Coupling device between fluid reservoir and master brake cylinder of motor vehicle braking system

一种联接装置、制动系统的技术,应用在液压制动传动装置、水库的布置、连接等方向,能够解决连接螺栓易变松、不可靠、失效等问题,达到不易失效、消除组装错误、改进组装容易性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

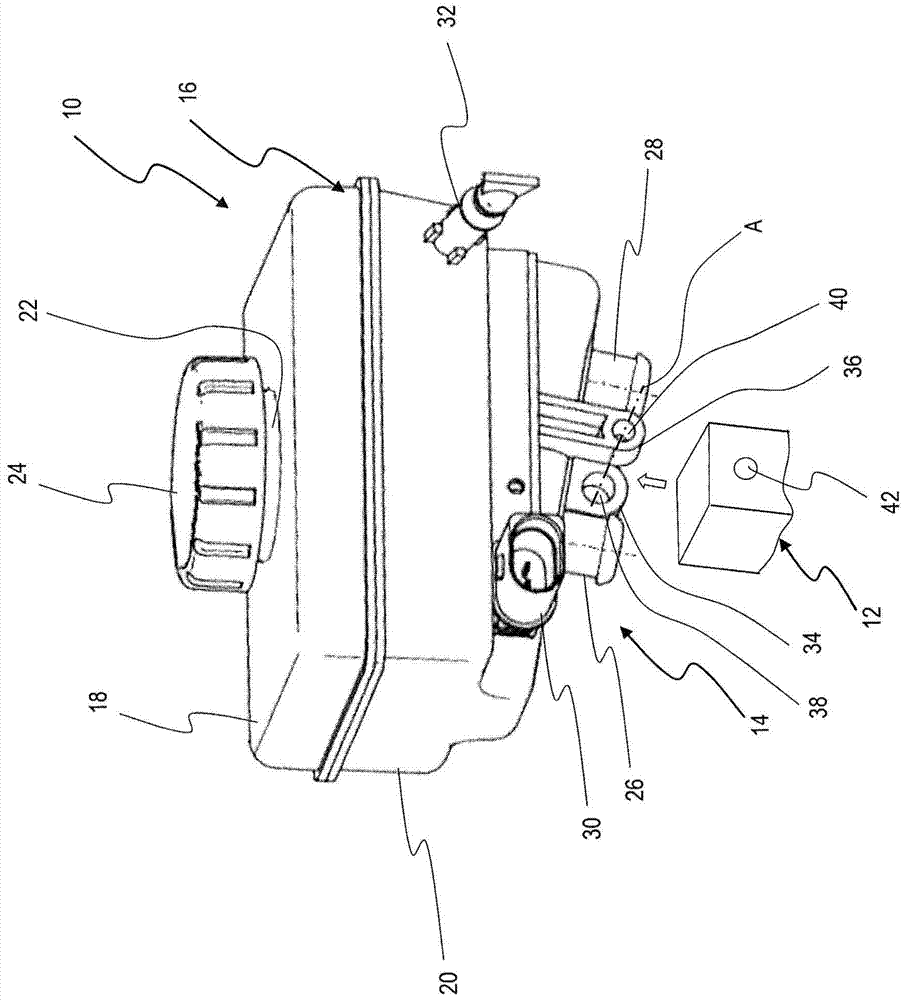

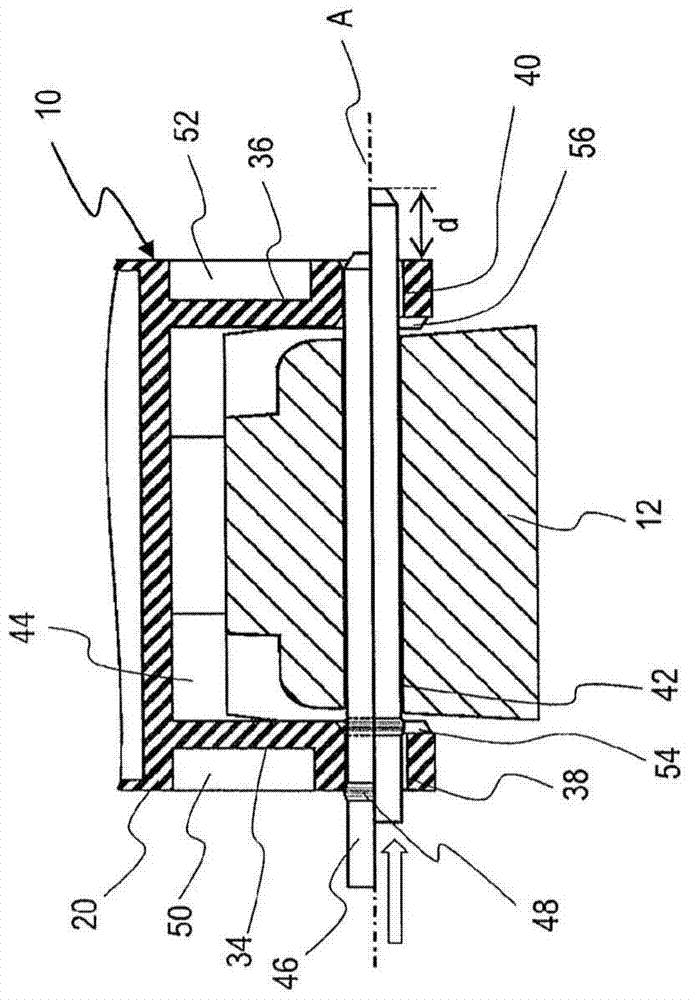

[0027] figure 1 A three-dimensional view is shown of a fluid reservoir 10 for mounting on a brake master cylinder, which is not shown in detail. On the master brake cylinder there is integrally formed a mounting part 12 which is connected to a fluid reservoir 10 by means of a coupling means 14, as will be described in detail below.

[0028]The fluid reservoir 10 is provided with a fluid container 16 consisting of two hollow bodies 18 , 20 which are welded to each other. The upper hollow body 18 has a filling neck 22 which provides access for replenishment and which can be closed by means of a cover 24 . The lower hollow body 20 has two connectors 26 , 28 on its underside, by means of which the lower hollow body can be fluid-tightly coupled to the master brake cylinder in a known manner. No further details were provided on this. Also evident on the lower hollow body 20 are the electrical connection sockets 30 of the fill level measuring device and a further filling neck 32 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com