Roller bearing seal assembly and a component thereof

A technology of roller bearings and seals, applied in the field of sealed railway roller bearings, can solve problems such as pull-out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

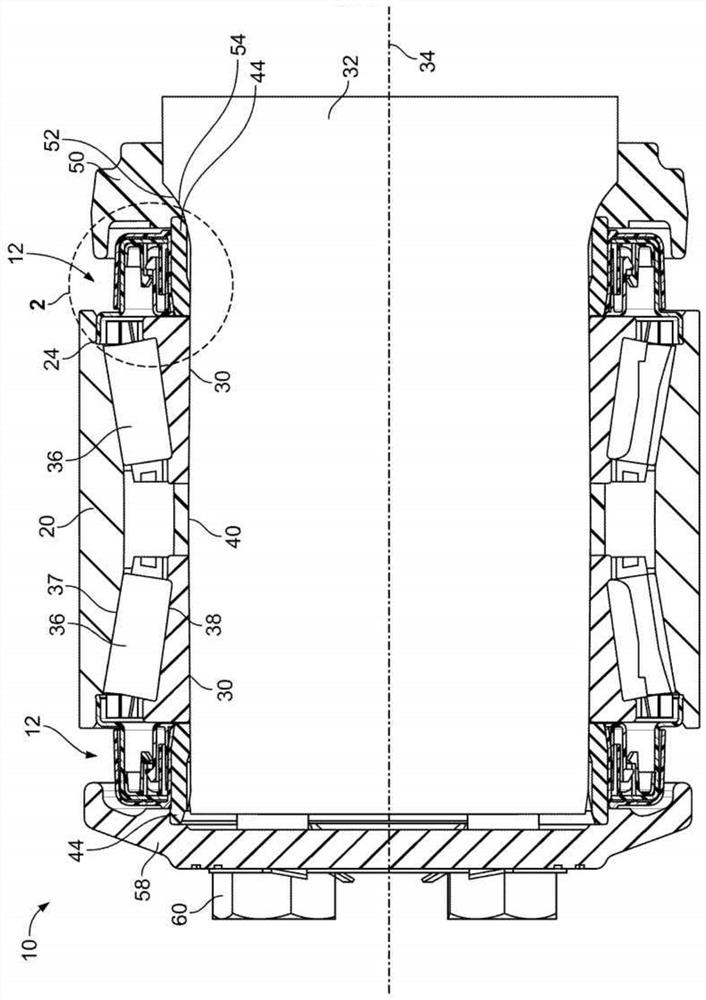

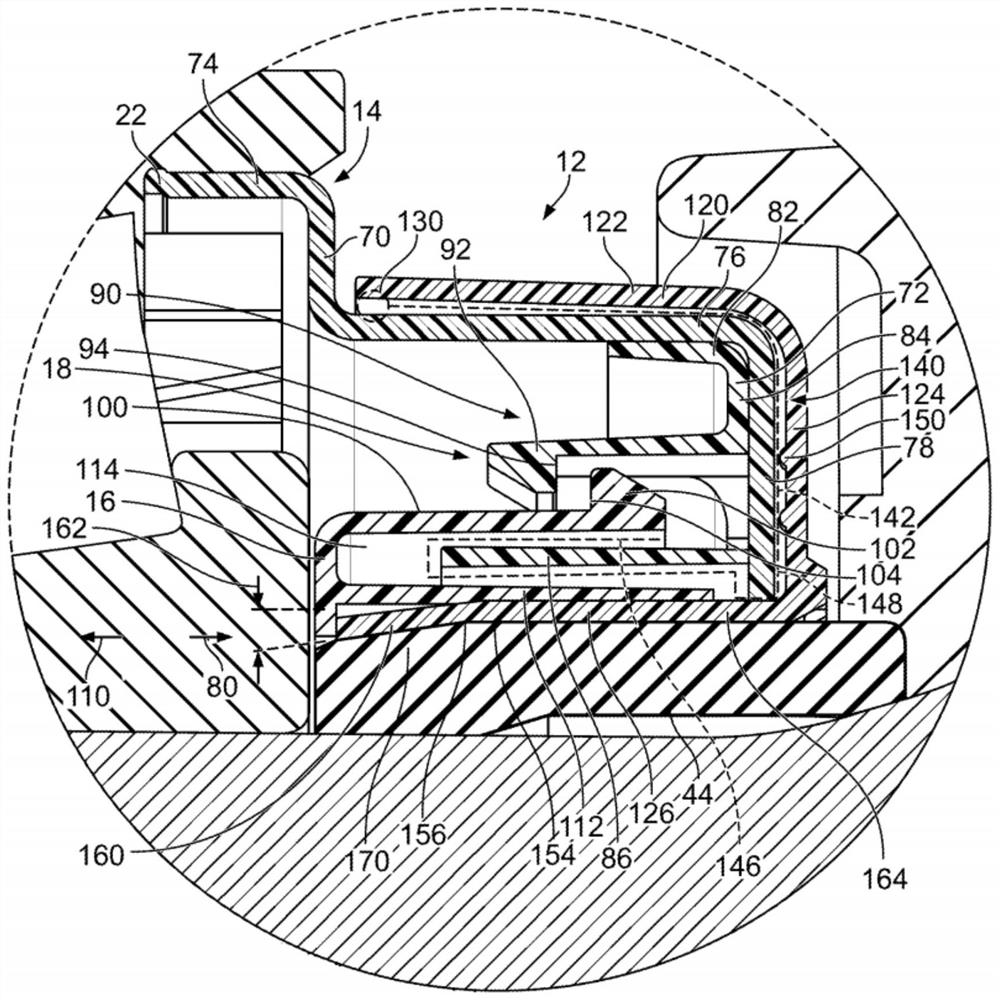

[0037] refer to figure 1 and figure 2 , the roller bearing 10 is provided with an assembly of roller bearing seals 12 each comprising a seal shell 14 and a rotor 16 forming a snap-fit connection therebetween 18 which improves the handling of the roller bearing seal assembly 12 during its transport and assembly with other components of the roller bearing 10 . The snap connection 18 improves the handling of the assembly 12 of the roller bearing seal, since the rotor 16 is prevented from falling out of the seal casing 14 once the snap connection 18 has been formed by pressing the rotor 16 into the casing 14 . Furthermore, the snap connection 18 allows the rotor 16 to rotate relative to the can 14 so that the joined can 14 and rotor 16 can be easily mounted to the bearing cup 20 and the bearing cup 20 of the roller bearing 10 during assembly of the roller bearing 10 . Grinding ring 44. This is in contrast to prior methods which press the rotor out of the seal case insert to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com