Machining method of large thin-wall bearing ring

A technology for thin-walled bearings and processing methods, which is applied in the field of processing large-scale thin-walled bearing rings, can solve the problems of inability to guarantee bearing surface quality, rotation accuracy, and low processing accuracy, and achieve scientific and reasonable processing routes and reduce heat treatment Large deformation and improved machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

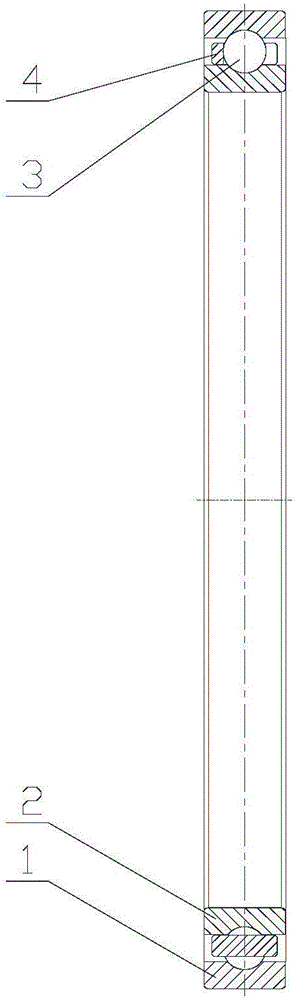

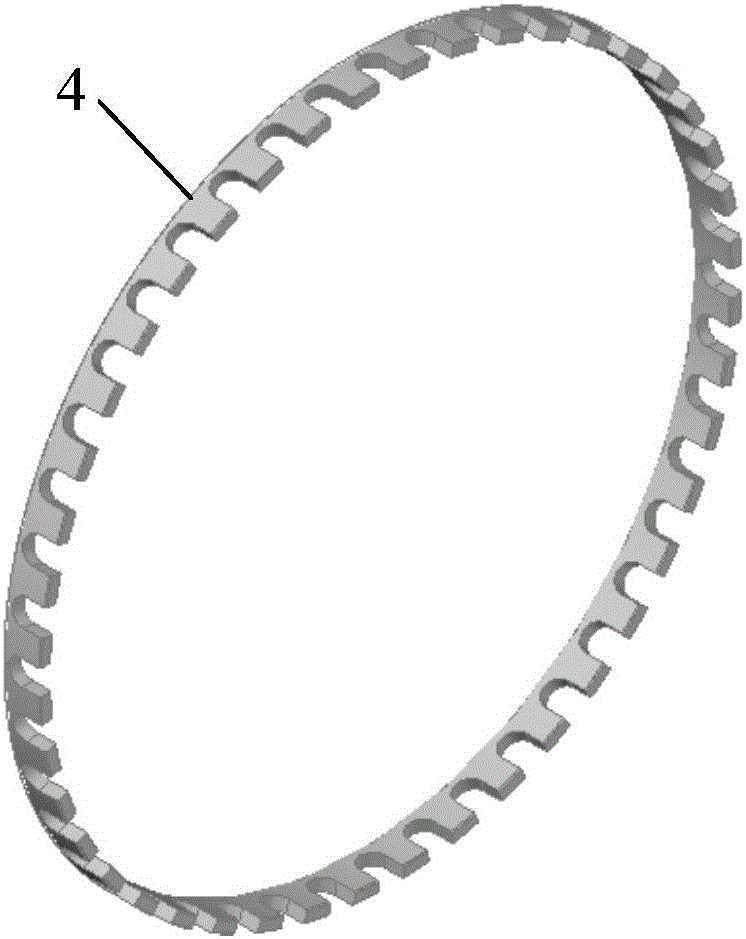

[0040] The processing method of the large thin-walled bearing ring in this embodiment includes inner ring processing and outer ring processing;

[0041] Inner ring processing includes the following steps:

[0042] 1) Pre-treatment: heat the inner ring blank to 200°C for 12 hours, then cool to room temperature;

[0043] 2) Ring heat treatment: heat the inner ring blank to 810°C for 28 minutes, then oil quench for 3 minutes to 170°C, and cool to room temperature;

[0044] 3) Low-temperature cold treatment: cool the inner ring body to -70°C for 2 hours, and then return to room temperature;

[0045] 4) Coarse grinding process, the steps are as follows: rough grinding the end face, rough grinding the outer diameter of the inner ring, rough grinding the groove of the inner ring, rough grinding the inner diameter, and repairing the chamfer to obtain a rough grinding product;

[0046] 5) Primary additional tempering: heat the obtained rough grinding product to 150°C for 24 hours, th...

Embodiment 2

[0061] The processing method of the large thin-walled bearing ring in this embodiment includes inner ring processing and outer ring processing;

[0062] Inner ring processing includes the following steps:

[0063] 1) Pre-treatment: heat the inner ring blank to 180°C for 14 hours, then cool to room temperature;

[0064] 2) Ring heat treatment: heat the inner ring blank to 820°C for 25 minutes, then oil quench for 5 minutes to 150°C, and cool to room temperature;

[0065] 3) Low-temperature cold treatment: cool the inner ring body to -65°C and keep it warm for 2.5 hours, then return to room temperature;

[0066] 4) Coarse grinding process, the steps are as follows: rough grinding the end face, rough grinding the outer diameter of the inner ring, rough grinding the groove of the inner ring, rough grinding the inner diameter, and repairing the chamfer to obtain a rough grinding product;

[0067] 5) Primary additional tempering: heat the obtained coarse grinding product to 140°C ...

Embodiment 3

[0082] The processing method of the large thin-walled bearing ring in this embodiment includes inner ring processing and outer ring processing;

[0083] Inner ring processing includes the following steps:

[0084] 1) Pre-treatment: heat the inner ring blank to 220°C for 10 hours, then cool to room temperature;

[0085] 2) Ring heat treatment: heat the inner ring blank to 815°C for 26 minutes, then oil quench for 4 minutes to 160°C, and cool to room temperature;

[0086] 3) Low-temperature cold treatment: cool the inner ring body to -75°C and keep it warm for 1.5h, then return to room temperature;

[0087] 4) Coarse grinding process, the steps are as follows: rough grinding the end face, rough grinding the outer diameter of the inner ring, rough grinding the groove of the inner ring, rough grinding the inner diameter, and repairing the chamfer to obtain a rough grinding product;

[0088] 5) Primary additional tempering: heat the obtained rough grinding product to 160°C for 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com