Auxiliary assembly structure for sliding rail

An auxiliary assembly and slide rail technology, which is applied in applications, household appliances, furniture parts, etc., can solve the problems of inability to apply drawer installation, poor applicability, and low assembly flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

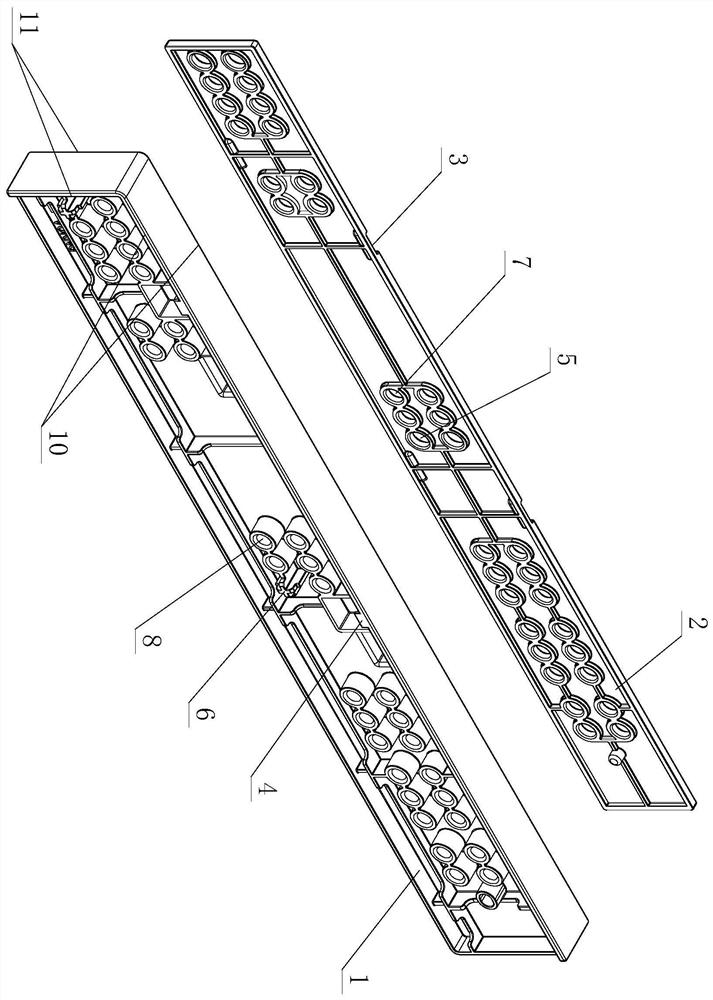

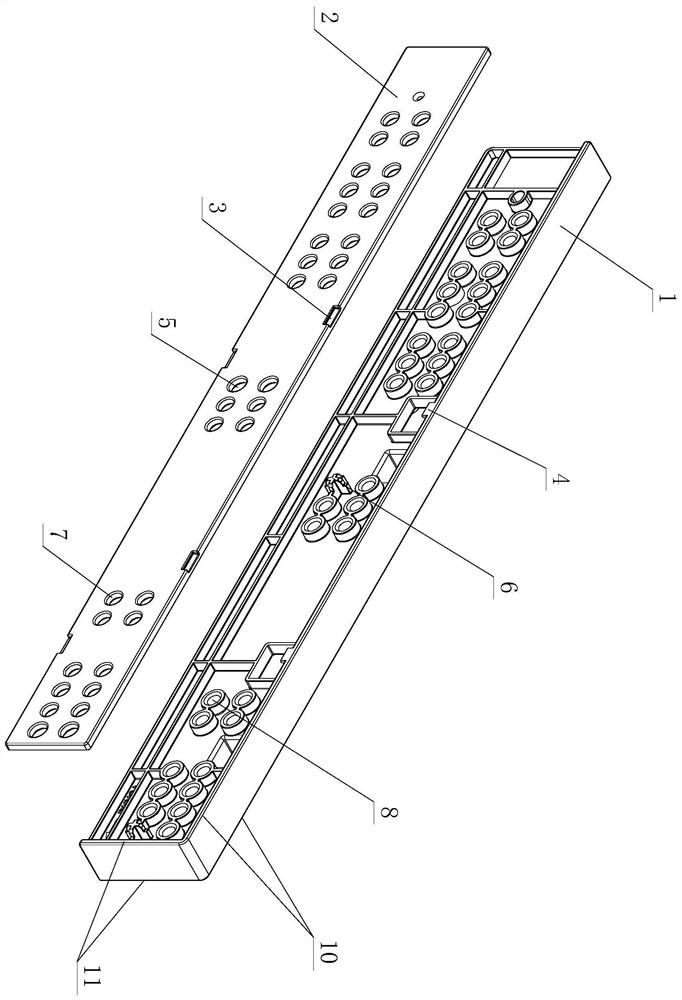

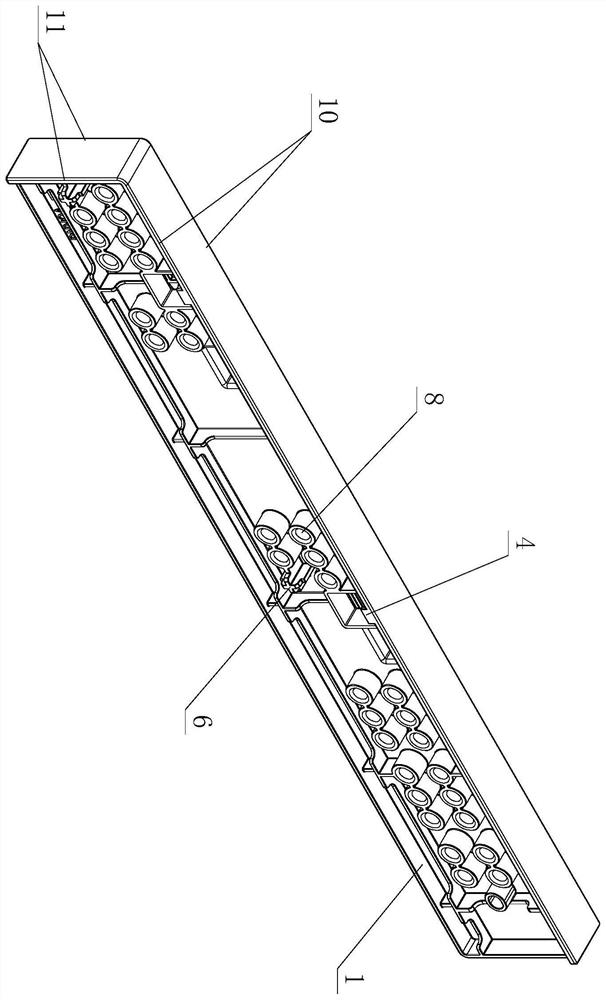

[0034] see Figure 1-Figure 8 , which is used for the auxiliary assembly structure of the slide rail, including the adapter 1 and the side member 2, the left and right sides of the adapter 1 are symmetrically provided with steps, and the thickness of the steps is basically the same as that of the side member 2; The side piece 2 is assembled on the left or right side of the adapter piece 1; when the side piece 2 is assembled, its outer surface is substantially flush with the outer surface of the adapter piece 1, and the top surface of the side piece 2 and / or The front end surface is at least partially covered by the step portion.

[0035] Specifically, the side piece 2 is provided with a side piece clamping portion 3; the adapter piece 1 is provided with an adapter clamping portion 4; on the adapter clip part 4 of the adapter piece 1.

[0036] The sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com