Double-face flip chip film

A chip-on-chip, double-sided technology, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of reduced bending times, difficult assembly, poor reliability, etc., to improve reliability and increase the number of bending times , the effect of increasing ease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

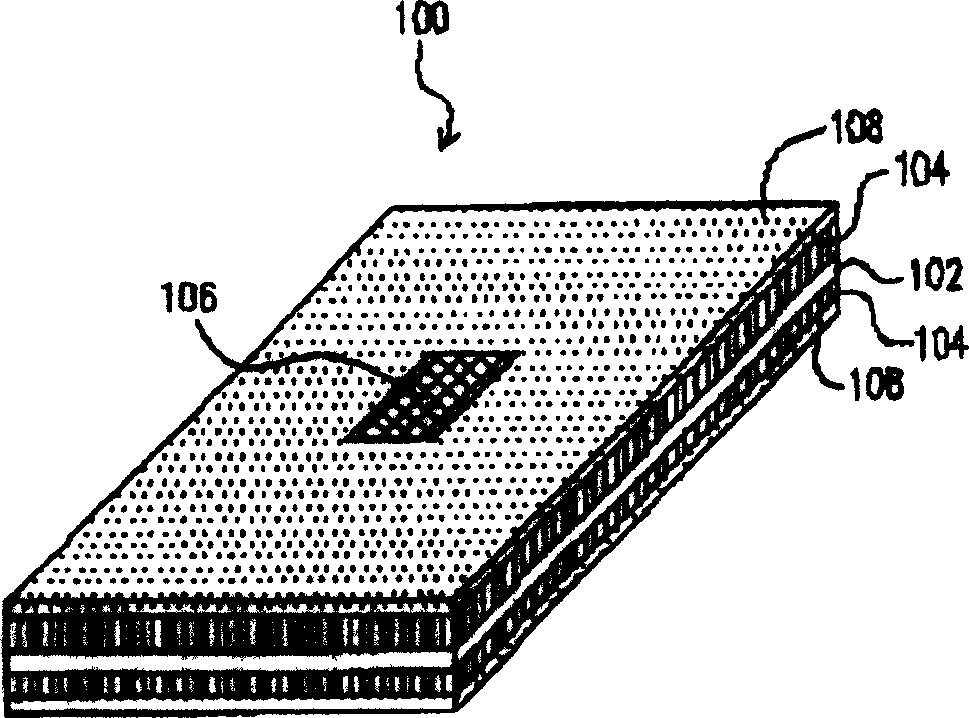

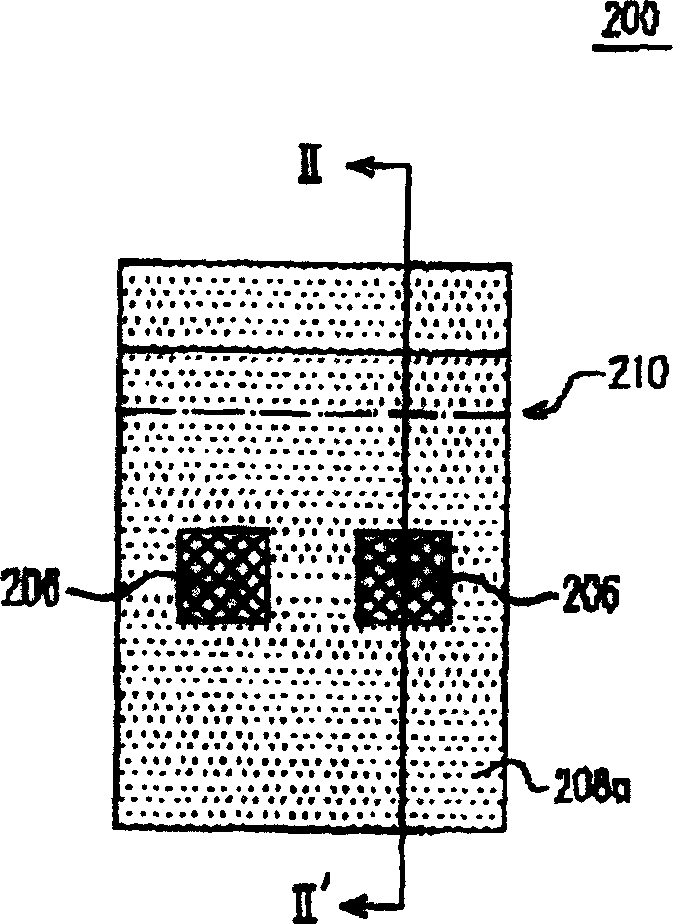

[0024] The double-sided chip-on-chip film of the present invention can be applied to various semiconductor elements or products, or applied to mobile phones and personal digital processors (PDAs), mainly in conjunction with the module packaging technology of liquid crystal displays (LCDs) therein. And the double-sided COF film of the preferred embodiment of the present invention is as Figure 2A and Figure 2B shown.

[0025] Figure 2A It is a schematic top view of a double-sided chip-on-chip film according to a preferred embodiment of the present invention, Figure 2B is Figure 2A The II-II′ section schematic diagram, please refer to Figure 2A and Figure 2B , the substrate 202 used in the double-sided chip-on-chip film 200 of the present invention is a flexible substrate, and its material can be selected from polyimide (Polyimide, PI), Teflon (Teflon), polyamide (Polyamide), polymethylmethacrylate (Polymethylmethacrylate), polycarbonate (Polycarbonate), polyester (P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com