Pneumatic disc brake caliper assembly

A disc brake and assembly technology, applied in the direction of brake type, axial brake, brake components, etc., can solve the problems that the service life cannot be effectively guaranteed, the overall rigidity and strength are not good, and the processing accuracy is high. Achieve the effect of ensuring work stability and service life, suppressing eccentric wear and dragging problems, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

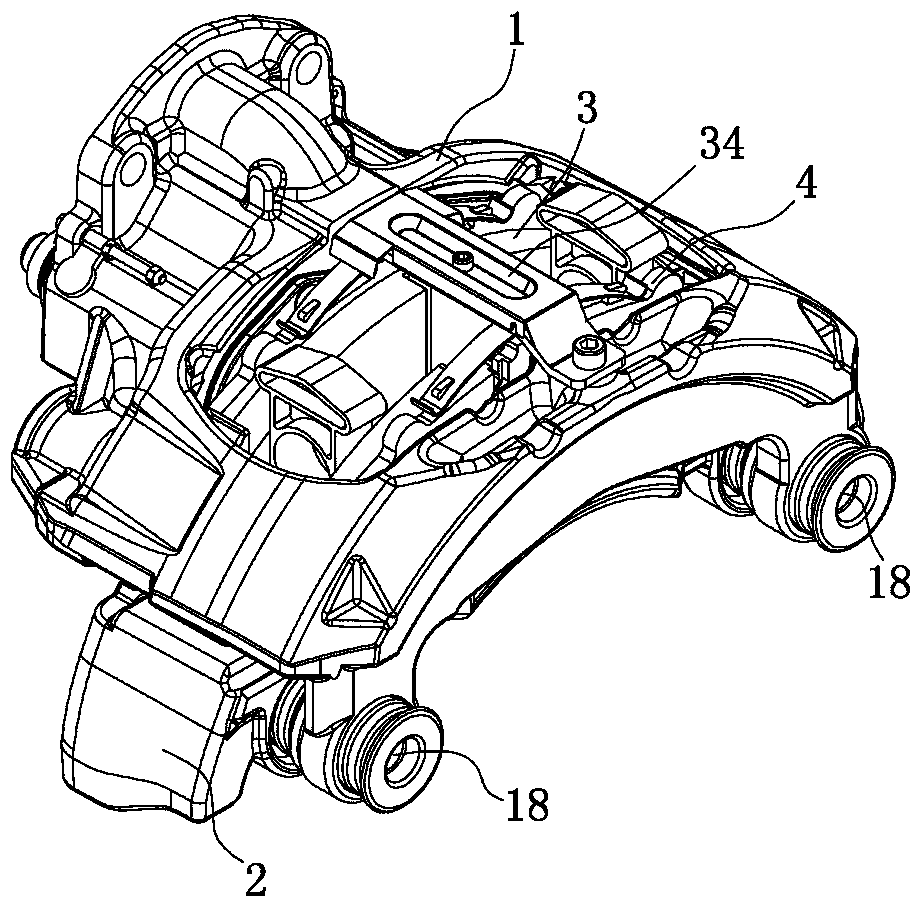

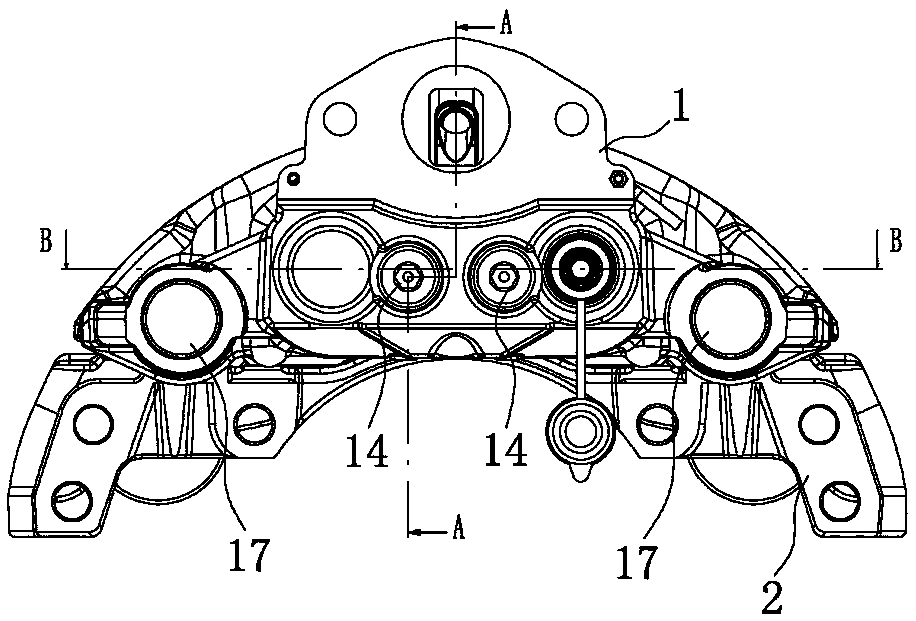

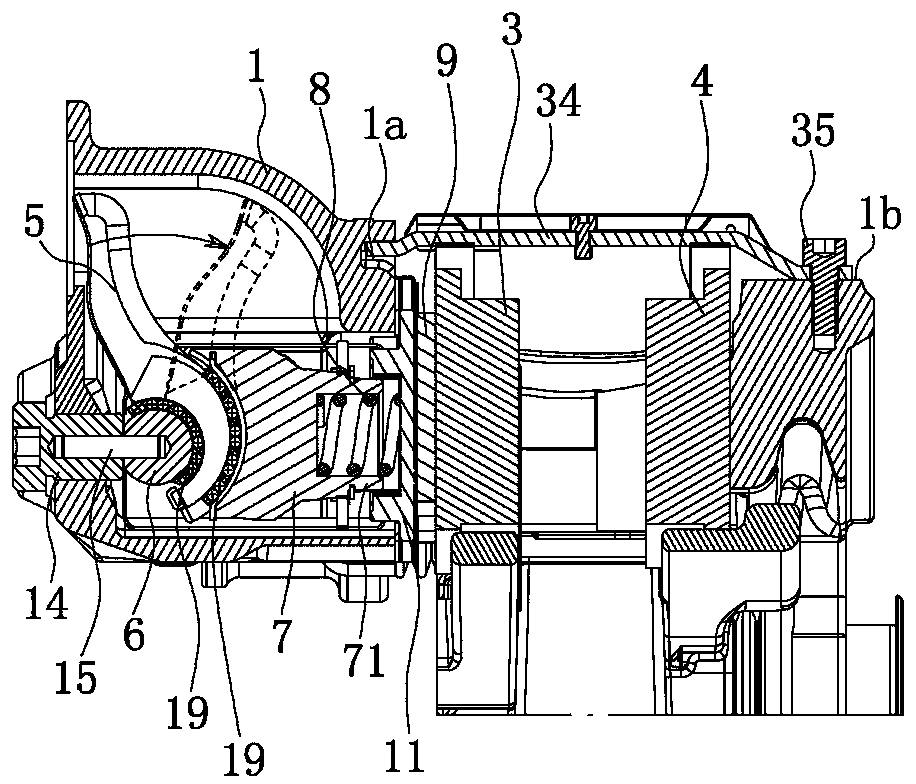

[0032] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6As shown, the pneumatic disc brake caliper assembly includes a caliper body 1, a force booster gap adjustment assembly and a bracket 2, and the main friction block 3 and the auxiliary friction block 4 are arranged on both sides of the bracket 2, and the caliper body 1 has a capacity for accommodating the booster. The chamber of the gap adjustment assembly, the booster gap adjustment assembly includes a pressure arm 5, a fixed rotating shaft 6, a thrust bracket 7, a bracket return spring 8, a pressure plate 9 and two push rods 10, and the clamp body 1 is fixedly connected with the cavity The cover plate 11 of the chamber cover, the outer en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com