Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Increased ease of assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

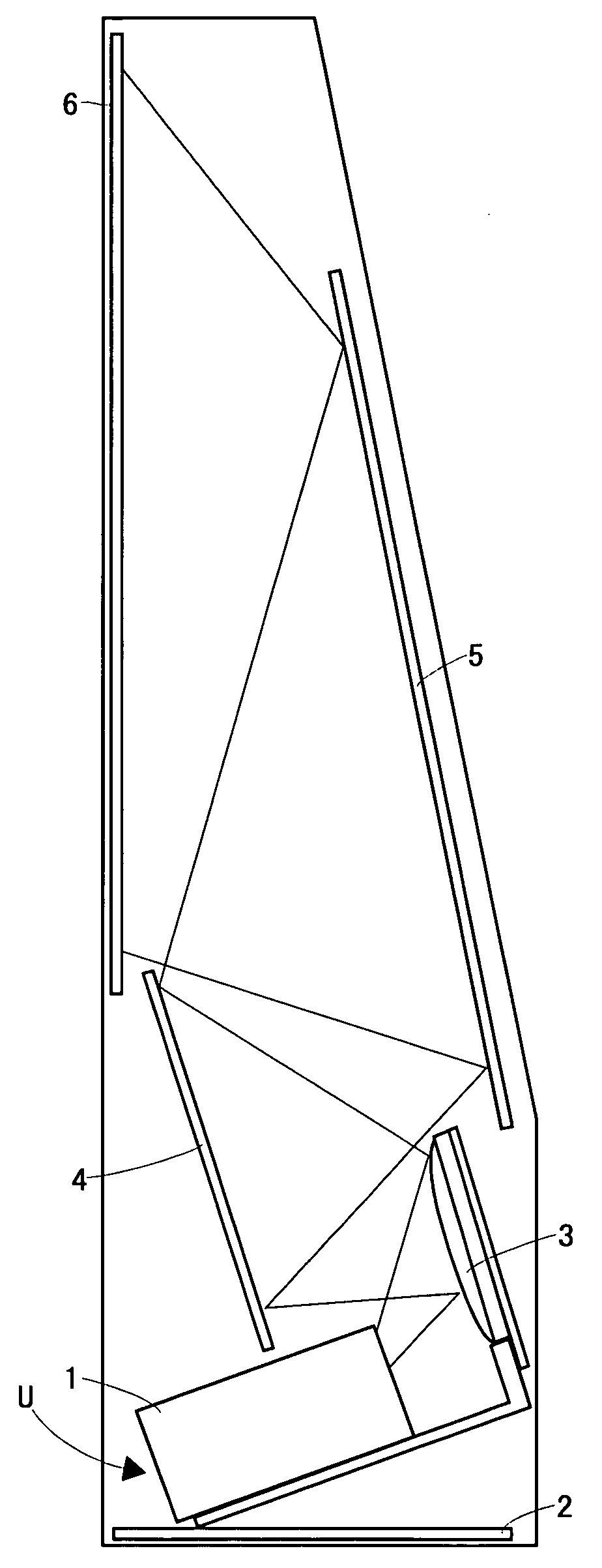

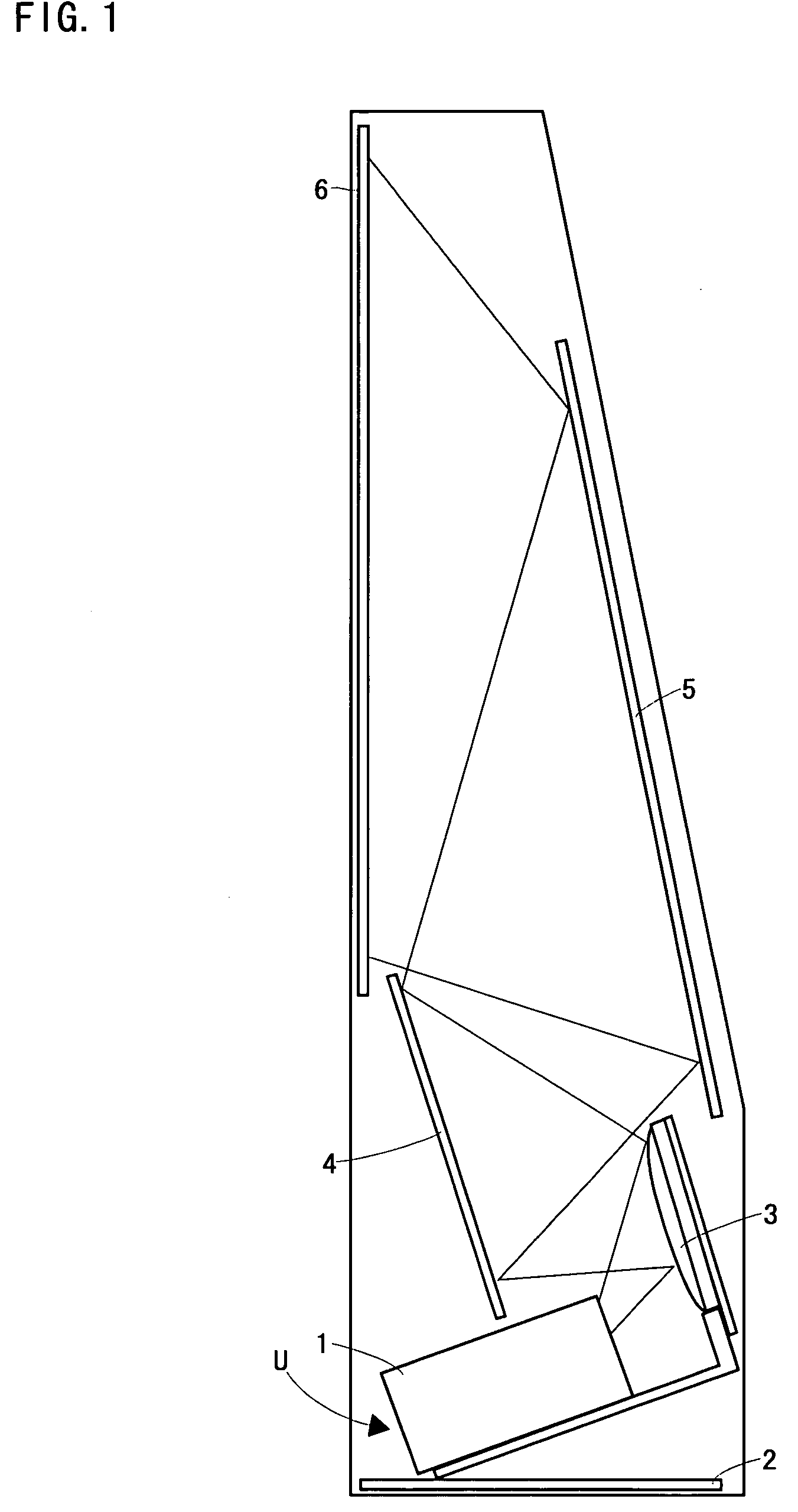

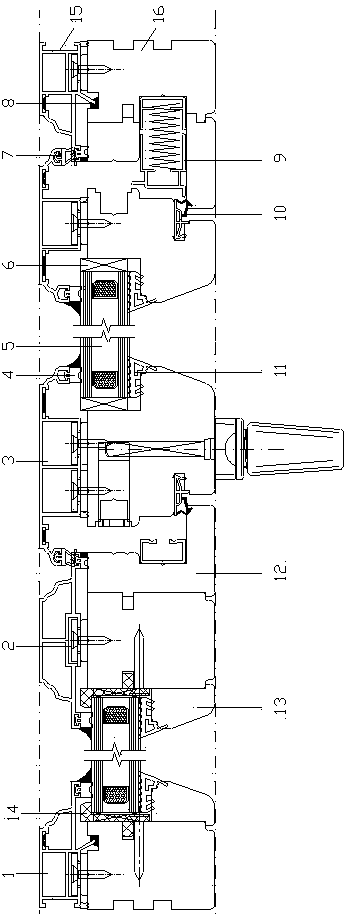

Rear projection display

InactiveUS20060139577A1Easily broughtImprove performanceBuilt-on/built-in screen projectorsColor television detailsLiquid-crystal displayLed array

A rear projection display, not requiring a dichroic prism, and capable of rendering a generation system of each image light in color independent of the other generation systems so as to optimally construct and improve easiness of assembly of, and so on, each generation system, is provided. Each unit for projecting image-light is formed of an LED array, a rod integrator, a liquid crystal display panel, and a projection lens. A projection optical axis of the projection lens of each unit for projecting image-light is parallel each other. A unit for projecting image light in red is provided with an LED array for emitting light of a wavelength band in red, a unit for projecting image light in green is provided with an LED array for emitting light of a wavelength band in green, and a unit for projecting image light in blue is provided with an LED array for emitting light of a wavelength band in blue. Each image light in color obtained as a result of passing through the liquid crystal display panel is projected by the projection lens, and displayed on a screen. As a result, each image light in color is superposed on the screen, and an image in full color is displayed.

Owner:SANYO ELECTRIC CO LTD

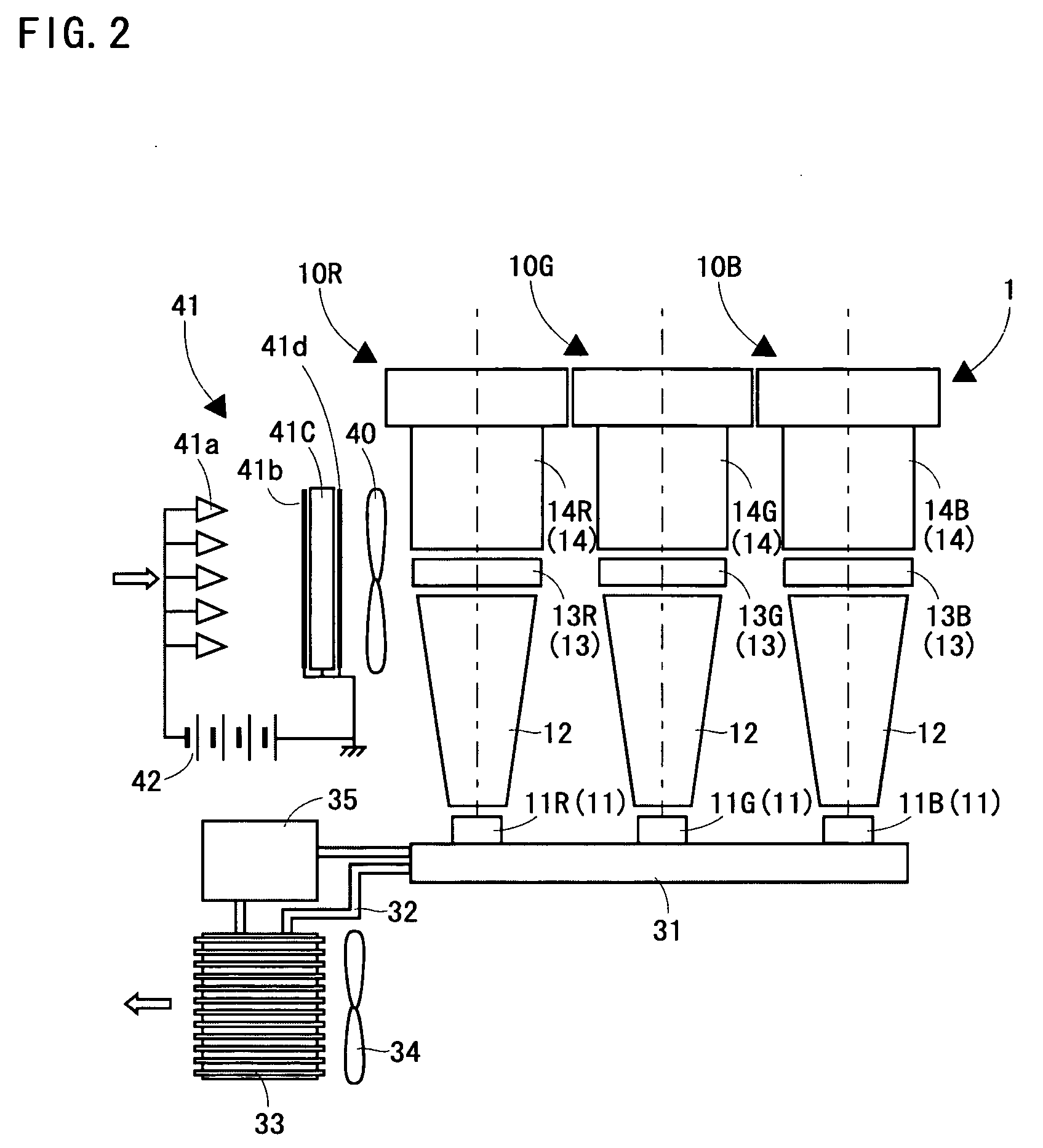

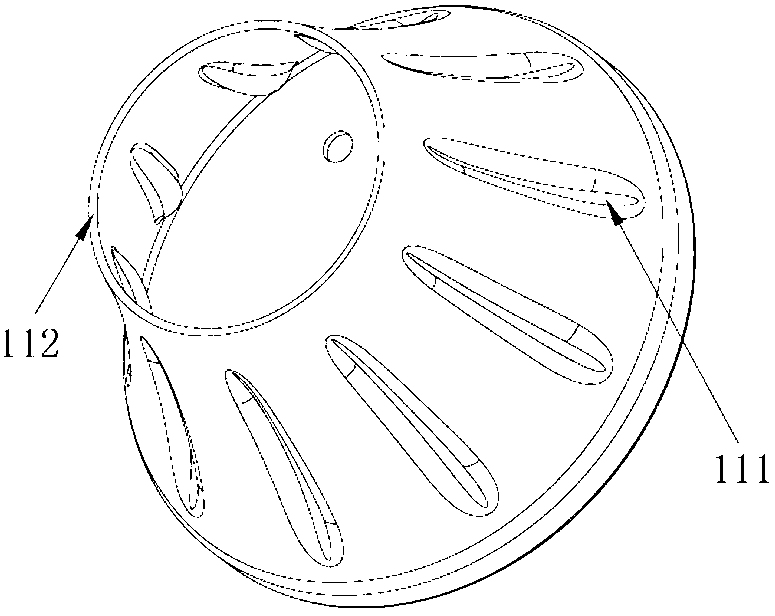

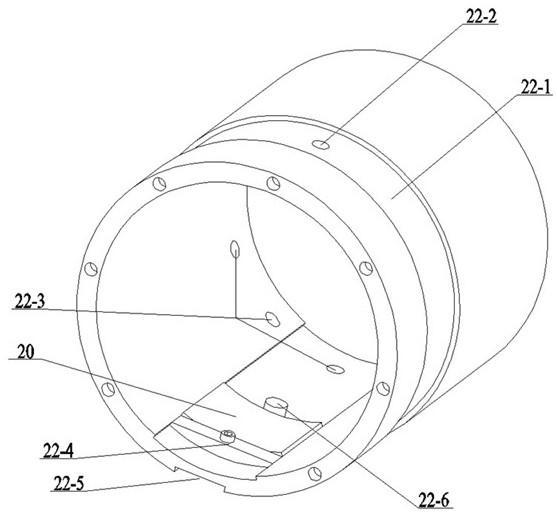

LED (Light-Emitting Diode) lamp bulb heat radiation lamp cup

InactiveCN102997201AImprove cooling effectHigh strengthPoint-like light sourceLighting heating/cooling arrangementsEngineeringLED lamp

The invention provides an LED (Light-Emitting Diode) lamp bulb heat radiation lamp cup, comprising a metal heat radiation lamp cup main body and a fixing bottom plate, wherein the metal heat radiation lamp cup main body and the fixing bottom plate are integrally punched and molded by using the same materials; and a heat radiation part for radiating heat is arranged on the outer surface of the metal heat radiation lamp cup main body. According to the LED lamp bulb heat radiation lamp cup, the metal heat radiation lamp cup main body and the fixing bottom plate are integrally punched and molded by using the same materials, so that the defect in the prior art that the heat conduction performance is poor due to the fact that the heat radiation lamp cup and the fixing bottom plate need to be combined can be overcome, and the heat conduction performance of the LED amp bulb heat radiation lamp cup and the fixing plate is good; the heat radiation lamp cup main body and the fixing bottom plate are integrally punched so that the high efficiency of production and the simplicity of assembling can improved; and meanwhile, an enhancing part of the outer surface of the heat radiation lamp cup main body can further enhance the heat radiation and the strength of an LED lamp bulb and the disadvantage caused by the materials is avoided.

Owner:BYD CO LTD

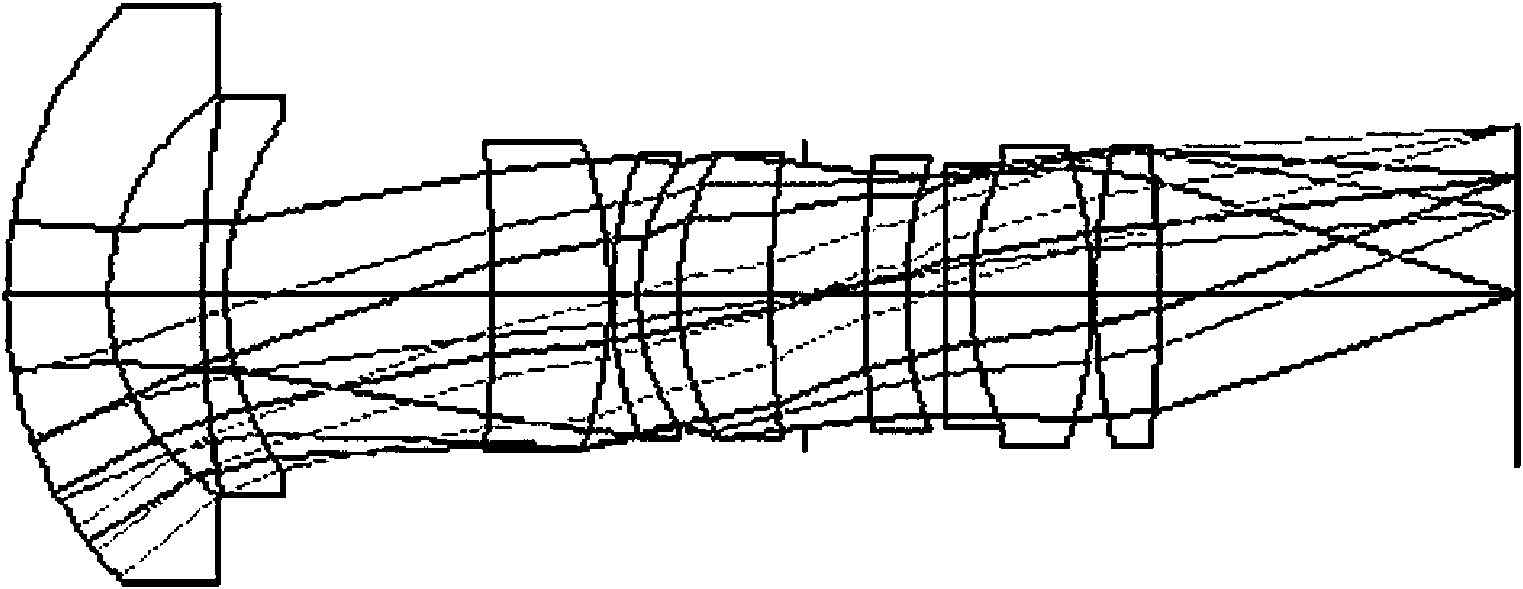

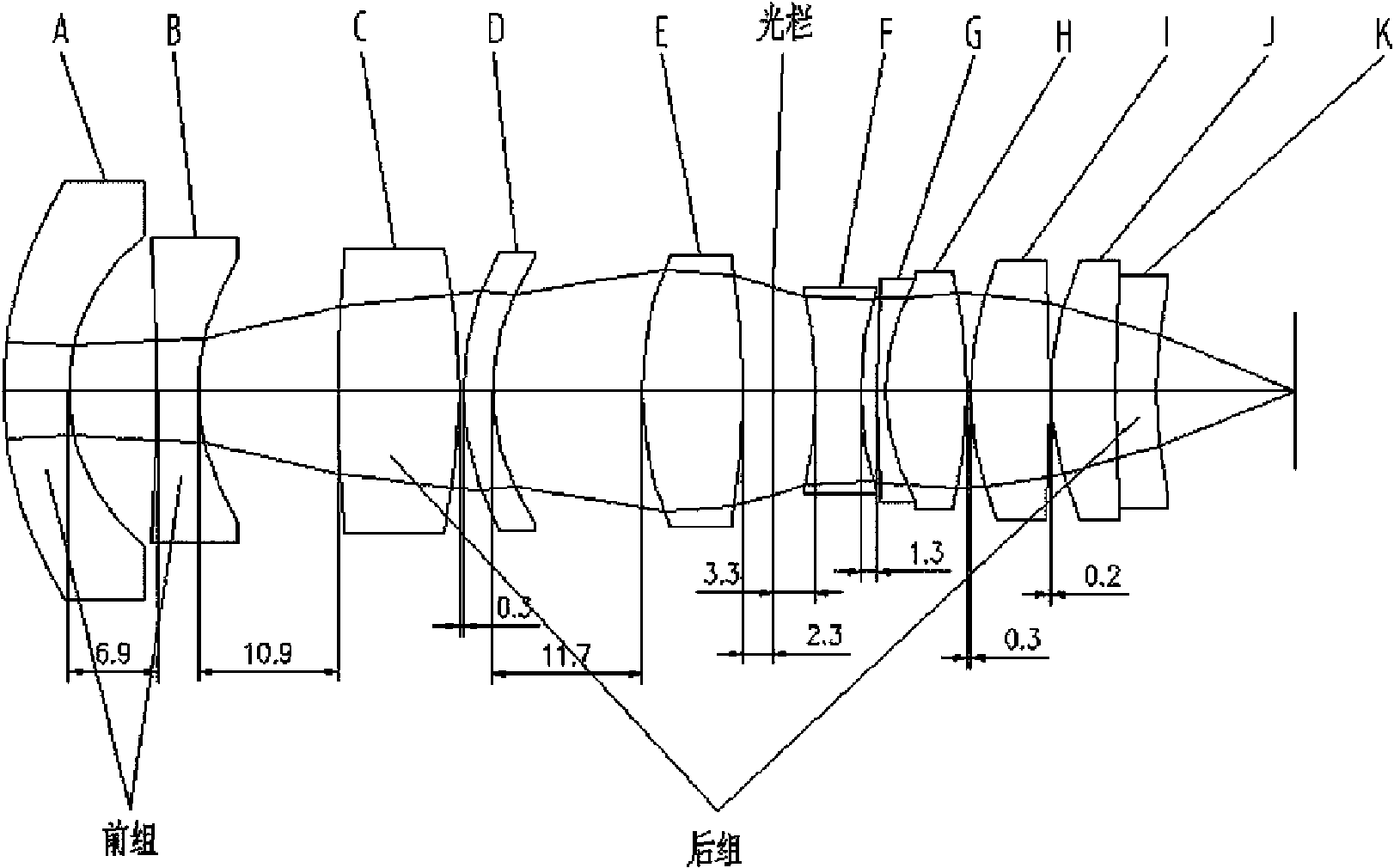

Wide-angle low-light high-resolution lens

The invention relates to a wide-angle low-light high-resolution lens, characterized in that, a front group with negative optical power and a rear group with positive optical power are respectively arranged in an optical structure of the lens in a direction of light from left to right in an incident manner, wherein, the front group is sequentially provided with two mutually-separated negative crescent lens A and B, and the rear group is sequentially provided with a double convex lens C, a negative crescent lens D, a double convex lens E, a diaphragm, a negative crescent lens F, a bonding groupGH tightly connected with a negative crescent lens G and a double convex lens H, a double convex lens I, and a bonding group JK tightly connected with a positive crescent lens J and a negative crescent lens K.

Owner:FUJIAN FORECAM OPTICS CO LTD

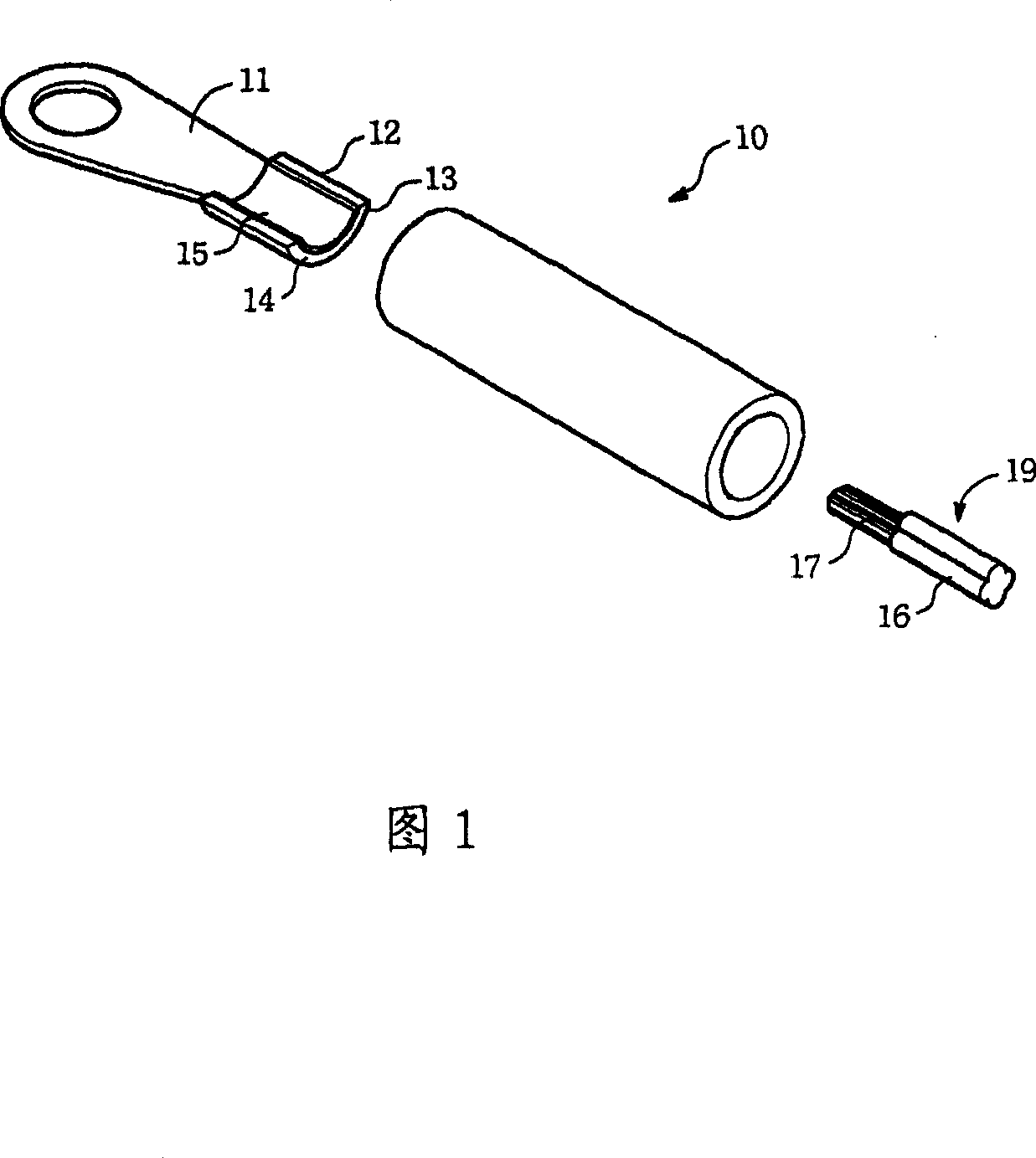

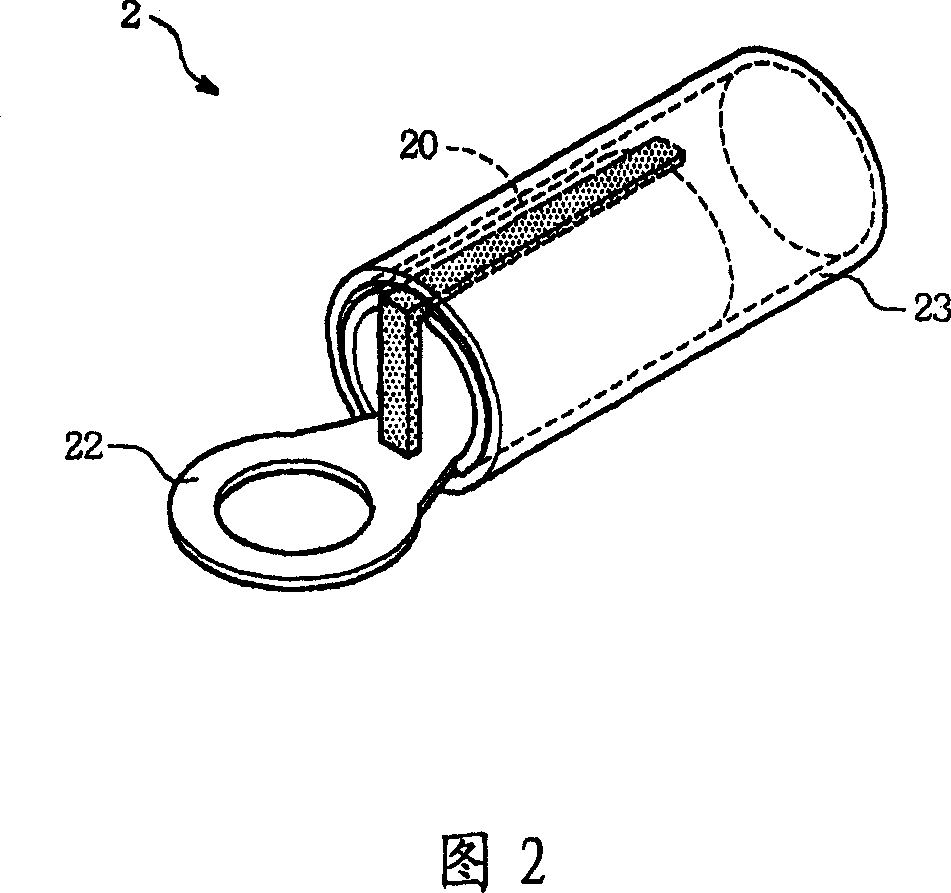

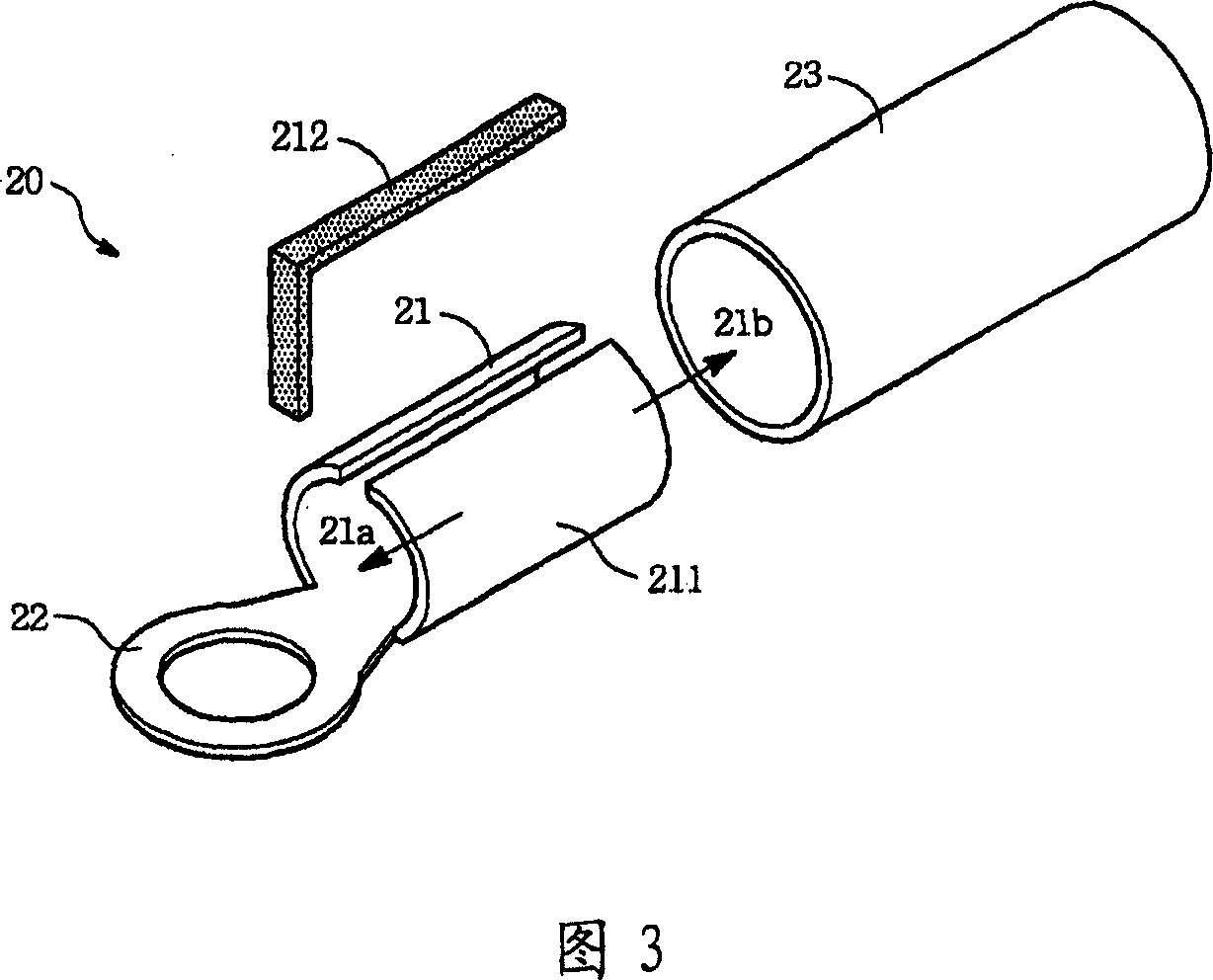

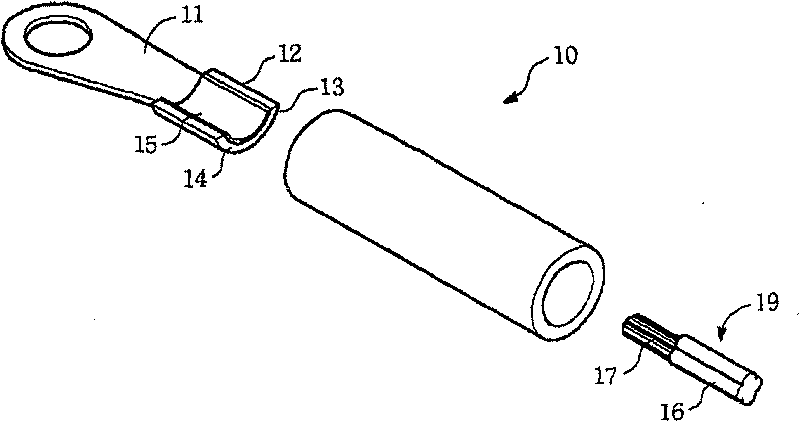

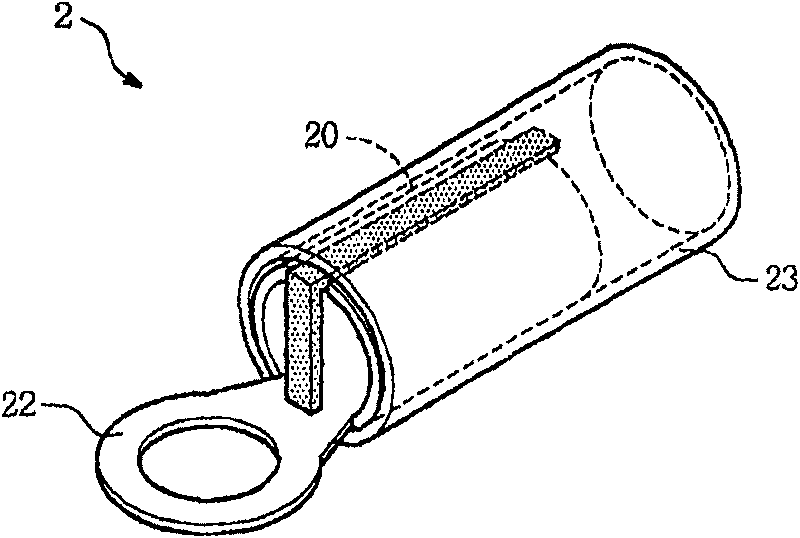

Connector and its making method

InactiveCN101055942AIncreased ease of assemblyImprove insulation performanceLine/current collector detailsSoldered/welded conductive connectionsJunction pointEngineering

A connector and its manufacturing methods. The connector includes a metal conductive terminal, a low melting point metal substance and an insulation casing; one end of the metal conductive terminal bends to form a vertical slotted C-type portion in order to accommodate a wire to insert, another end is used to connect the external conductive junction point; the low melting point metal substance is tabled in the vertical slot of the C-type portion and the insulation casing is coverd on the outside of the C-type portion and the low melting point metal substance; When heating up the low melting point metal substance and the insulation casing, the low melting point metal substance is melted to connect with the C-type portion and the wire conductive core in the C-type portion, while the insulation casing properly contracts to coat the metallic conductive terminals and the wires, in order to complete the combination of the connector and the wire.

Owner:KS TERMINALS INC

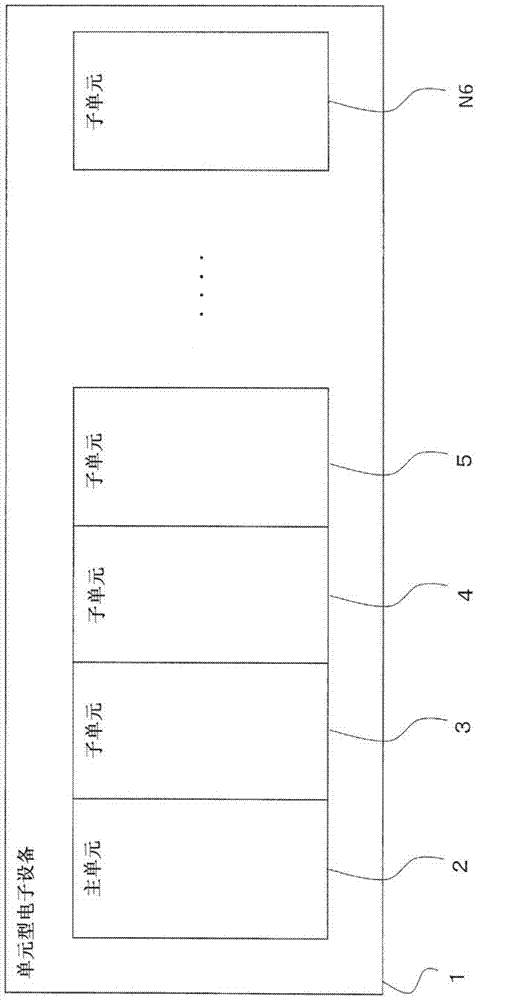

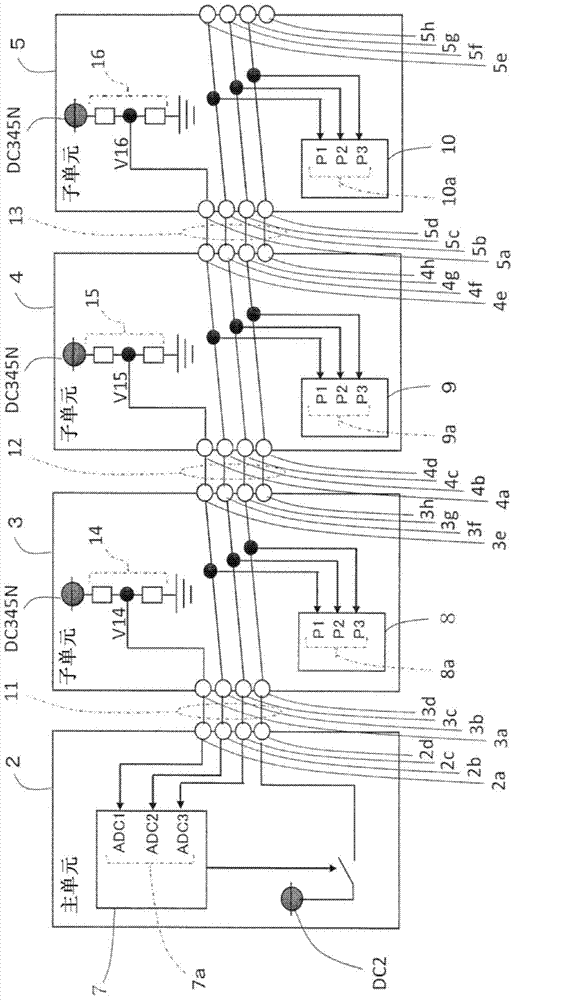

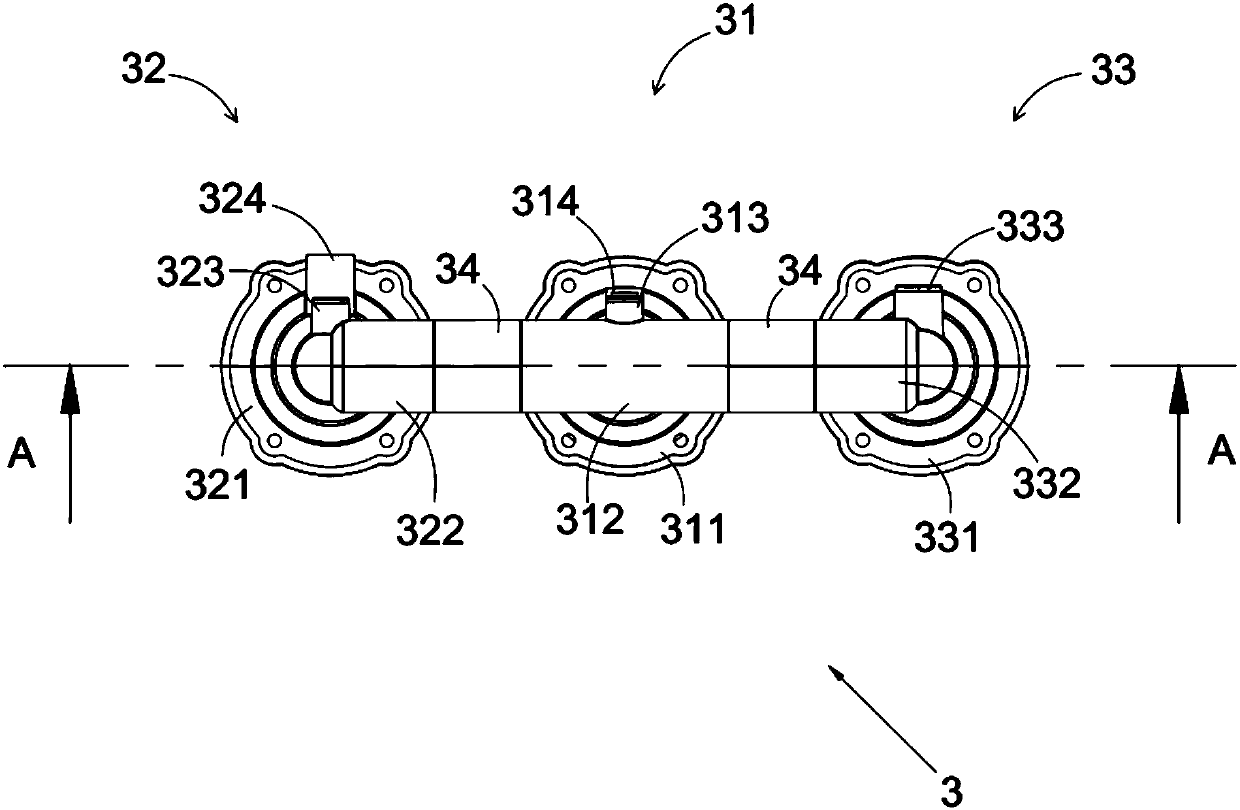

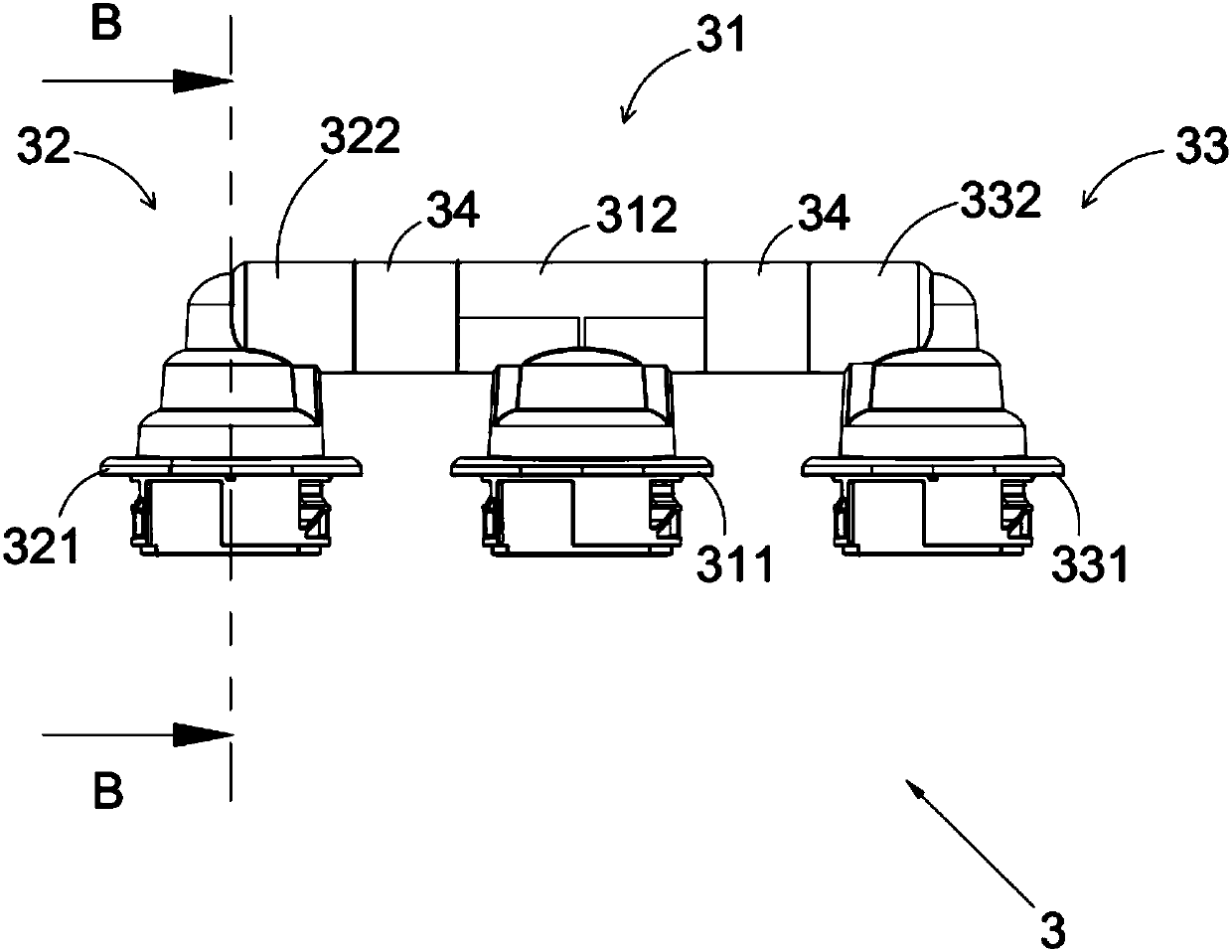

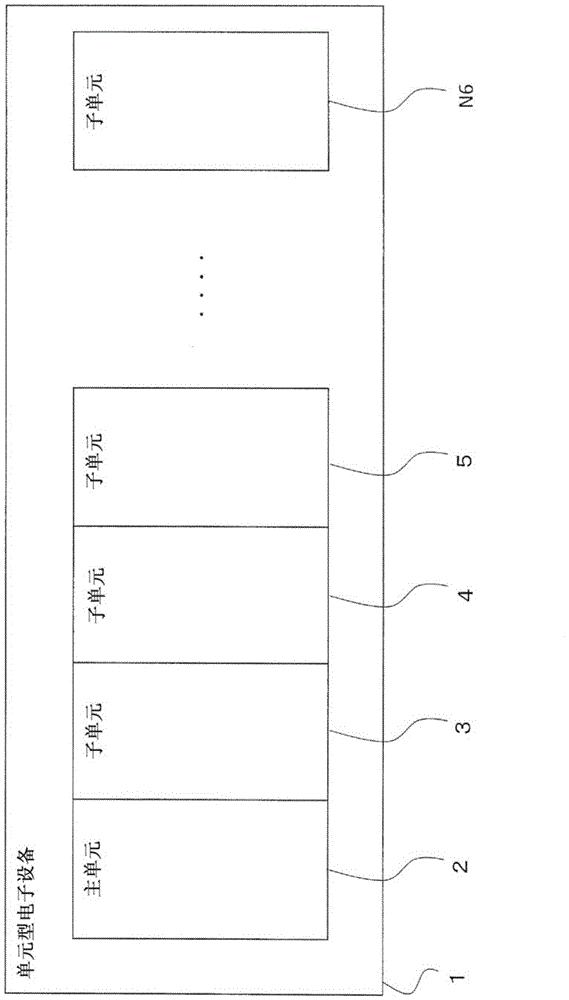

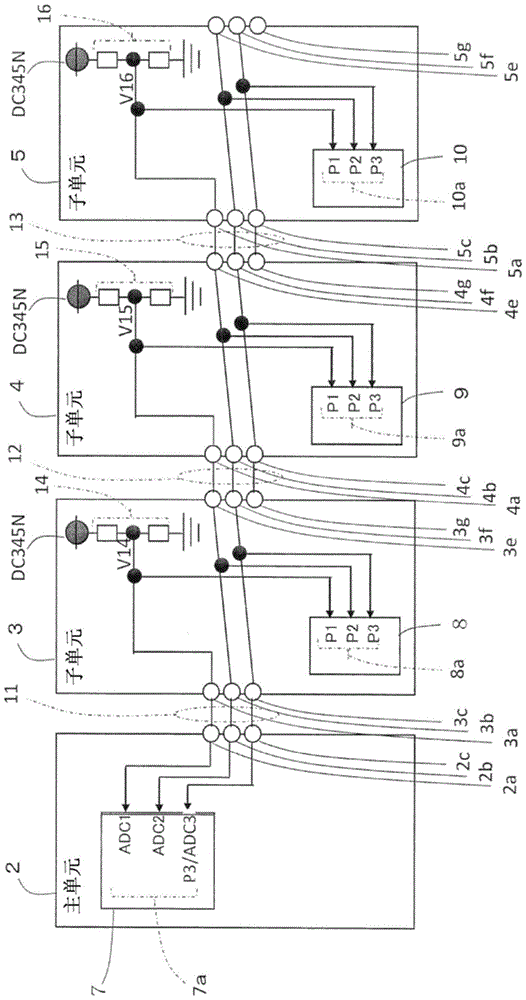

Unit-type electronic equipment

ActiveCN104298186AComponent reductionIncreased ease of assemblyTotal factory controlProgramme total factory controlMicrocomputerEngineering

The invention provides unit-type electronic equipment which is composed of a main unit and multiple subunits and allows reduction of hardware composition elements, simplification of software, and improvement of assembling easiness. The unit-type electronic equipment comprises the multiple subunits (3...). The multiple subunits are all subordinate units having micro computers (8...) which collect and store measured amounts, and individual voltage setting parts (14...) which output individual voltages. The output voltages of all the individual voltage setting parts of the multiple subunits are mutually different voltage levels (V14...), and the output voltages of the different voltage levels are detected by a micro computer (7) of the main unit. Based on the output voltages of the different voltage levels, the micro computer of the main unit identifies the respective types of the multiple subunits.

Owner:MITSUBISHI ELECTRIC CORP

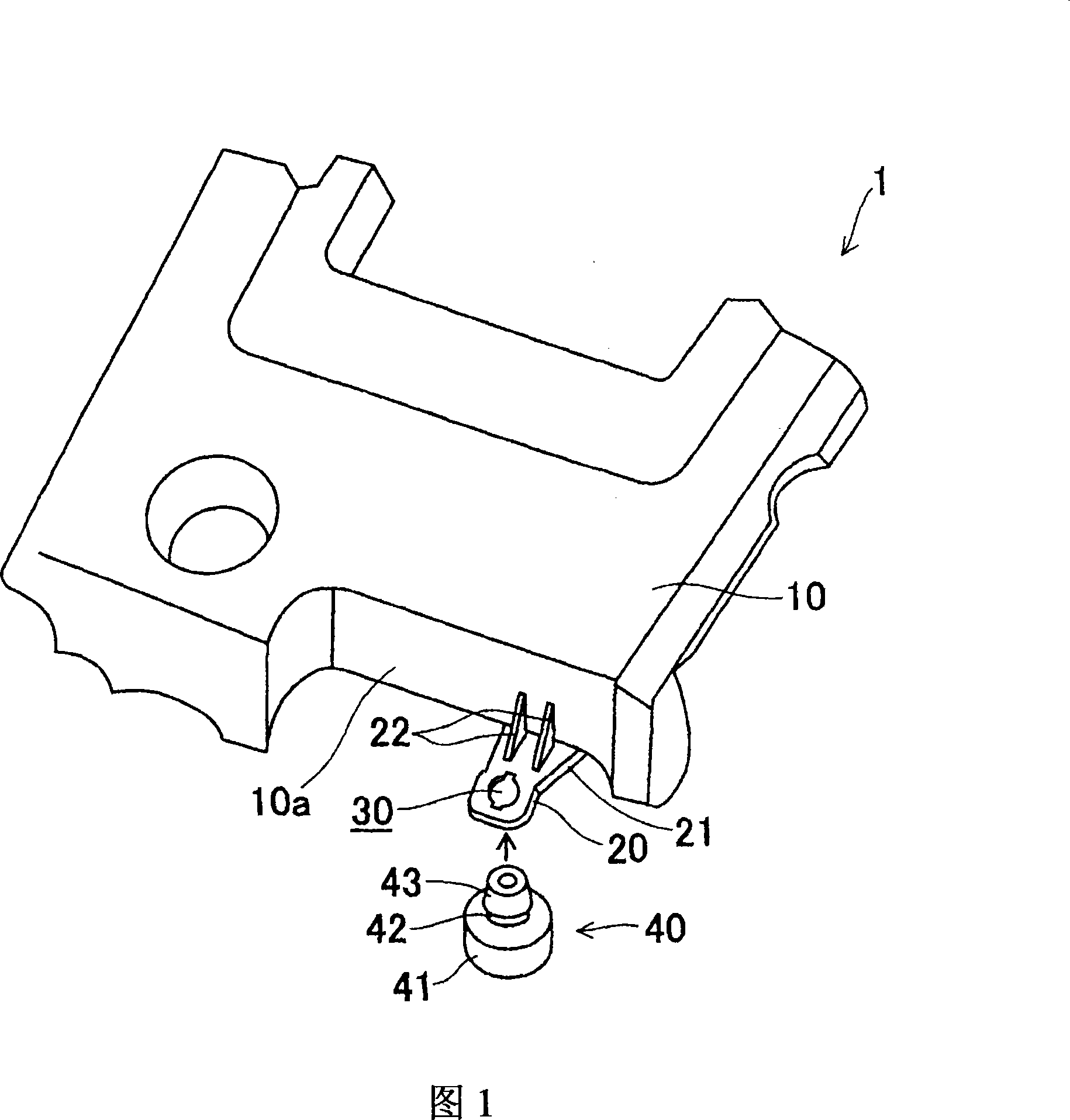

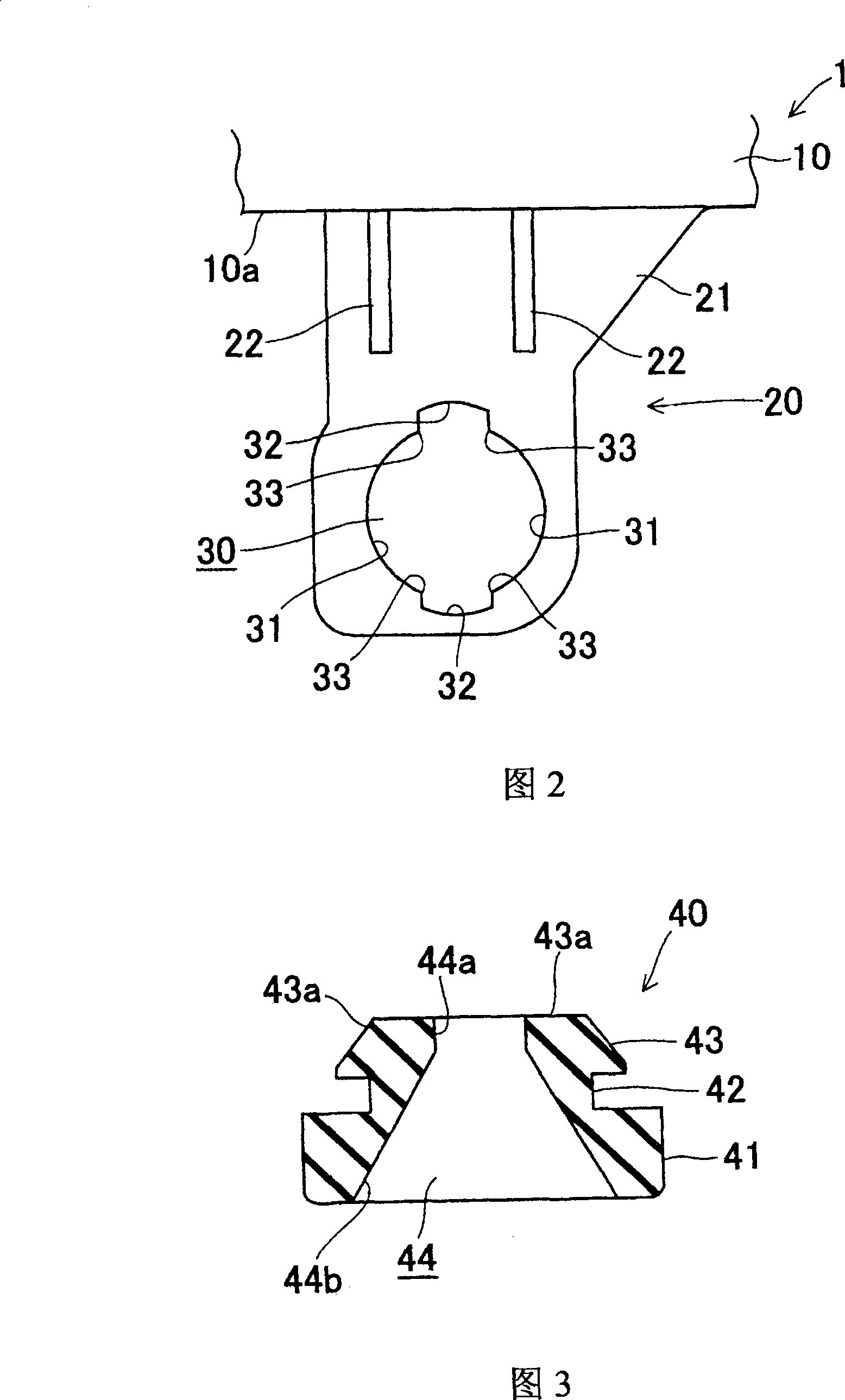

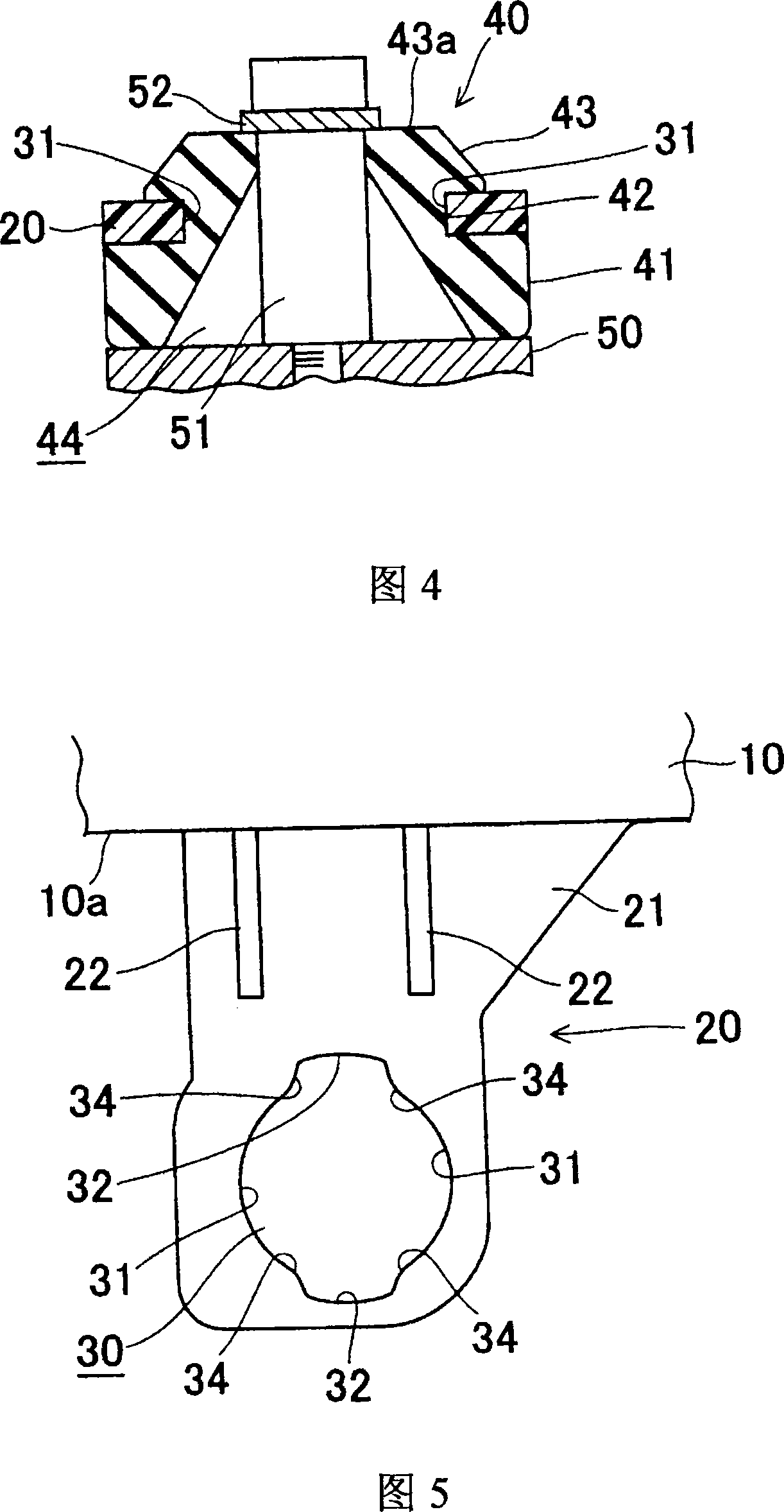

Engine cover

InactiveCN101244727AMaintain posture stability and drop resistanceIncreased ease of assemblySpringsSuperstructure subunitsEngineeringMechanical engineering

The invention provides an engine hood, which ensures the strength of a soleplate integrally arranged on the engine hood, and increases the assembling facility of the rubber mount relative to the mounting hole. The engine hood (1) has a hood main body (10); an assembling base plate (20), integrally arranged on the hood main body (10) and impenetrated with circular mounting holes (30); and a rubber mount assembled and kept in the circular mounting holes (30), which include the following parts: at least a circular tabling trough (31), with a corresponding arc with the tabling neck of the rubber mount; and a conceding trough (32) arranged at least one position of the circumference of the circular mounting holes (30). When the conceding trough (32) performs the assemble of the rubber mount relative to the circular mounting holes (30), the head part of the rubber mount is partly entered.

Owner:TOYODA GOSEI CO LTD

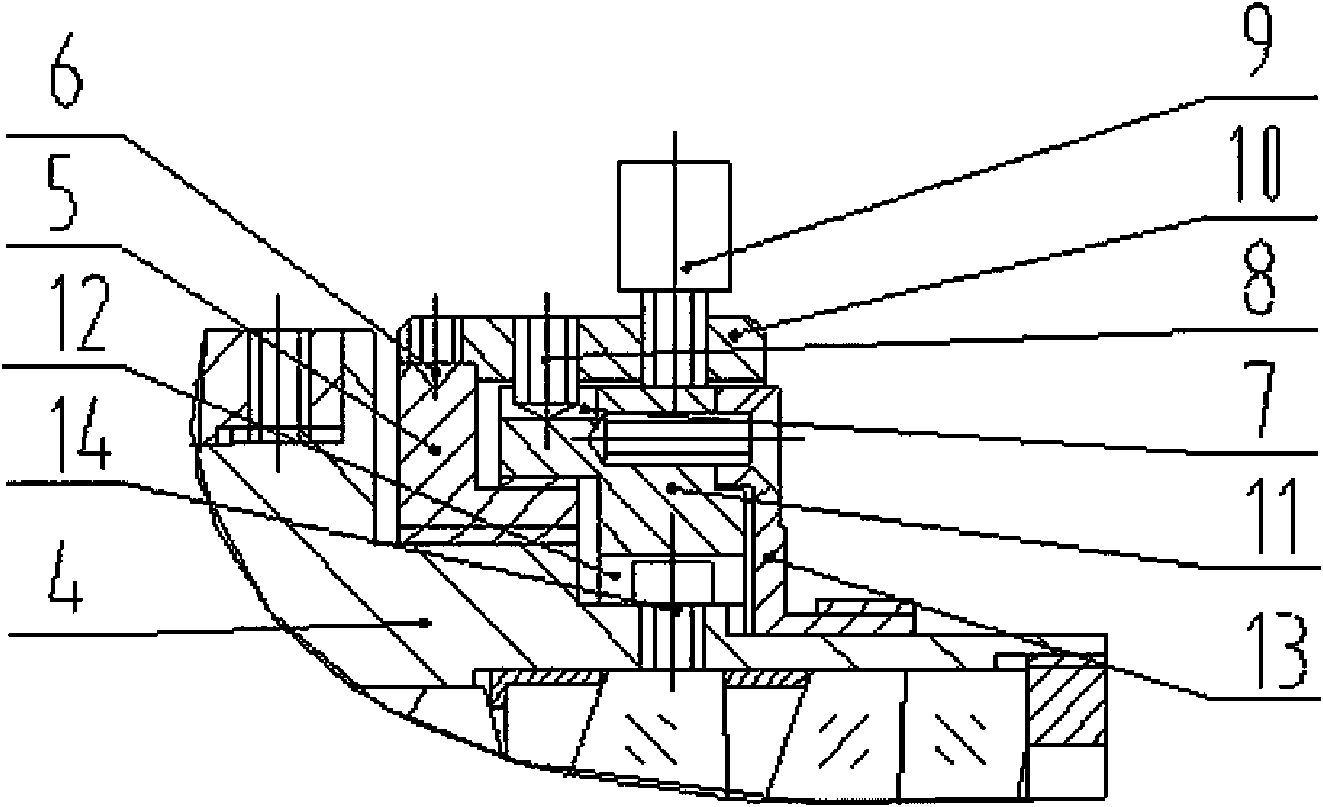

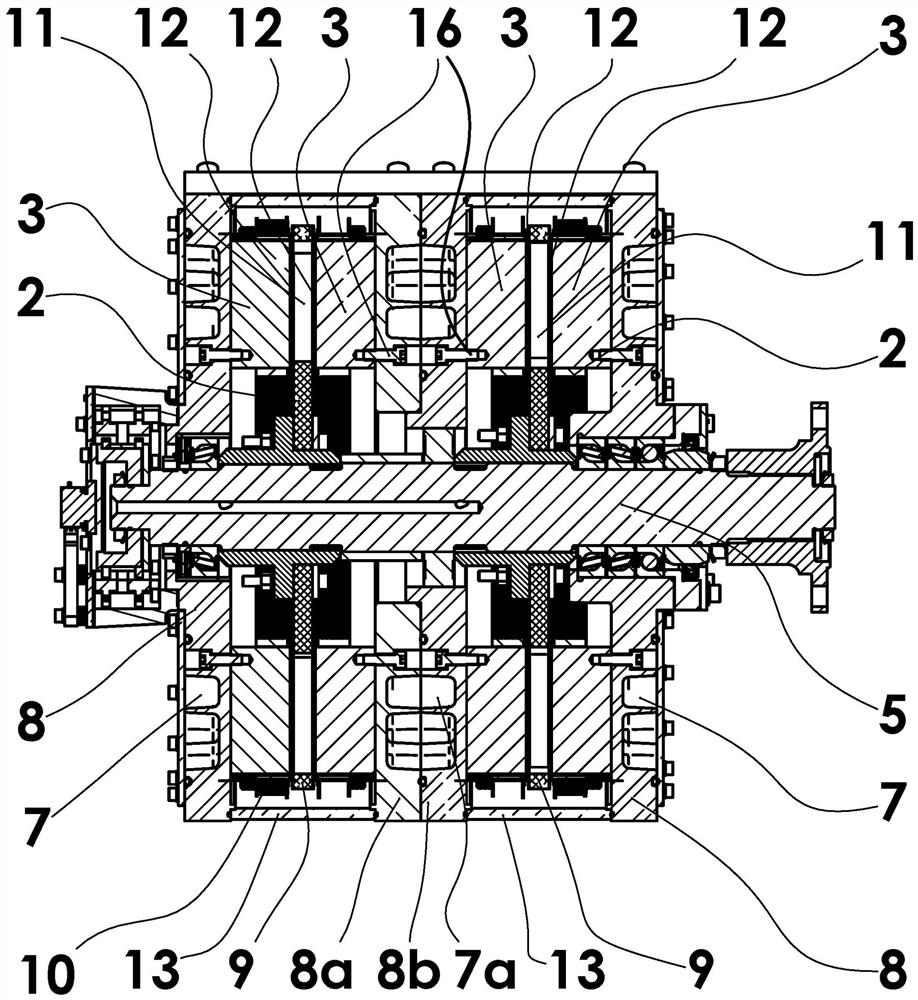

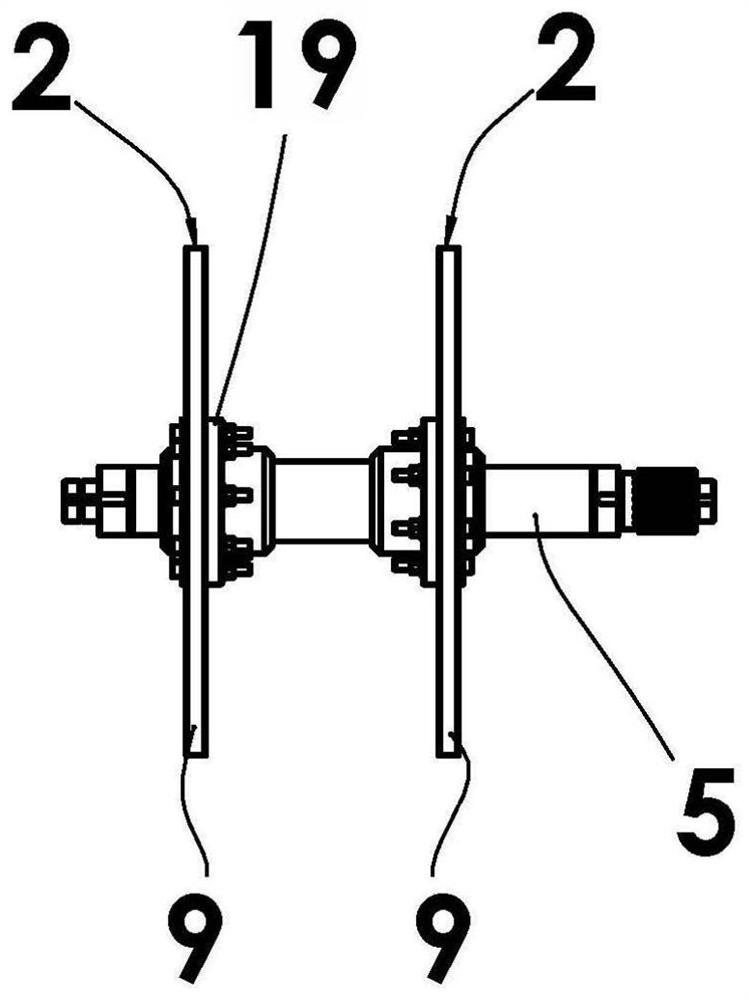

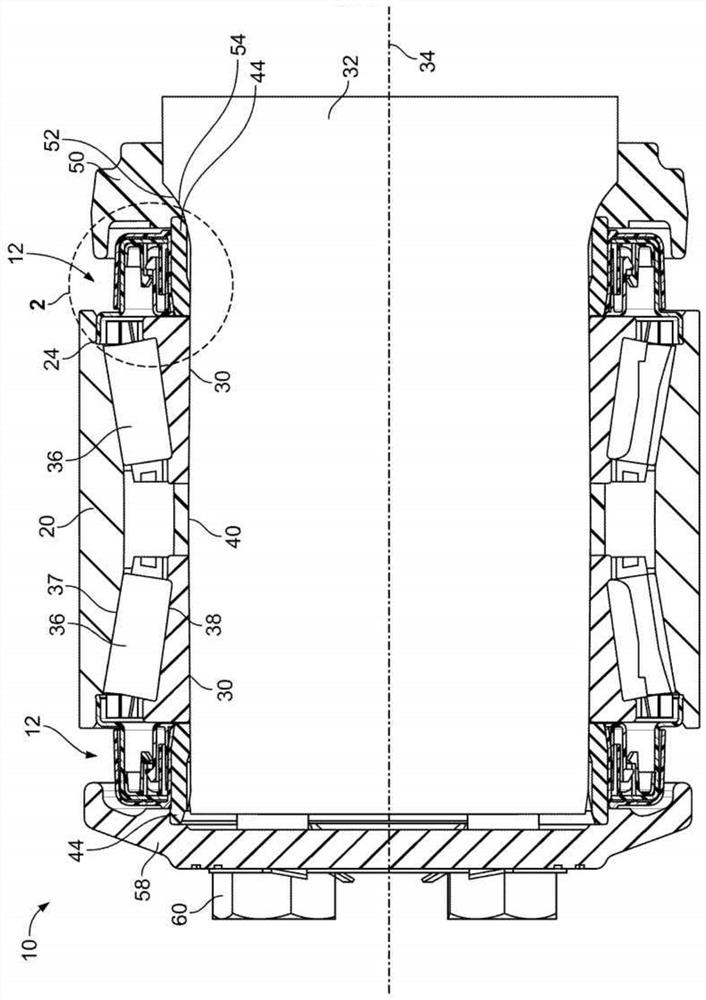

Electromagnetic motor or generator with two rotors, four stators and an integrated cooling system

ActiveCN111742473AReduce starting torqueSmall sizeAssociation with control/drive circuitsWindingsSynchronous motorClassical mechanics

The invention relates to a permanent-magnet synchronous motor or generator comprising at least one rotor (2) and at least one stator (3, 8). The motor comprises two rotors (2), four stators (3, 8) anda cooling system (7, 7a) comprising three cooling circuits (7, 7a), i.e. two outer circuits (7) which are each accommodated in a longitudinal outer wall of a casing (8), adjacent to an outermost stator (3, 8), for cooling said outermost stator (3, 8), and an intermediate circuit (7a) located between the two innermost stators (3, 8) in the motor for simultaneously cooling said two stators (3, 8),the central shaft (5) being common to the two rotors (2) which are connected to the central shaft (5) by mechanical means.

Owner:万络公司

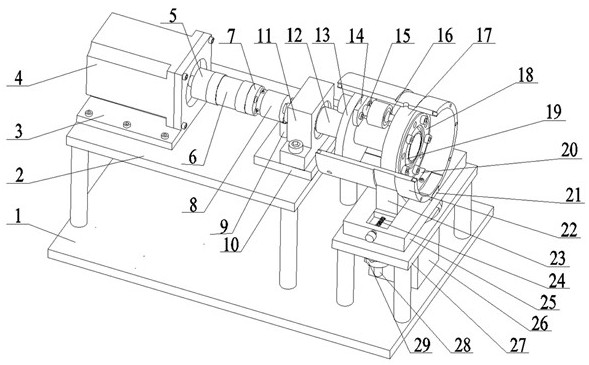

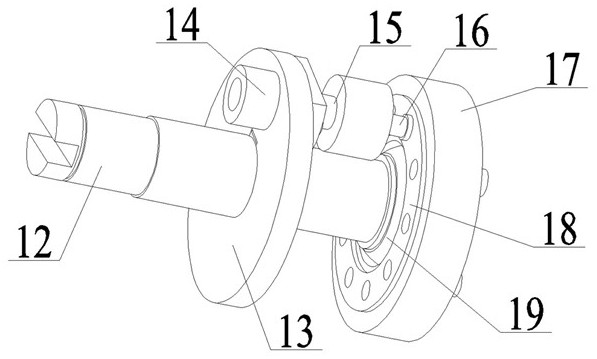

Bearing bush self-adaptive contact friction wear test device

ActiveCN112782024AAvoid eccentric wearStable full-time adaptive contactInvestigating abrasion/wear resistanceDrive shaftCoupling

The invention discloses a bearing bush self-adaptive contact friction wear test device, which relates to the field of bearing bush friction wear experiment test equipment, and mainly comprises a motor, a coupler, a torque sensor, a slip ring, a transmission shaft, a turntable, a linear bearing, a slide bar, a ball rod joint bearing, an expansion sleeve, a radial joint bearing, a bearing bush clamp, a triangular block, a force transmission plate, an air cylinder and the like. The ring sample and the bearing bush sample in the device are in sliding friction. By adding the self-adaptive contact device, the ring sample and the bearing bush sample are in full-time stable contact, the eccentric wear phenomenon is overcome, and the accuracy of a friction wear test result is improved; the loading and unloading stability of the device is improved by additionally arranging the spring at the triangular block for lifting the bearing bush clamp; oil outlets are formed in different height positions of the bearing bush clamp, so that the adaptability of a friction-wear test under various lubricating oil quantities is improved; and by simplifying the device and reducing the volume, the assembling easiness and green economy of the test device are improved.

Owner:JIANGSU UNIV OF SCI & TECH

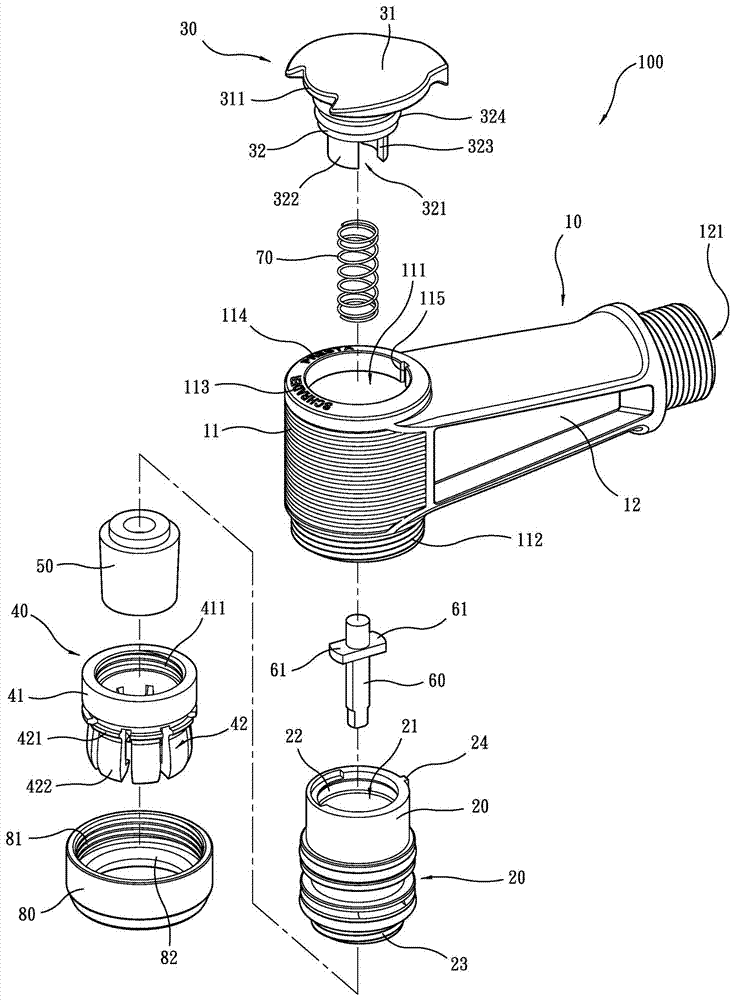

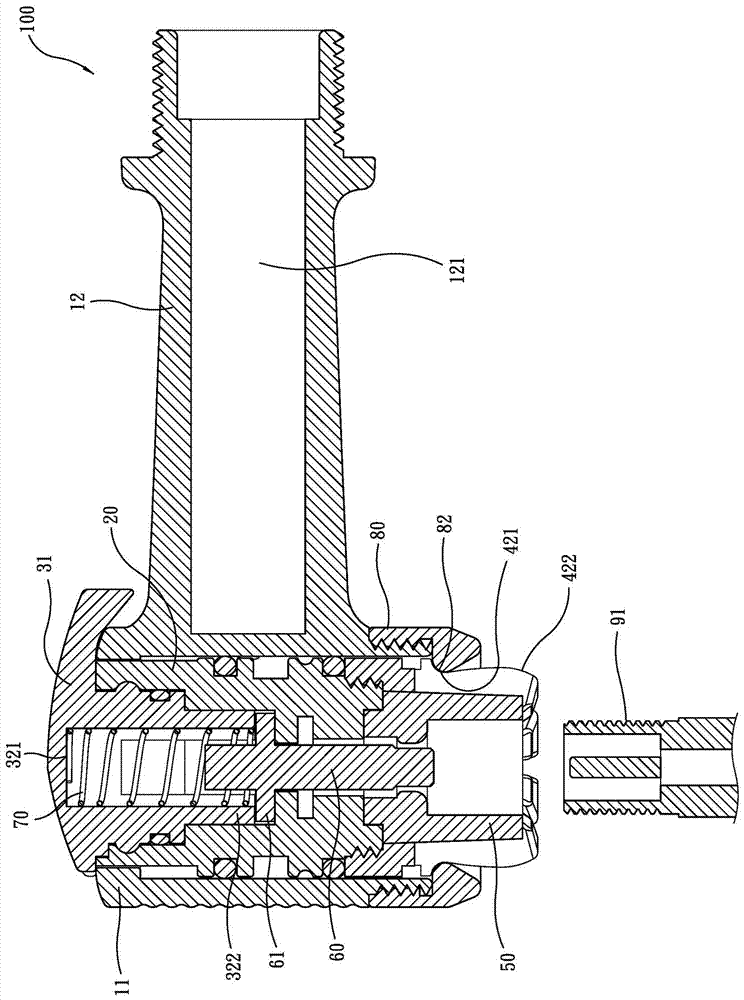

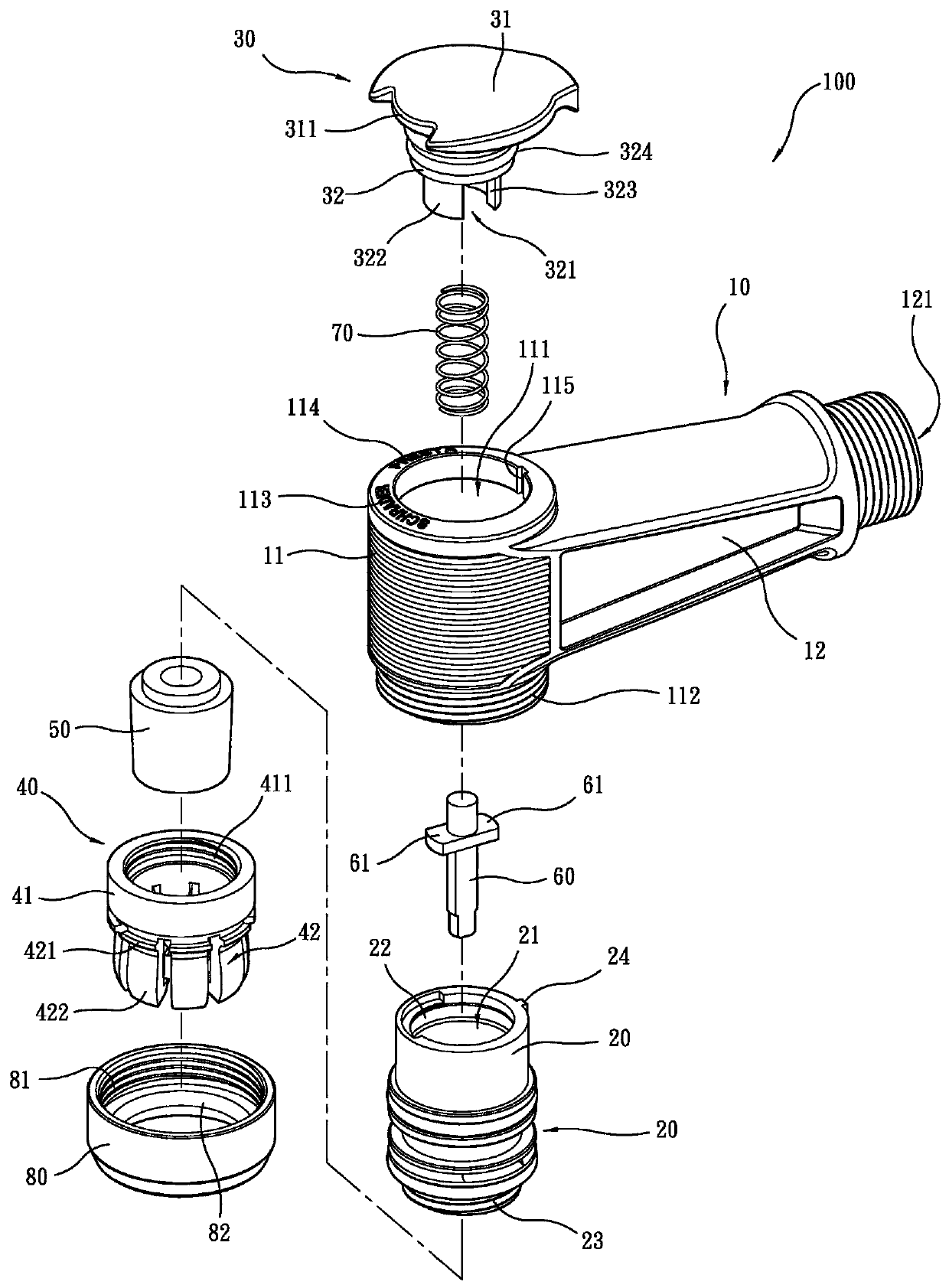

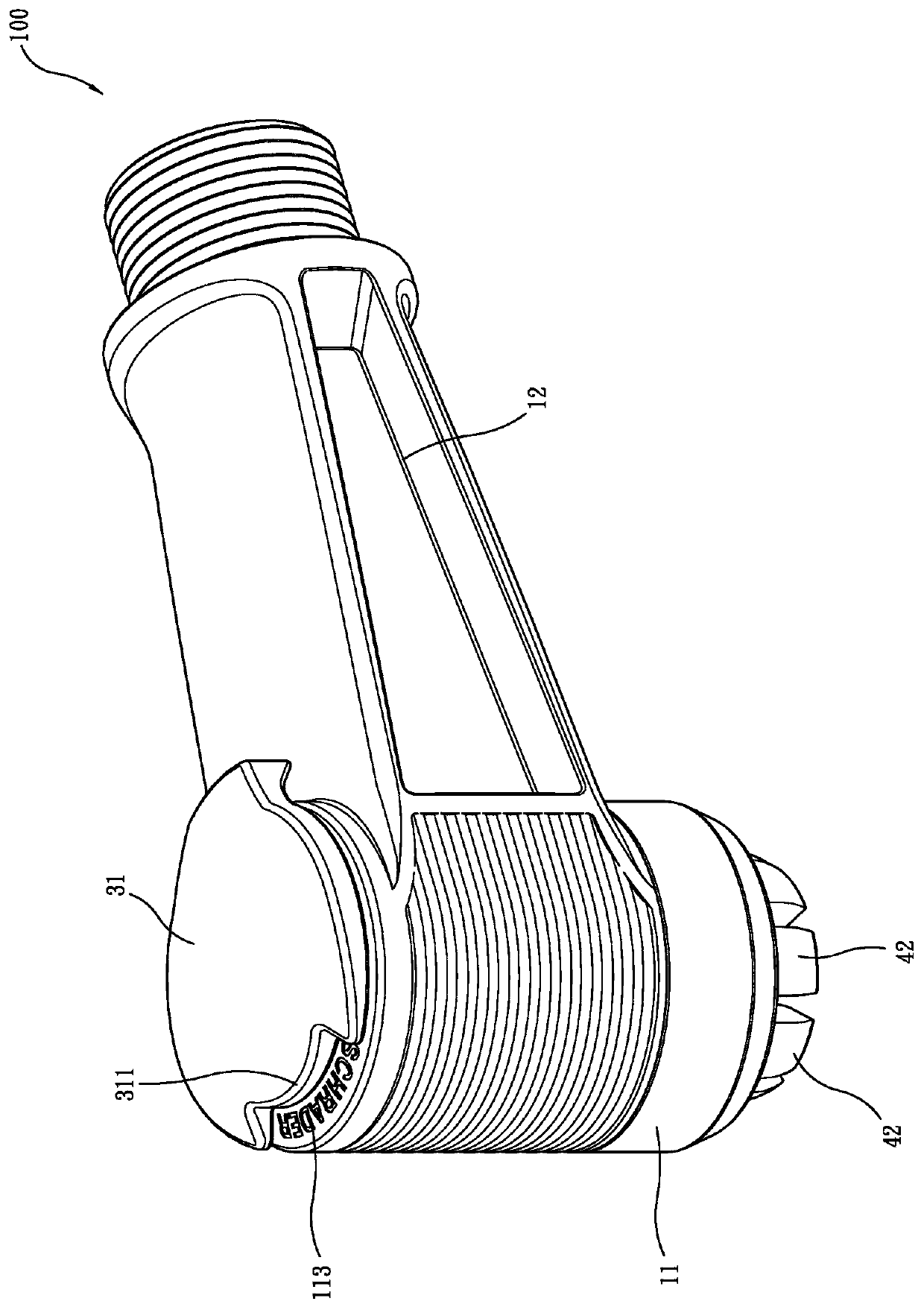

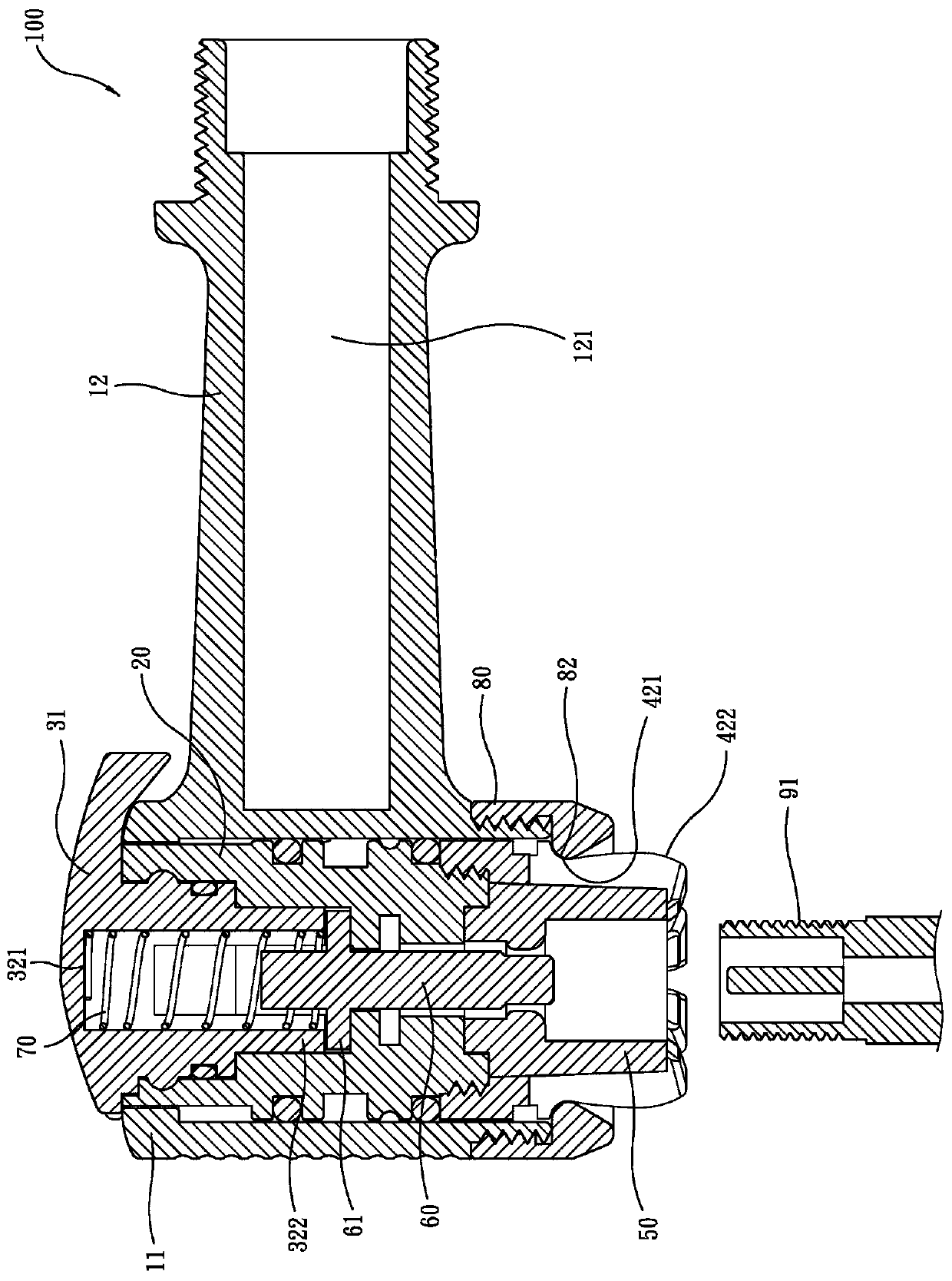

Rotary clamping jaw type valve

A rotary clamping jaw type valve includes a valve body, an inner cylinder, a rotary cover, a clamping jaw, a bundle ring, an ejector pin, a spring and an action ring. The valve body is provided with a containing chamber with the top and the bottom being through; the inner cylinder is placed in the containing chamber of the valve body and axially provided with an axial hole in a penetrating mode; the rotary cover is rotatably combined with one end of the inner cylinder and located at the top end of the valve body; an indicating area is arranged at one end of the rotary cover, and the other end of the rotating cover is provided with a containing groove extending inwards, two pressing walls and two sliding grooves, wherein the two pressing walls are located on the two opposite sides of the containing groove, and the two sliding grooves are located in the other two opposite sides of the containing groove; a ring part is arranged at one end of the clamping jaw, and a plurality of claw parts are annularly arranged at the other end of the clamping jaw; the bundle ring has the elastic deformation capacity and is placed in the clamping jaw; the ejector pin is placed in the axial hole of the inner cylinder, and two convex wings are arranged on the two opposite sides of the ejector pin; the spring is placed in the containing groove of the rotary cover and abuts against one end of the ejector pin; and the action ring is combined at the bottom end of the valve body, and an annular flange is arranged on the inner peripheral face of the action ring. The rotary clamping jaw type valve is more convenient to operate, low in manufacturing cost, easy to assemble, and capable of promoting the clamping force to an American valve and a French valve.

Owner:BETO ENG & MARKETING

Aluminum-clad wood out-opening window

InactiveCN103883204AImprove heat insulationImprove sealingInsect protectionWindow/door framesEngineeringCost performance

The invention discloses an aluminum-clad wood out-opening window. The aluminum-clad wood out-opening window comprises a frame, a mullion, a sash, insulated glass, outdoor glass rubber strips, indoor glass rubber strips, outer-side opening rubber strips and inner-side opening rubber strips. Each of the frame, the mullion and the sash is formed by composting of outer-side aluminum alloy sections and inner-side wood sections, inner and outer surfaces of the frame, the mullion and the sash are flush, the inner sides of the frame and the mullion are provided with turning materials, one outer-side opening rubber strip and one inner-side opening rubber strip are arranged on one wood section on the inner side of the sash and one aluminum section on the outer side of the sash respectively, a built-in folding screen is inlaid on the inner side of an opening frame, and an embedded aluminum section is arranged between each outer-side aluminum alloy section and the corresponding inner-side wood section. Heat insulation, sealing performance, sound insulation, anti-mosquito performance and easiness in assembly of the aluminum-clad wood out-opening window are improved remarkably, and the aluminum-clad wood out-opening window has high cost performance.

Owner:NANTONG HAIYING WOOD IND

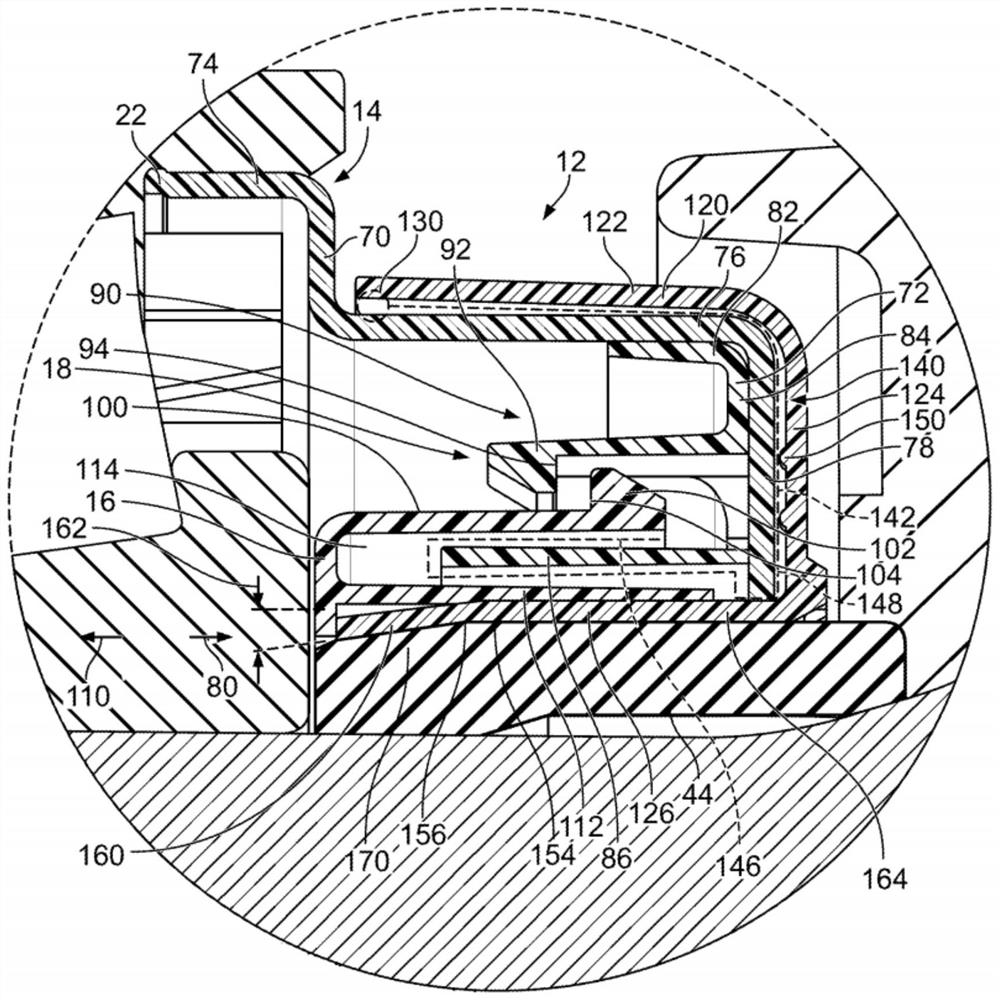

Roller bearing seal assembly and a component thereof

ActiveCN112513482ASimplify the assembly processFirmly connectedEngine sealsRoller bearingsClassical mechanicsStructural engineering

In accordance with one aspect of the present disclosure, a roller bearing seal assembly is provided that includes a seal case and a rotor having a unitary, one-piece construction. The rotor is connected to the seal case and is rotatable relative to the seal case about an axis. The seal case and rotor include interfering portions that limit axial separation of the rotor and the seal case. In one embodiment, the rotor and seal case include at least one snap-fit connection that permits the rotor and seal case to be readily assembled. The at least one snap-fit connection includes the interfering portions which inhibit axial separation of the rotor and seal case after the rotor and seal case have been assembled.

Owner:AMSTED RAIL CO INC

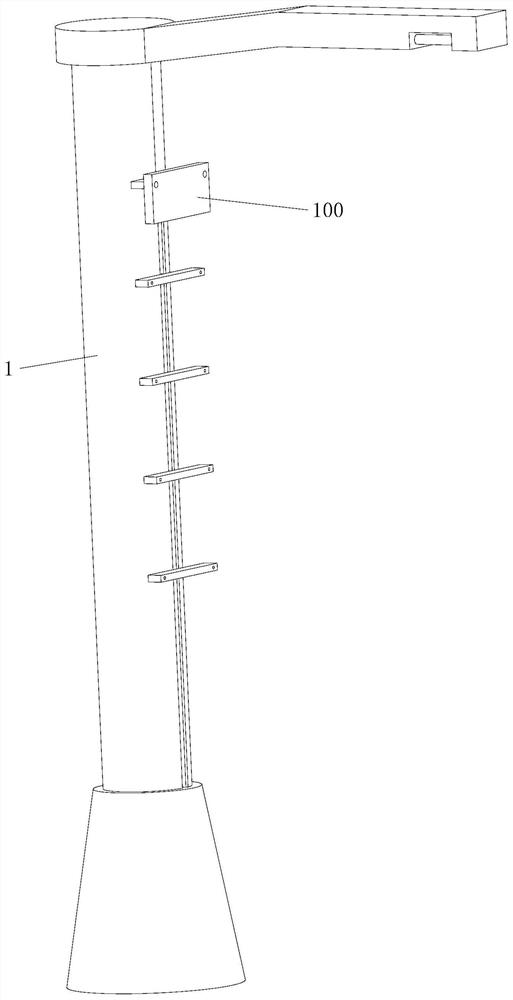

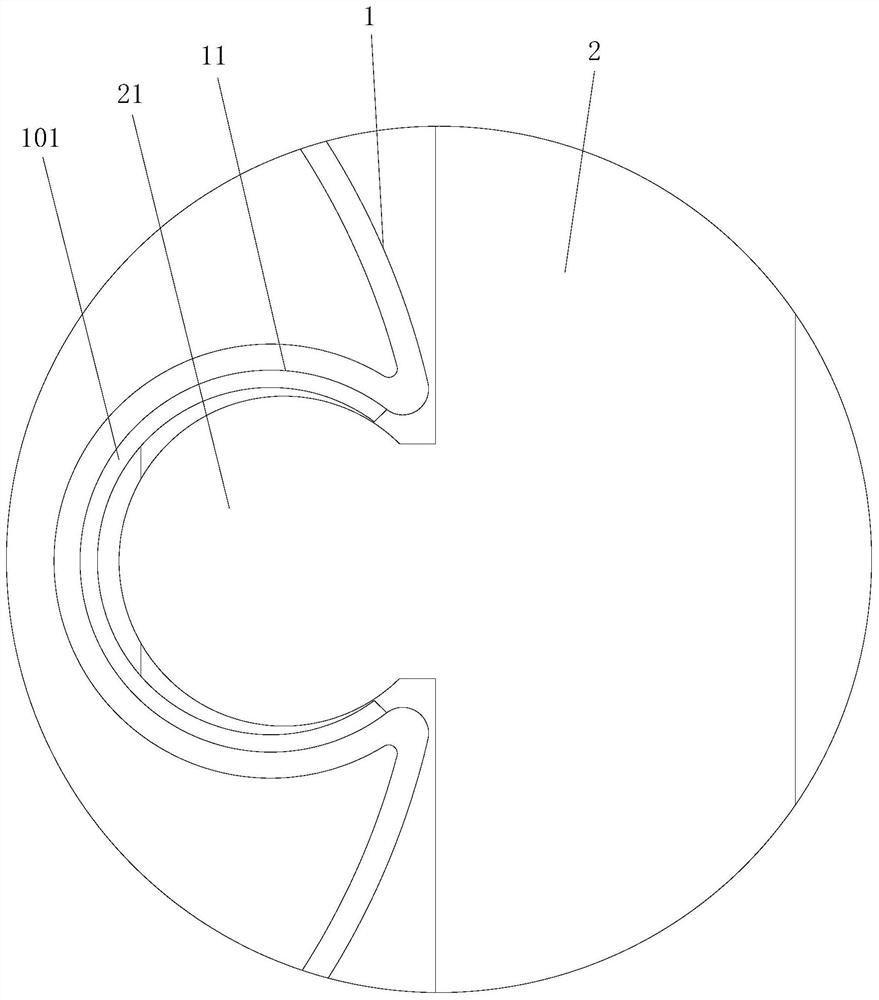

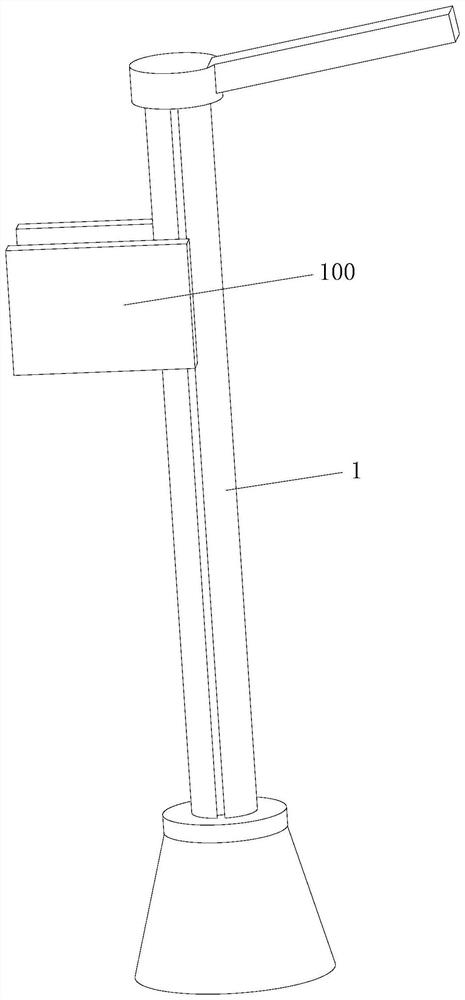

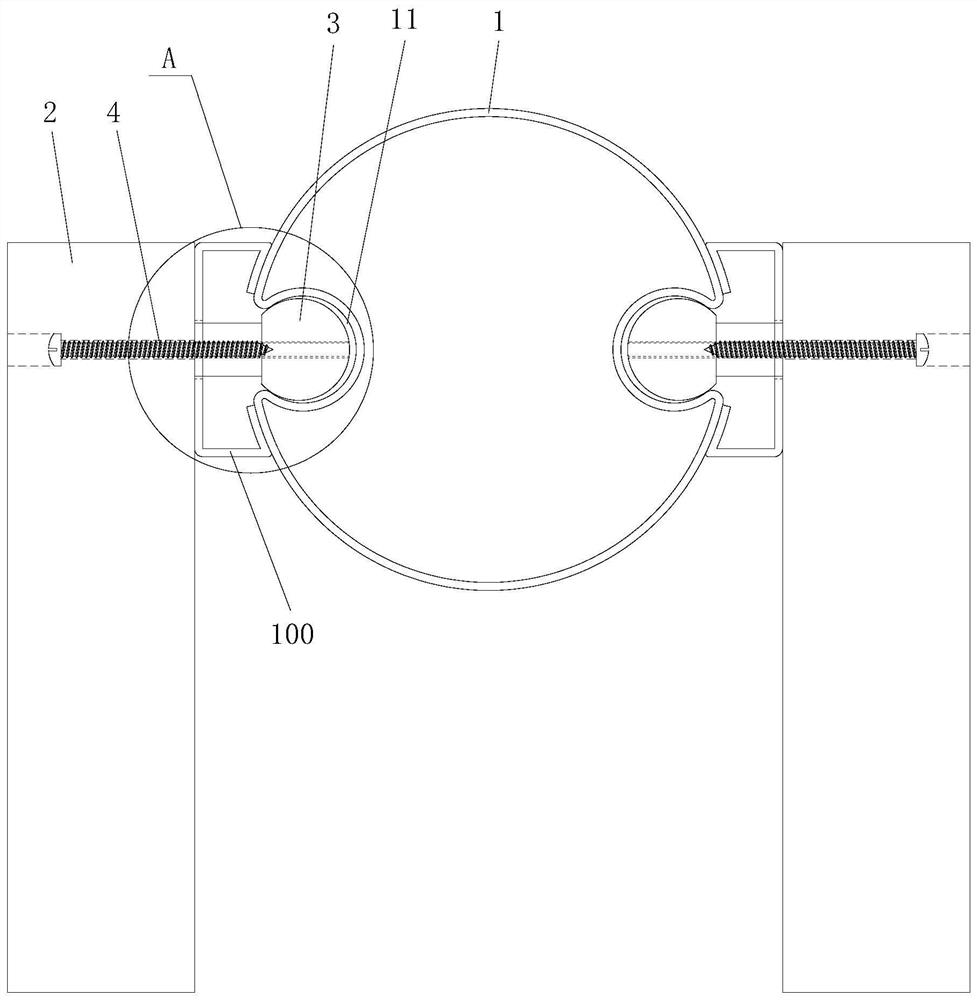

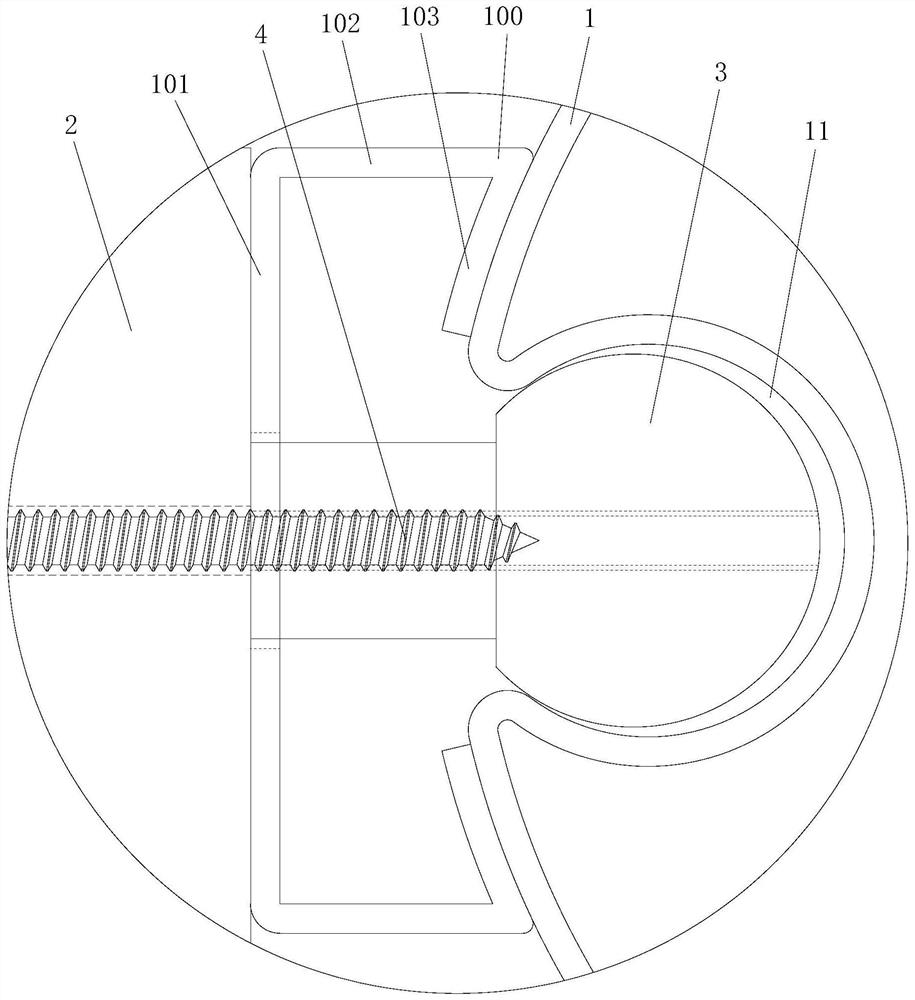

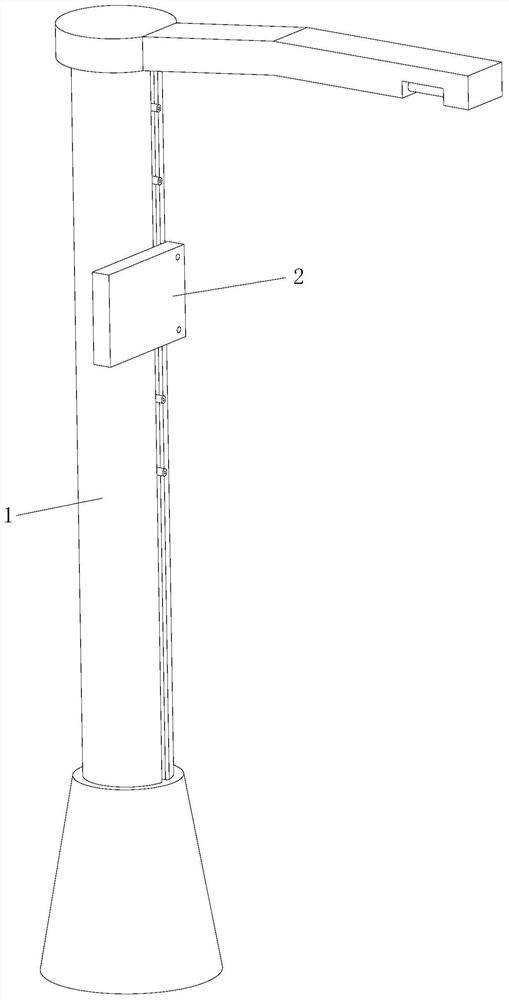

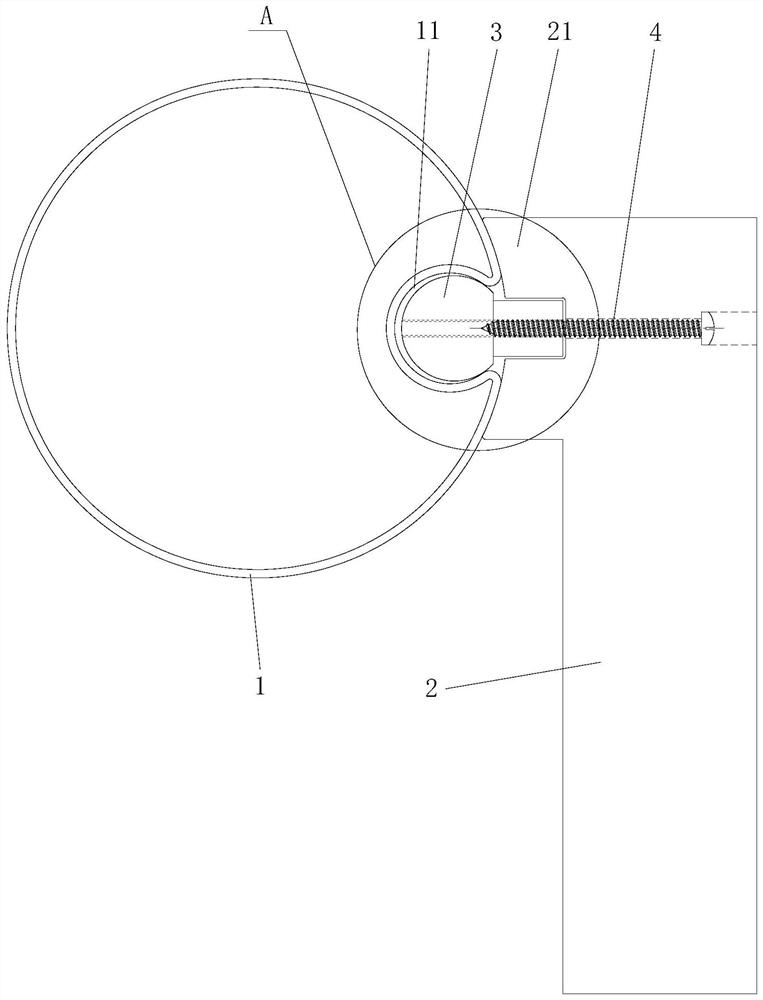

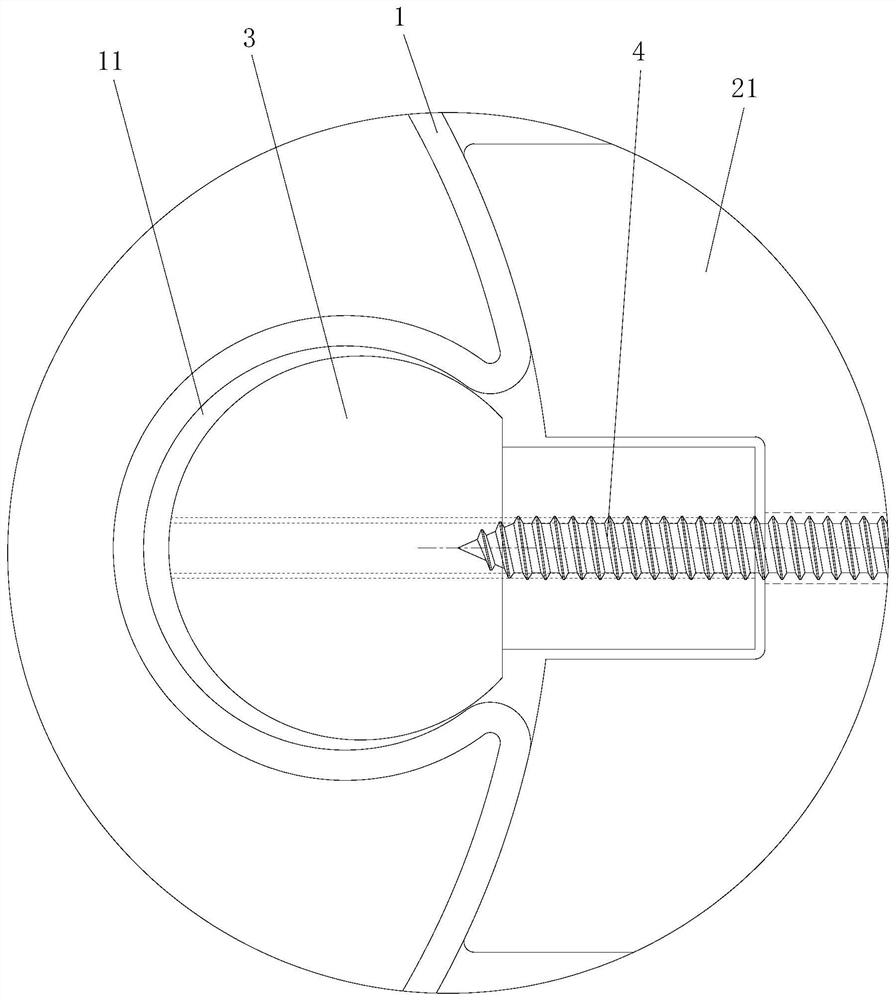

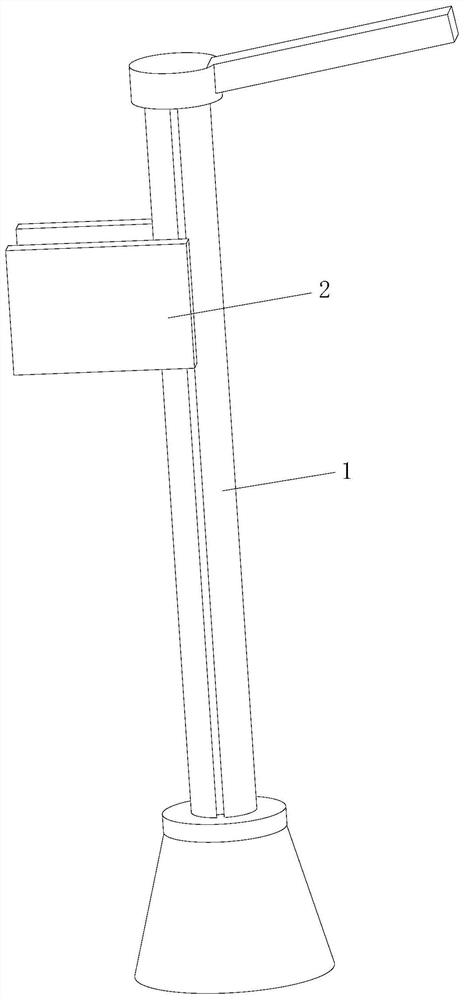

Lamp post system based on groove mounting structure

PendingCN111810922AImprove the limit effectUnlimited quantityMechanical apparatusLighting support devicesEngineeringMechanical engineering

The invention discloses a lamp post system based on a groove mounting structure. The system involves a lamp post main body, more than one mounting base and more than one functional part, wherein the lamp post main body is provided with a mounting groove extending in the length direction, the mounting base is provided with a connecting part arranged in the mounting groove, the mounting base is connected with a positioning mechanism used for fixing the connecting part in the mounting groove, and at least one functional part is arranged on at least one mounting base. The system has the advantagesof being simple and compact in structure, low in cost, easy and convenient to assemble, high in mounting flexibility, convenient to adjust, good in aesthetic property, good in connection stability and reliability and the like.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD +1

Lamp post system adopting groove mounting structure

PendingCN111853618AEasy to disassembleImprove installation stabilityLighting support devicesLight fasteningsEngineeringMechanical engineering

The invention discloses a lamp post system adopting a groove mounting structure. The lamp post system comprises a lamp post main body and one or more functional parts, the lamp post main body is provided with one or more mounting grooves extending in the length direction, each functional part is connected with one or more connecting parts through a detachable connecting mechanism, each connectingpart is detachably mounted in the corresponding mounting groove, and one or more supporting parts for preventing the functional parts from moving relative to the lamp post body are arranged between the functional parts and the lamp post body correspondingly. The system has the advantages of simple and compact structure, low cost, simplicity and convenience in assembly, convenience in adjustment, good attractiveness, good connecting stability and reliability and the like.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD +1

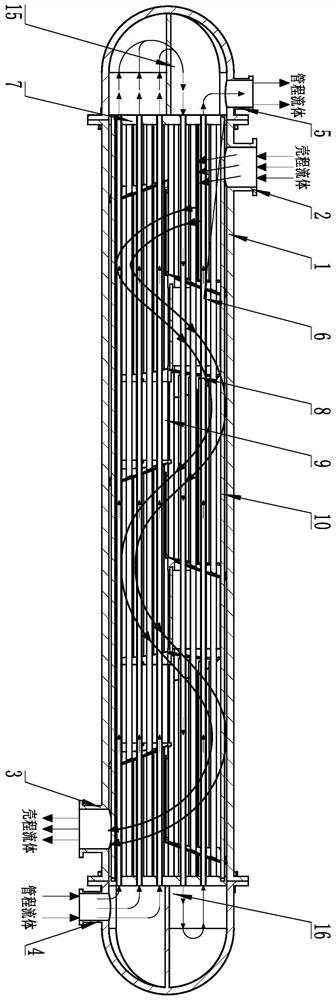

A stepped oblique flow spiral baffle heat exchanger

ActiveCN110530175BImprove heat transfer coefficientAvoid damageHeat exhanger sealing arrangementHeat exchanger casingsPlate heat exchangerEngineering

The invention relates to a stepped oblique flow spiral baffle plate heat exchanger. A plurality of groups of spiral periodic baffle plate groups are arranged in the shell; each spiral periodic baffleplate group comprises a plurality of oblique flow curved surface baffle plates which are spirally arranged in the circumferential direction and have different phases; a certain inclination angle is formed between the inclined flow curved surface baffle plate and the cross section of the shell; every two adjacent oblique flow curved surface baffle plates in the shell are connected with a baffle plate through two adjacent straight edges located on the corresponding oblique flow curved surface baffle plate to form a step shape. The oblique flow curved surface baffle plates with the same phase inthe shell form an oblique flow curved surface baffle plate group, wherein the oblique flow curved surface baffle plate group in the same group is supported by a plurality of pull rods, and the pull rods are fixedly connected with the tube plate. The stepped oblique flow spiral baffle plate heat exchanger is easy to machine and assemble, low in cost and capable of avoiding flow leakage of a triangular area between two connected baffle plates.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Rotary jaw type air nozzle

A rotary clamping jaw type valve includes a valve body, an inner cylinder, a rotary cover, a clamping jaw, a bundle ring, an ejector pin, a spring and an action ring. The valve body is provided with a containing chamber with the top and the bottom being through; the inner cylinder is placed in the containing chamber of the valve body and axially provided with an axial hole in a penetrating mode; the rotary cover is rotatably combined with one end of the inner cylinder and located at the top end of the valve body; an indicating area is arranged at one end of the rotary cover, and the other end of the rotating cover is provided with a containing groove extending inwards, two pressing walls and two sliding grooves, wherein the two pressing walls are located on the two opposite sides of the containing groove, and the two sliding grooves are located in the other two opposite sides of the containing groove; a ring part is arranged at one end of the clamping jaw, and a plurality of claw parts are annularly arranged at the other end of the clamping jaw; the bundle ring has the elastic deformation capacity and is placed in the clamping jaw; the ejector pin is placed in the axial hole of the inner cylinder, and two convex wings are arranged on the two opposite sides of the ejector pin; the spring is placed in the containing groove of the rotary cover and abuts against one end of the ejector pin; and the action ring is combined at the bottom end of the valve body, and an annular flange is arranged on the inner peripheral face of the action ring. The rotary clamping jaw type valve is more convenient to operate, low in manufacturing cost, easy to assemble, and capable of promoting the clamping force to an American valve and a French valve.

Owner:BETO ENG & MARKETING

Integrated water line structure of water purifier

PendingCN107899424AGuaranteed firmnessReduce the chance of water leaksWater/sewage treatment bu osmosis/dialysisReverse osmosisProcess engineeringWater leak

Owner:KINGCLEAN ELECTRIC

Connector and its making method

InactiveCN101055942BIncreased ease of assemblyImprove insulation performanceLine/current collector detailsSoldered/welded conductive connectionsJunction pointEngineering

A connector and its manufacturing methods. The connector includes a metal conductive terminal, a low melting point metal substance and an insulation casing; one end of the metal conductive terminal bends to form a vertical slotted C-type portion in order to accommodate a wire to insert, another end is used to connect the external conductive junction point; the low melting point metal substance istabled in the vertical slot of the C-type portion and the insulation casing is coverd on the outside of the C-type portion and the low melting point metal substance; When heating up the low melting point metal substance and the insulation casing, the low melting point metal substance is melted to connect with the C-type portion and the wire conductive core in the C-type portion, while the insulation casing properly contracts to coat the metallic conductive terminals and the wires, in order to complete the combination of the connector and the wire.

Owner:KS TERMINALS INC

Lamp post system adopting groove mounting structure

PendingCN111853636AEasy to disassembleImprove the limit effectMechanical apparatusLighting support devicesEngineeringMechanical engineering

The invention discloses a lamp post system adopting a groove mounting structure. The lamp post system comprises a lamp post body and one or more functional parts, the lamp post body is provided with an installation groove extending in the length direction, connecting parts corresponding to the functional parts are detachably installed in the installation groove, and the functional parts are connected with the corresponding connecting parts through detachable connecting mechanisms. The system has the advantages of simple and compact structure, low cost, simplicity and convenience in assembly, convenience in adjustment, good attractiveness, good connecting stability and reliability and the like.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD +1

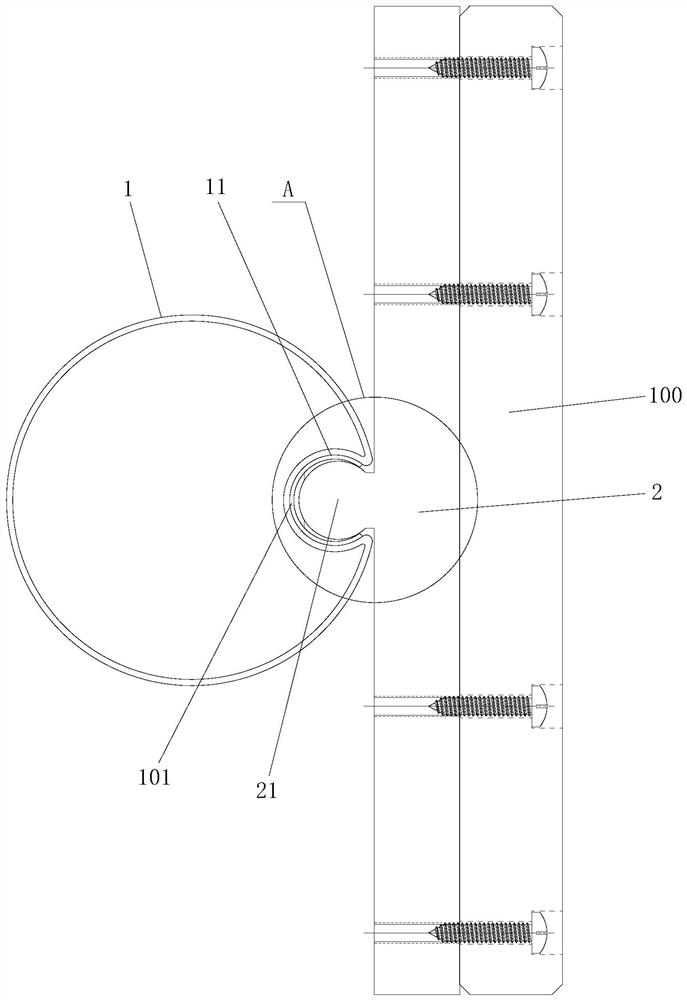

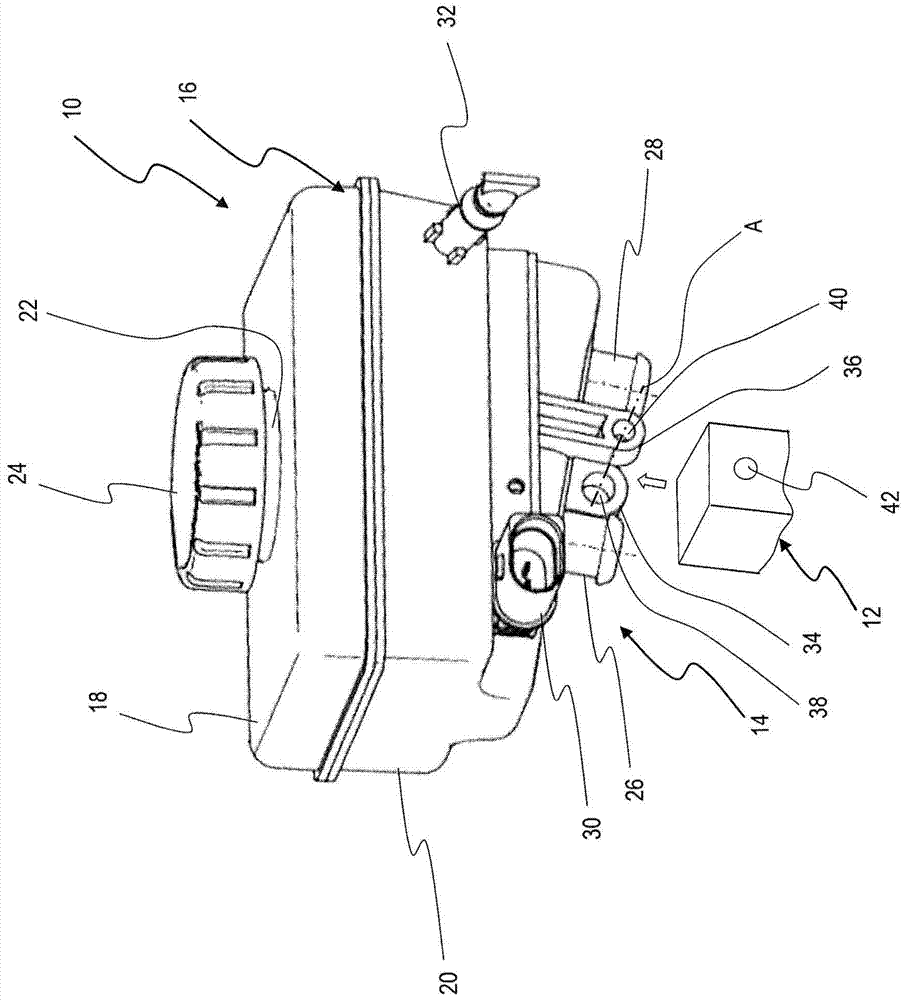

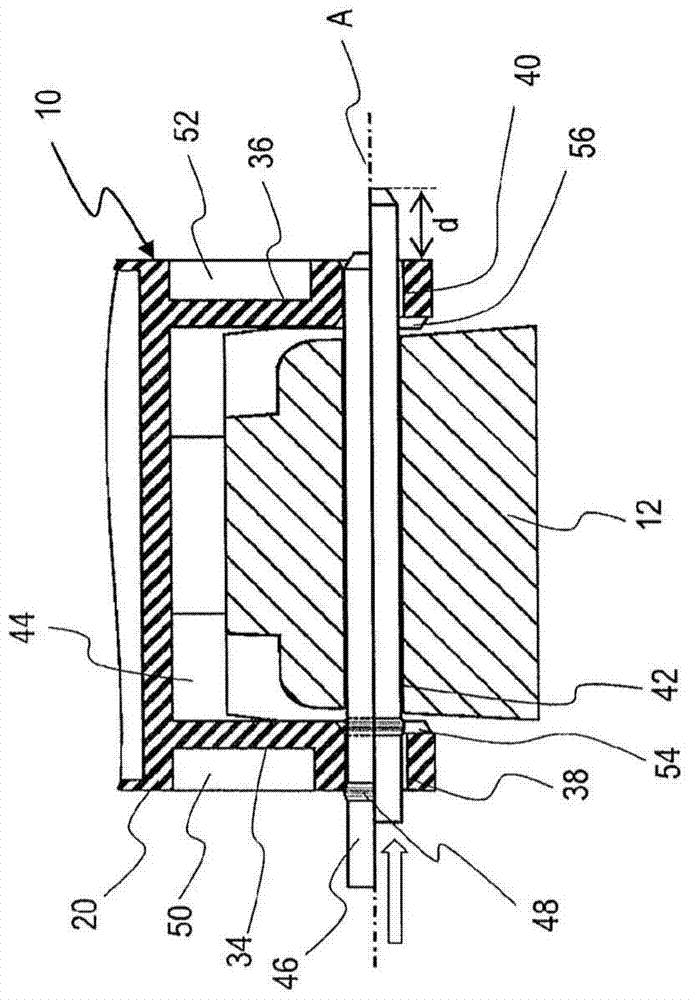

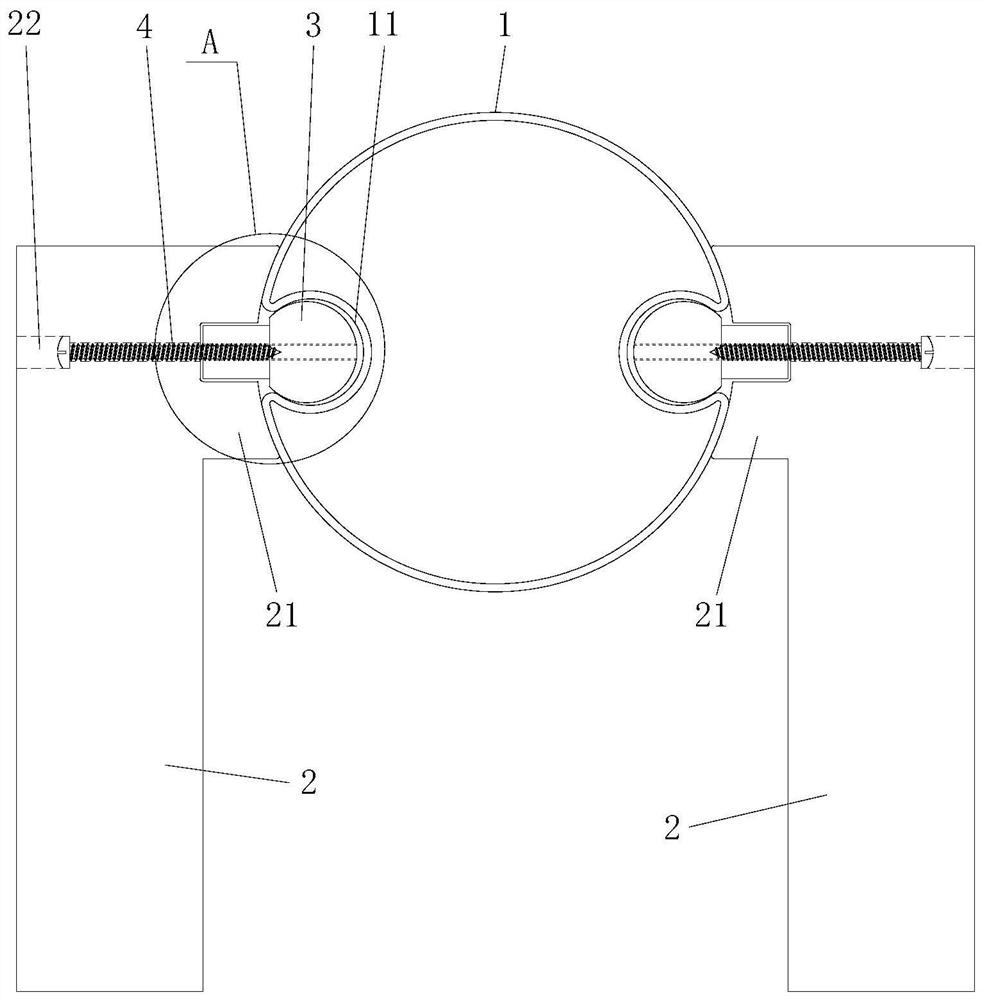

Coupling device between fluid reservoir and master brake cylinder of motor vehicle braking system

InactiveCN104968542BSimple designExtend the lifespanFluid braking transmissionReservoir arrangementsCouplingMaster cylinder

The invention relates to a coupling device between a fluid reservoir (10) and a master brake cylinder, wherein two coupling arms (34, 36) each having a coupling opening (38, 40) are arranged on one of the parts , and on the other part is arranged a mounting part (12) with a receiving hole (42), the two coupling arms (34, 36) are engaged on the mounting part (12) such that the coupling opening (38, 40) and said receiving hole (42) are aligned relative to each other along a common axis (A), wherein in order to couple said mounting part (12) to said two coupling arms, a The coupling pin (46) is inserted into the opening (38, 40) and said receiving hole (42), and is fixed relative to at least one coupling arm (34, 36) or said mounting portion (12), wherein said The coupling pin (46) is formed with a cylindrical shank and at least one radially protruding locking protrusion (48).

Owner:LUCAS AUTOMOTIVE GMBH

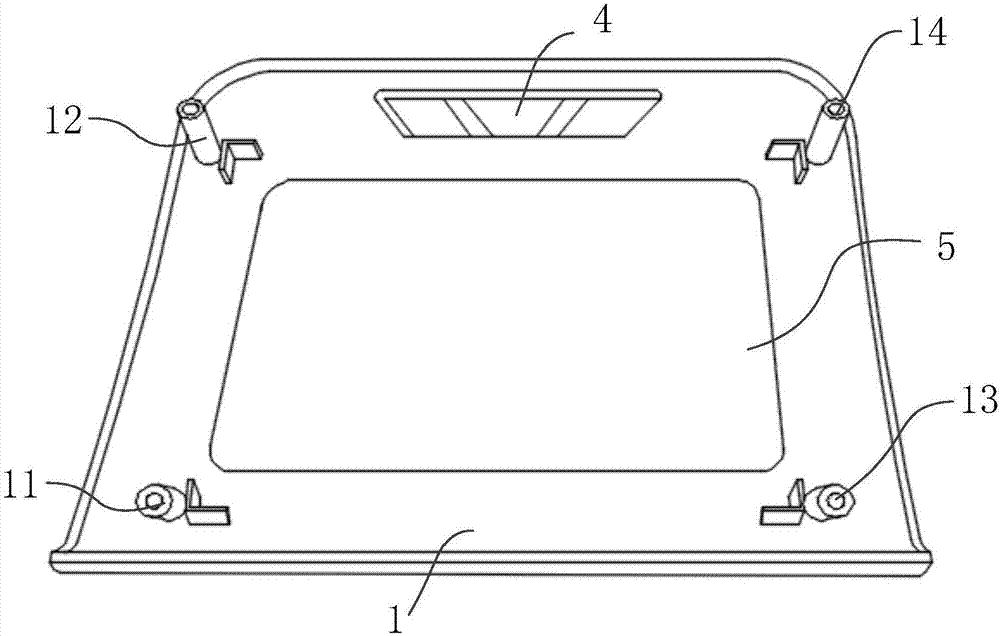

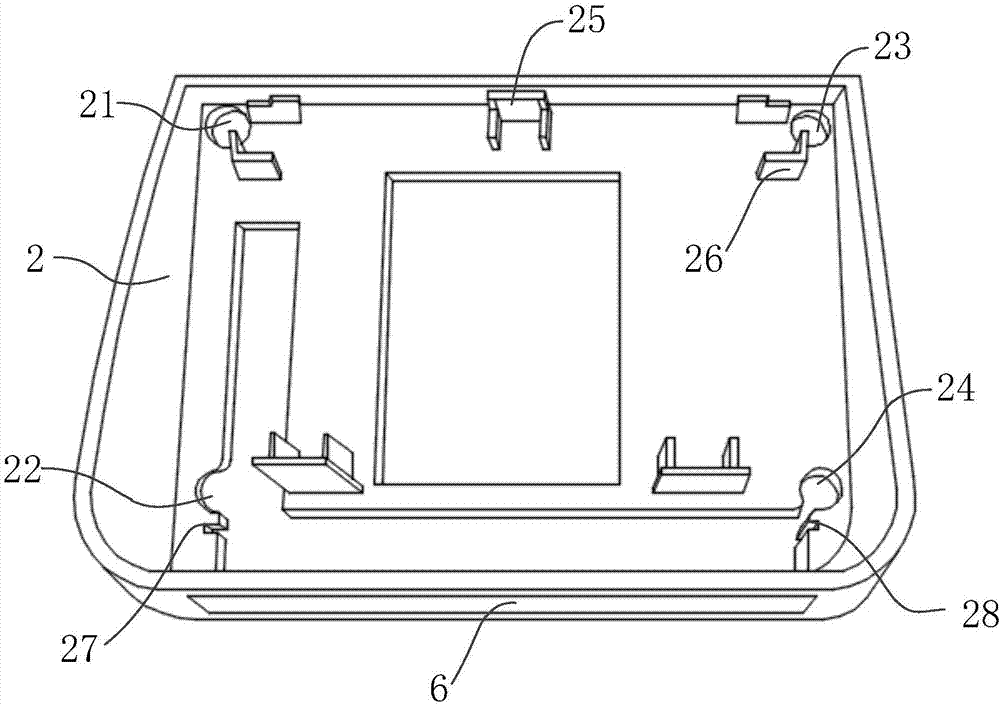

Automobile parking brake switch assembly

InactiveCN104554205BImprove rigid wear resistanceIncreased ease of assemblyHand actuated initiationsDriver/operatorEngineering

Owner:SUZHOU RUIYAN ELECTRONICS TECH CO LTD +1

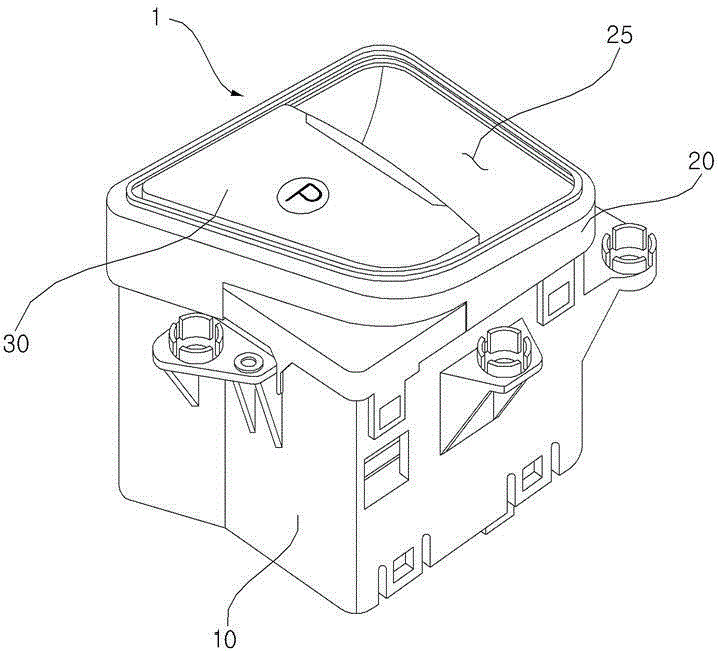

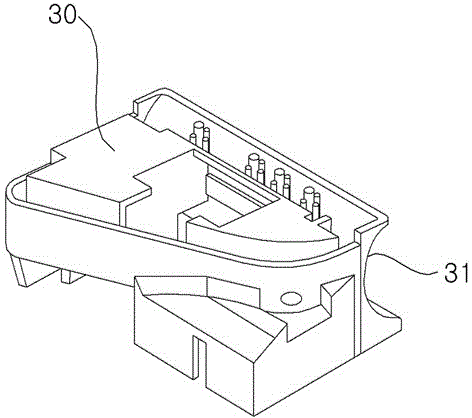

Easy-to-assemble tire pressure controller shell structure

PendingCN107878127AIncreased ease of assemblyImprove convenienceTyre measurementsStructural engineeringMechanical engineering

The invention provides an easy-to-assemble tire pressure controller shell structure. The easy-to-assemble tire pressure controller shell structure comprises a tire pressure controller shell, the tirepressure controller shell comprises an upper shell, a surface cover and a bottom cover, and the surface caver is located between the upper shell and the bottom cover; the back side of the upper shellis provided with a male seat, and the bottom cover is provided with a female seat; and the surface cover is provided with a fixed hole for allowing the male seat and the female seat to penetrate through, and the male seat penetrates through the fixed hole and is in assembled connection with the female seat. According to the easy-to-assemble tire pressure controller shell structure, through assembling connection of the male seat and the female seat, the easy degree of tire pressure controller assembling is increased accordingly, so that the production convenience is greatly improved, the service life of the product is longer, the practicability is high, and popularization is convenient.

Owner:GUANGDONG FEIKETE ELECTRONICS TECH CO LTD

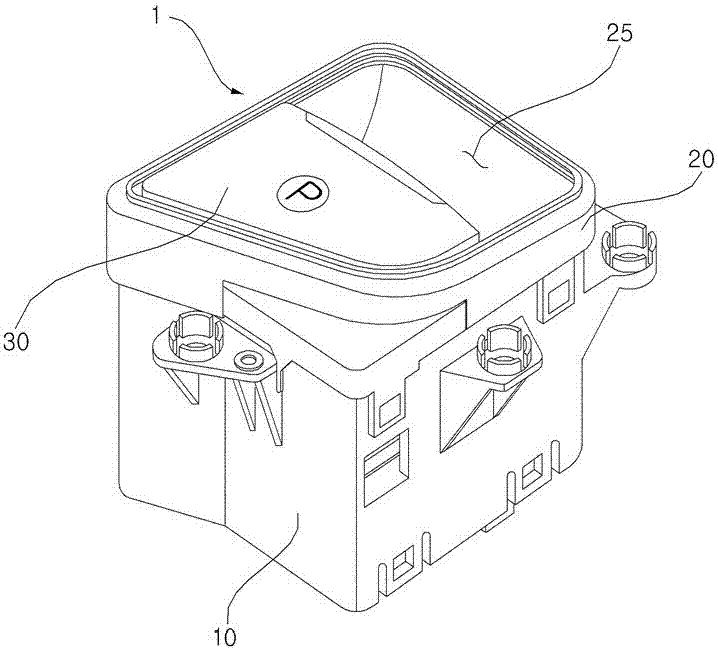

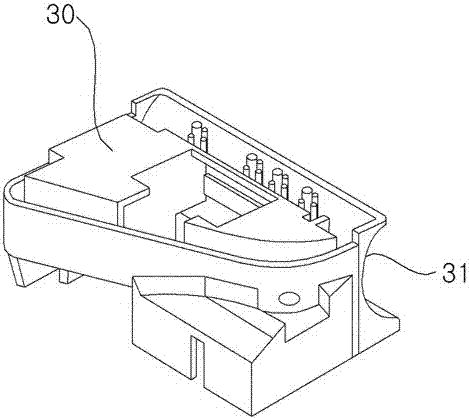

Vehicle parking brake switch assembly

InactiveCN104554205AImprove rigid wear resistanceIncreased ease of assemblyHand actuated initiationsEngineeringHabit

The invention discloses a vehicle parking brake switch assembly. The vehicle parking brake switch assembly comprises a mounting body part, a facing body part and an operation rod, wherein the mounting body part is inserted into a vehicle center control seat and is internally provided with a printed circuit board of a vehicle master controller; the facing body part is mounted on the upper end of the mounting body part in a joint manner and is provided with an operation groove part; fingers of an operator can be inserted into the operation groove part; the facing body part is provided with a hinge protruding part; the operation rod is provided with a hinge inserting opening which serves as a rotation center; the operation rod is rotationally installed in the operation groove part of the facing body part; a specific curvature radiused circular part is arranged between the base surface for starting protruding and the peripheral surface of the hinge protruding part on the hinge protruding part. Through the adoption of the design of the circular part of the switch assembly, the resistance to rigid abrasion of the hinge protruding part is improved; the switch assembly is effectively suitable for driver habits with different switch operation forces; meanwhile, the simplicity and convenience in assembly of the operation rod are improved.

Owner:SUZHOU RUIYAN ELECTRONICS TECH CO LTD +1

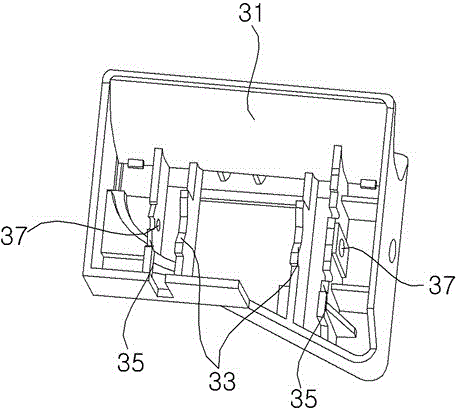

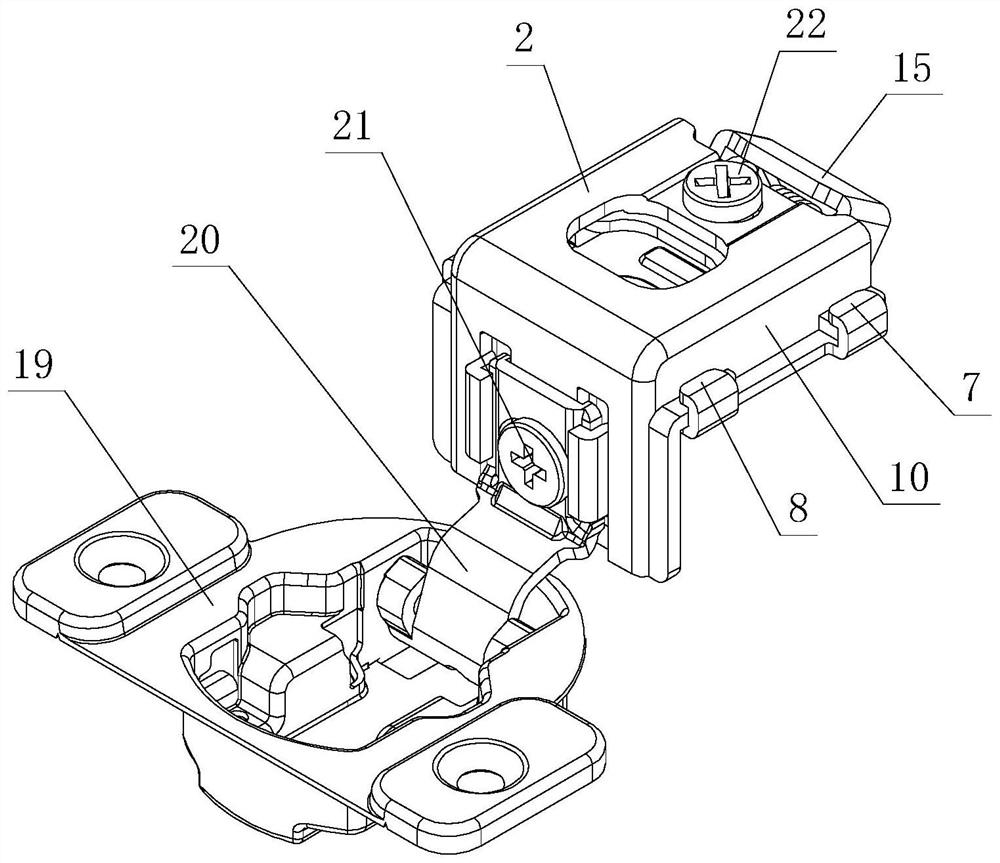

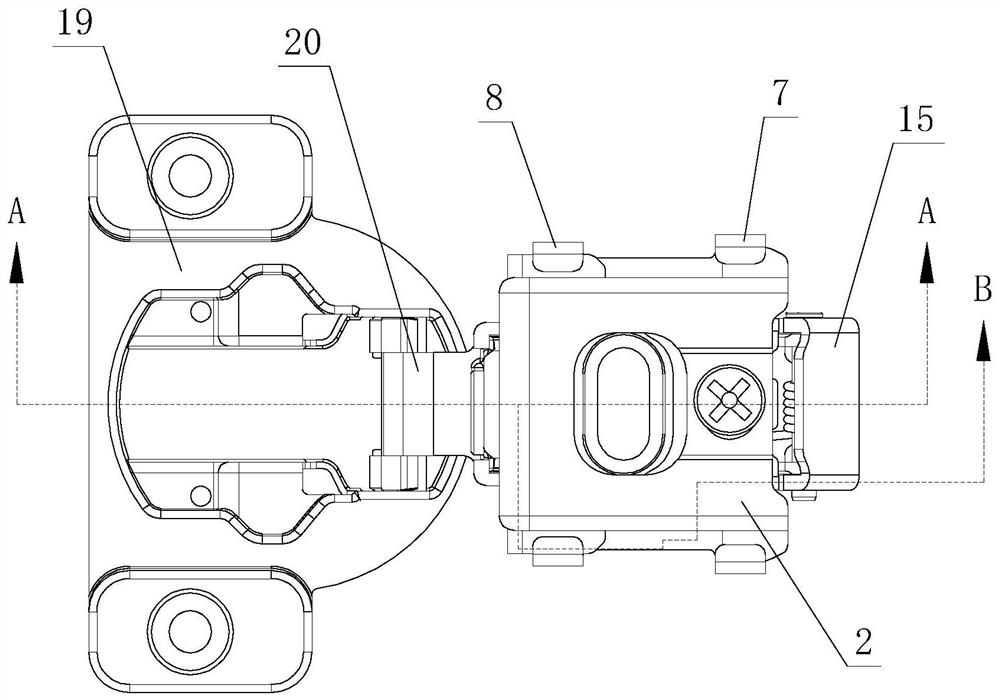

Simple and convenient disassembly and assembly structure of furniture hinge

PendingCN112854926AImprove assembly compactnessAvoid voidsWing accessoriesPin hingesStructural engineeringAssembly structure

The invention discloses a simple and convenient disassembly and assembly structure of a furniture hinge. The simple and convenient disassembly and assembly structure comprises a hinge assembly and a fixed base, and the hinge assembly comprises a connecting arm and a middle piece which are connected in a matched mode; the connecting arm or the middle piece is provided with at least two assembling parts, and an assembling notch is formed between the at least two assembling parts; at least two assembly matching parts are arranged on the fixed base, and an assembly matching notch is formed between the at least two assembly matching parts; and the connecting arm or the middle piece is sequentially assembled on the at least two assembly matching parts in a translation sliding manner through the at least two assembly parts, or the connecting arm or the middle piece is pre-positioned and placed on the fixed base through the matching of the assembly notch and the assembly matching notch, and the at least two assembling parts are respectively assembled on the at least two assembly matching parts in a translation sliding manner. Through the improvement of the structure, the structure has the advantages of being reasonable in structure, compact in connection of all components, low in manufacturing cost, easy to produce and implement, wide in application range, rapid, simple and convenient to disassemble and assemble, firm in assembly and the like, and practicability is high.

Owner:GUANGDONG DTC HARDWARE PRECISION MFG CO LTD

A prefabricated wall, room structure and construction method for large spaces

ActiveCN108978945BIncreased ease of assemblyQuick buildWallsSound proofingClassical mechanicsCantilever

Owner:BEIJING NEW BUILDING MATERIALS PLC

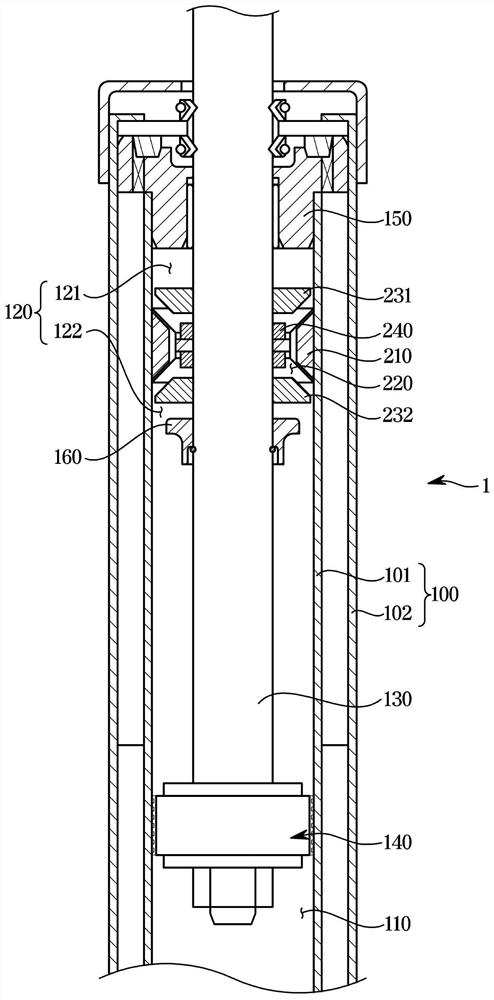

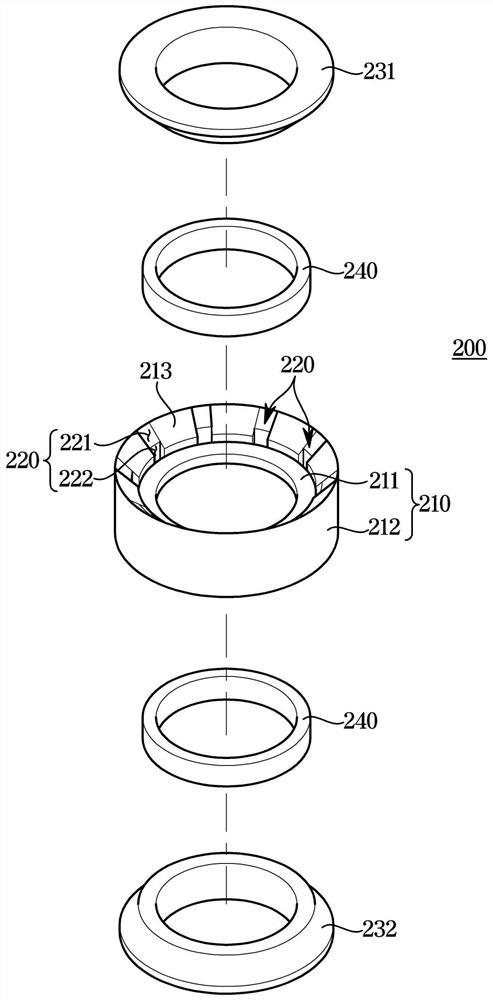

Shock absorber

PendingCN114763818ASimple structureImprove ride comfort performanceSpringsGas and liquid based dampersExpansion chamberPiston rod

The invention relates to a shock absorber. According to one aspect of the present invention, there may be provided a shock absorber comprising: a cylinder filled with a fluid; a piston valve which is installed on a piston rod that reciprocates inside the cylinder and divides the space inside the cylinder into an expansion chamber and a compression chamber; the guide rod is arranged at the upper part of the air cylinder so as to guide the piston rod to move; a stopper coupled to the outside of the piston rod; and a flow piston valve coupled through the piston rod, dividing the expansion chamber into an upper chamber and a lower chamber, and provided with a plurality of bypass flow paths to communicate the upper chamber and the lower chamber. Wherein, when the piston rod is in a stretching stroke, the limiting stopper partially clings to the flow piston valve from the lower part and raises the flow piston valve, so that the flow rate of the fluid passing through the bypass flow path is adjusted.

Owner:HL MANDO CORP

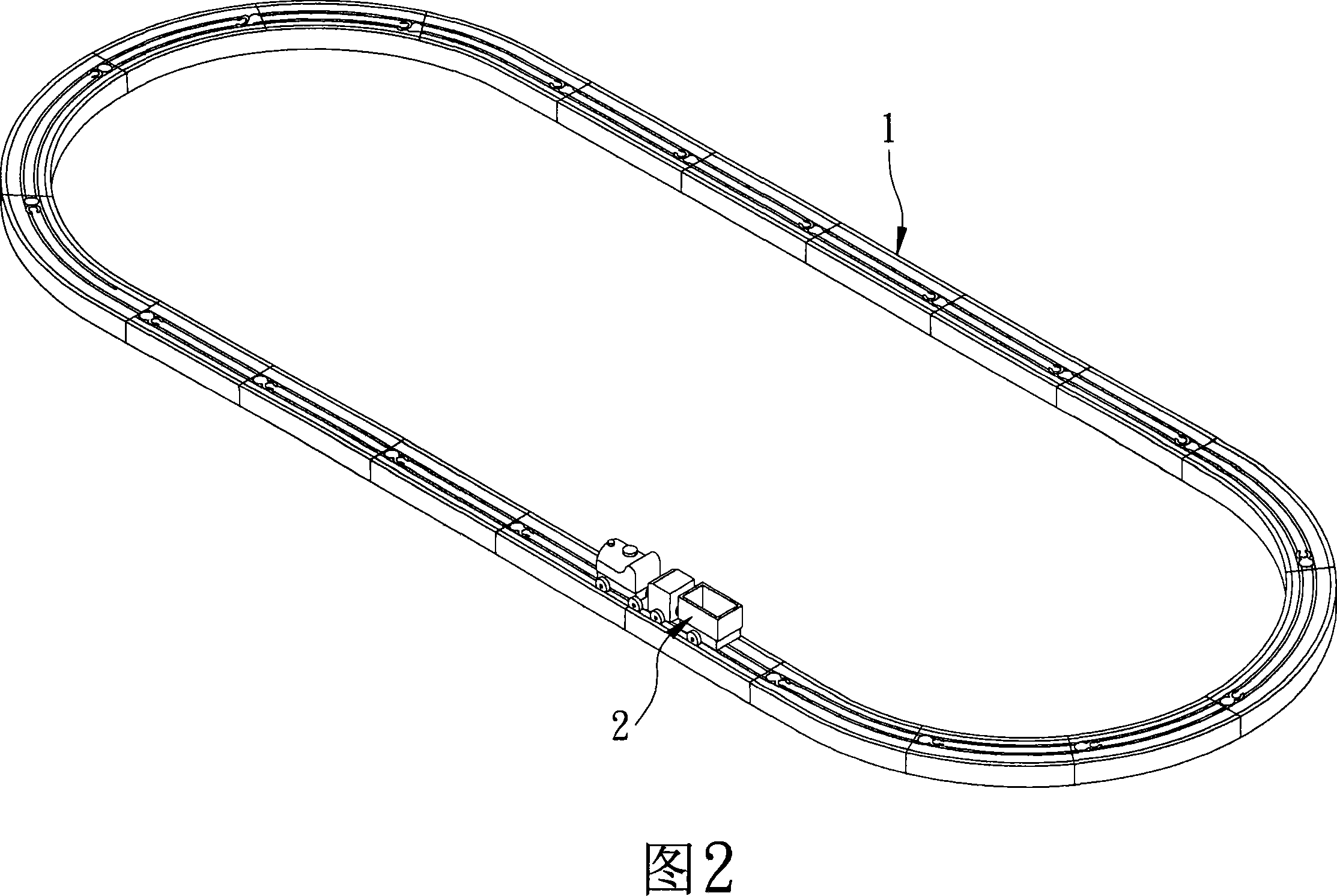

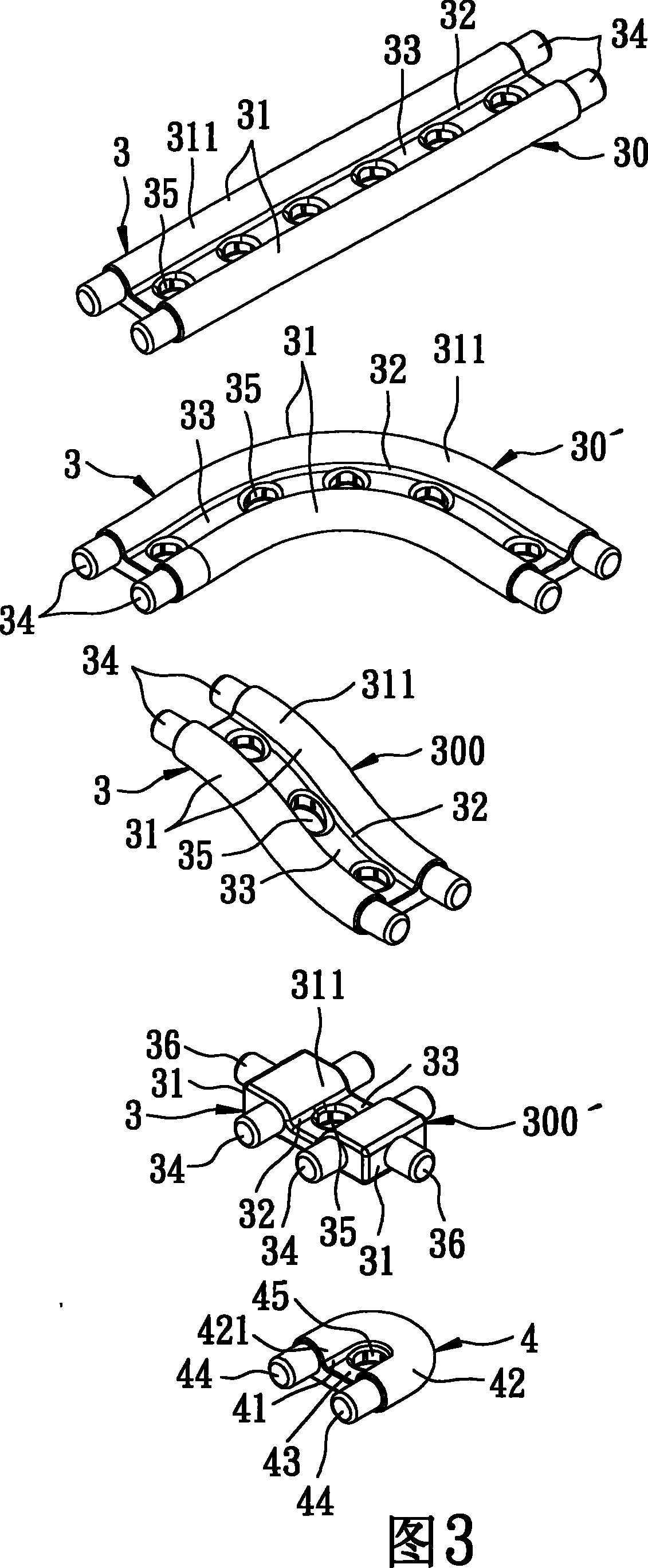

Building block track group

ActiveCN101474484BIncreased ease of assemblyIncrease variabilityModel railwaysEngineeringMechanical engineering

Owner:GENIUS TOY TAIWAN CO LTD

Lamp post system using multi-groove mounting structure

PendingCN111853723AEasy to disassembleEasy loading and unloadingMechanical apparatusLighting support devicesEngineeringMechanical engineering

The invention discloses a lamp post system using a multi-groove mounting structure. The lamp post system using the multi-groove mounting structure comprises a lamp post body and more than one functional piece. The lamp post body is provided with more than two mounting grooves extending in the length direction, each functional piece is connected with more than one connecting piece through a detachable connecting mechanism, and each connecting piece is detachably mounted in the corresponding mounting groove. The lamp post system has the advantages of simple and compact structure, low cost, simplicity and convenience in assembly, high mounting flexibility, convenience in adjustment, attractiveness, high connection stability and reliability and the like.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD +1

Cell type electronic equipment

ActiveCN104298186BComponent reductionIncreased ease of assemblyTotal factory controlProgramme total factory controlMicrocomputerEngineering

The invention provides unit-type electronic equipment which is composed of a main unit and multiple subunits and allows reduction of hardware composition elements, simplification of software, and improvement of assembling easiness. The unit-type electronic equipment comprises the multiple subunits (3...). The multiple subunits are all subordinate units having micro computers (8...) which collect and store measured amounts, and individual voltage setting parts (14...) which output individual voltages. The output voltages of all the individual voltage setting parts of the multiple subunits are mutually different voltage levels (V14...), and the output voltages of the different voltage levels are detected by a micro computer (7) of the main unit. Based on the output voltages of the different voltage levels, the micro computer of the main unit identifies the respective types of the multiple subunits.

Owner:MITSUBISHI ELECTRIC CORP

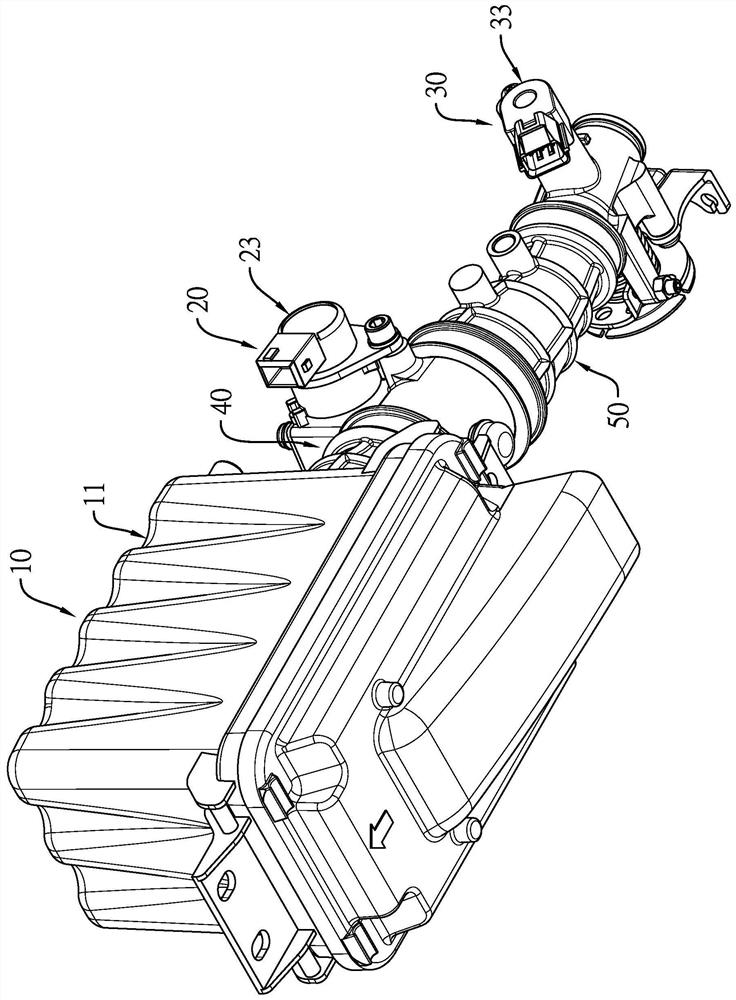

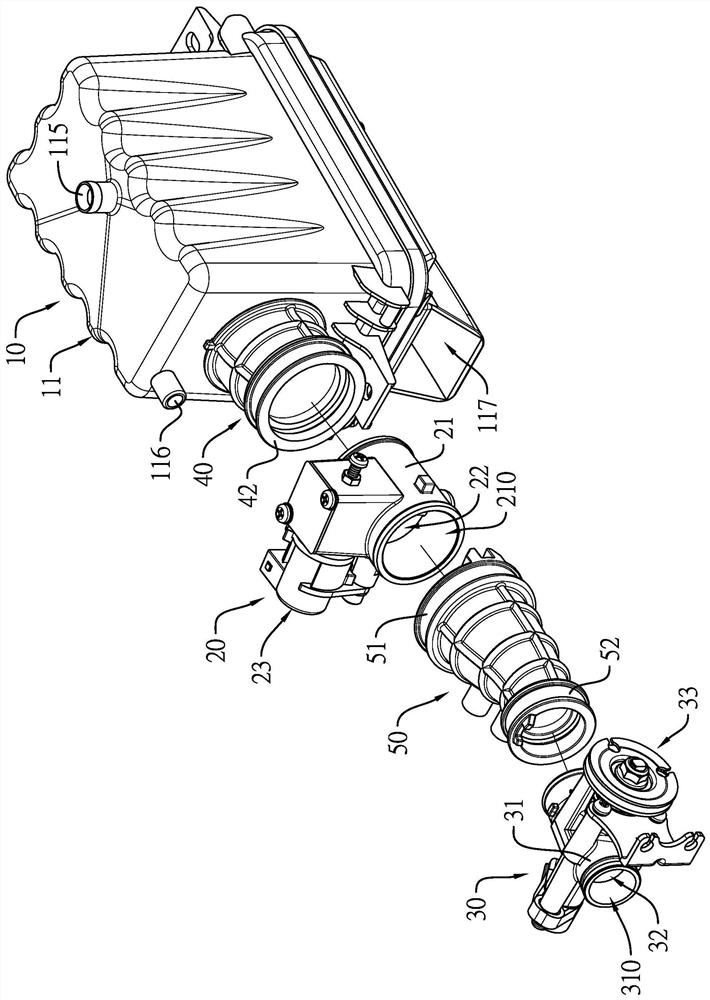

Single air inlet channel type air inlet adjusting structure

PendingCN114576051AImproves ease of assemblySave spaceInternal combustion piston enginesAir cleaners for fuelAir filterEngineering

The invention relates to a single-air-inlet-channel type air inlet adjusting structure which is used for being connected with an engine of a power system and adjusting the air inlet amount of the engine, and the single-air-inlet-channel type air inlet adjusting structure comprises an air filter with a filtering material, an adjusting control valve, a throttling valve, a first pipe fitting and a second pipe fitting. The first pipe fitting is connected between the air filter and the adjusting control valve, and the second pipe fitting is connected between the adjusting control valve and the throttling valve to form an air inlet channel in series, so that a single air inlet channel type simplified structure is adopted, the air inlet channel is controlled to be within a proper length range, the cost is reduced, and in the high-low-speed operation process of an engine, the air inlet channel can be effectively controlled. And the air inflow of the engine can be directly regulated and controlled.

Owner:AEON MOTOR CO LTD

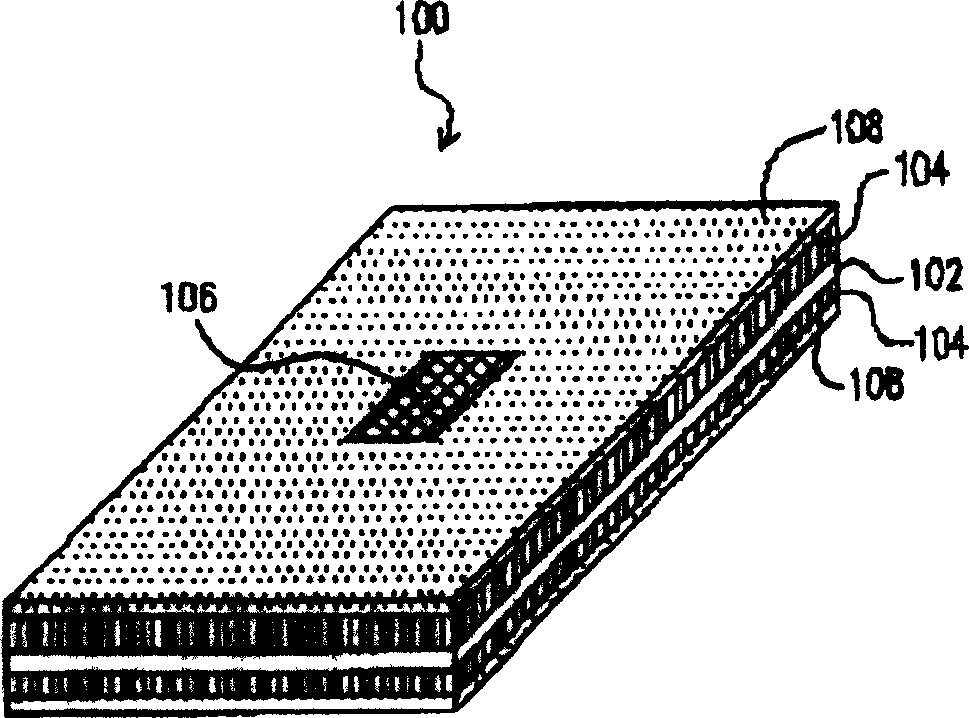

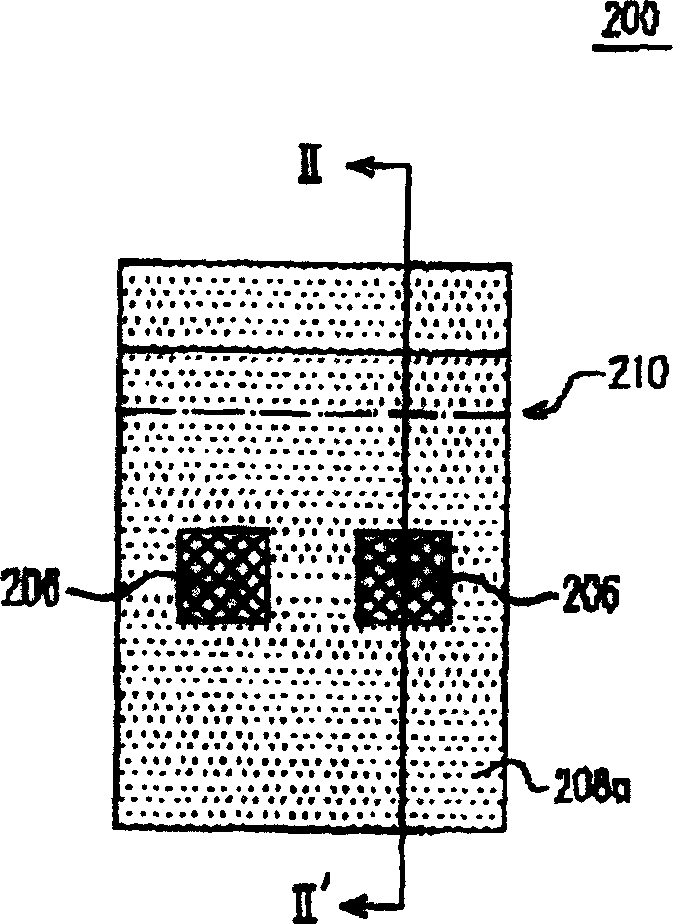

Double-face flip chip film

InactiveCN1567575AImprove easeIncrease the number of bendsSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical conductor

The invention discloses a double-surface coated crystal film, at least composed of a flexible substrate, two conductor films situated on the right surface and at the back of the substrate and a covering layer on the conductor film. And it has a bending region for bending the bendable substrate, and the conductor film and covering layer cannot exist at the back of the substrate in the bending region. Because the double-surface film chip is designed by using the no-conductor film and covering-layer at the back of the substrate in the bending region, it can increase the number of bending times and bending easiness, and improve the convenience for mounting.

Owner:TPO DISPLAY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com