Contact system of circuit breaker

A contact system and circuit breaker technology, applied in the directions of circuit breaker contacts, circuit breaker parts, circuits, etc., can solve the problems of difficult automation, reduced contact welding resistance, reduced structural strength, etc. Time withstand current value, easy automatic installation, and the effect of improving work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

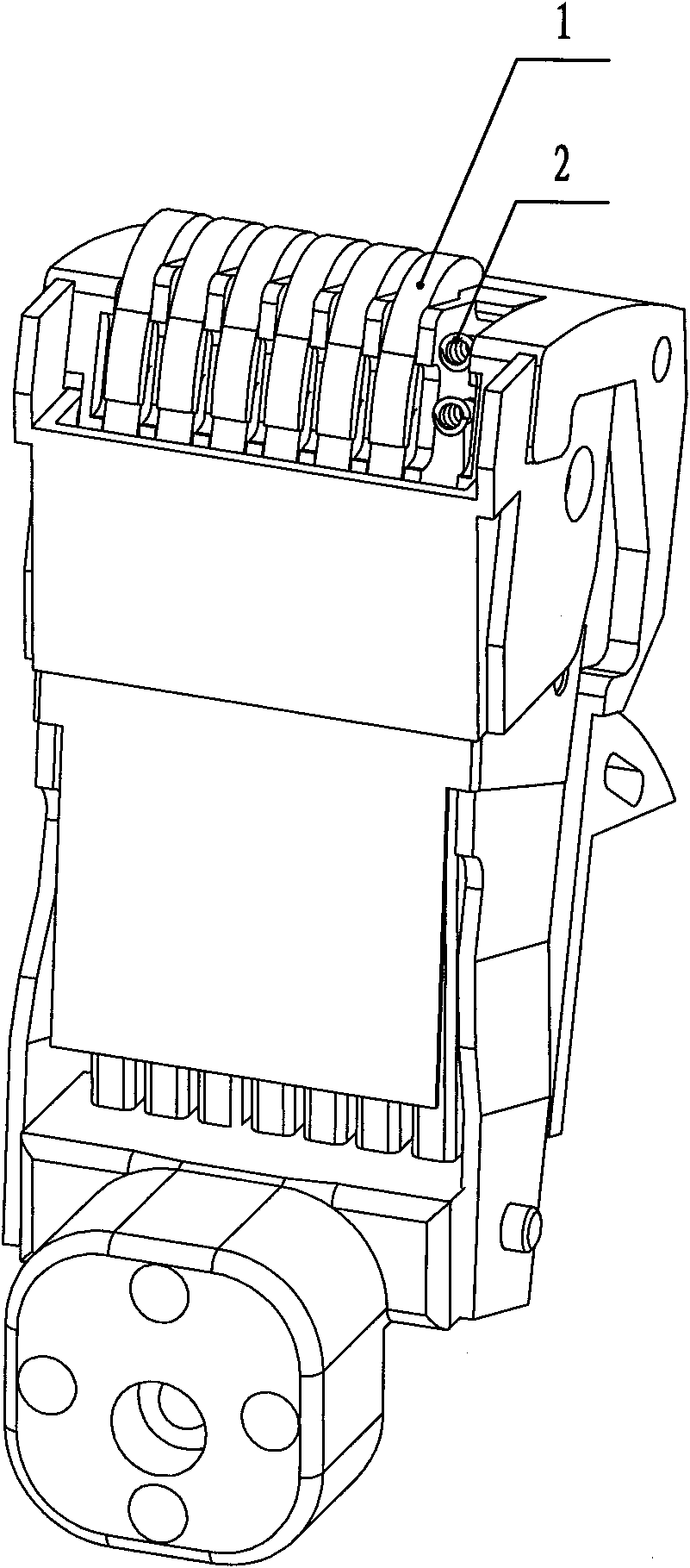

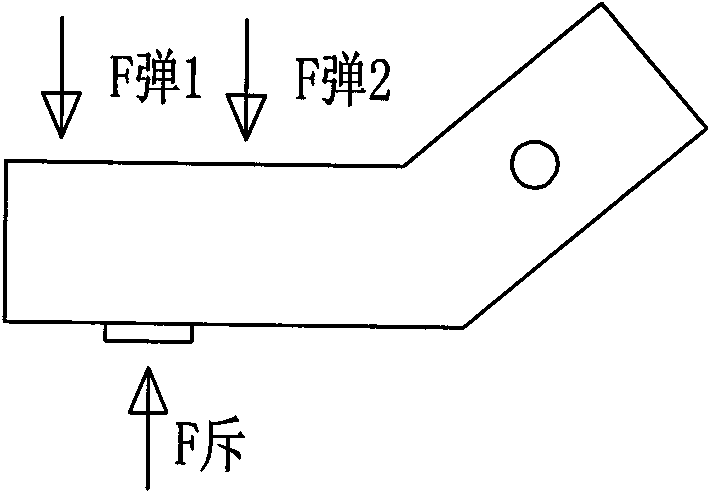

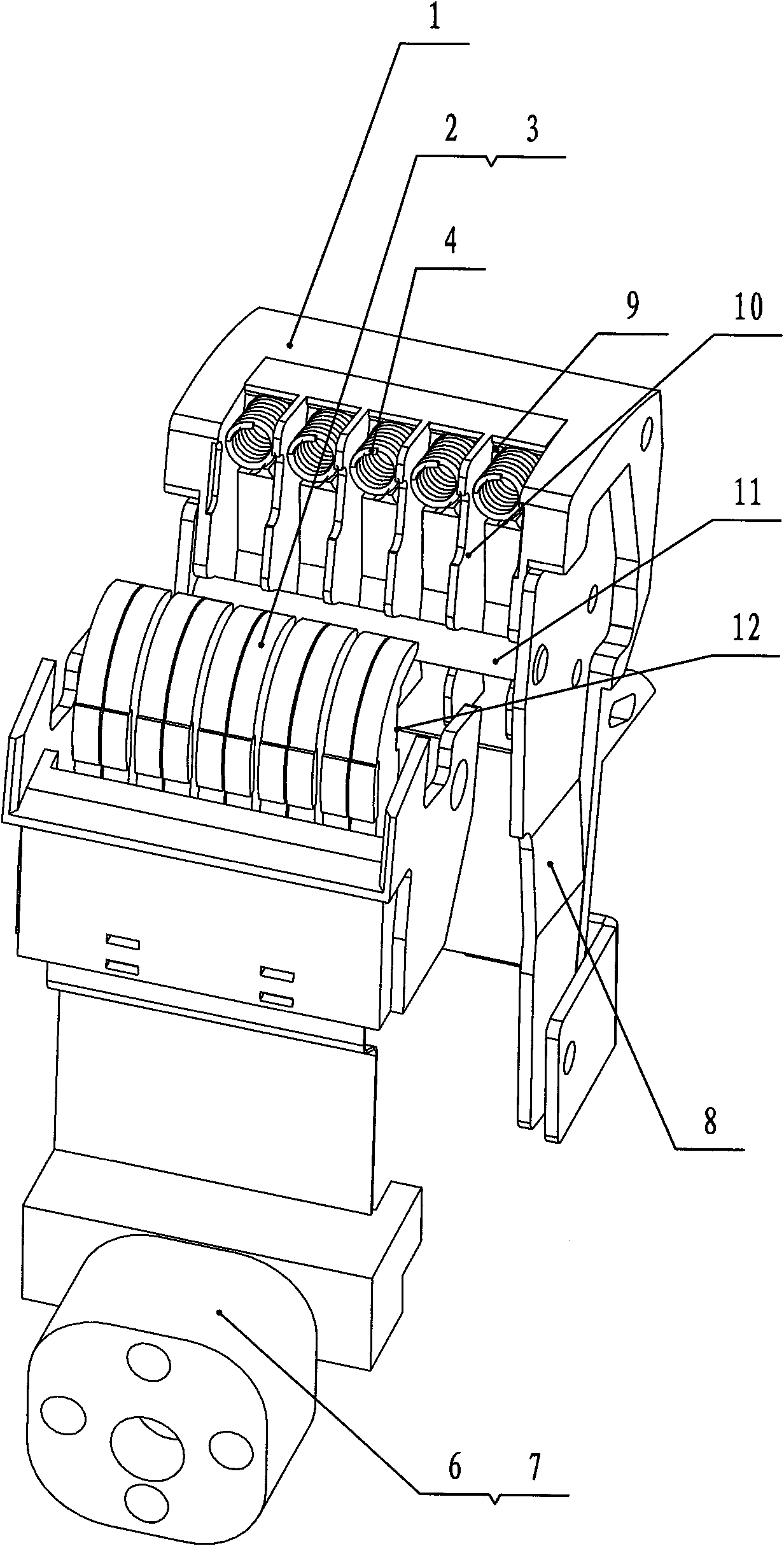

[0024] The invention relates to a contact system of a circuit breaker, which includes contact fingers, contact springs, and contact supports. Together, the two ends of the shaft are supported by the holes on the two splints, and the contact spring is placed between the belly of the contact finger and the interval of the isolation grid, wherein: no less than one contact finger is used as a group, and each group of contact fingers One or two sets of contact springs are shared between the finger and the isolation barrier sheet. Blocking sheets are sandwiched between the contact fingers in a group of contact fingers. A set of contact springs contains no less than one spring. The specifications of a group of contact springs can be the same or different. Each spring in a group of contact springs is arranged in parallel or coaxially. The isolation barrier sheet is integrally formed with the contact support.

[0025] Describe in detail below in conjunction with accompanying drawin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com