Bearing bush self-adaptive contact friction wear test device

A friction and wear test and self-adaptive technology, which is applied in the direction of measuring devices, testing wear resistance, instruments, etc., can solve the problems of eccentric wear of bearing bush samples, and achieve the effect of improving accuracy, improving universality and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

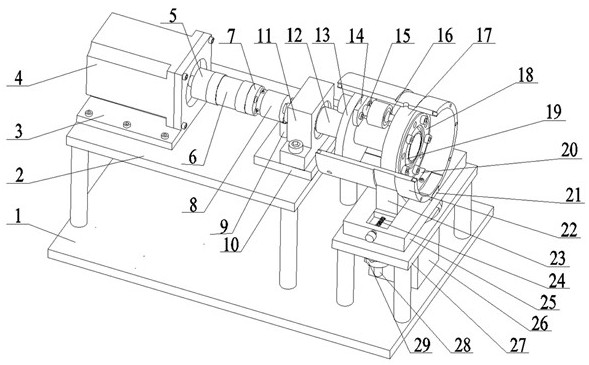

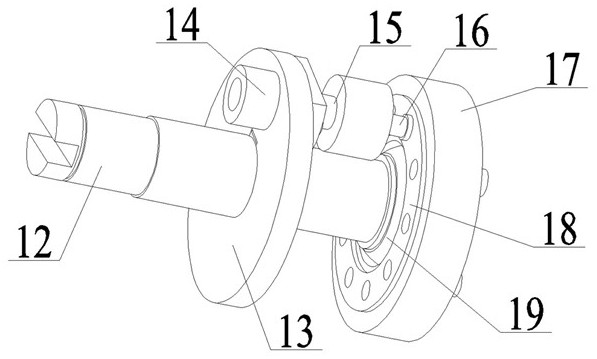

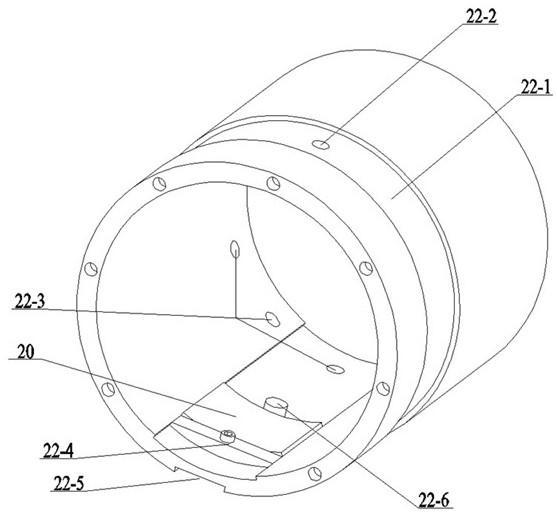

[0024] Such as figure 1 and figure 2 The shown friction and wear test device for self-adaptive contact of bearing pads is mainly composed of a motor 4, a left coupling 5, a right coupling 7, a torque sensor 6, a slip ring 8, a limiter 9, and a bearing seat 11 , bearing backing plate 10, transmission shaft, turntable 13, linear bearing 14, slide rod 15, ball joint bearing 16, expansion sleeve 18, radial joint bearing 19, bearing bush fixture 22, triangular block 23, force transmission plate 25, cylinder 26 and supporting plate 27 constitute. The motor 4 is connected with the support plate 2 through the motor base 3, and the support plate 2 is fixed on the base plate 1; the left end of the left coupling 5 is connected to the output shaft of the motor 4 through a key, and the right end of the left coupling 5 passes through Screwed to the left end of the torque sensor 6; the left end of the right shaft coupling 7 is threaded to the right end of the torque sensor 6, and the righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com