Bi-direction expansion fixed-connecting assembly device

A technology for fixing components and connecting components, applied in the direction of fixtures, mechanical equipment, etc., can solve the problem of affecting the movement of all-aluminum furniture cabinets, affecting the beauty and grade of all-aluminum furniture cabinets, affecting the firmness and reliability of aluminum alloy sheet assembly and connection, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

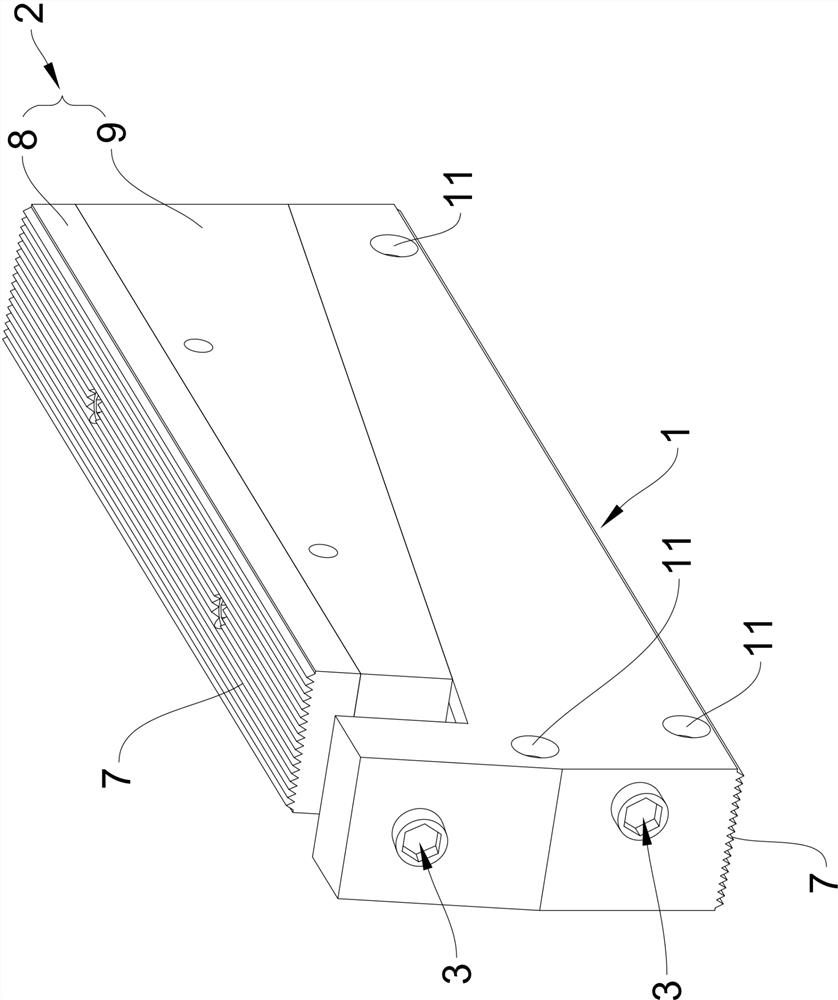

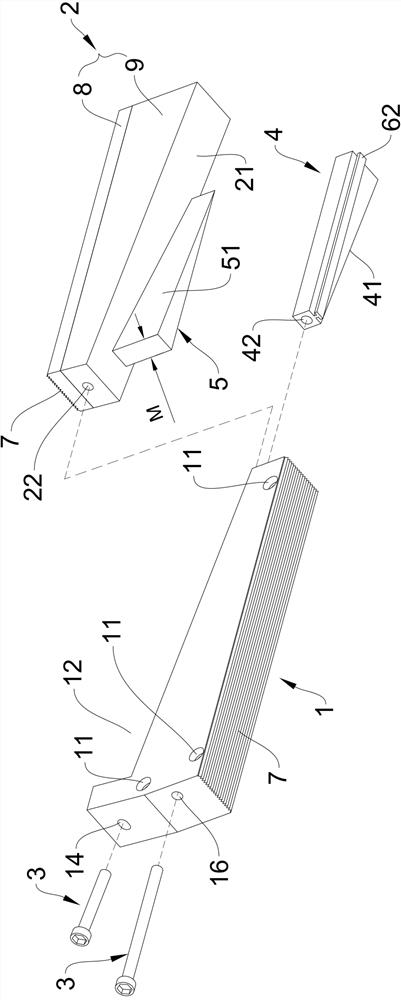

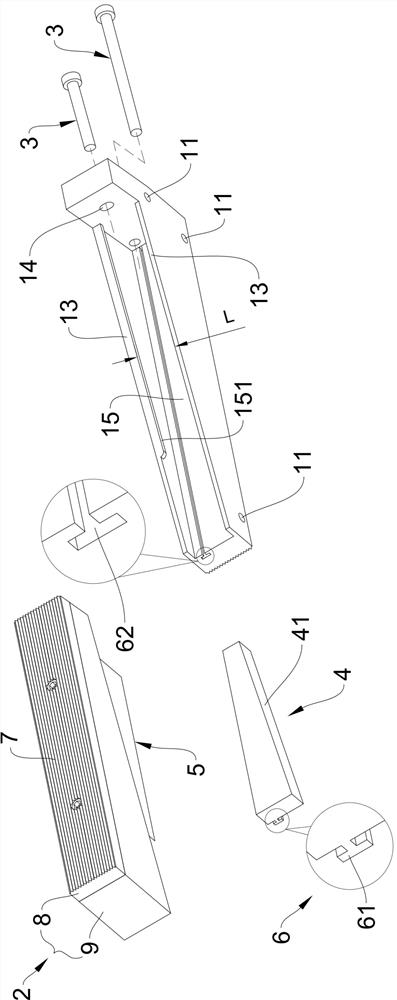

[0021] Such as Figure 1 to Figure 3 As shown, a two-way expansion-fixed connection component device according to the present invention includes a fixed component 1 , a movable component 2 and a locking bolt 3 . In order to achieve the purpose proposed by the present invention, the fixed component 1 is provided with a transverse fixing hole 11, that is, as figure 1 shown. The number of the transverse fixing holes 11 can be set according to the length of the fixed component 1 and the movable component 2 as required. The fixed component 1 and the movable component 2 are generally processed to be close to the width of the plate or workpiece to be applied. Such as Figure 9 As shown, the fixing assembly 1 is in this way, using screws 40 to fix one of the plates or the side of the workpiece.

[0022] Such as figure 2 and image 3 As shown, the fixed assembly 1 is also provided with a storage recess 12 for the movable assembly 2 to be stored, and a first fitting slope 13 is a...

Embodiment 2

[0029] The difference between the second embodiment and the first embodiment is that the first embodiment adopts the fitting strip 4 as the component that generates the lateral movement of the pressing movable assembly 2, thereby eliminating the problem of the gap between workpieces. In the second embodiment, the joint bar 4 is eliminated, and two sets of joint slopes and one set of joint side slopes are used to realize the lateral movement of the compressing movable assembly 2, thereby eliminating the gap problem between workpieces. The principles and effects of other aspects are basically the same as those of the first embodiment. The technical scheme of the second embodiment is specifically as follows: Figure 5 As shown, it includes a fixed assembly 1, a movable assembly 2 and a locking bolt 3 and the like. In order to achieve the purpose proposed by the present invention, the fixed component 1 is provided with a transverse fixing hole 11, that is, as figure 1 shown. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com