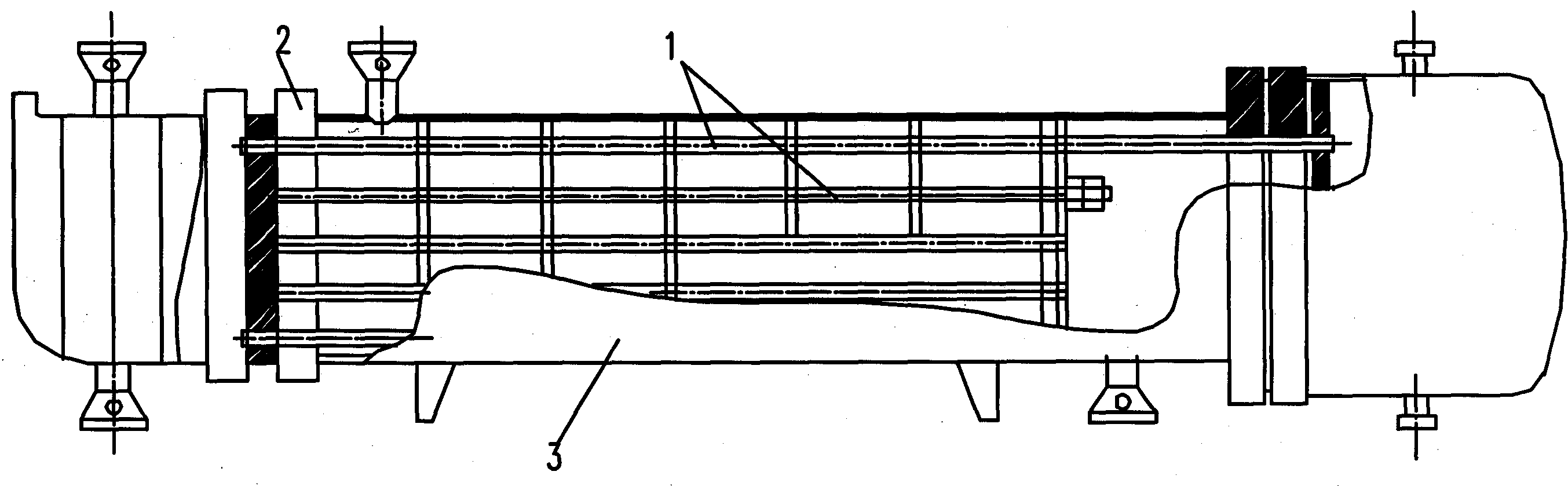

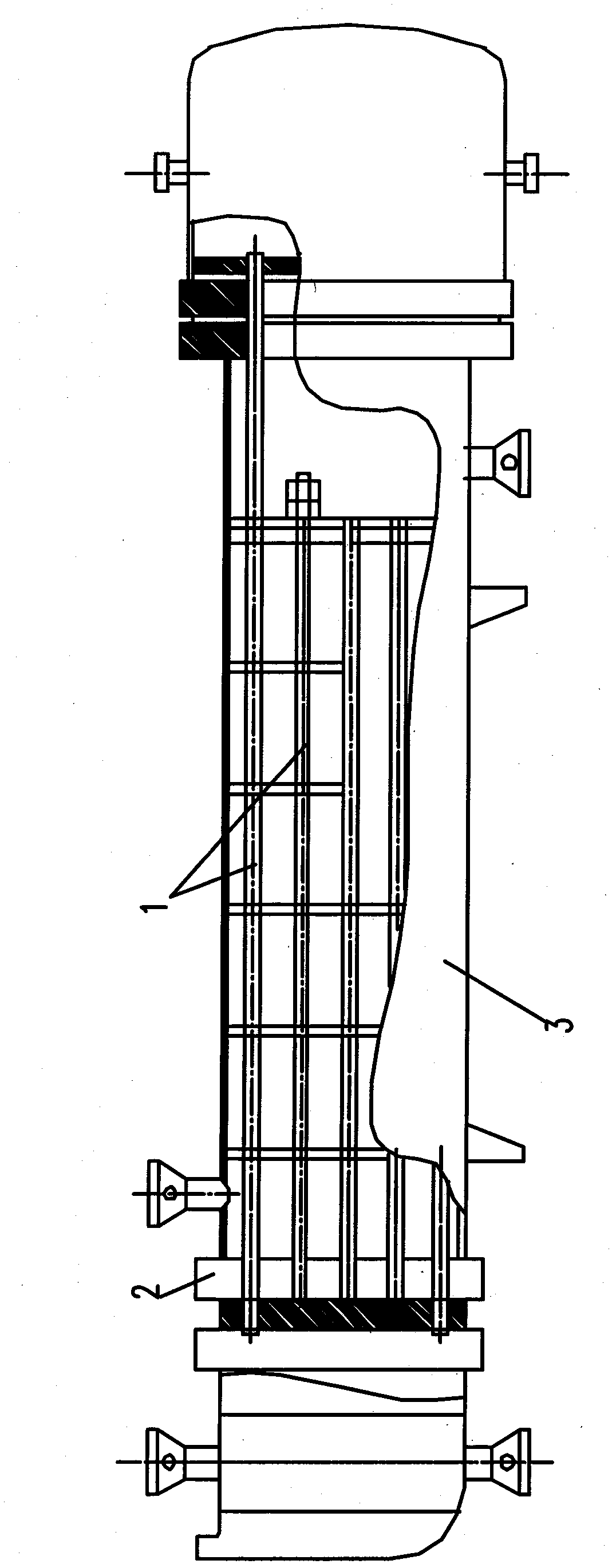

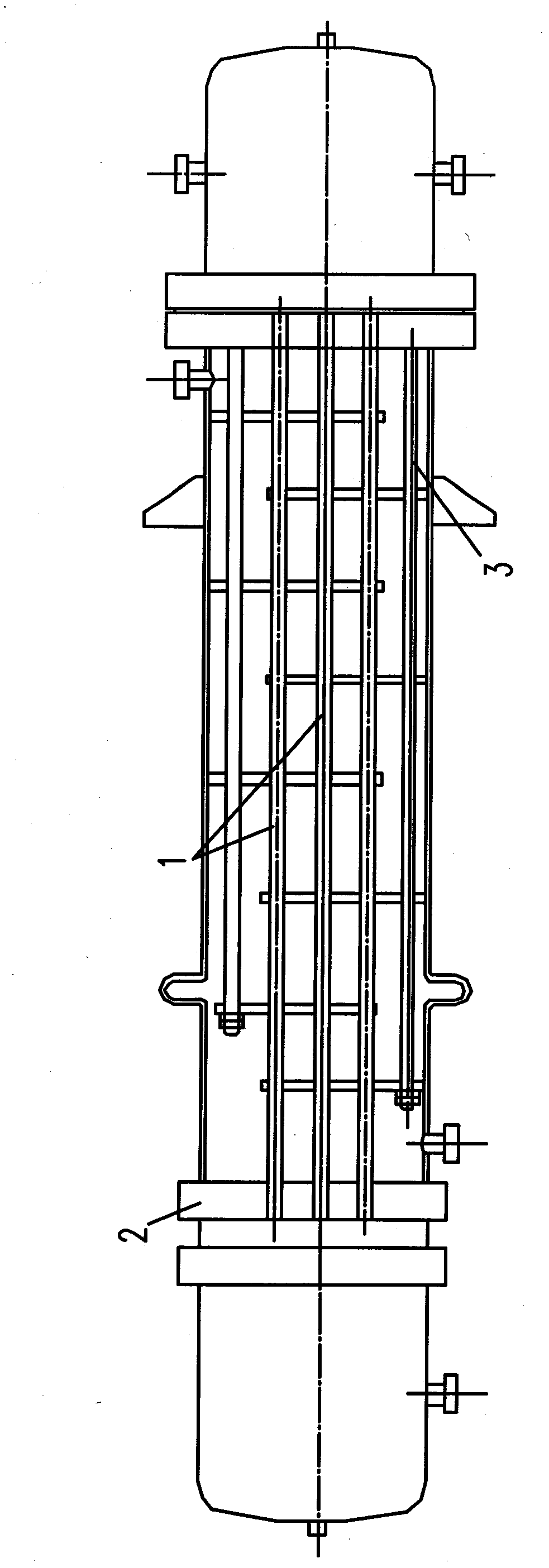

Heat exchange equipment applying multi-layer heat exchange tubes

InactiveCN102095324AImprove heat transfer efficiencyLow manufacturing costChemical industryTubular elementsFertilizerPetroleum

The invention discloses heat exchange equipment applying multi-layer heat exchange tubes. The heat exchange equipment at least comprises a tube bundle body, wherein a tube plate is arranged on the tube bundle body, and a plurality of multi-layer heat exchange tubes are penetrated in the tube plate; each multi-layer heat exchange tube at least comprises an outer tube, and the outer tube is internally provided with a medium channel; the medium channel is internally provided with a heat exchange part which divides the heat exchange channel into a direct heat exchange area exchanging heat with the outer tube and an indirect heat exchange area exchanging heat with the heat exchange part; and the heat exchange medium in the indirect heat exchange area exchanges heat energy with the heat exchange medium of the direct heat exchange area through the heat exchange part. In the invention, because the multi-layer heat exchange tubes are adopted, the heat exchange efficiency of the indirect heat exchange is greatly increased. The heat exchange equipment also has the advantages of low cost, convenience for manufacturing, and the like and is suitable for various industries such as petroleum, chemical engineering, chemical fertilizers, boilers, pharmacy, food, power, nuclear energy, environmental protection, heat supply, and the like.

Owner:SHANGHAI KEMI STEEL TUBE

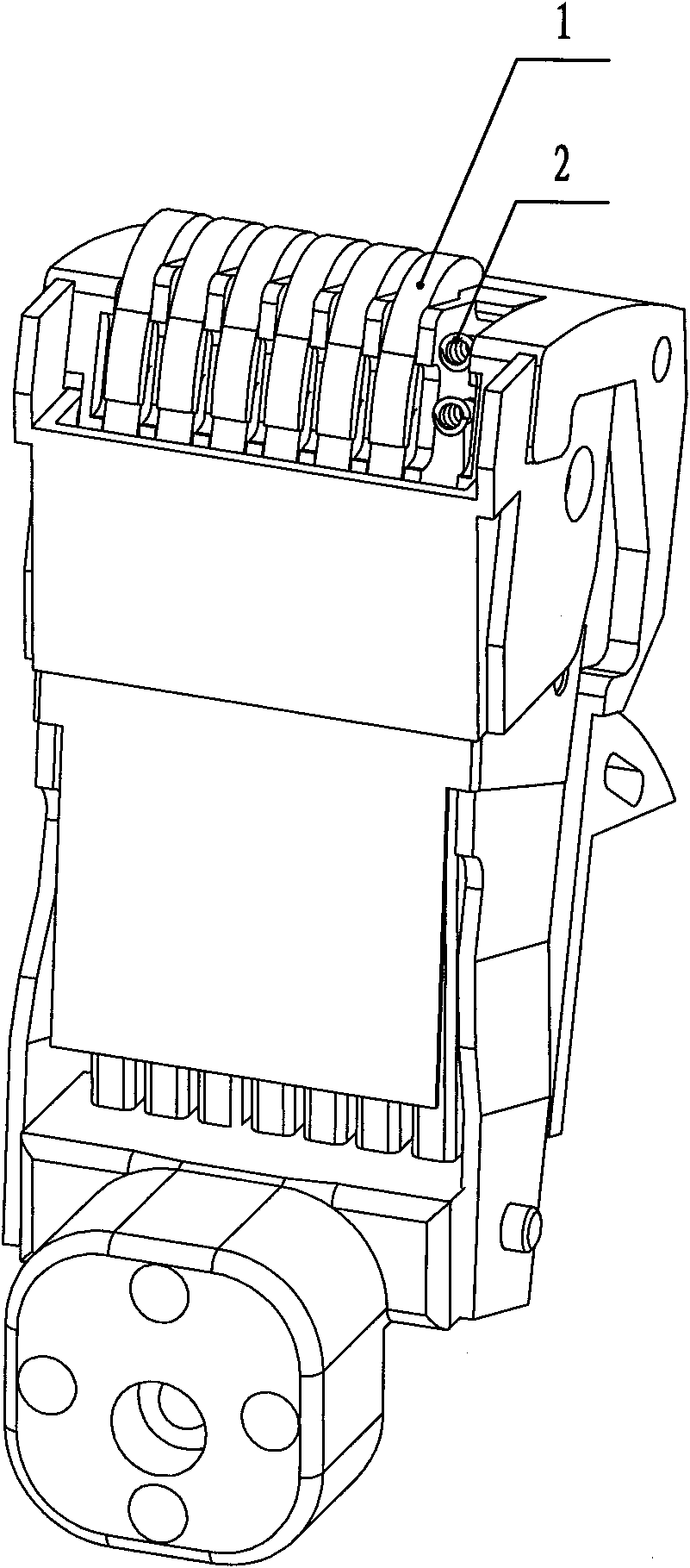

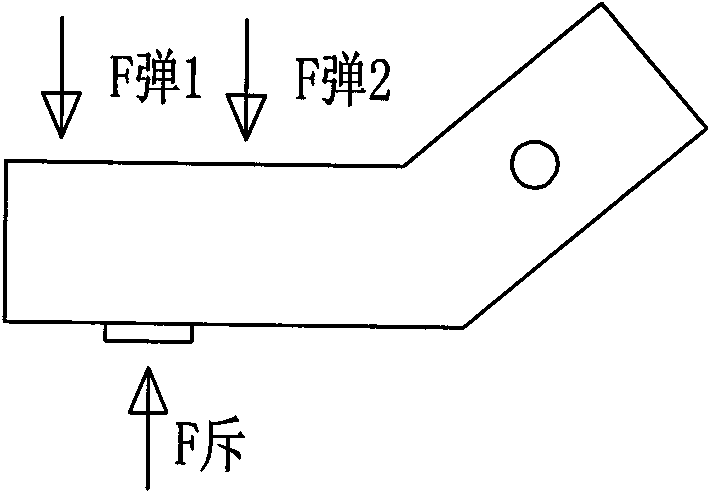

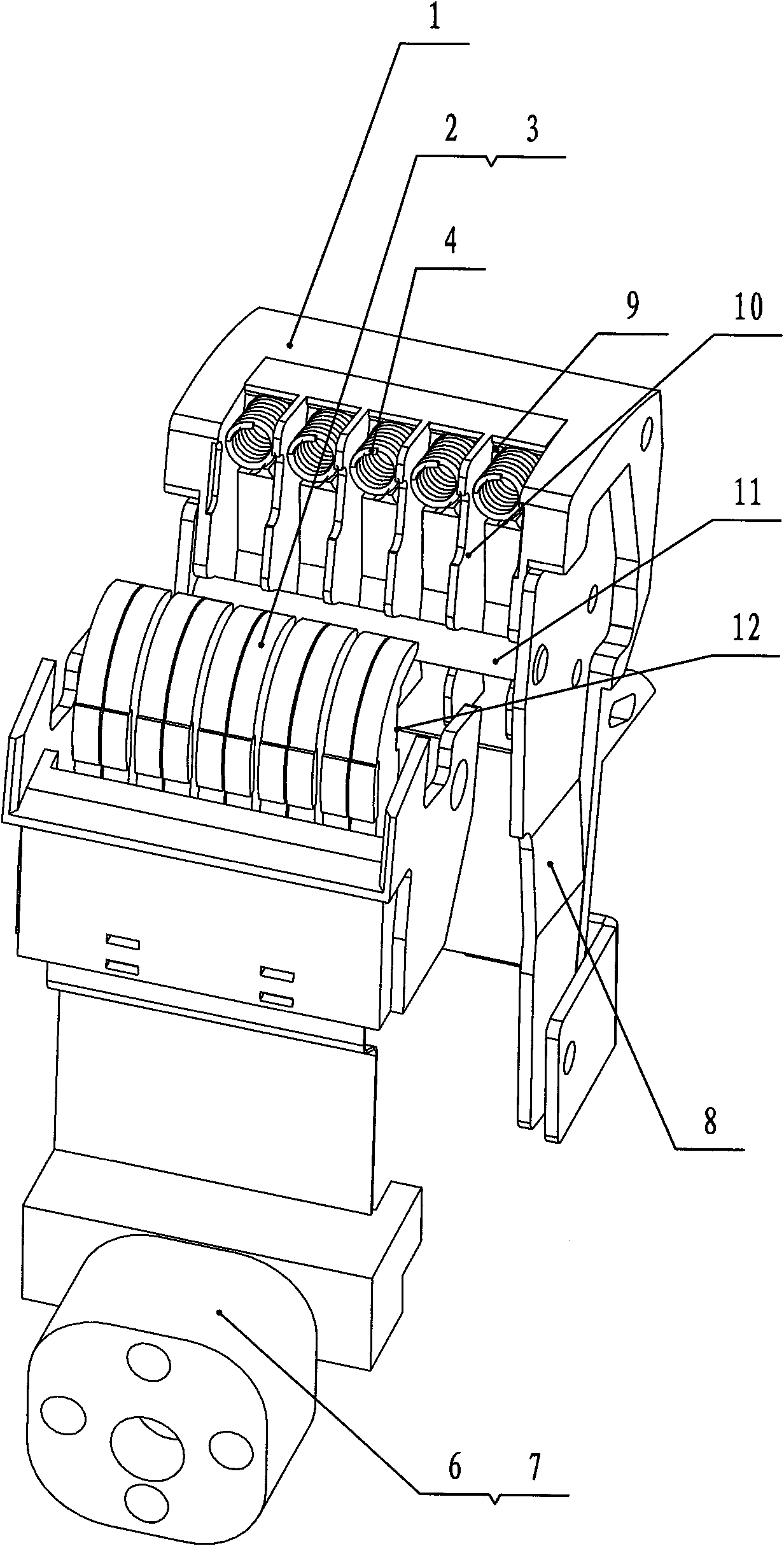

Contact system of circuit breaker

InactiveCN102315046ASolve the problem of occupying too much space in the contact systemReduce the numberProtective switch detailsCircuit-breaking switch contactsPower flowGrating

The invention relates to a contact system of a circuit breaker. The contact system comprises a plurality of contact fingers, contact springs and a contact support, wherein two sides of the contact support are fixed by splints; isolation grating sheets are arranged on the contact support; the plurality of contact fingers are connected together by a shaft; two ends of the shaft are supported by holes in the two splints; the contact springs are arranged in gaps between the stomachs of the contact fingers and the isolation sheets; the contact system is characterized in that: more than one contact finger forms one group; and each group of contact fingers share a group of contact springs. By the contact system, the shorttime withstand current of the circuit breaker can be increased and the whole service life of the circuit breaker can be prolonged.

Owner:BEIJING PEOPLES ELECTRIC PLANT

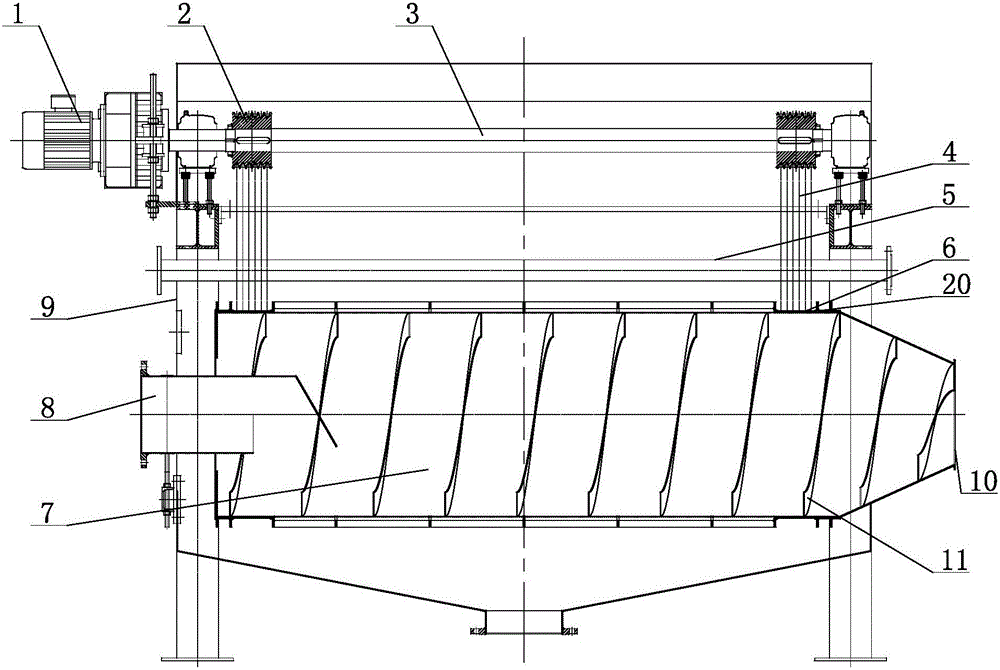

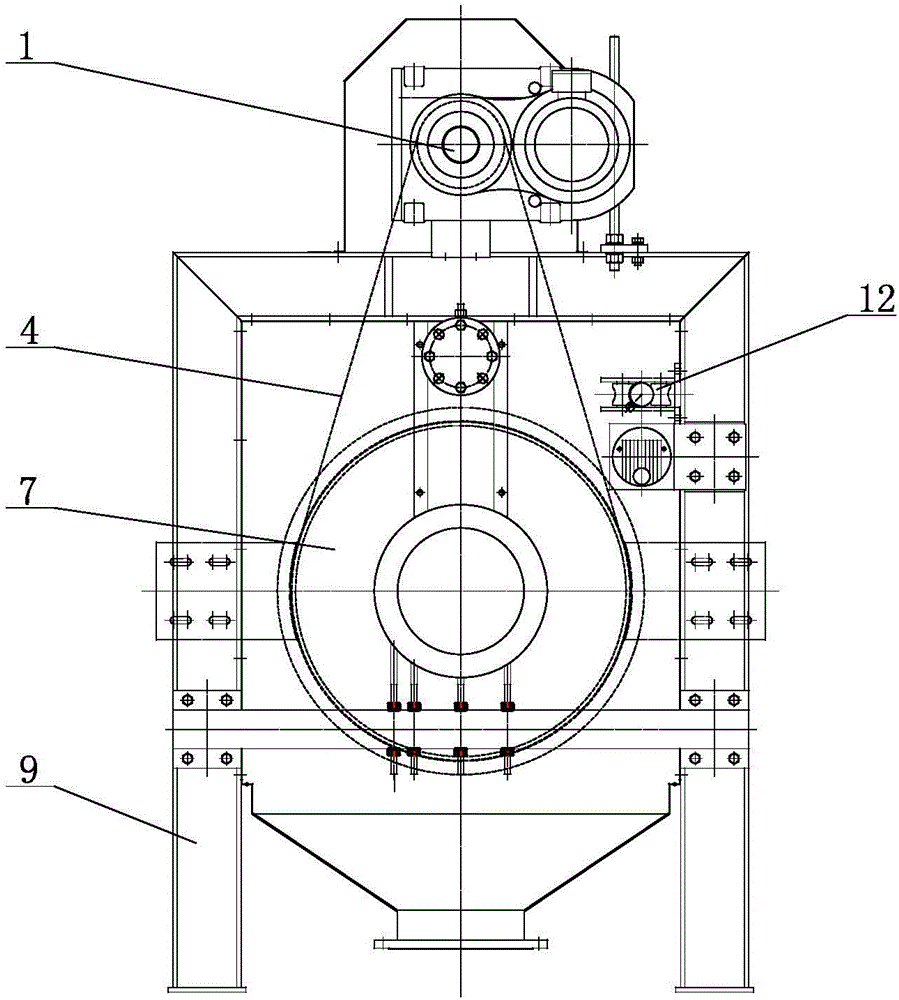

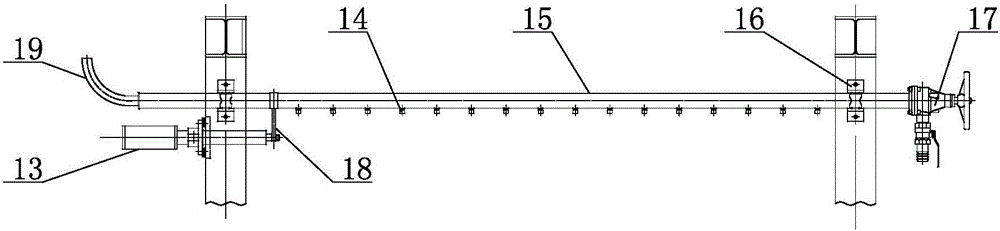

Drum-type pulp washer

ActiveCN106731153AHigh recovery rateSimple structurePaper material treatmentMoving filtering element filtersIndustrial waste waterDrive motor

The invention relates to a drum-type pulp washer. The drum-type pulp washer is used for earlier stage slagging separation of pulping equipment, the interception and transportation of the municipal industrial waste water garbage, or other general suspension-containing water treatment and purification. The drum-type pulp washer comprises a screen cylinder, the screen cylinder is installed on a frame, a dilution water pipe is arranged above the screen cylinder, a main shaft transmission device is arranged above the dilution water pipe, the main shaft transmission device comprises a driving motor and a main shaft, the output end of the driving motor is connected to the main shaft, two ends of the main shaft are provided with driving belt wheels, driving belt installation grooves are arranged at the outer side of the screen cylinder corresponding to the driving belt wheels, the driving belt wheels are connected to the driving belt installation grooves through driving belts, the dilution water pipe and the main shaft transmission device are installed on the frame, and one side above the screen cylinder is provided with a mobile cleaning device. Compared with the existing advanced tailings treatment device such as a pressure-type tailings sieve, the drum-type pulp washer greatly simplifies a system process and reduces power consumption. Compared with the vibrating frame flat screen, the drum-type pulp washer can greatly improve the sorting efficiency and optimize the operating environment.

Owner:SHANDONG CHENZHONG MACHINERY

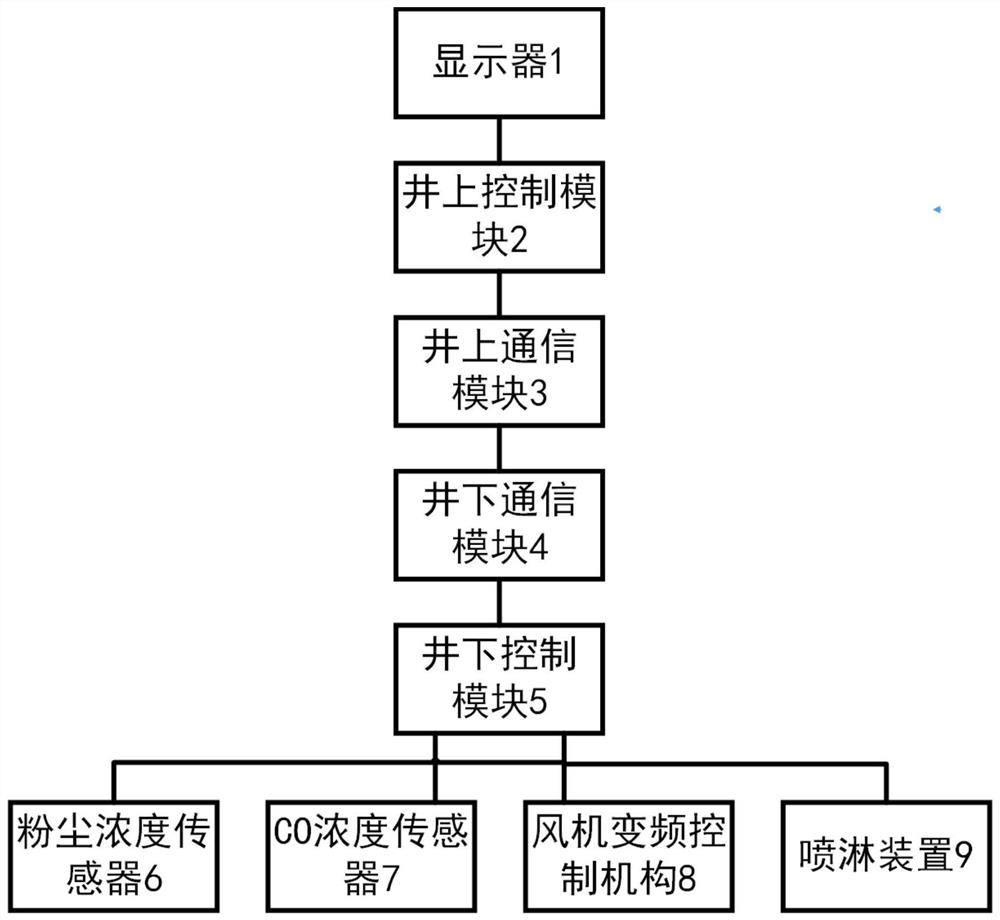

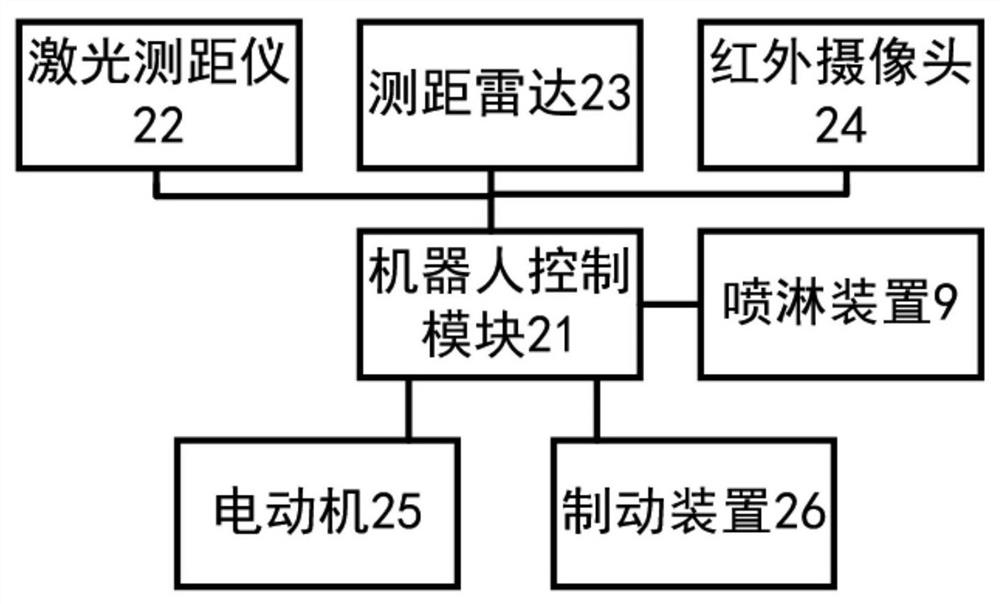

Downhole intelligent monitoring system based on Internet of Things

ActiveCN113556701ASolve maintenance difficultiesSolve the measurement real-timeTransmission systemsParticular environment based servicesDust controlThe Internet

The invention provides a downhole intelligent monitoring system based on the Internet of Things. The downhole intelligent monitoring system comprises a display, a ground control module, a downhole control module, a ground communication module, a downhole communication module, a dust concentration sensor, a CO concentration sensor, a fan variable-frequency control mechanism and a spraying device. The downhole control module obtains downhole dust and CO concentration through the dust concentration sensor and the CO concentration sensor, and when the downhole dust and CO concentration exceed threshold values, the downhole control module starts the spraying device and the fan variable-frequency control mechanism to conduct dust removal, dust falling and ventilation operation. The downhole control module transmits dust and CO concentration information to the ground control module through the downhole communication module and the ground communication module, and the ground control module displays related data on the display. According to the invention, the full-automatic operation of reducing the concentration of dust and CO in the mine production operation is realized, the generation of dust and CO in the downhole production operation is inhibited from the source, the burden of workers is reduced, and the health of the workers is guaranteed.

Owner:SHANDONG UNIV OF SCI & TECH

Heat exchange pipe and on-line pipe-making processing technique thereof

InactiveCN102230754AIncrease the heat exchange areaLow costChemical industryTubular elementsThermal energyNuclear power

The invention discloses a heat exchange pipe, which comprises an outer pipe at least. The interior of the outer pipe serves as a medium passage. A heat exchange element is configured inside the medium passage. The heat exchange element divides the medium passage into a direct heat exchange zone which exchange heat with the outer pipe and an indirect heat exchange zone which exchange heat with the heat exchange element. The heat exchange medium inside the indirect heat exchange zone exchanges heat with the heat exchange medium inside the direct heat exchange zone via the heat exchange element. In addition, the invention provides an on-line pipe-making processing technique of the pipe, which is adopted to overlap the outer pipe with the heat exchange element by means of an on-line welding technique. Because the heat exchange element is configured inside the outer pipe, the heat exchange area of the heat exchange pipe provided by the invention is increased, which greatly improves the heat exchange efficiency of the indirect heat exchange zone so that the heat exchange pipe provided by the invention is superior to the current heat exchange pipes in terms of the overall heat exchange efficiency. In addition, the invention has low cost and is convenient for manufacturing, and the heat exchange pipe provided by the invention can be applied to high-efficiency heat exchangers or heat exchanging equipment of multiple industries like petroleum, chemicals, fertilizer, boilers, pharmacy, foodstuff, electric power, nuclear power, environmental protection, heat supply and the like.

Owner:SHANGHAI KEMI STEEL TUBE

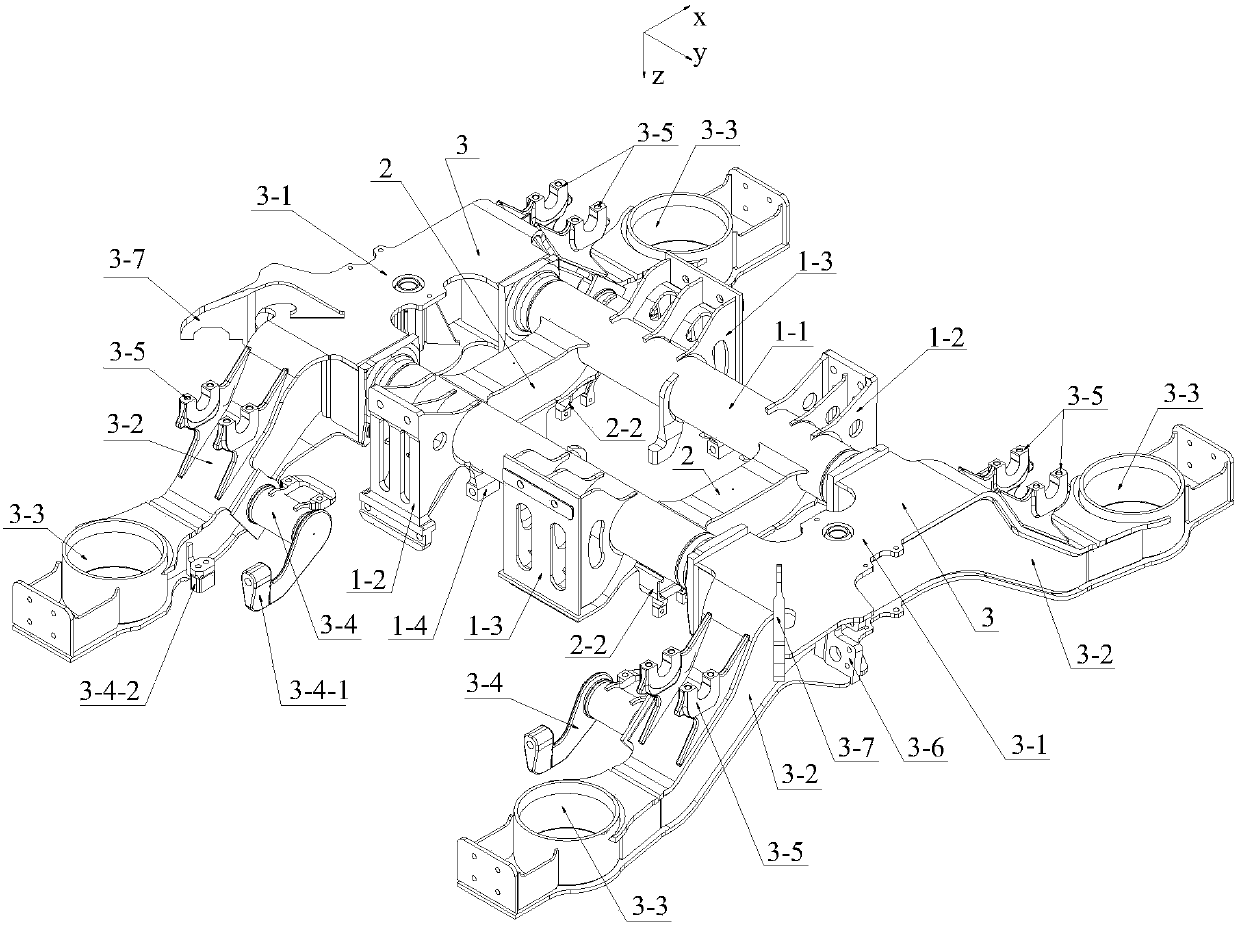

Dumper frame and dumper

PendingCN112249160AResistant to complex and changeable harsh working conditionsIncreased torsional stiffnessUnderstructuresVehicle frameClassical mechanics

A dumper frame comprises a right longitudinal beam and a left longitudinal beam which are symmetrically arranged, and a bumper assembly, a front lower gantry beam, a second cross beam, a third cross beam, a middle rear cross beam assembly and a tail cross beam which are sequentially connected between the left longitudinal beam and the right longitudinal beam from front to back; the sizes of the box-shaped sections of the left longitudinal beam and the right longitudinal beam are kept unchanged from front to back; and at least one surface of the second cross beam, the third cross beam, the middle rear cross beam assembly and the tail cross beam overlaps the left longitudinal beam and the right longitudinal beam. According to the dumper frame, the torsional rigidity and strength are greatlyimproved, complex and changeable severe working conditions of a mine can be resisted, and the design service life is long. The invention further relates to a dump truck with the dump truck frame.

Owner:ZOOMLION HEAVY IND CO LTD

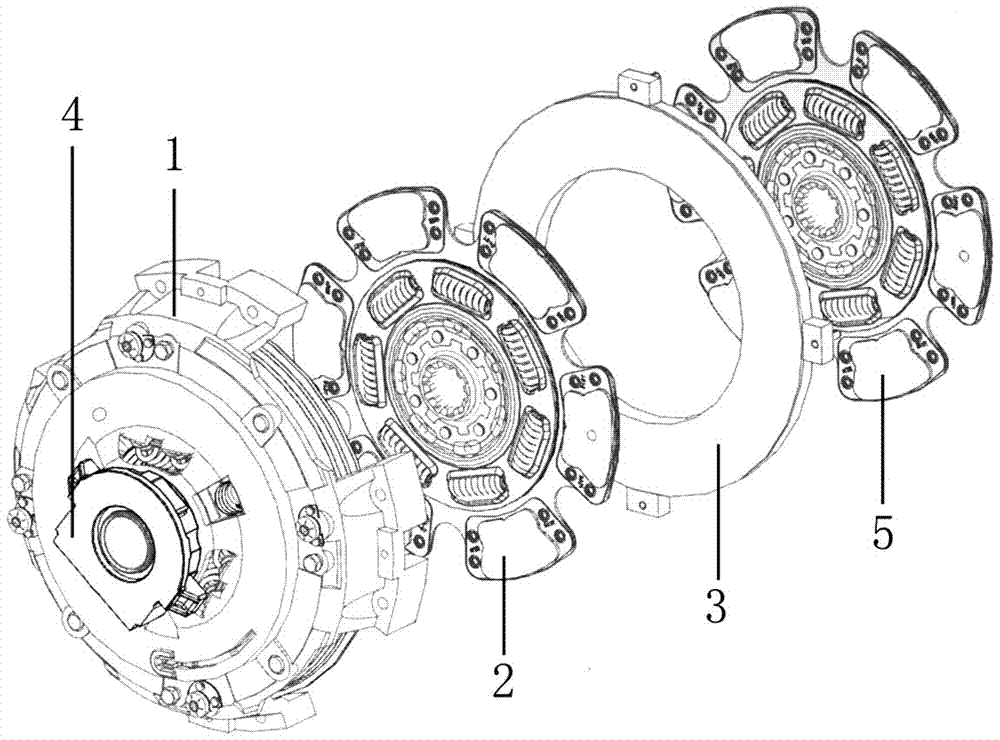

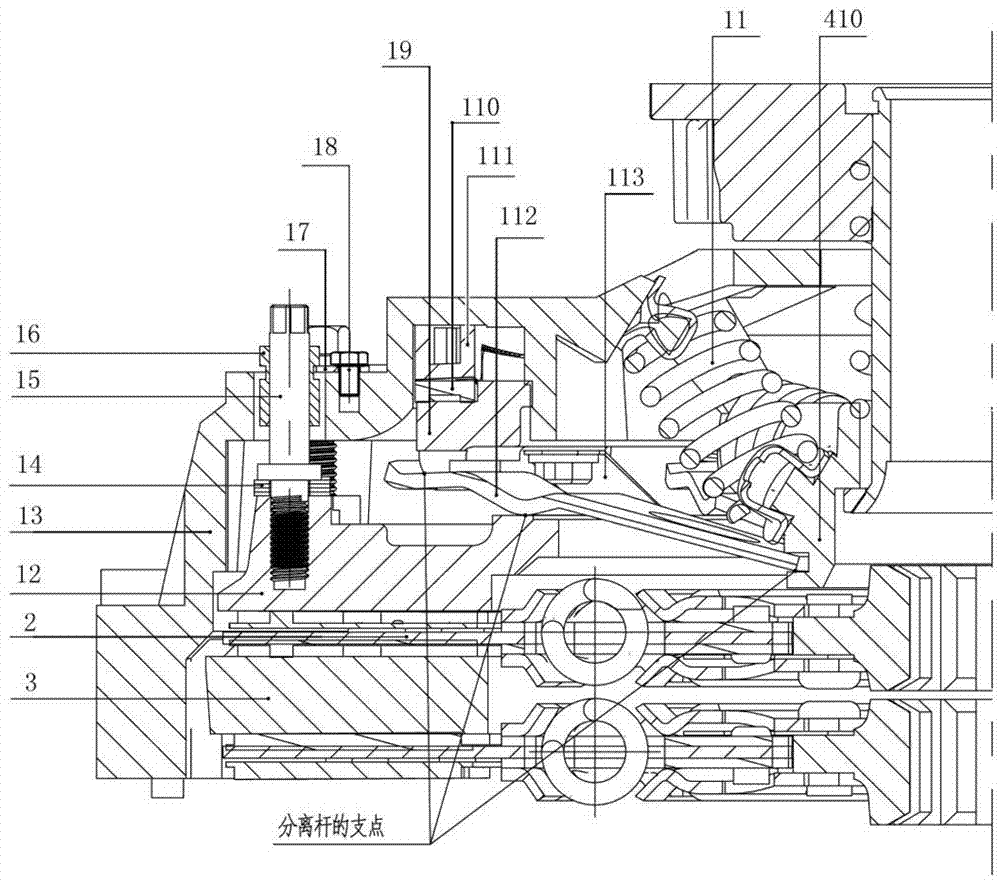

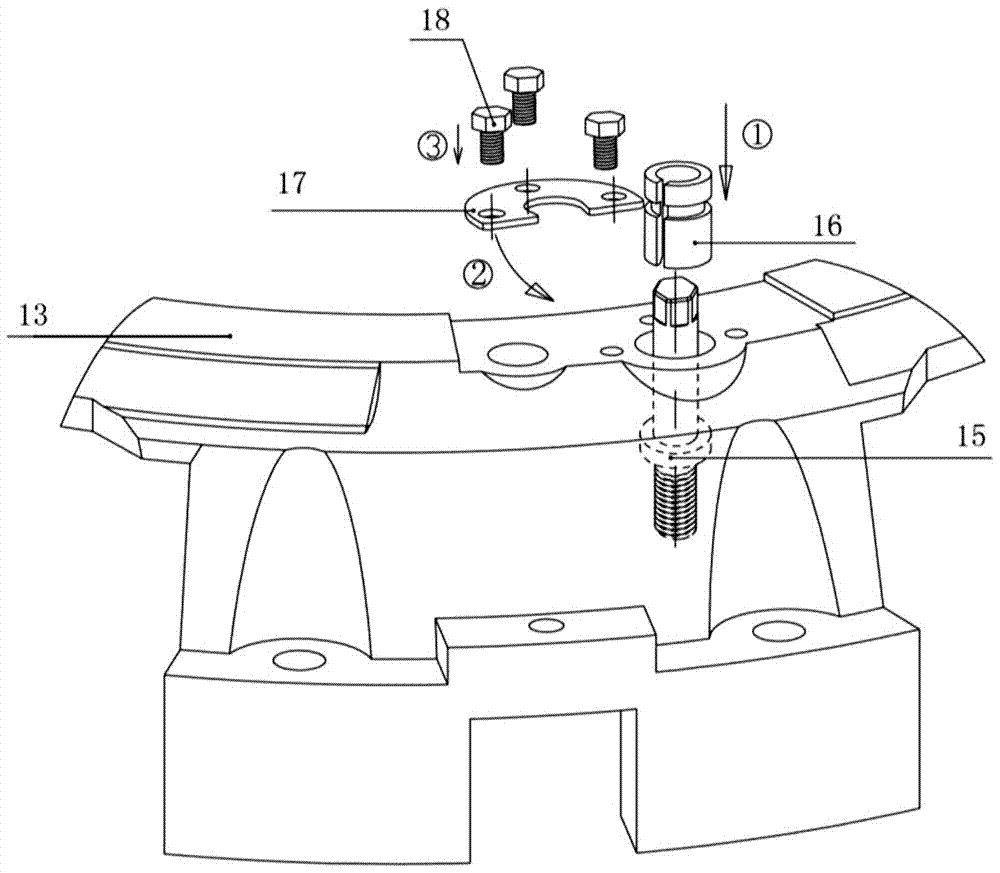

Clutch assembly capable of automatically compensating wear

The invention discloses a clutch assembly capable of automatically compensating wear. The clutch assembly comprises a cover assembly with an induction device, a driven disc inner sheet assembly, a middle pressing disc, a release bearing assembly and a driven disc outer sheet assembly; the cover assembly with the induction device is connected with the middle pressing disc through limitation grooves in a pressing cover; the driven disc inner sheet assembly is pressed between the cover assembly with the induction device and the middle pressing disc; and the driven disc outer sheet assembly is located on the outer side of the middle pressing disc and is pressed between the middle pressing disc and an engine flywheel. The clutch assembly capable of automatically compensating the wear has the characteristics that the wear of a friction component can be inducted by the clutch assembly, so that relative sliding of adjustment rings in the cover assembly is caused and the worn part of the friction component is compensated; the clutch assembly is simple in structure; within the range of the life of a friction sheet, stable performance parameters of the pressing disc can be kept; and the design service life of a clutch is prolonged.

Owner:日照普拉沃夫机械制造有限公司

Converging flow joint insert system at an intersection between adjacent transitions extending between a combustor and a turbine assembly in a gas turbine engine

InactiveUS20170114652A1Eliminates stress formationProlong lifeContinuous combustion chamberEngine manufactureCombustorEngineering

A transition duct system for routing a gas flow from a combustor to the first stage of a turbine section in a combustion turbine engine, wherein the transition duct system includes one or more converging flow joint inserts forming a trailing edge at an intersection between adjacent transition ducts is disclosed. The transition duct system may include a transition duct having an internal passage extending between an inlet to an outlet and may expel gases into the first stage turbine with a tangential component. The converging flow joint insert may be contained within a converging flow joint insert receiver and disconnected from the transition duct bodies by which the converging flow joint insert is positioned. Being disconnected eliminates stress formation within the converging flow joint insert, thereby enhancing the life of the insert. The converging flow joint insert may be removable such that the insert can be replaced once worn beyond design limits.

Owner:SIEMENS ENERGY INC

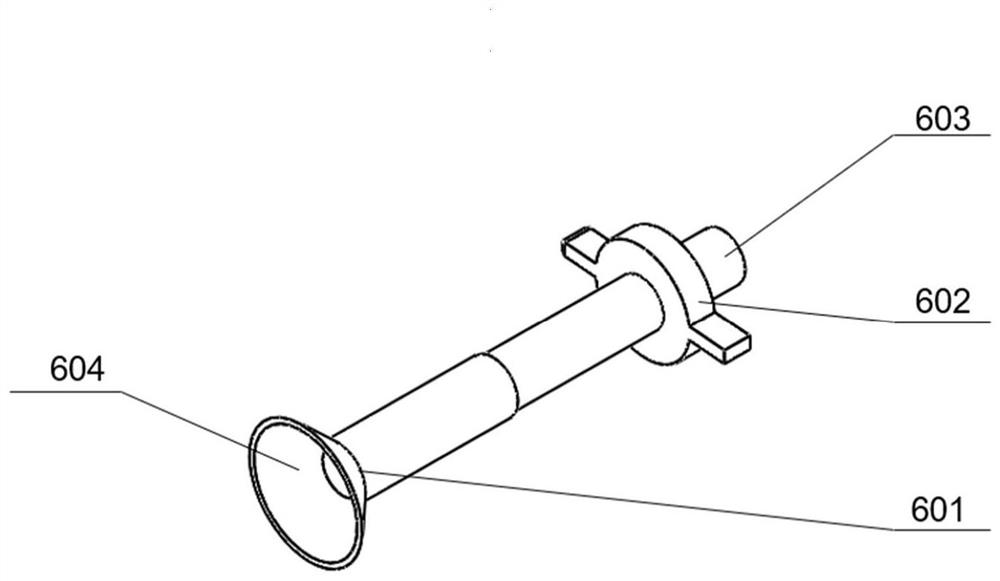

Battery expansion displacement and temperature in-situ measurement device

PendingCN114440974AAchieve temperatureRealize in-situ measurementMeasurement apparatus componentsElectrical batteryEngineering

The invention discloses a battery expansion displacement and temperature in-situ measurement device, and the device comprises a fixing device which is provided with a plurality of sensor clamps surrounding a preset position of a battery; the clamping device is mounted on the fixing device and is used for clamping two opposite end surfaces of the battery respectively, so that the battery is fixed at a preset position of the battery; the clamping device comprises a cylindrical battery clamping device for clamping a cylindrical battery and a square battery clamping device for clamping a square battery; and the measuring device comprises a plurality of dial indicators and / or infrared temperature sensors which are respectively arranged on the sensor clamp and are used for measuring the temperature and displacement of the side surface of the battery. The device can be used for simultaneously measuring the radial displacement or the surface temperature of the cylindrical batteries with multiple sizes in the working process in situ. And a special clamp is adopted to adapt to batteries with different sizes.

Owner:SHANGHAI UNIV OF ENG SCI

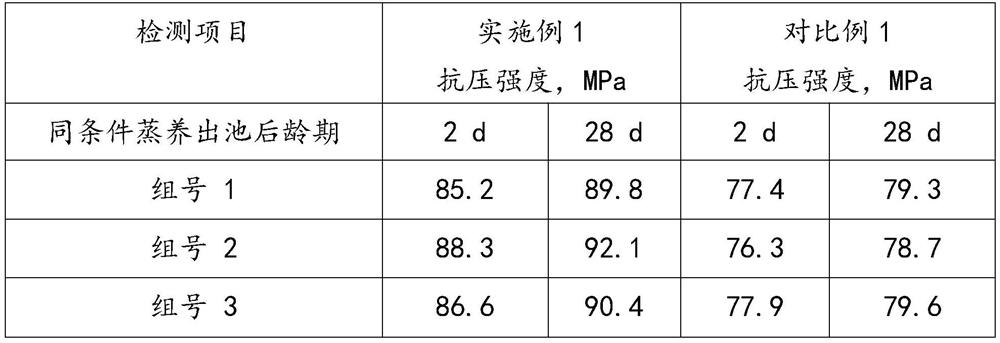

Preparation method of non-autoclaved high-performance prefabricated pipe pile

InactiveCN112776166AImprove performanceImprove bearing capacitySolid waste managementShaping reinforcementsArchitectural engineeringPipe

The invention provides a preparation method of a non-autoclaved high-performance prefabricated pipe pile. The method adopts the following steps including taking special cement for the pipe pile, an S115-grade composite admixture, a high-performance water reducing agent, machine-made sand and gravel as raw materials, preparing concrete, uniformly stirring, preparing a reinforcement cage, distributing and tensioning, centrifugally forming, carrying out normal-pressure steam curing, demolding, carrying out quality inspection, putting into a product storage yard and the like to obtain the finished non-autoclaved high-performance prefabricated pipe pile. The method is simple in process and low in cost, the prepared finished non-autoclaved high-performance prefabricated pipe pile has good stability, hitting (pressing) resistance, permeability resistance and corrosion resistance, the product design life is prolonged, durability is remarkably improved, conversion from common high-strength concrete to high-performance concrete of the pipe pile is achieved, and the concepts of ecological priority, green development and high-quality development in the new era are realized.

Owner:沧兴管桩有限公司

Converging flow joint insert system at an intersection between adjacent transitions extending between a combustor and a turbine assembly in a gas turbine engine

InactiveUS9803487B2Eliminates stress formationProlong lifeContinuous combustion chamberEngine manufactureCombustorEngineering

A transition duct system for routing a gas flow in a combustion turbine engine is provided. The transition duct system includes one or more converging flow joint inserts forming a trailing edge at an intersection between adjacent transition ducts. The converging flow joint insert may be contained within a converging flow joint insert receiver and may be disconnected from the transition duct bodies by which the converging flow joint insert is positioned. Being disconnected eliminates stress formation within the converging flow joint insert, thereby enhancing the life of the insert. The converging flow joint insert may be removable such that the insert can be replaced once worn beyond design limits.

Owner:SIEMENS ENERGY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com