Rotary jaw type air nozzle

A technology of rotating clamps and air nozzles, used in mechanical equipment, couplings, etc., can solve the problems of complex American air nozzles and French air nozzles, the clamping force of complex American air nozzles, the high manufacturing cost of components, and the lack of intuitive operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to enable your review committee to have a further understanding and recognition of the features and features of the present invention, the following preferred embodiments are listed below with accompanying drawings:

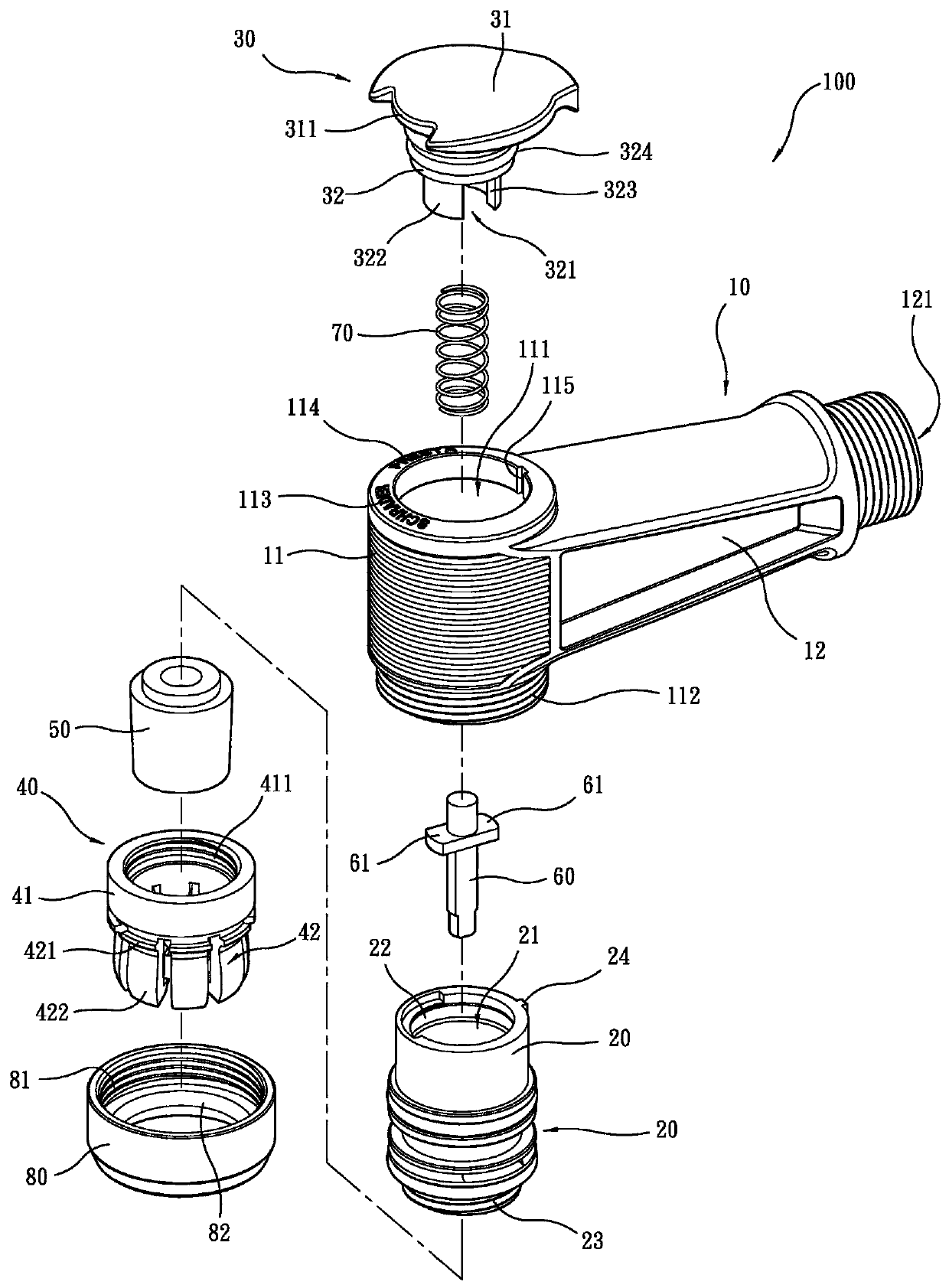

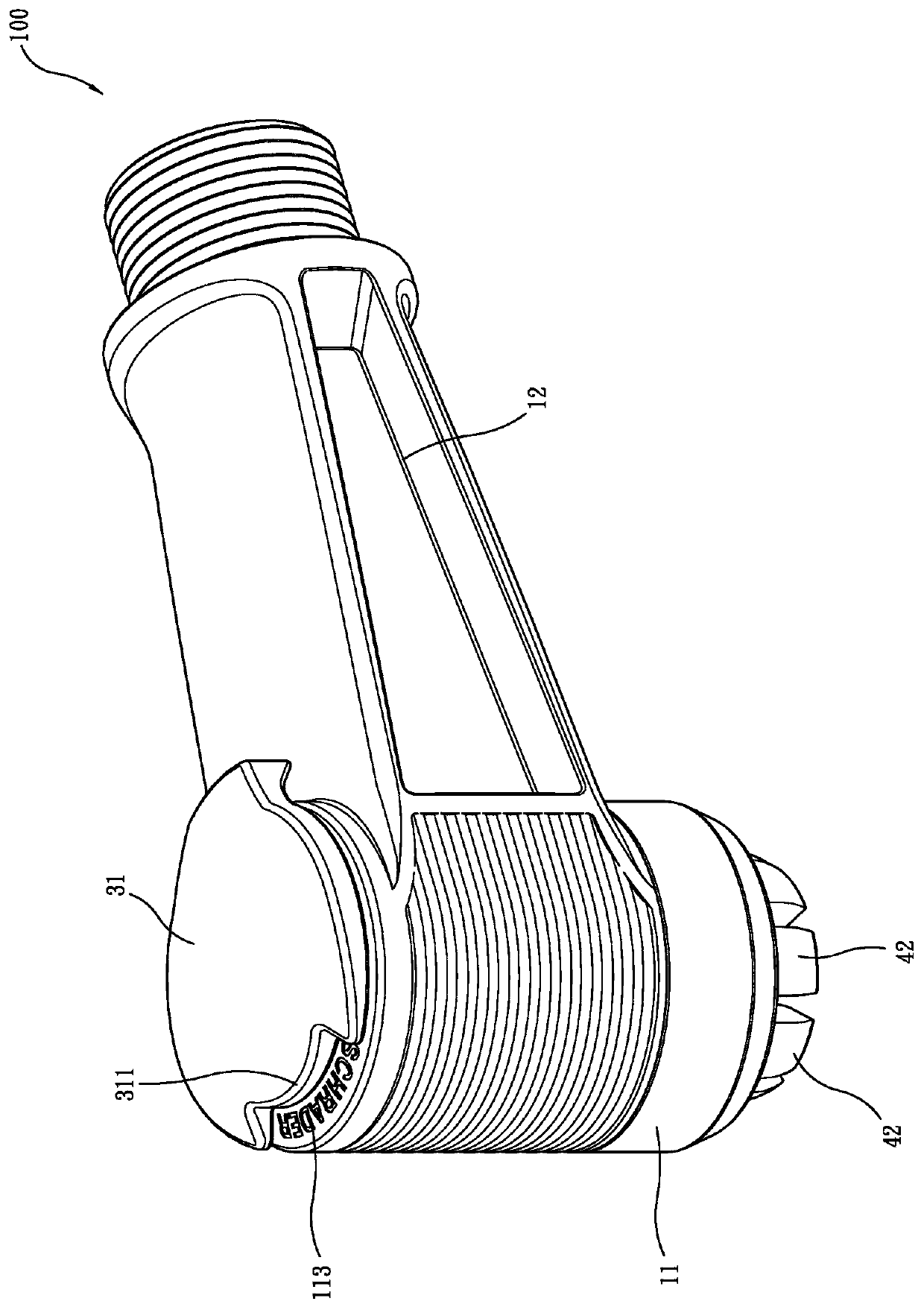

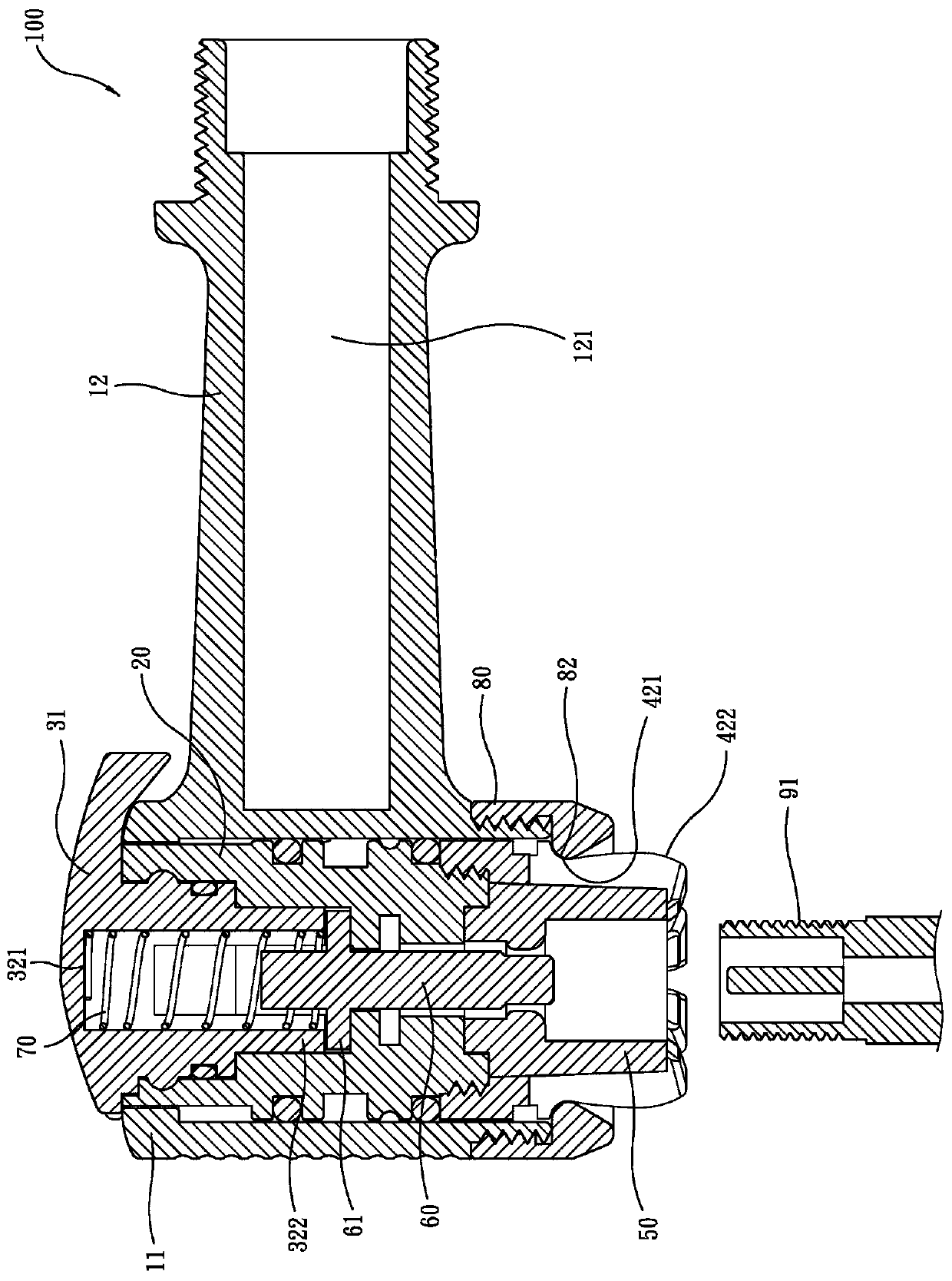

[0050] see Figure 1 to Figure 8 , A rotary jaw type air nozzle 100 provided by a preferred embodiment of the present invention mainly includes an air nozzle body 10, an inner cylinder 20, a screw cap 30, a jaw 40, a beam ring 50, A thimble 60, a spring 70 and an action ring 80, wherein:

[0051] see Figure 1 to Figure 3 , the air nozzle body 10 has an accommodating portion 11 and a connecting portion 12; Screw thread 112, the top of the accommodating portion 11 has an American symbol 113 and a French symbol 114, the connecting portion 12 is integrally connected to one side of the accommodating portion 11, and has an inflatable passage connecting the accommodating chamber 111 to the outside world 121.

[0052] see Figure 1 to Figure 3 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com