Simple and convenient disassembly and assembly structure of furniture hinge

A hinge, a simple technology, applied in the direction of hinges with pins, building structures, door/window accessories, etc., can solve the problems of difficult disassembly and assembly for users, failure to meet user needs, inconvenient disassembly and assembly operations, etc., to avoid false Position or adjustment failure, improve adjustment accuracy, easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

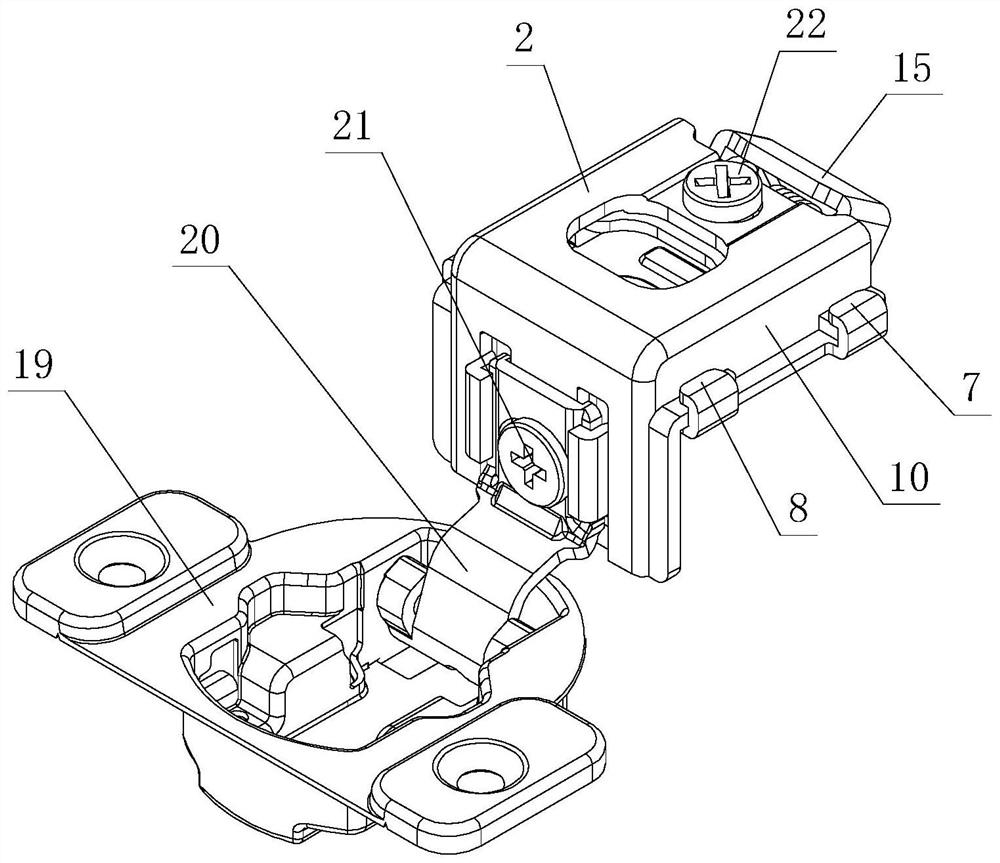

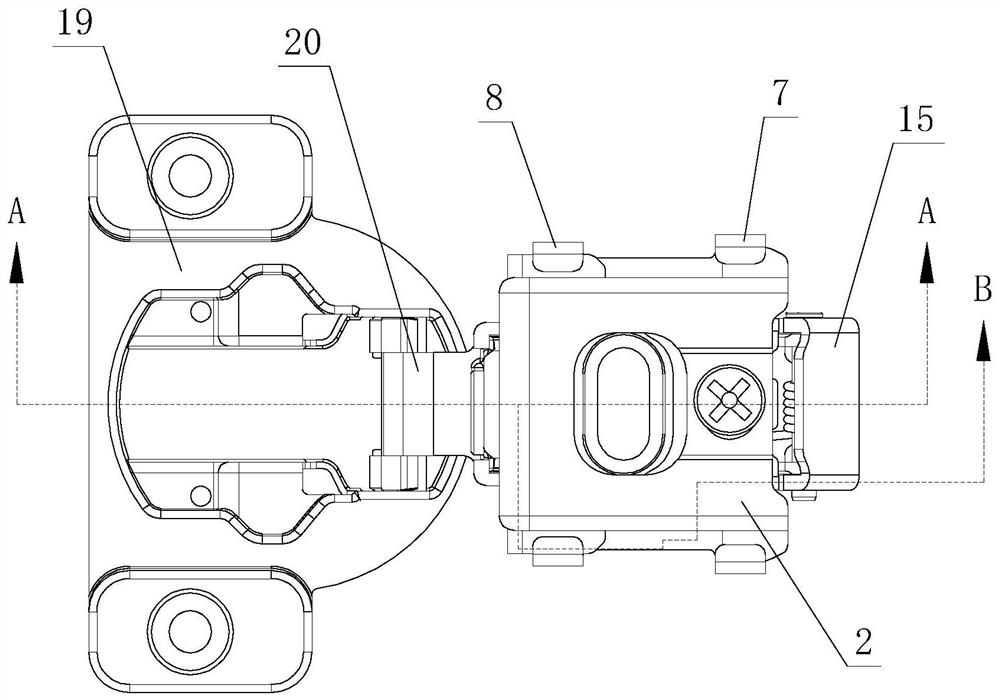

[0043]SeeFigure 1 - Figure 15 The simple disassembly structure of the furniture hinge includes a hinge assembly and a fixed base 1, and the hinge assembly includes at least a connecting arm 2, an intermediate member 3 that is coupled to the connecting arm 2; the connecting arm 2 is provided with at least two assemblies. The unit, at least two assembly portions are provided with an assembly notch 6; the fixed base 1 is provided with at least two assembly fittings, and the at least two assembly mating portions are provided with an assembly mating gap 9.

[0044]The connecting arm 2 is sequentially mounted on at least two assembly fittings by at least two assembly portions.

[0045]Alternatively, the connecting arm 2 is placed on the fixed base 1 by the mating predetermined bit of the assembly mating gap 9, and then passes through the at least two assembly portions to the at least two assembly partitions.

[0046]Specifically, at least two assembly portions include the front fitting portion 4 a...

no. 2 example

[0061]SeeFigure 16 ,Figure 17 The simply disassembly structure of the furniture hinge is different from the first embodiment in that the middle member 3 is provided with at least two assembly portions.

[0062]The middleware 3 is sequentially mounted on at least two assembled fittings by at least two assembly portions.

[0063]Alternatively, the middleware 3 is placed on the fixed base 1 by the mating predetermined position of the assembly mating gap 9, and then passes through the at least two assembly portions to the at least two assembly fitting portions.

[0064]Specifically, the front and rear spacers are disposed on the front and rear spacers of the front and rear spacers, and the assembly notch 6 is formed on the front and rear spacing between the front and rear spacings.

[0065]The middle member 3 is placed on the fixed base 1 by assembling the gap 6.

[0066]More specifically, the front fitting portion 4 and the rear fitting portion 5 are disposed on the left and right limit flange 11.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com