Dumper frame and dumper

A dump truck and frame technology, applied in the field of dump trucks, can solve problems such as low torsional stiffness and strength, large deformation, and harsh working conditions, so as to improve torsional stiffness and strength, easy to process and shape, and maintain a consistent height change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further illustrate the technical means and functions adopted by the present invention to achieve the intended invention purpose, the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

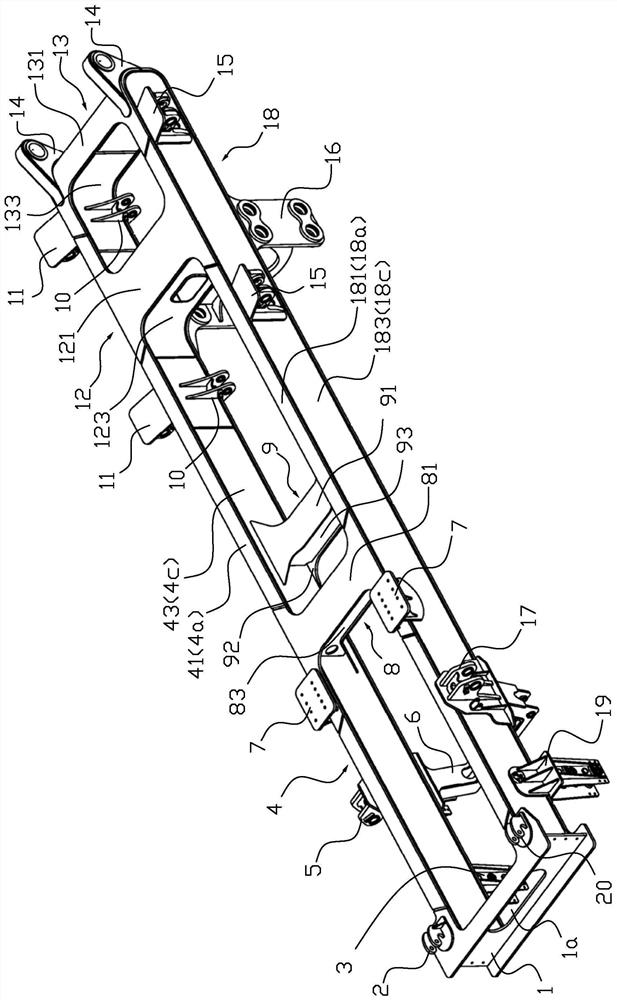

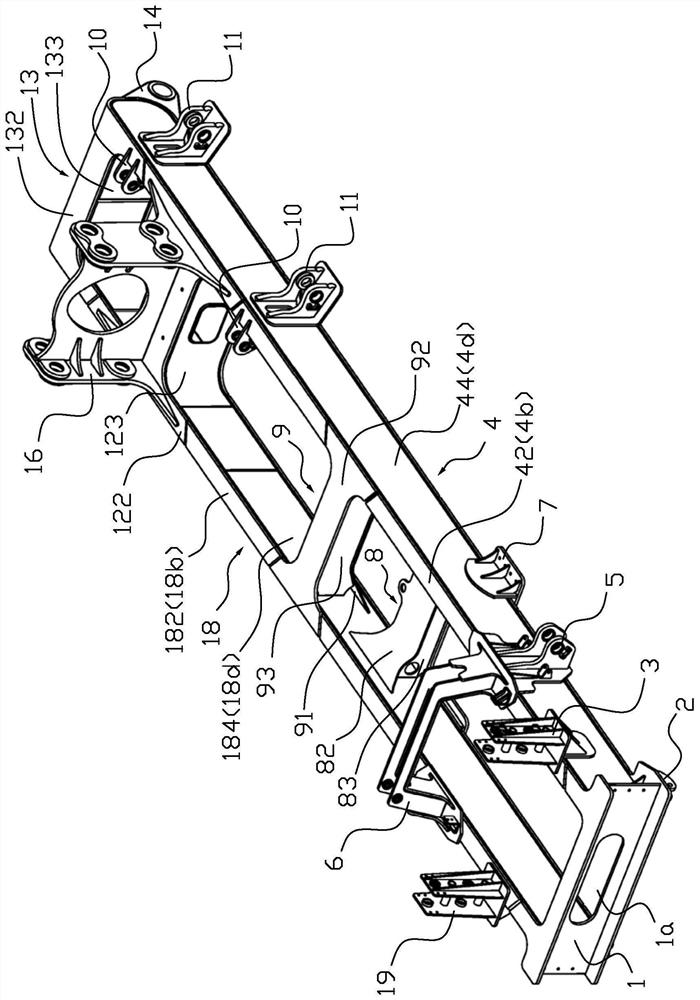

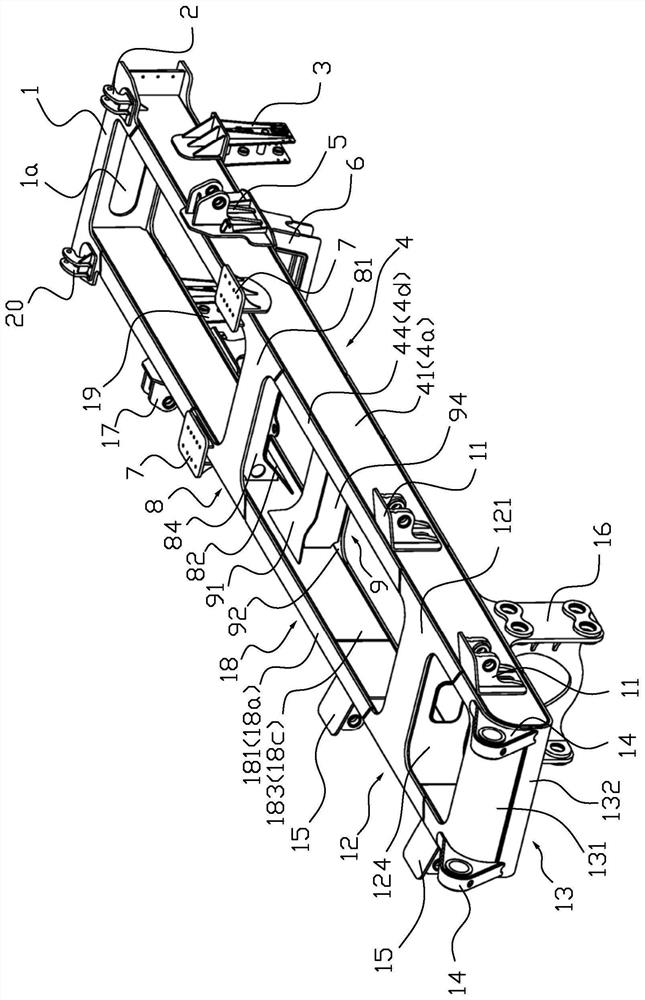

[0030] Please also refer to Figure 1 to Figure 4 , the dump truck frame of the present invention can be used as the frame of a 100-ton mining dump truck, but it is not limited thereto. The dump truck frame has a structure of six horizontal beams and two vertical beams, specifically including symmetrically arranged right longitudinal beams 18 and left longitudinal beams 4, and the bumper assembly 1 that is sequentially connected between the left longitudinal beams 18 and the right longitudinal beams 4 from front to back. , The front lower gantry beam 6, the second beam 8, the third beam 9, the middle and rear beam assembly 12 and the tail beam 13. The second crossbeam 8 , the third crossbeam 9 , the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com