Quick disassembly and assembly structure for furniture hinge

A hinge device and hinge technology, applied to pin hinges, building structures, door/window accessories, etc., can solve the problems of inconvenient disassembly and assembly, failure to meet the needs of users, and difficulty in disassembly and assembly of users, and achieve improved The effect of adjusting accuracy, quick disassembly and assembly, and avoiding false positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

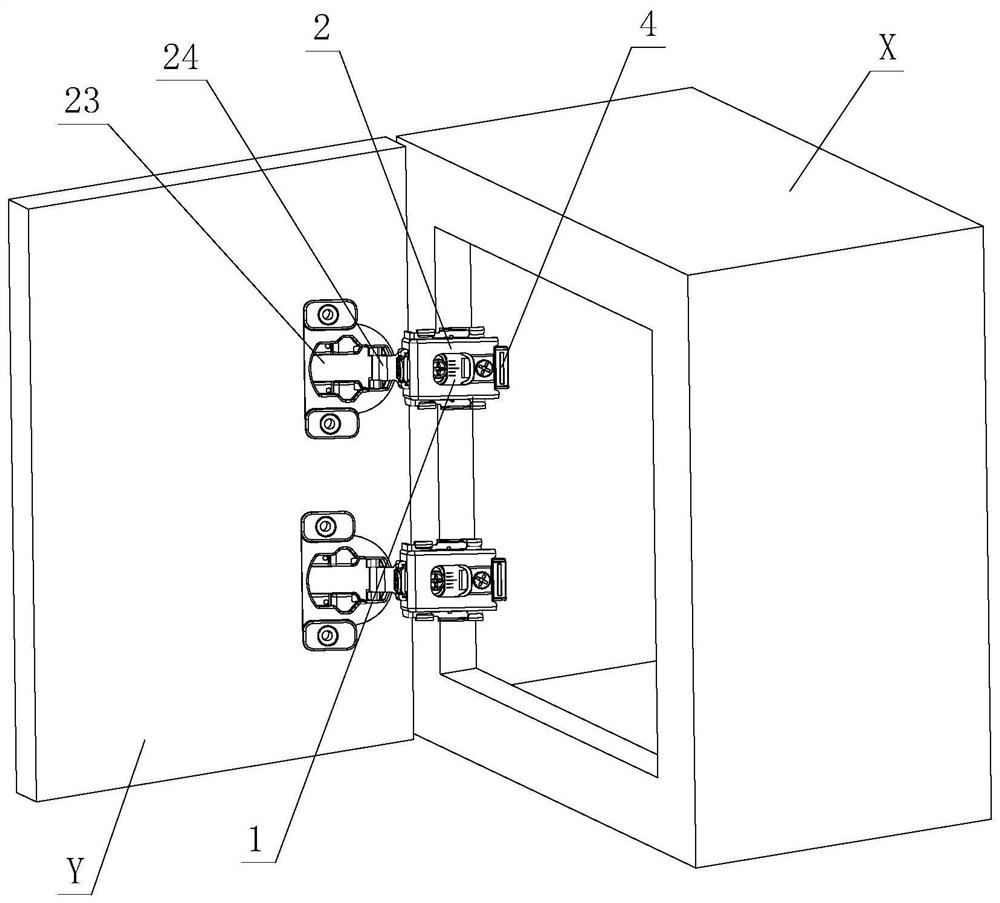

[0045] see Figure 1-Figure 16 , which is used for the quick disassembly and assembly structure of furniture hinges, including furniture cabinet body X, furniture door body Y, hinge device and fixed base 1; the hinge device is fixedly arranged on the furniture door body Y, and the fixed base 1 is fixedly arranged on the furniture cabinet body on X.

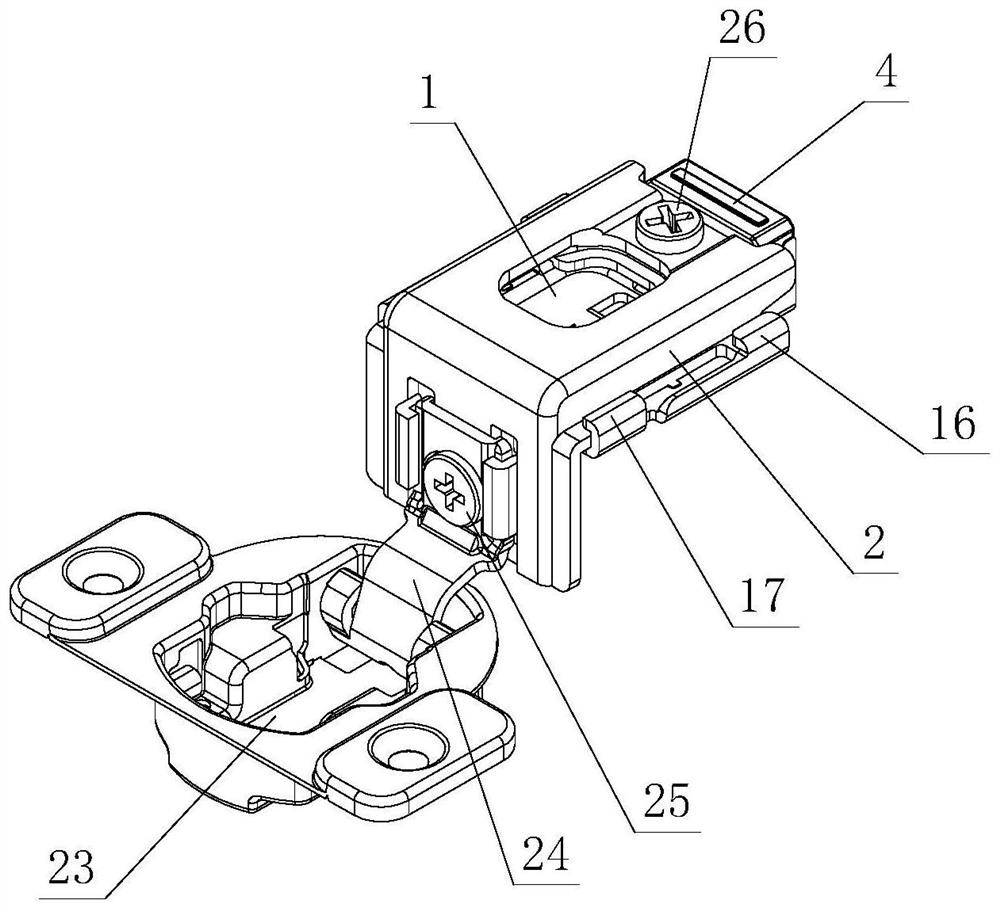

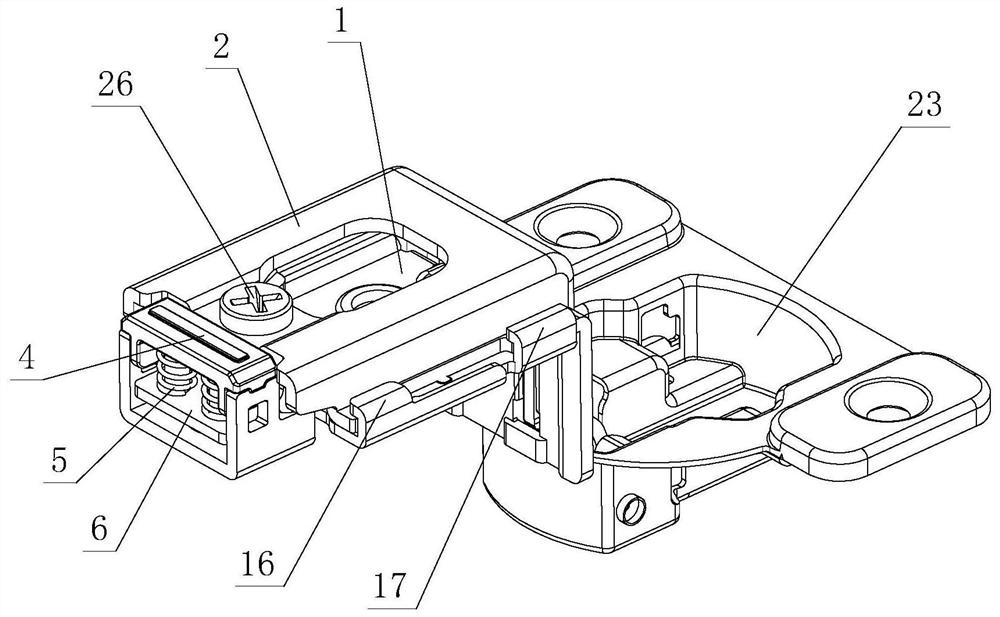

[0046] The hinge device at least includes a connecting arm 2; the connecting arm 2 is provided with an assembly part and a fastening part 3; the fixed base 1 is provided with an assembly matching part and a fastening part 4; on the part; the buckle 4 elastically slides on the fixed base 1, and is fastened or separated from the buckle part 3 when sliding; the hinge device and the fixed base 1 are assembled through the sliding assembly of the assembly part and the assembly matching part, and The sliding fastening of the fastening part 4 and the fastening part 3 realizes the fixed connection, and the fixed assembly between the furni...

no. 2 example

[0066] see Figure 17 , Figure 18 , which is used for the quick disassembly and assembly structure of furniture hinges, it is different from the first embodiment in that: the front assembly part 13 and the rear assembly part 14 are arranged on the left and right sides of the middle part 12 in a spaced manner, and form a Assembly notch 15.

[0067] The middle piece 12 is placed on the fixed base 1 through the pre-positioning of the assembly gap 15 and the assembly gap 18, and then linearly slides and fits the front assembly portion 16 and the rear assembly portion 17 respectively through the front assembly portion 13 and the rear assembly portion 14. superior.

[0068] The front assembling part 13 and the rear assembling part 14 are arranged on the left and right limiting flanges 22 in a front-rear spaced manner.

[0069] The hinge arm 24 is integrated with the connecting arm 2 .

[0070] Other unmentioned parts are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com