Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Increased chance of impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

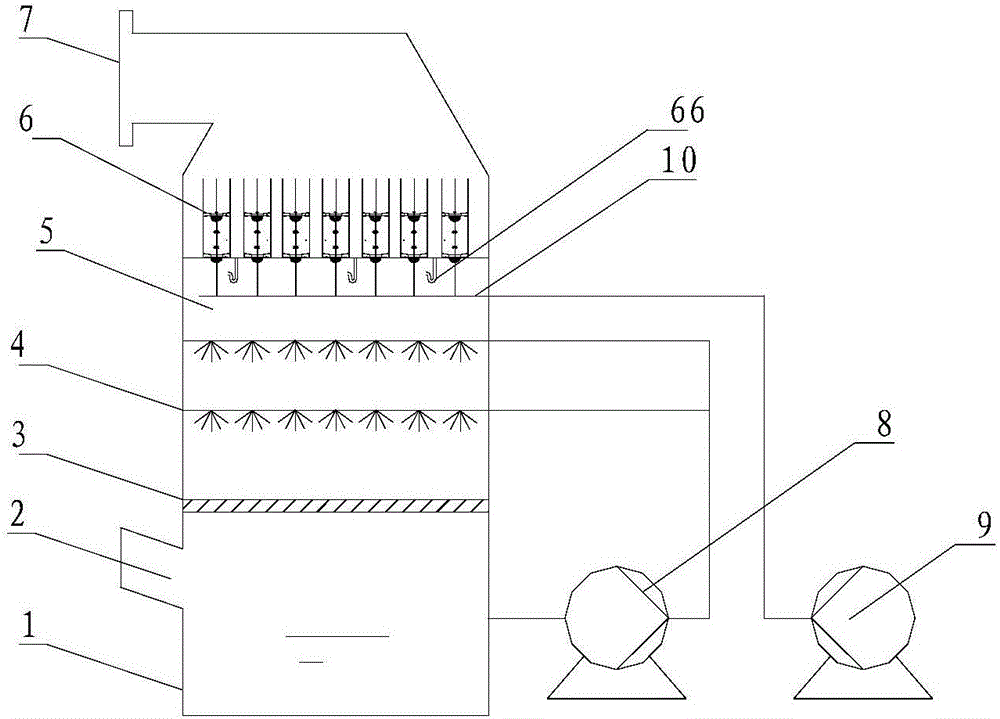

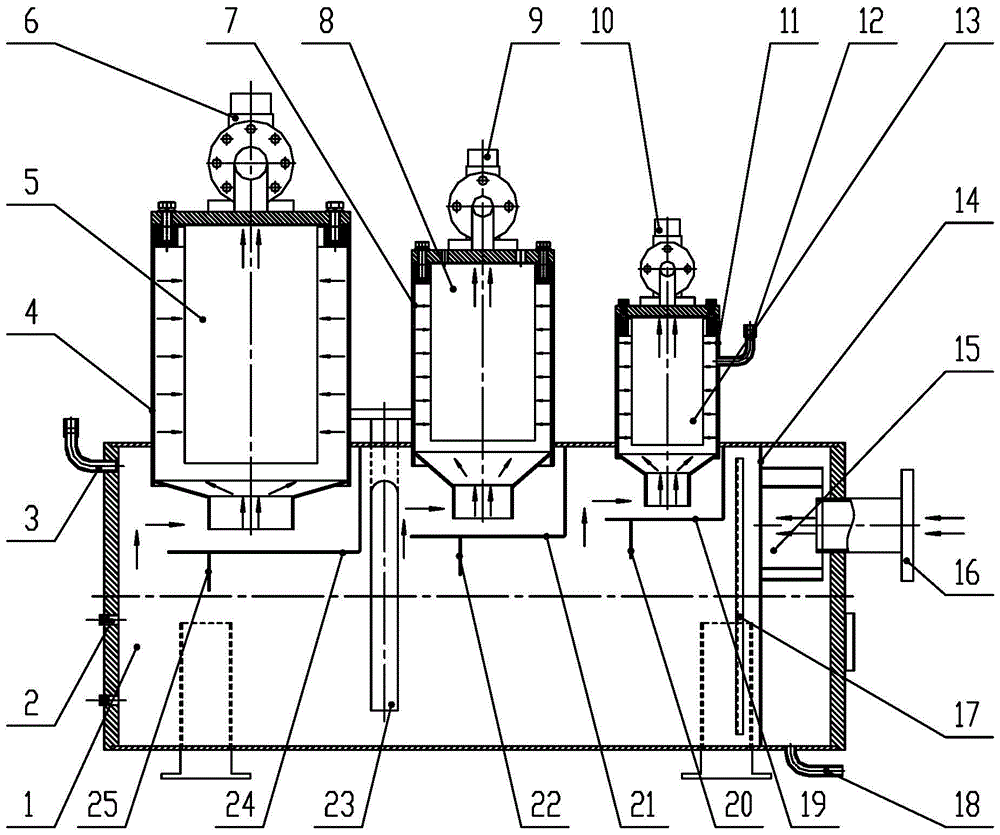

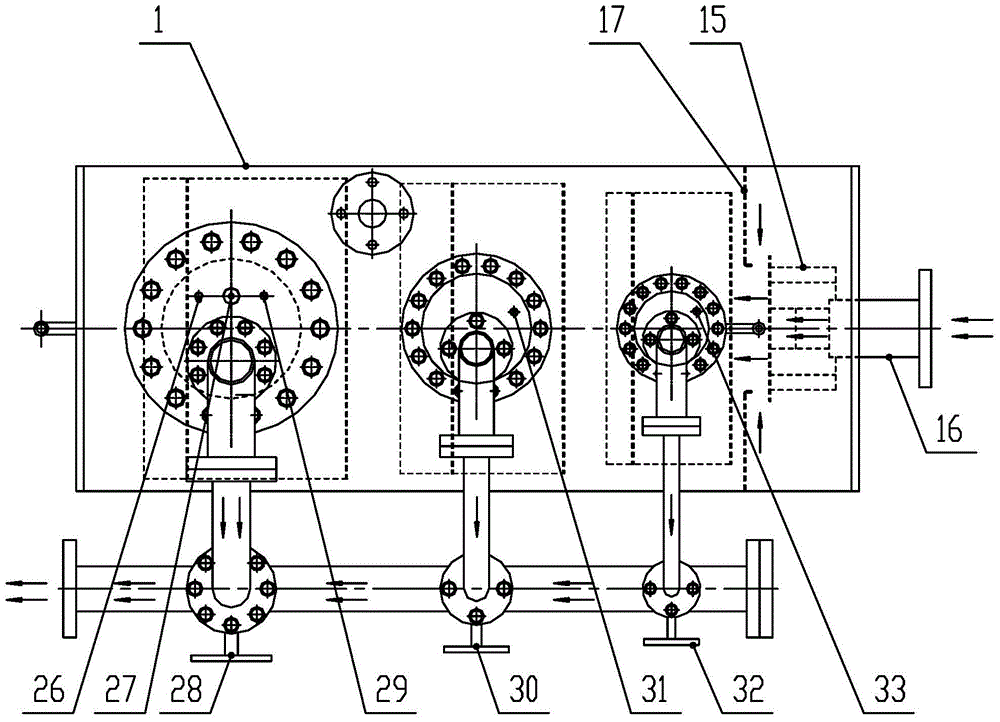

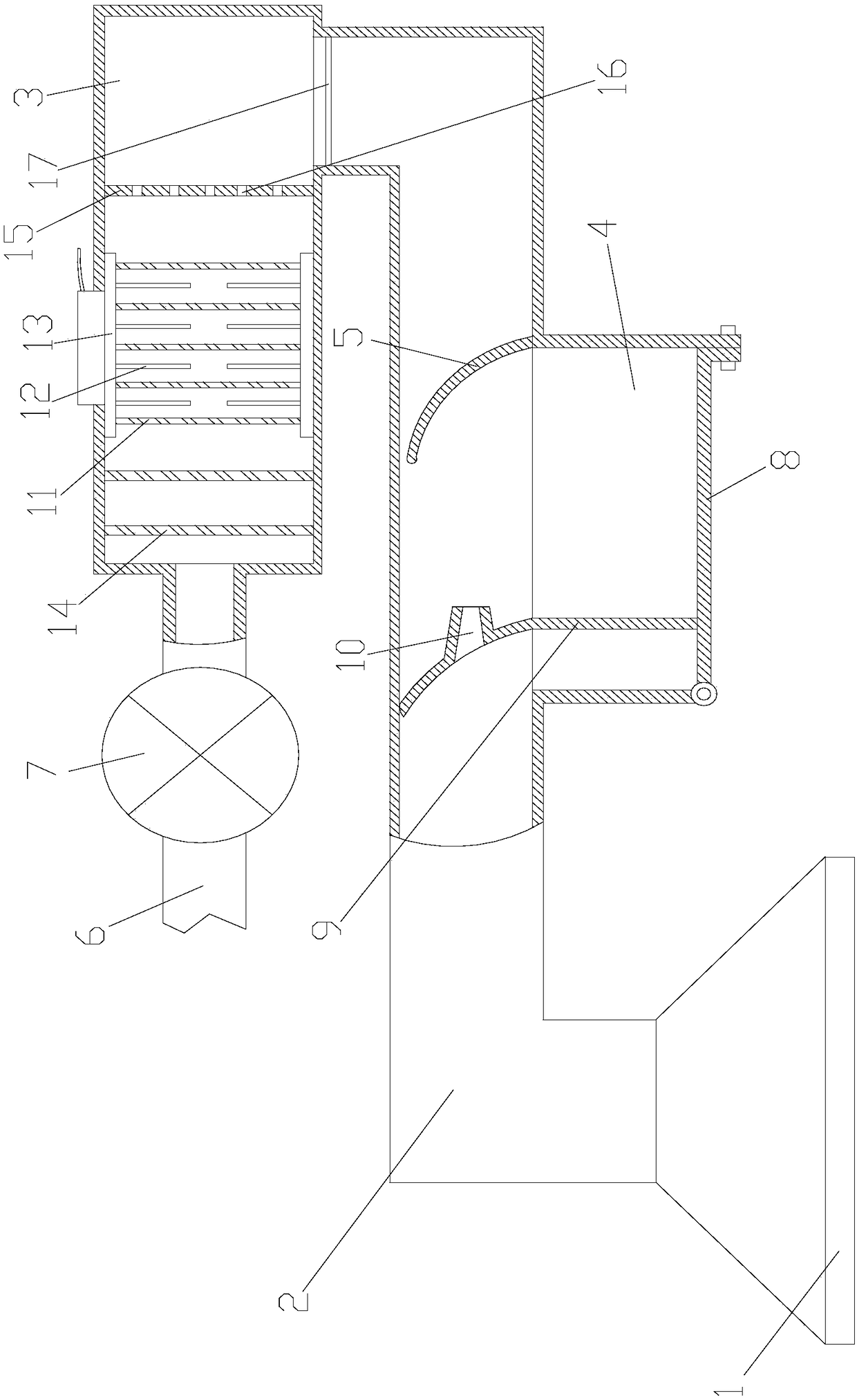

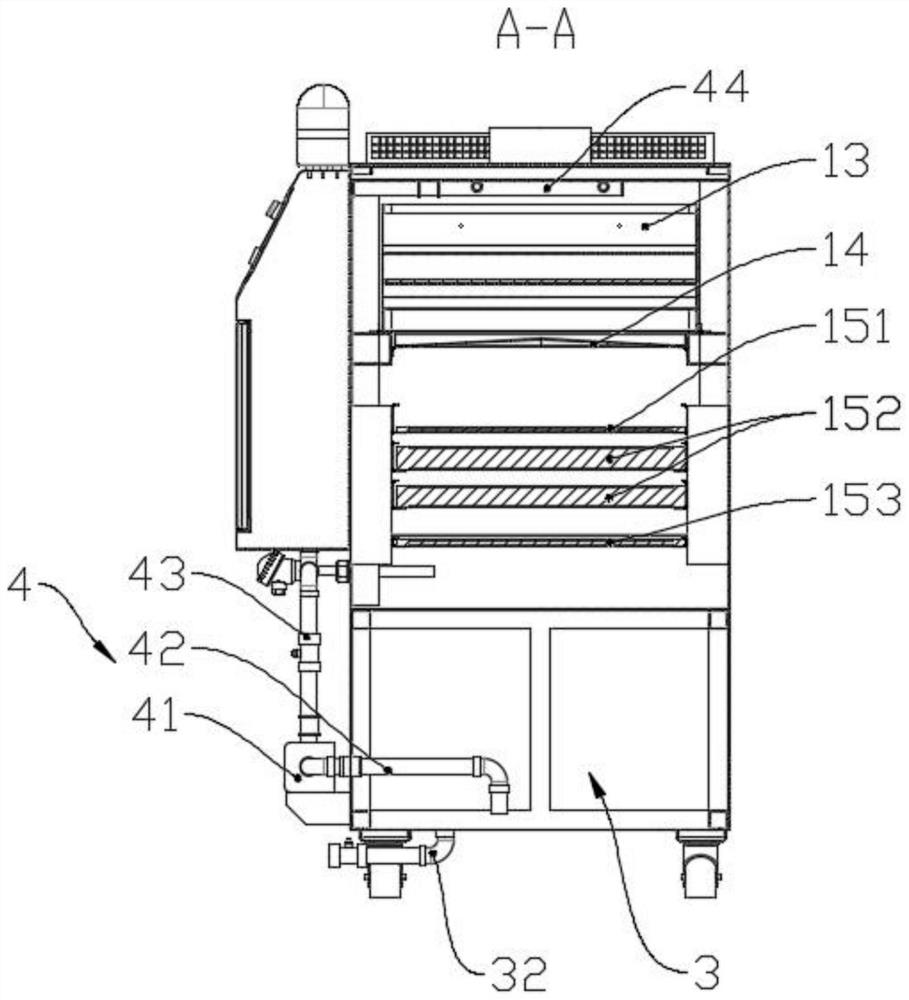

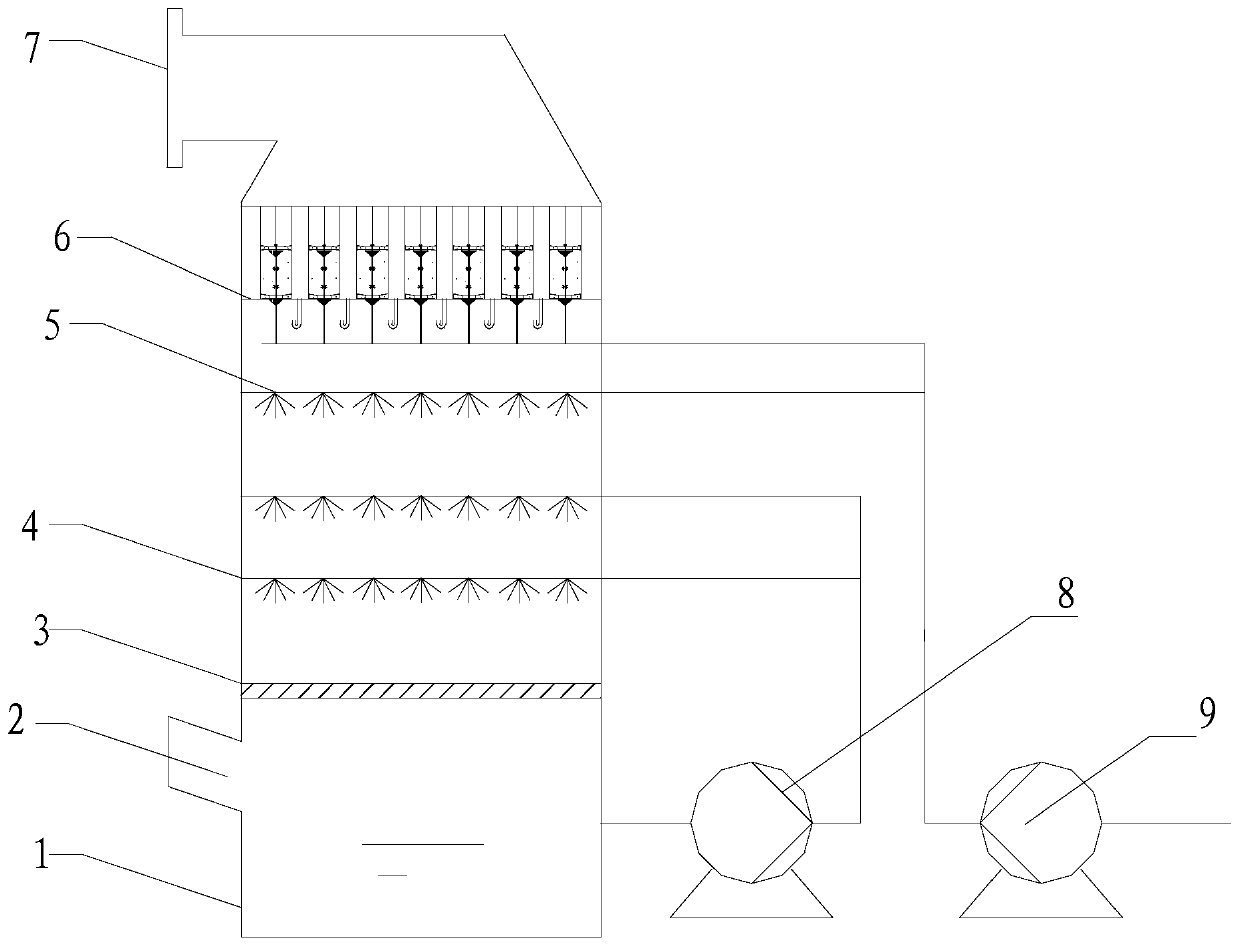

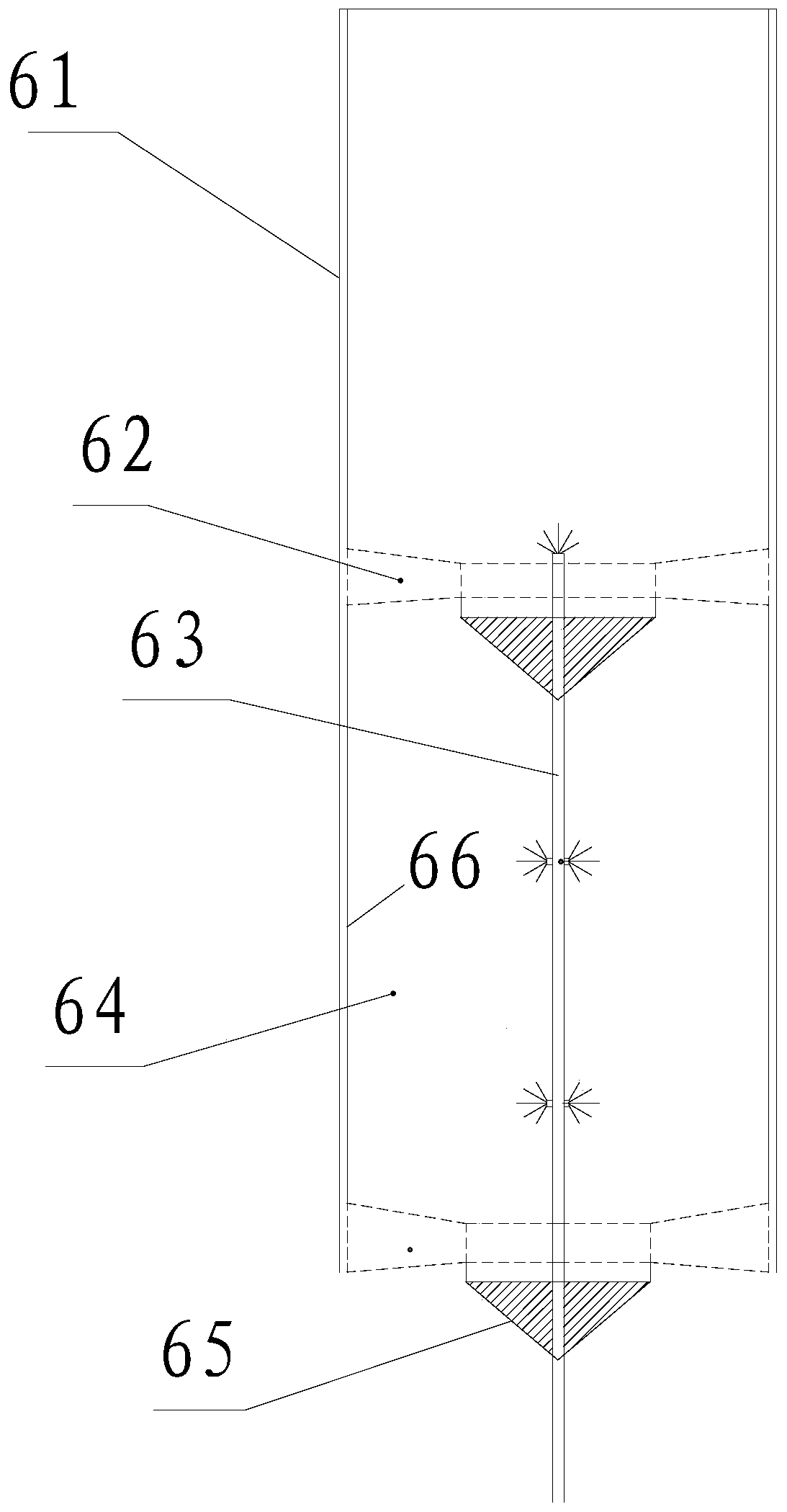

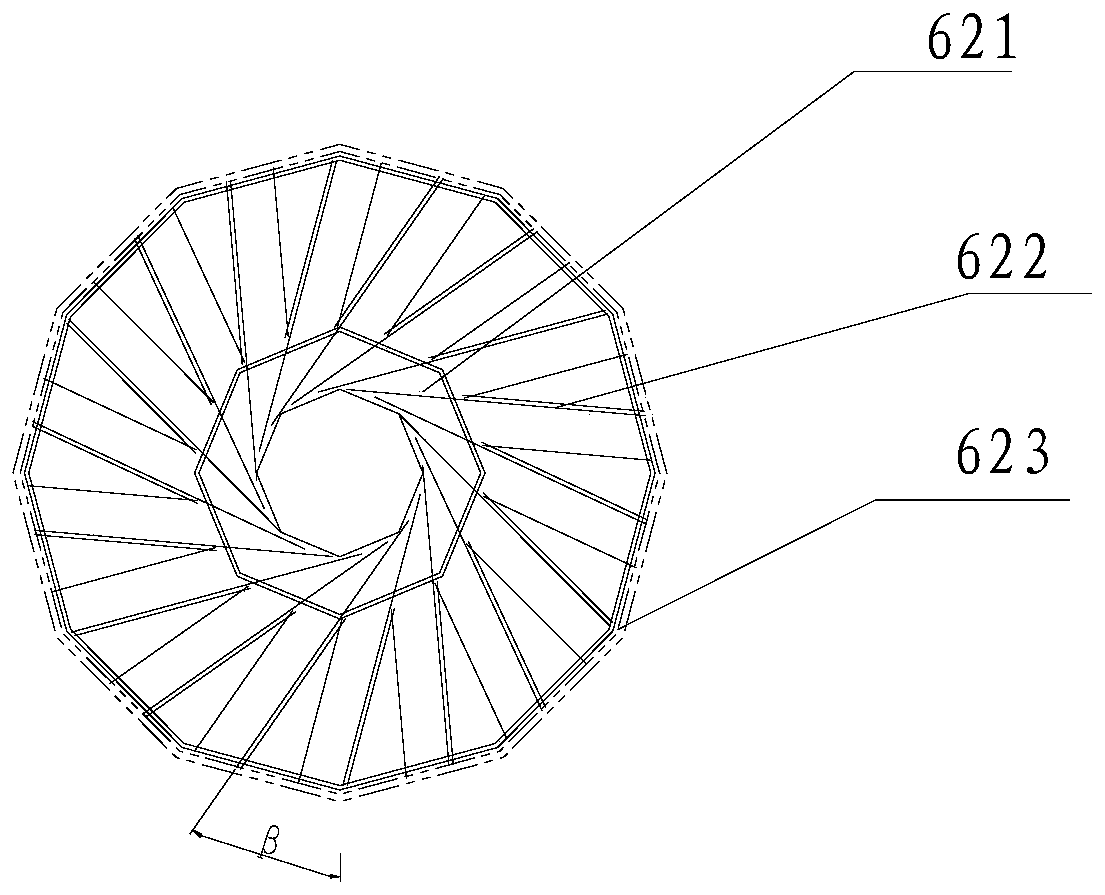

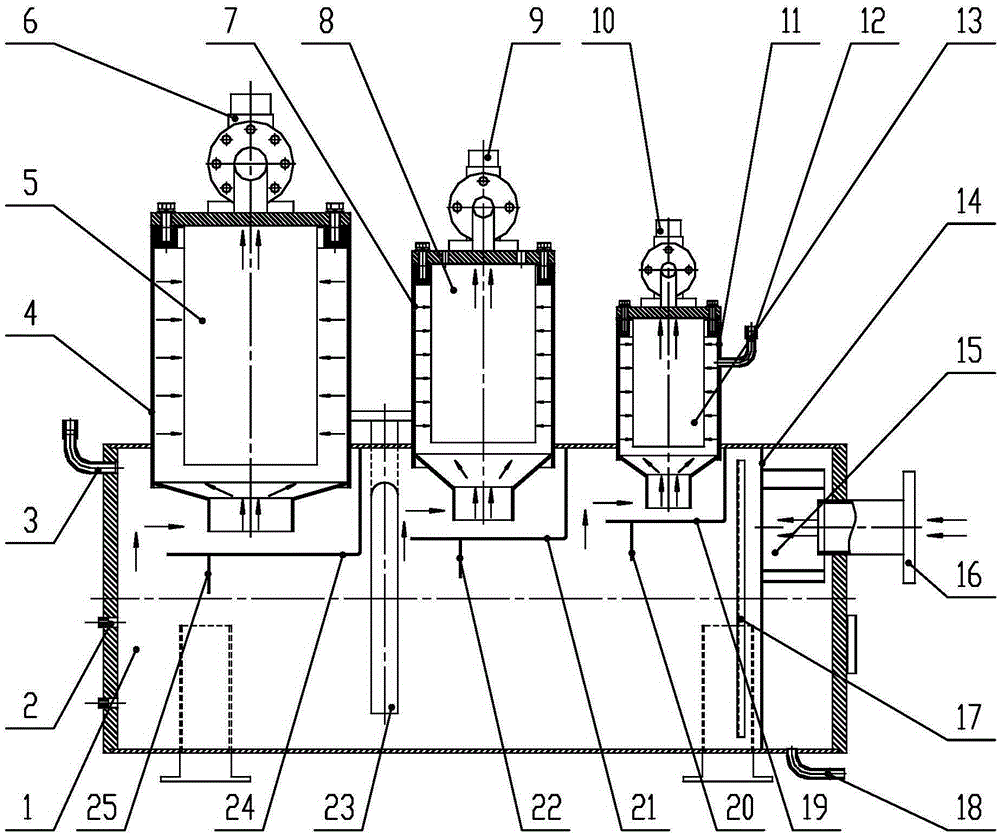

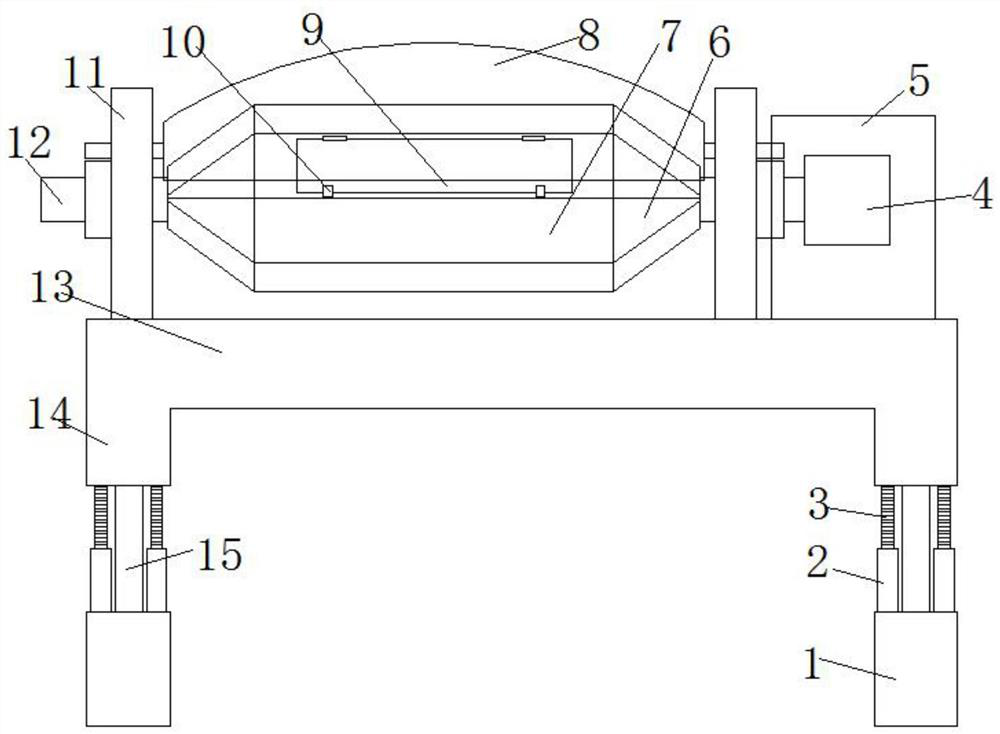

Device and process for coordinative treatment of smoke desulfuration and dedusting

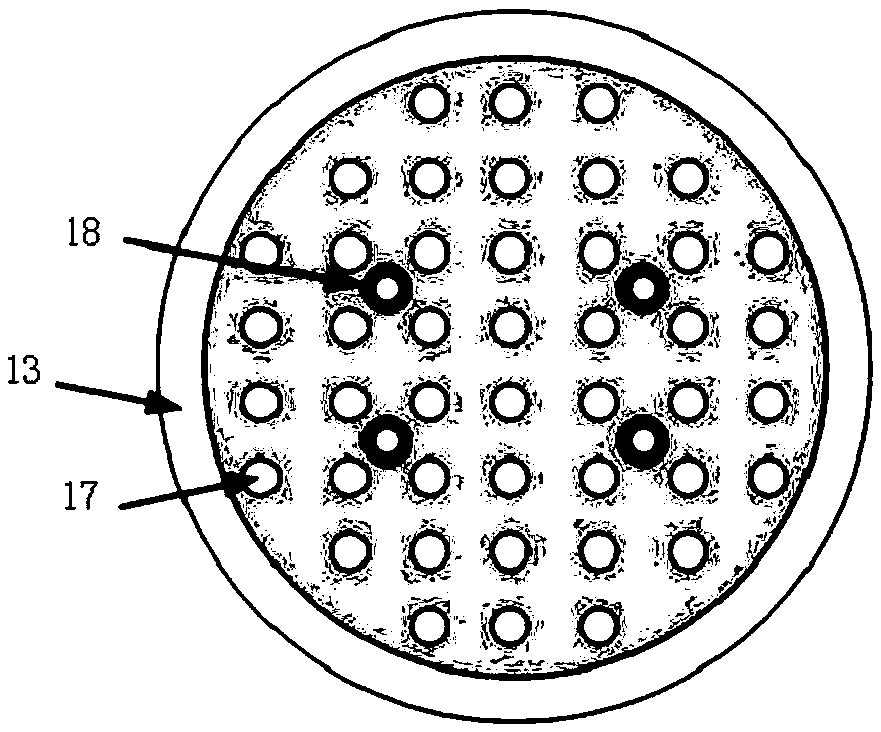

ActiveCN105854561AIncreased chance of impactImprove dust removal efficiencyDispersed particle separationCycloneLiquid layer

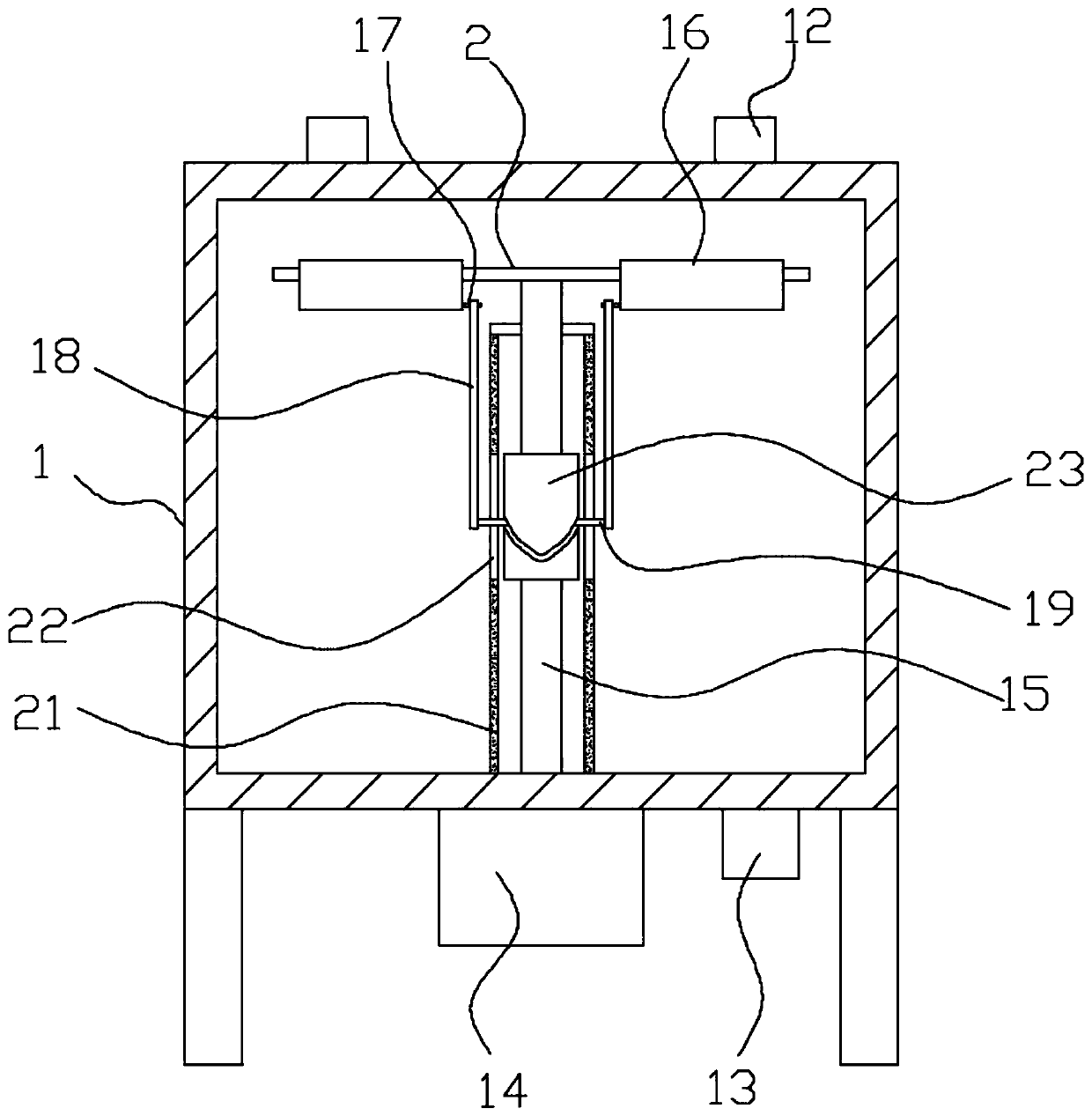

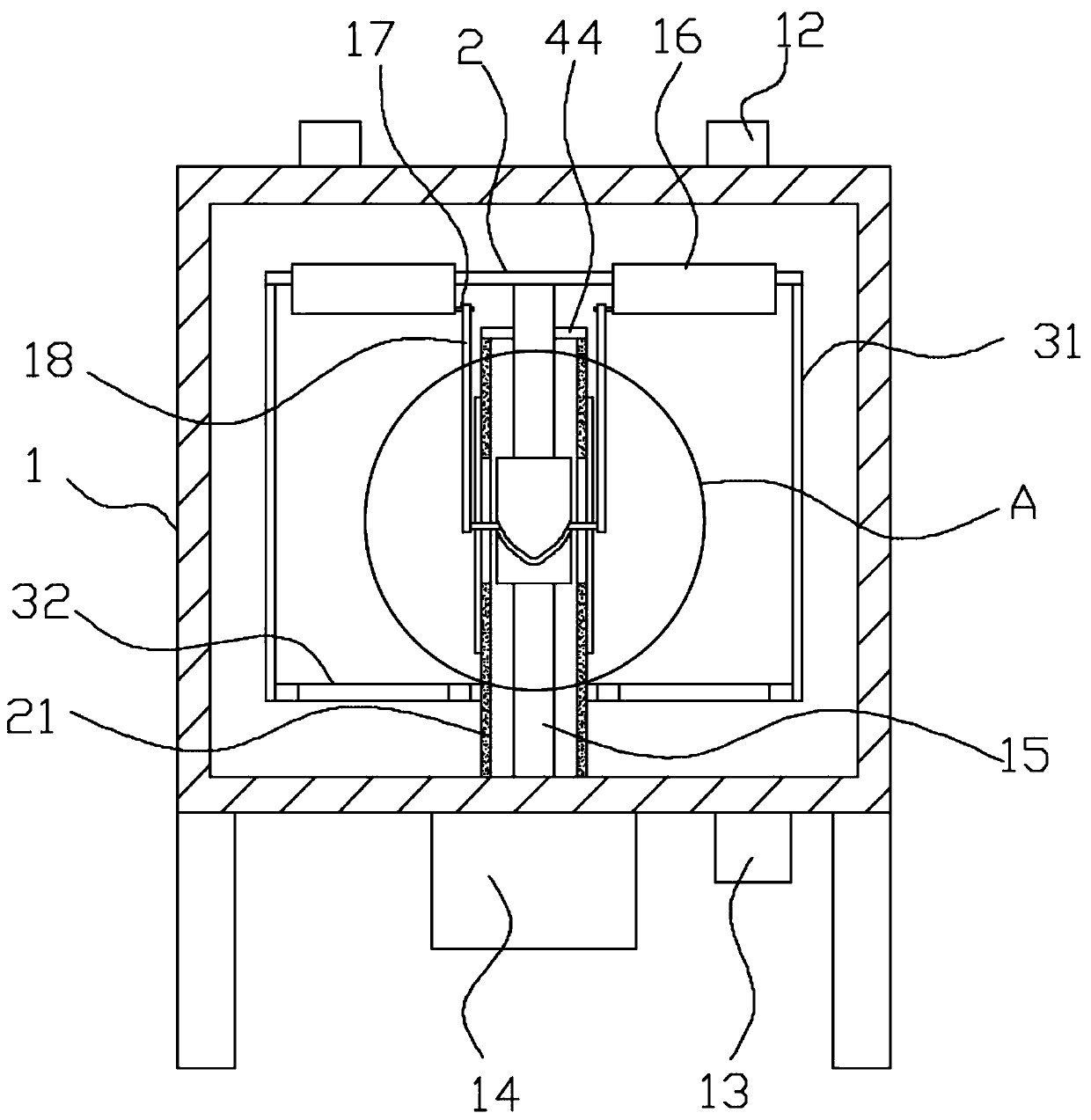

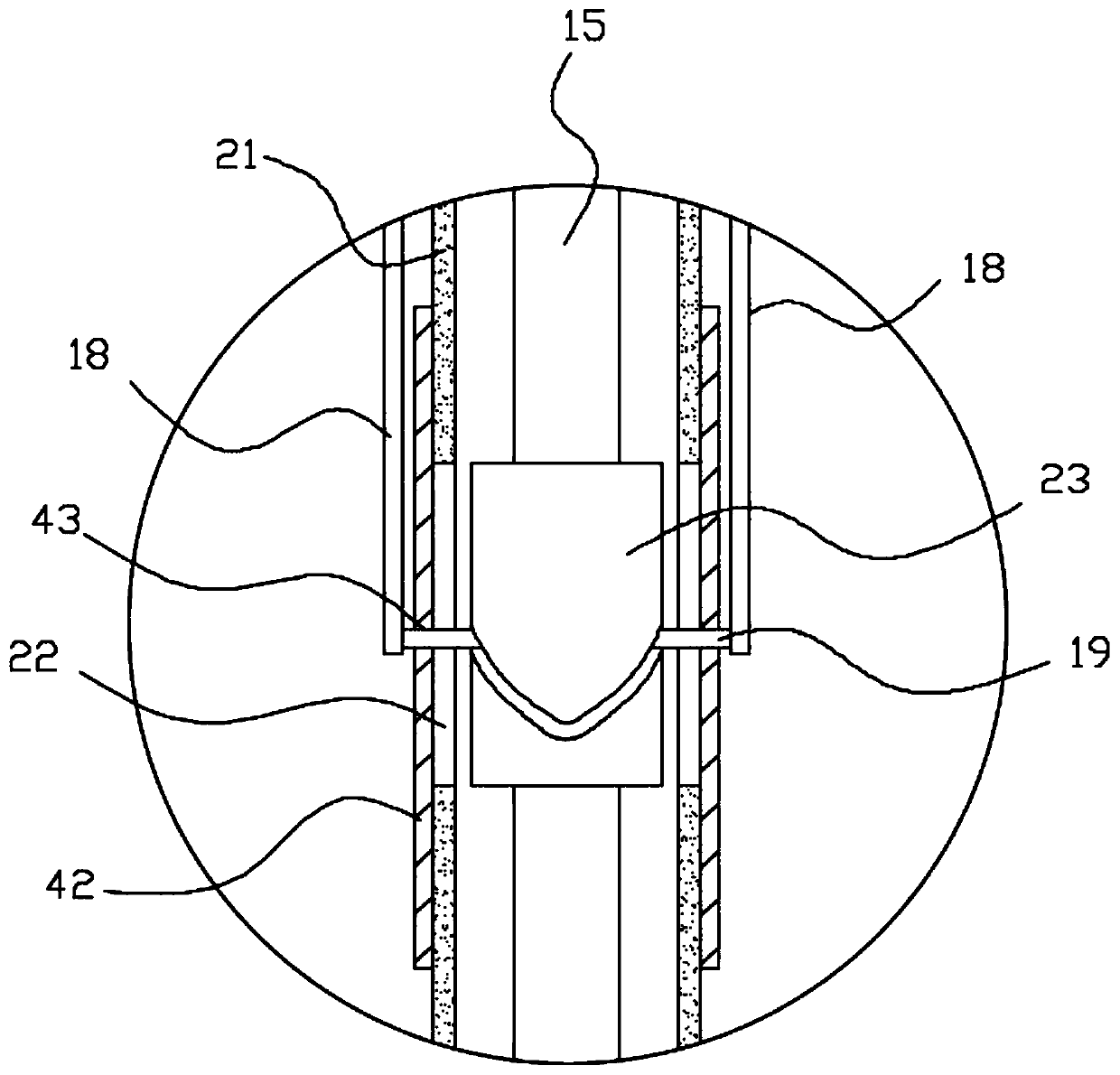

The invention discloses a device and a process for coordinative treatment of smoke desulfuration and dedusting. The process includes that crude smoke enters an absorption tower and sequentially pass through a tray layer, a spray layer, a sedimentation and cooling area and an efficient demisting layer and out of the outlet of the absorption tower, the smoke entering the absorption tower in the tray layer is reshaped and rises up at uniform speed over the section of the absorption tower, SO2 in the smoke and size in the accumulative liquid layer and the sprayer layer above the tray can be effectively removed, saturated smoke with small size drops and dust can be settled through the cooling area after desulfurized, and size drops and dust may be abundantly settled. The size drops and dust unsettled can enter a cyclone demister layer along with airflow and be removed through cyclone and collision, and clean smoke treated can be discharged from the outlet of the absorption tower. By the process of reshaping the smoke and sequentially spraying, absorbing and efficiently removing dust and mist, desulfurization, and demisting and dedusting efficiency of the wet-method desulfurization device is improved, and operation energy consumption is lowered.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

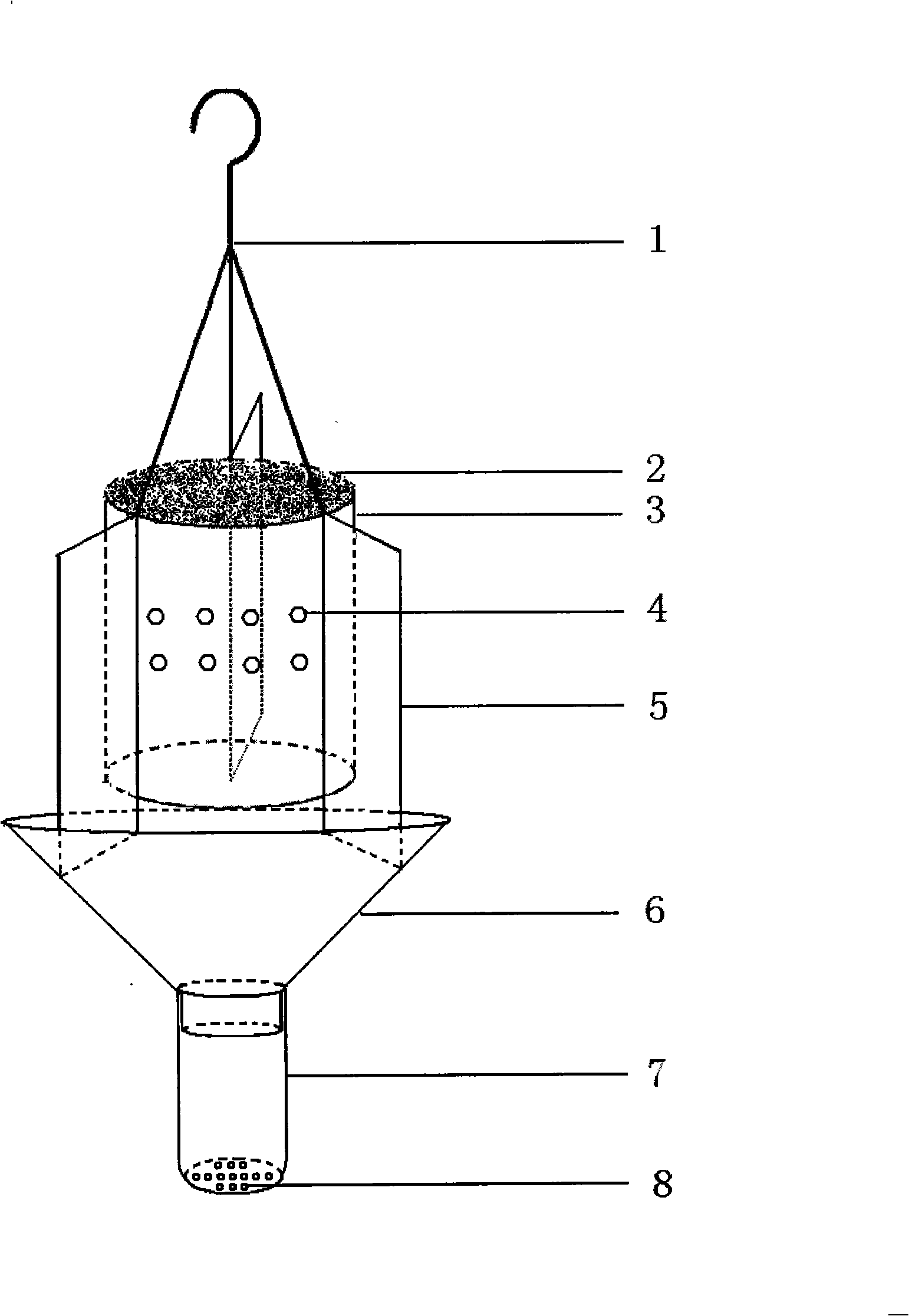

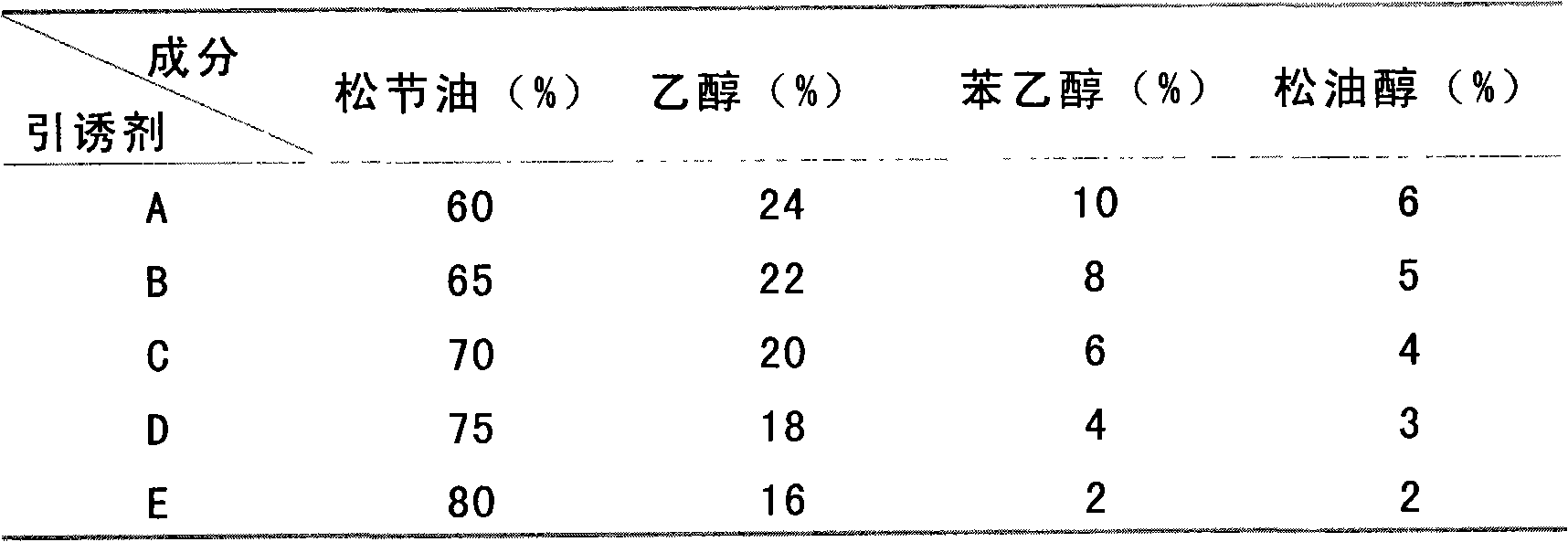

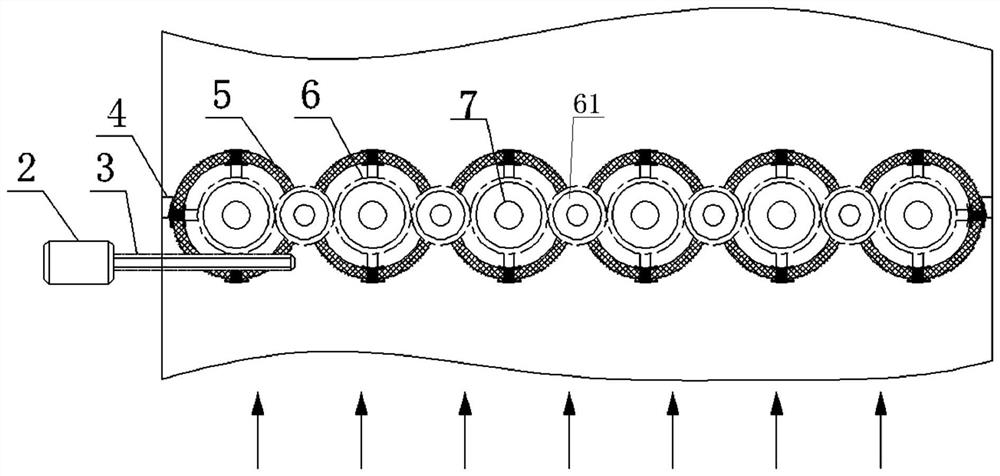

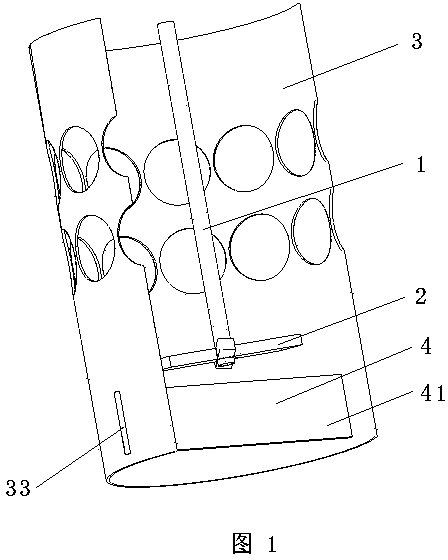

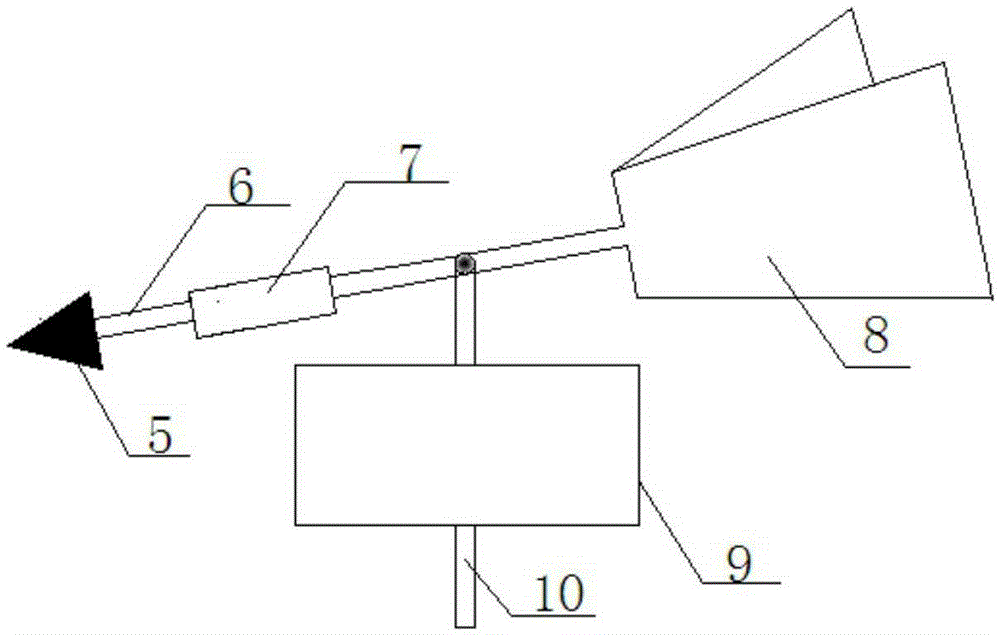

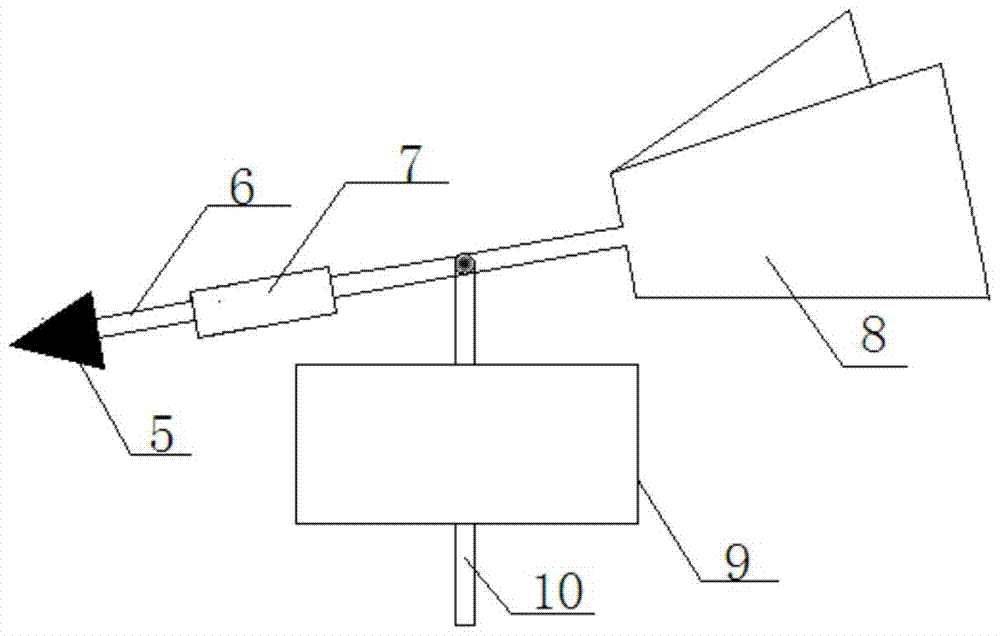

Monochamus alternatus imago attractant and trap thereof

InactiveCN101554178AGood trapping effectStrong ability to seduceBiocidePest attractantsPhenethyl alcoholTurpentine

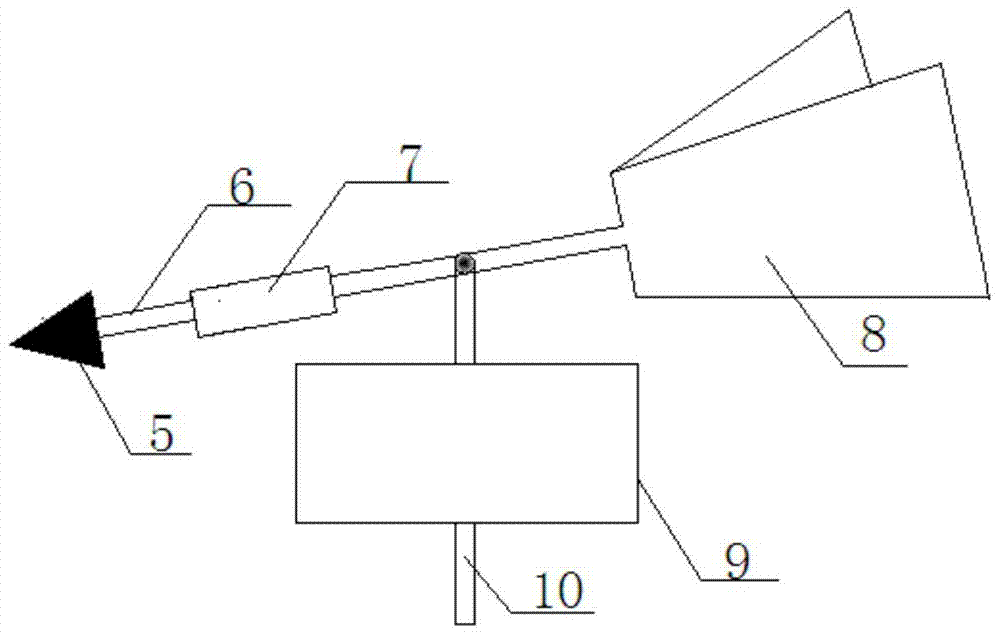

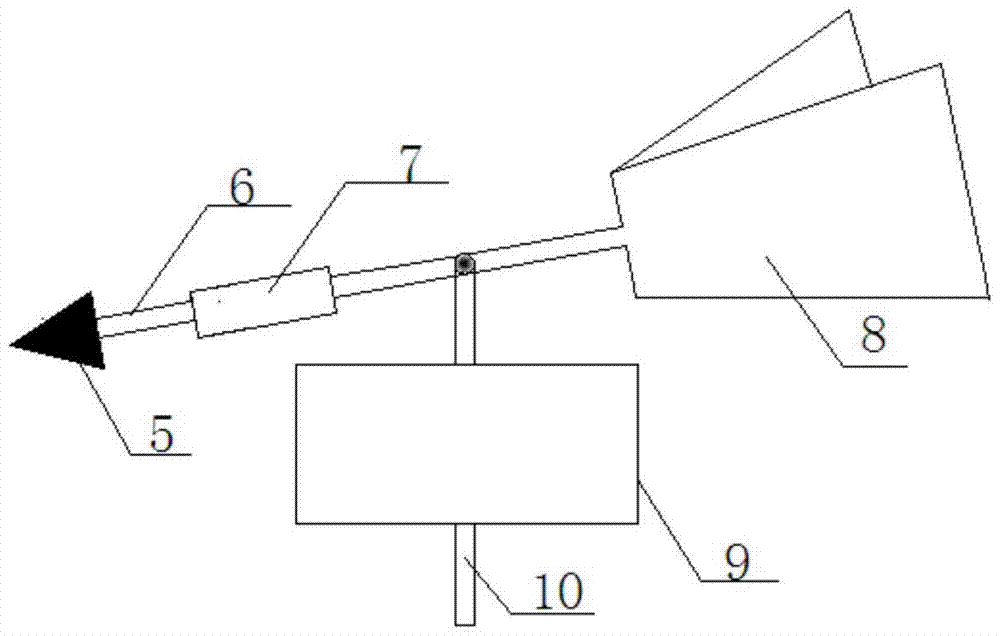

The invention relates to a monochamus alternatus imago attractant and a trap thereof, which belong to the technical field of pest control. The volume percents of the components of the attractant are 60 to 80 percent of oil of turpentine, 16 to 24 percent of alcohol, 2 to 10 percent of phenethyl alcohol and 2 to 6 percent of terpineol. The volume percents of each component of the attractant are 24.64 to 32.86 percent of alpha-pinene, 22.91 to 30.55 percent of beta-pinene, 6.51 to 8.68 percent of 3-carene, 2.97 to 3.96 percent of beta-phellandrene, 0.74 to 0.99 percent of terpinolene, 0.62 to 0.83 percent of laurene, others for 1.60 to 2.13 percent, 16 to 24 percent of alcohol, 2 to 10 percent of phenethyl alcohol and 2 to 6 percent of terpineol. The trap consists of a cylindrical body (3), a funnel-shaped imago picking device (6) arranged at the lower part of the body (3), and an imago collecting bottle (7) connected with the lower end of the funnel-shaped imago picking device (6). The attractant has the advantages of convenient preparation, simple usage and long lasting period, and is a nuisanceless plant protection product; and the trap has the advantages of simple structure, low cost, long service life and good attracting effect, and can be wildly applied to the monochamus alternatus imago control in the field.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

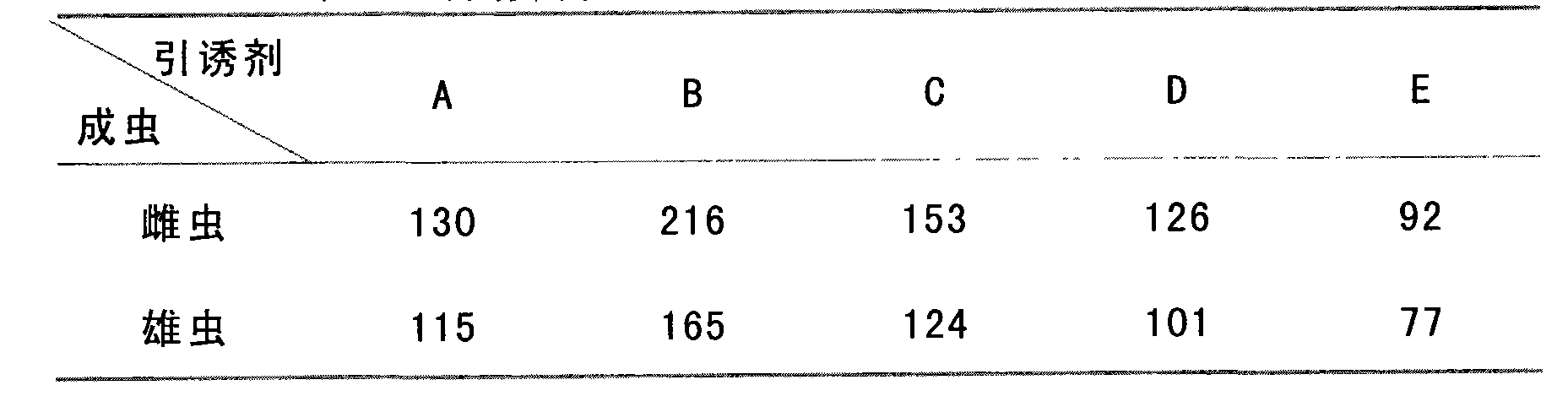

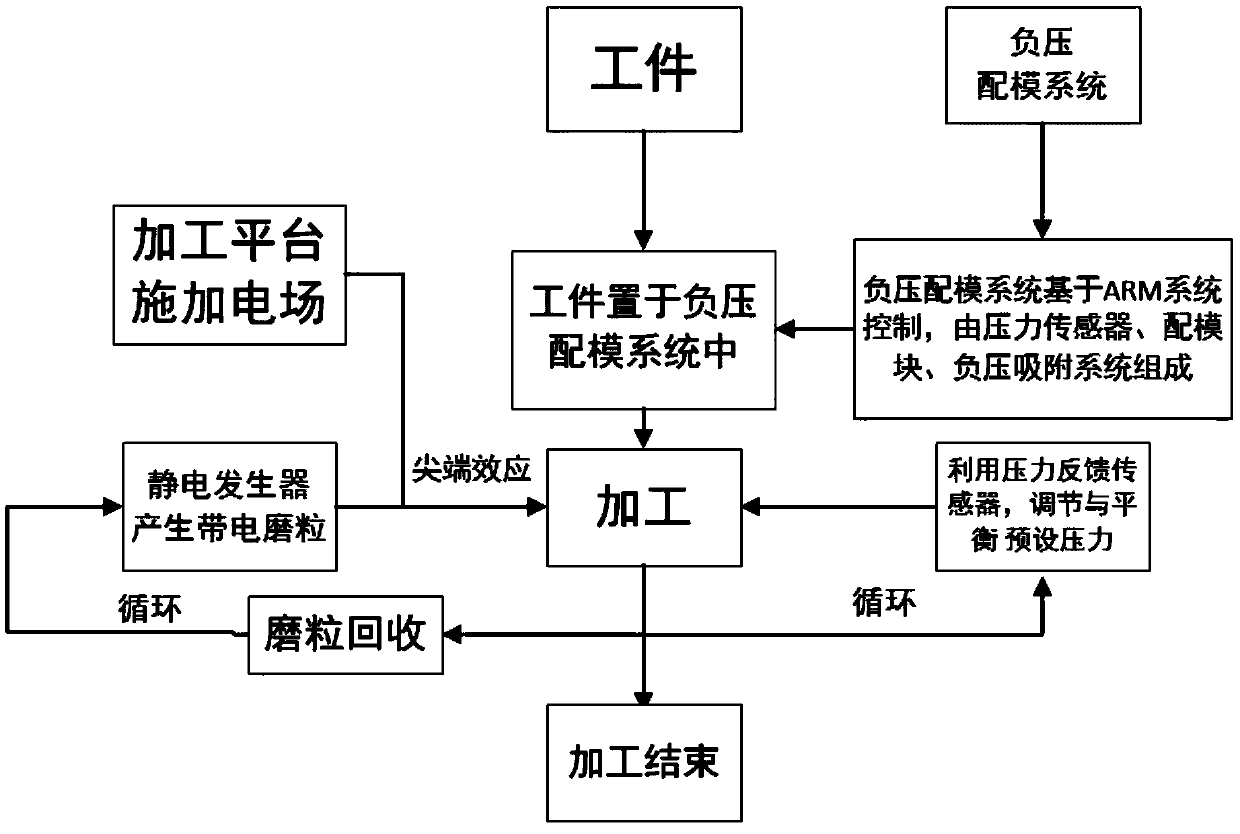

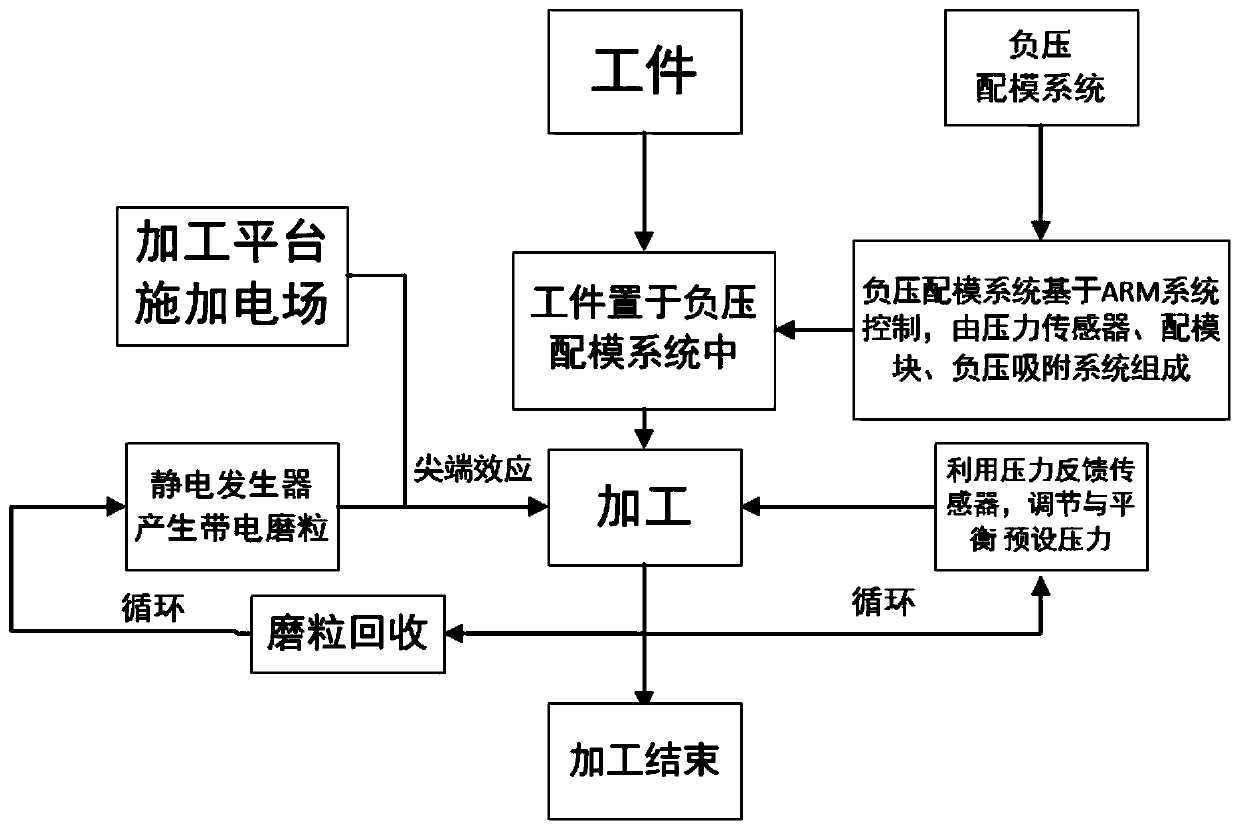

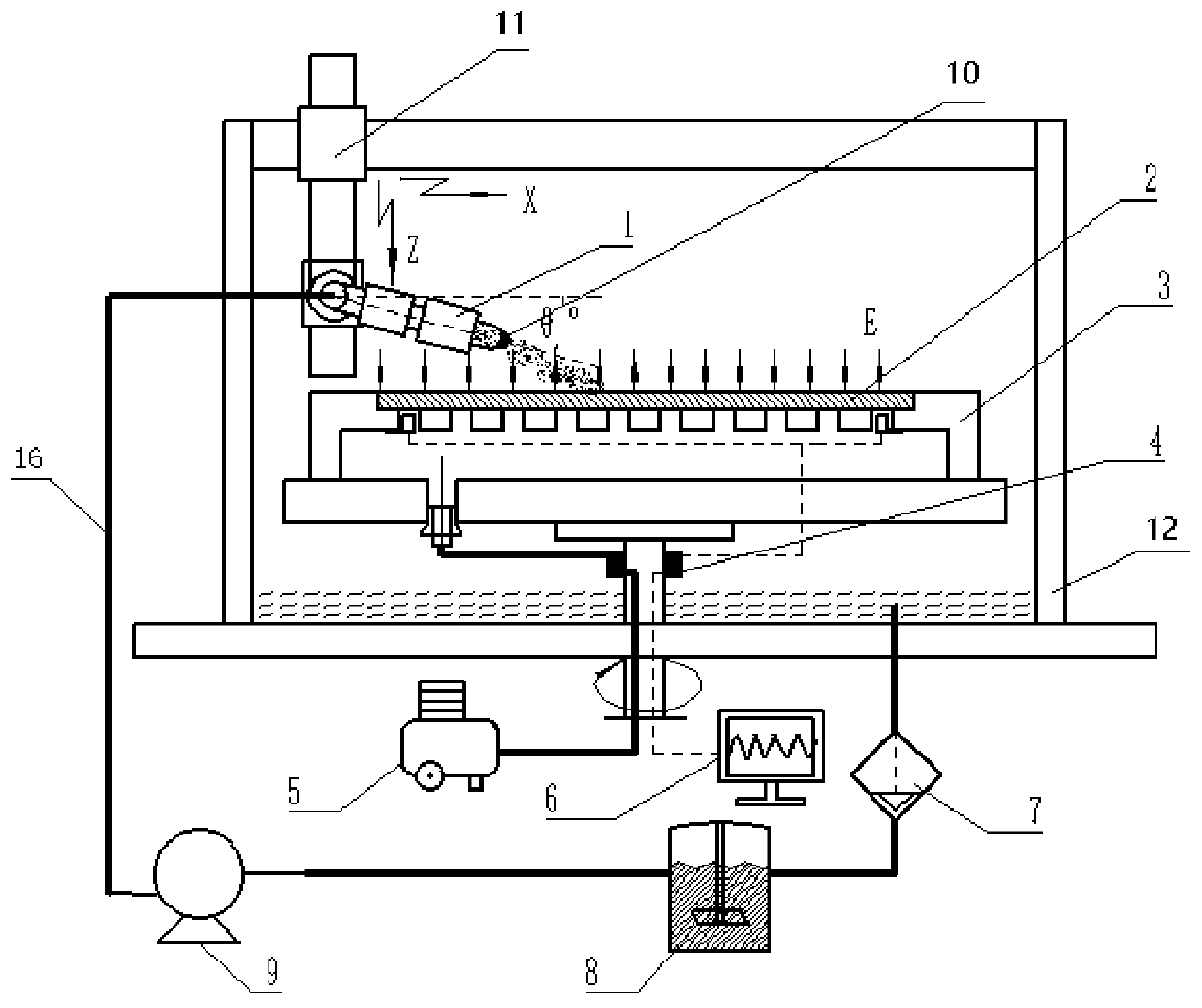

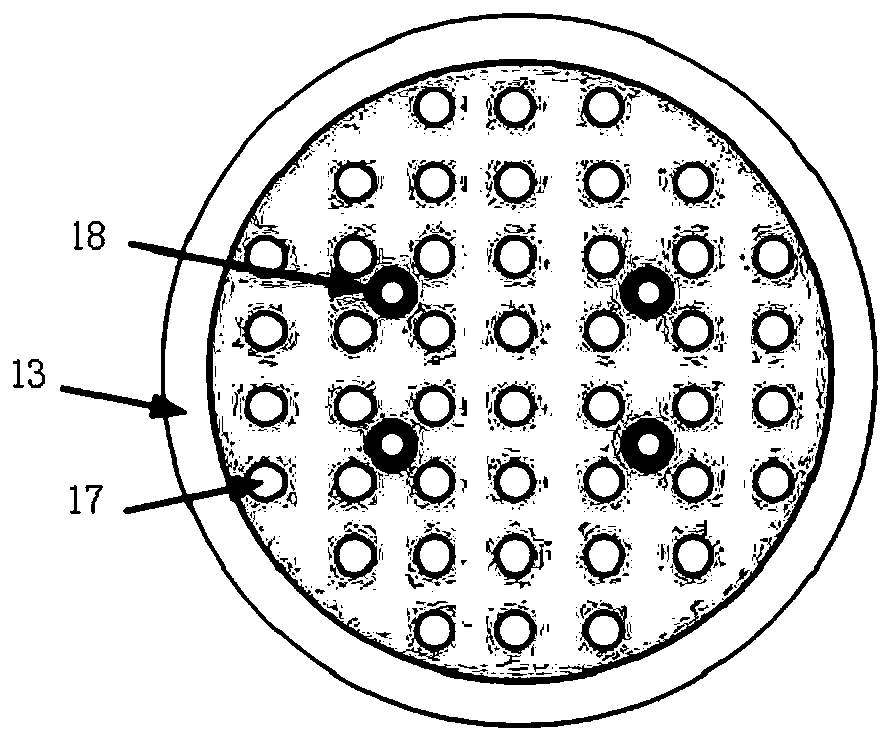

Static electricity controllable abrasive particle flow processing method based on charge tip aggregation effect

ActiveCN109551374AControllable distributionReduce particle size unevennessAbrasive machine appurtenancesMicroscopic scaleHigh pressure

The invention discloses a static electricity controllable abrasive particle flow processing method based on a charge tip aggregation effect. An abrasive particle flow with non-electrolyte as a carrieris subjected to a high-voltage electrostatic field to be charged, so that the distribution of the abrasive particles in the flow field can be controlled, and negative influences produced by abrasiveparticle size unevenness and large-particle-size abrasive particles in the processing process are reduced; an electric field is applied to the flow field, the distribution characteristics of the abrasive particles with the negative charge on the collision area on the surface of a workpiece with the positive charge are changed through the electric charge tip aggregation effect, the possibility of collision of the abrasive particles to the microscopic surface crest of the workpiece is increased, workpiece surface crest removal is accelerated, the flow-in angle of the abrasive particles is periodically swung in a pulse mode, the optimal polishing alternating force acting on the workpiece is obtained by effectively adjusting and controlling the pulse frequency and the swing angle, and it is ensured that the high-quality surface is obtained on the premise of efficient removal.

Owner:ZHEJIANG UNIV OF TECH

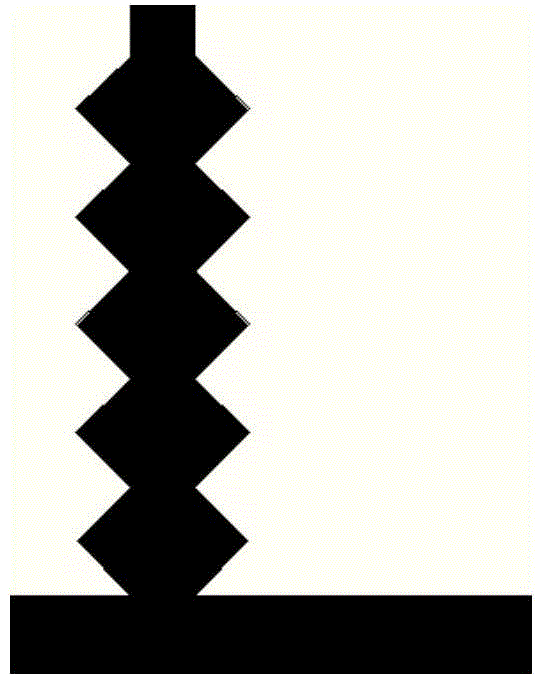

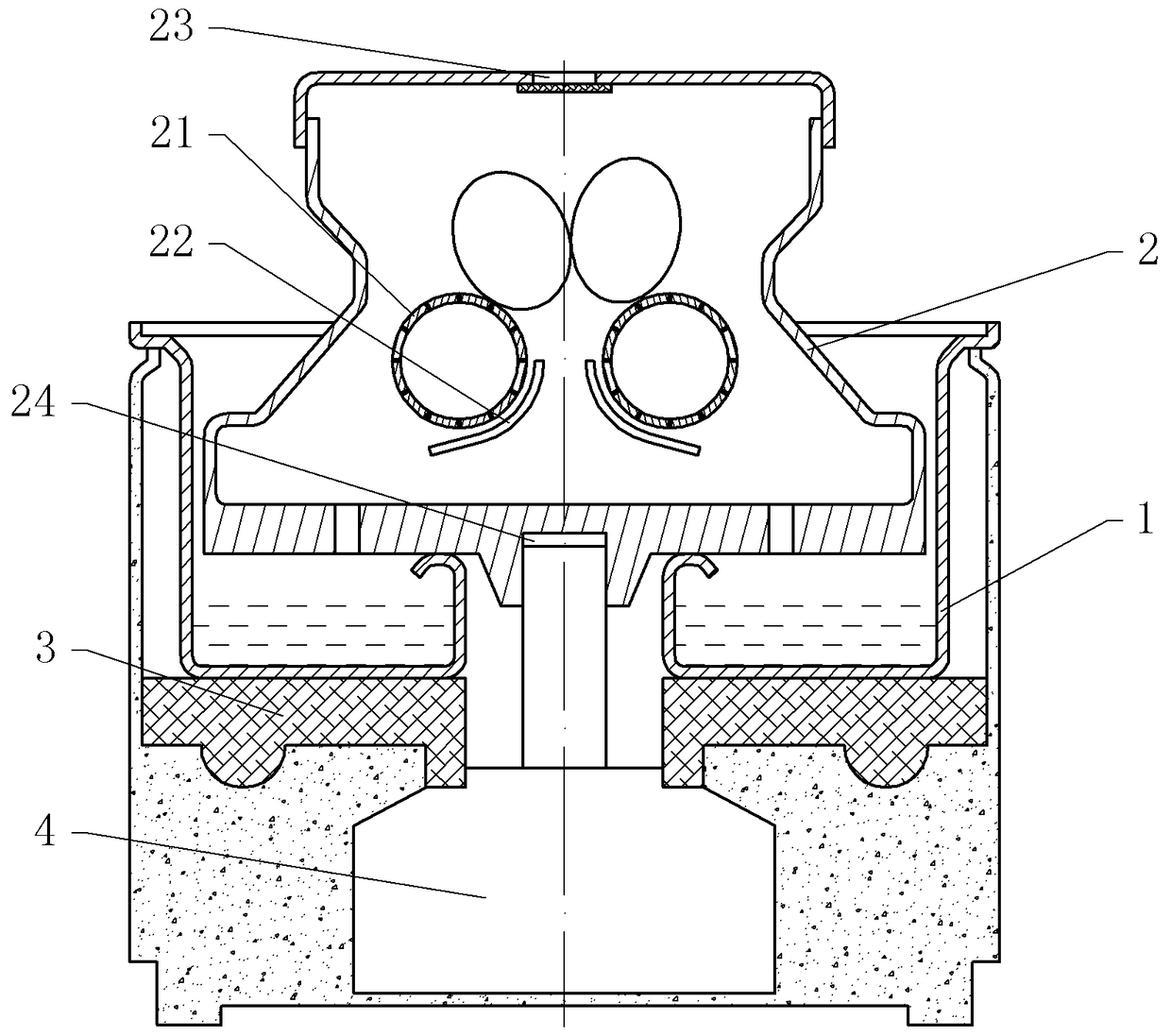

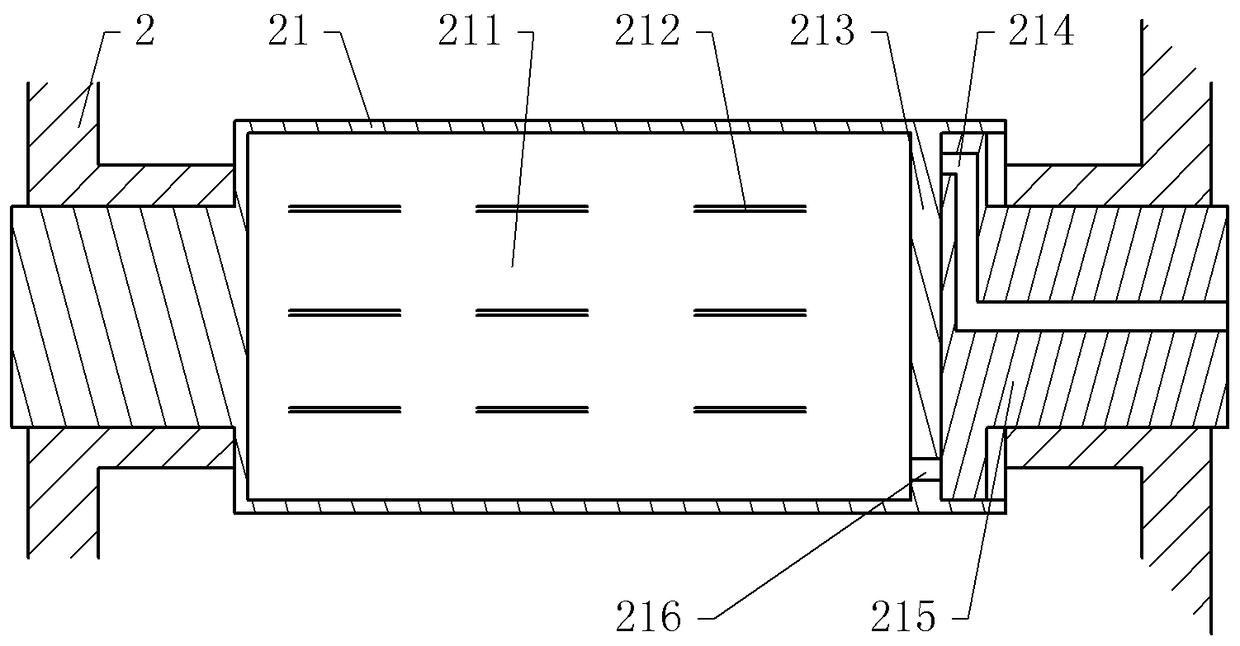

Labyrinth type oil-gas separation chamber with additionally mounted turbine

ActiveCN104131860AReduce the temperatureIncrease flow rateMachines/enginesCrankcase ventillationEngineering plasticCrankcase

The invention relates to a labyrinth type oil-gas separation chamber with an additionally mounted turbine. The labyrinth type oil-gas separation chamber comprises a labyrinth oil-gas separator, a pressure adjusting valve, a non-woven filter element and the turbine. The pressure adjusting valve is arranged on the wall of the labyrinth type oil-gas separation chamber, and mixed oil mist from a crankcase enters the labyrinth type oil-gas separation chamber through the pressure adjusting valve and a mixed oil mist inlet. The turbine is assembled at a free end of a camshaft, the nonwoven filter element capable of filtering oil and water in mixed gas is arranged in an inlet of the turbine, and an outlet of the turbine is connected with the labyrinth type oil-gas separation chamber through a connector. An indented baffle made of engineering plastics is arranged in the labyrinth type oil-gas separator. The temperature of flowing oil mist in a labyrinth is effectively decreased by rotation of the turbine, flow rate of the oil mist is increased, condensation speed of elaioplast is increased, and pressure at a gas outlet is increased.

Owner:HANGZHOU DIANZI UNIV

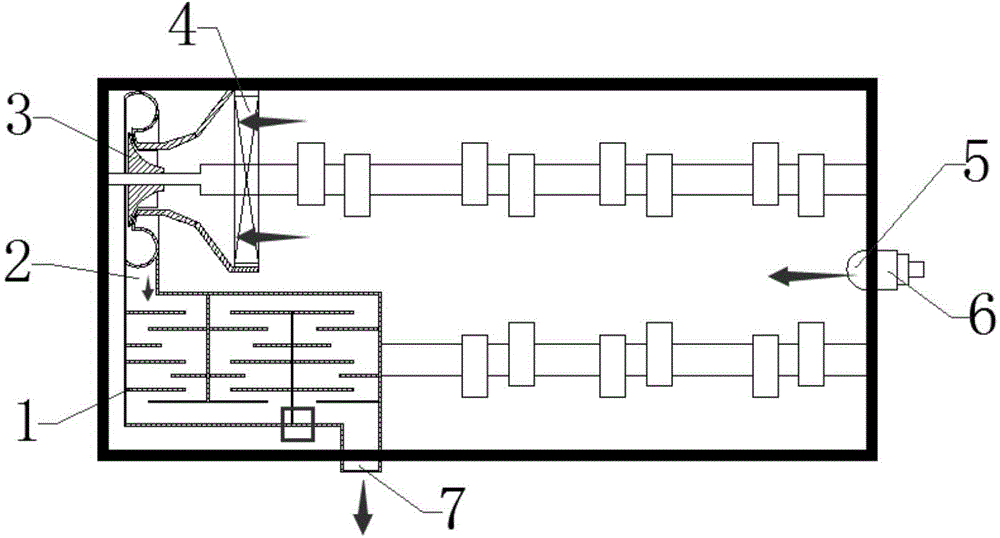

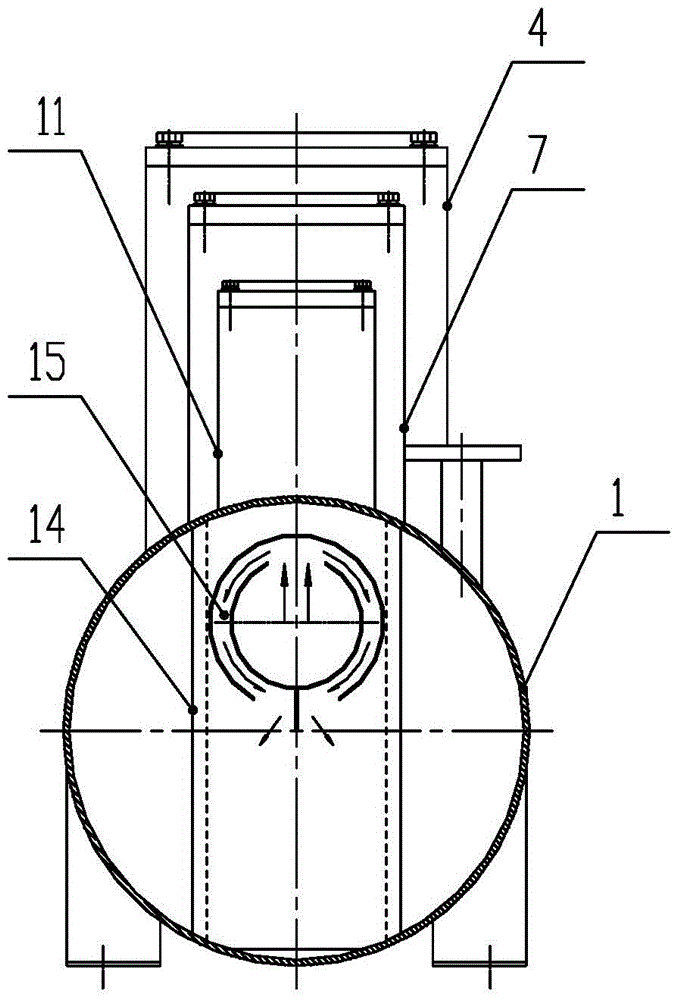

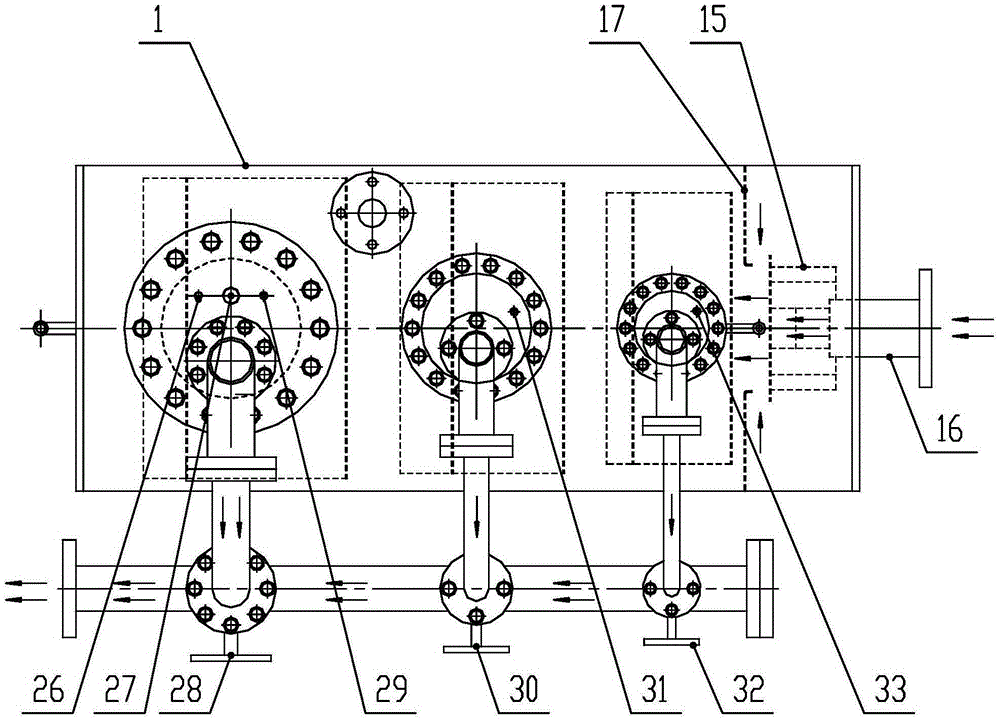

Oil and gas separator with adjustable flow and parallel multi-branches

ActiveCN105822558ASimple structureGood degreasing effectRotary/oscillating piston pump componentsLiquid fuel engine componentsFiltrationEngineering

The invention relates to an oil and gas separator with adjustable flow and parallel multi-branches. A feeding pipe transporting the gas-oil mixture, an oil outlet pipe connected with an oil pump and an exhaust pipe system discharging gas separation material are disposed on a cylindrical shell. The cylindrical shell is provided with a centrifuging oil-removing unit, a labyrinth-type oil-removing unit and at least two columns of filtering oil-removing units in order, and the outlets of the filtering oil-removing units are connected with the exhaust pipe system. A plurality of filtering oil-removing units have different sizes. The exhaust pipe system comprises a plurality of exhaust pipes corresponding with the filtering oil-removing units one-to-one, and each exhaust pipe is provided with a minimal pressure valve and a valve used for opening and closing the pipeline at the position near the outlet of each filtering oil-removing unit. The oil and gas separator integrates the effect of filtration, gravity and centrifugal force, and the technical requirement of the test system with wide range, high efficiency and low cost can be solved by means of different combination mode of parallel-type controllable exhaust pipe system, so that the functions of cyclic utilization of the lubricating oil and performance test of multi-standard compressor can be realized efficiently and reliably.

Owner:HEFEI GENERAL MACHINERY RES INST

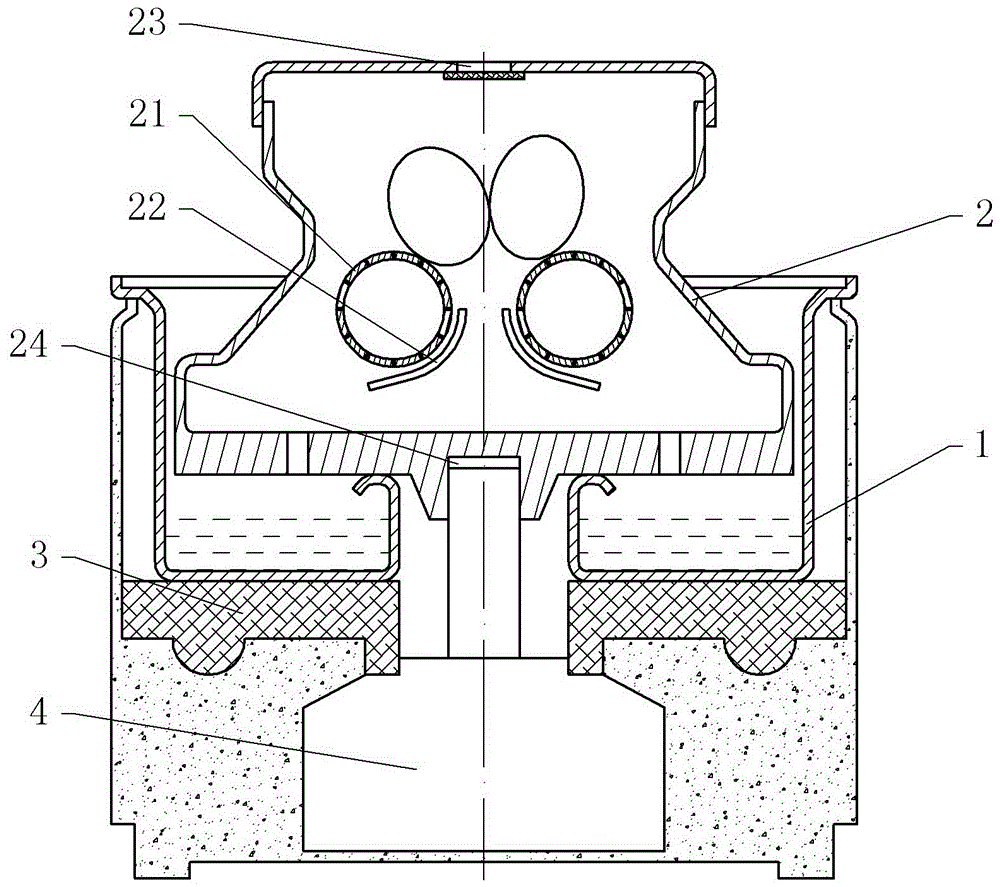

Boiled egg shelling apparatus

InactiveCN106580141AReduce destructive powerFacilitate depositionEgg-cookersEngineeringAir compressor

The invention discloses a boiled egg shelling apparatus and relates to a food processing apparatus. The boiled egg shelling apparatus comprises a shell breaker; the shell breaker is a container and is cylindrical in shape; a central axis hole is formed in the bottom surface of the shell breaker and connected with a power apparatus; the power apparatus drives the shell breaker to rotate; a pair of shelling shafts are arranged in the shell breaker; a gap between the shelling shafts is smaller than the outer diameter of an egg; the pair of shelling shafts rotate in the opposite direction at the same speed; a water container is arranged below the shell breaker; the lower part of the water container clings to an electric heating plate; the motion directions of the close ends of the shelling shafts are both upward; cavities are formed in the shelling shafts; a plurality of air holes connected with each cavity are formed in the surface of the shelling shaft; an included angle of 30-90 degrees is formed between each air hole and the radial direction of each cavity; an air compressor is arranged and connected with the cavities; an air outlet is formed in the top of the shell breaker; and arc-shaped baffles are arranged at the lower parts of the shelling shafts. According to the apparatus, automatic shelling can be realized and the egg can be prevented from being scratched.

Owner:CHONGQING SHUNTAI FOOD

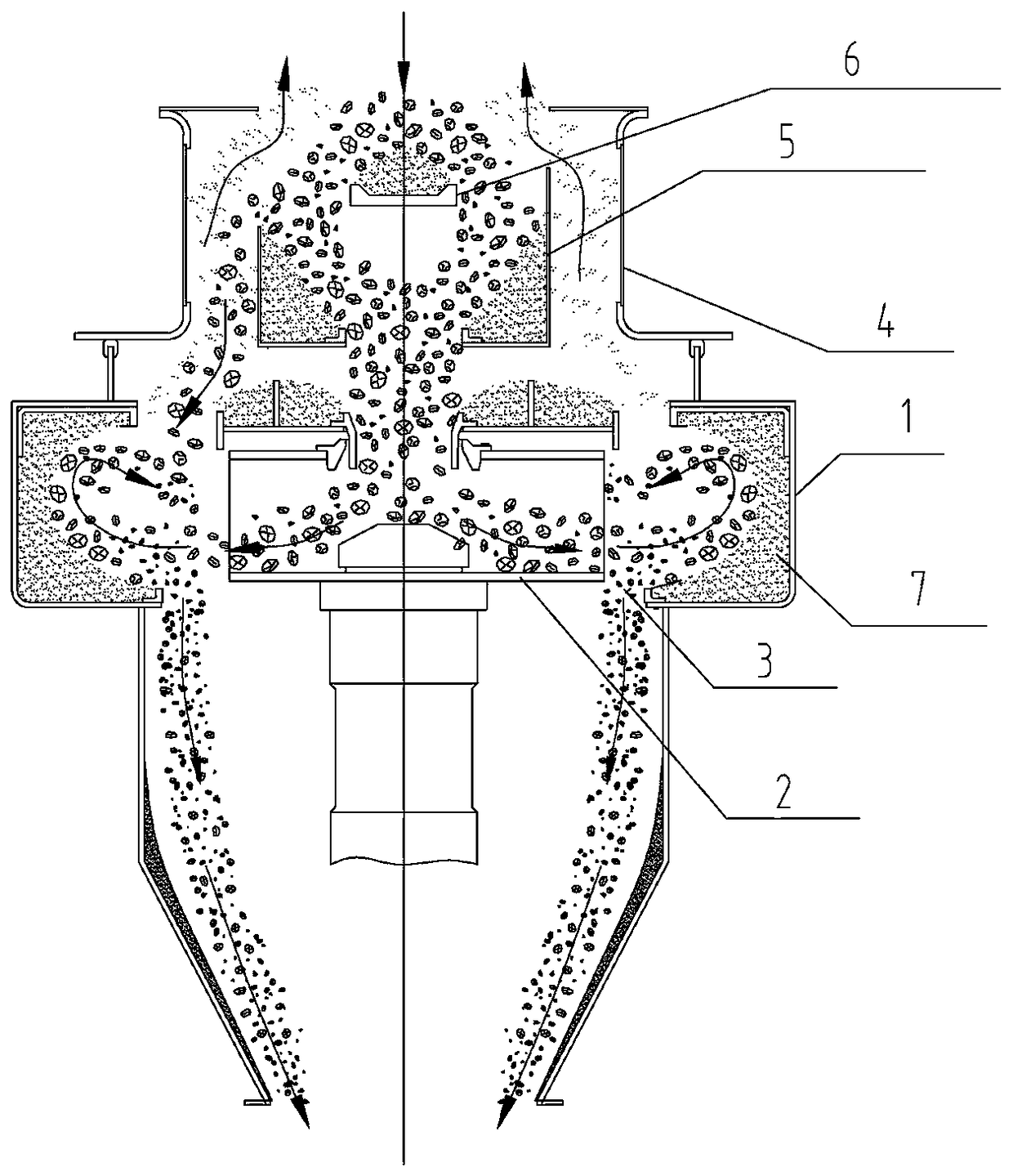

Vertical shaft impact crusher with multiple shaping functions

The invention relates to building material crushing devices, in particular to a vertical shaft impact crusher with multiple shaping functions. The vertical shaft impact crusher is simple in structureand reasonable in design and comprises a crushing chamber and a rotor, wherein a crushing cavity is formed in the crushing chamber, and the rotor is rotatably arranged in the crushing chamber througha spindle. A discharge port is arranged at the bottom of the crushing cavity, a dispensing chamber is arranged at the top of the crushing chamber, a dispensing inner cylinder is arranged in the dispensing chamber, and a bulk tray is arranged at the center of an opening of the dispensing inner cylinder. The side wall of the dispensing inner cylinder is heightened, the top of the side wall of the dispensing inner cylinder is higher than the height of the bulk tray, an outlet at the bottom of the dispensing inner cylinder corresponds to an inlet of the rotor, the radius of the rotor is increased,and the distance between the outer side wall of the rotor and the inner wall of the crushing cavity is increased. The circumference of the rotor is provided with grinding plates evenly distributed, rotor ejection ports are left between the grinding plates, and the ratio of the surface area of the sides of the grinding plates to the rotating surface area of the rotor is 4-7:10. The collision probability of a material striking back and the rotor is increased, and the shaping of the ridge corners of the material is improved.

Owner:HENAN LIMING HEAVY IND SCI & TECH

Labyrinth oil and gas separation chamber with turbine installed

ActiveCN104131860BReduce the temperatureIncrease flow rateMachines/enginesCrankcase ventillationOil separationCrankcase

The invention relates to a labyrinth oil-gas separation chamber equipped with a turbine. The invention includes a labyrinth oil-gas separator, a pressure regulating valve, a non-woven fabric filter core and a turbine. The pressure regulating valve is arranged on the wall of the labyrinth oil-gas separation chamber, and the mixed oil mist from the crankcase enters the labyrinth oil-gas separation chamber through the pressure regulating valve and the mixed oil mist inlet. The turbine is assembled on the free end of the camshaft, and the inlet of the turbine is provided with a non-woven filter element which can filter the water and oil in the mixed gas; the outlet of the turbine is connected with a labyrinth oil-air separator through an interface. A toothed baffle made of engineering plastics is arranged inside the labyrinth oil-gas separator. The rotation of the turbine in the invention effectively reduces the temperature of the flowing oil mist in the labyrinth, increases the flow rate of the oil mist, increases the condensation rate of the oil particles, and increases the pressure of the air outlet.

Owner:HANGZHOU DIANZI UNIV

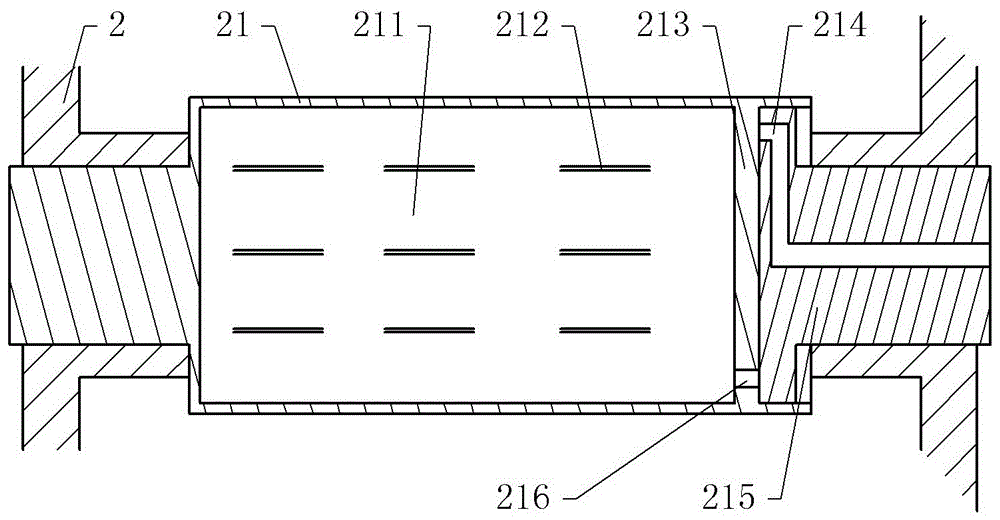

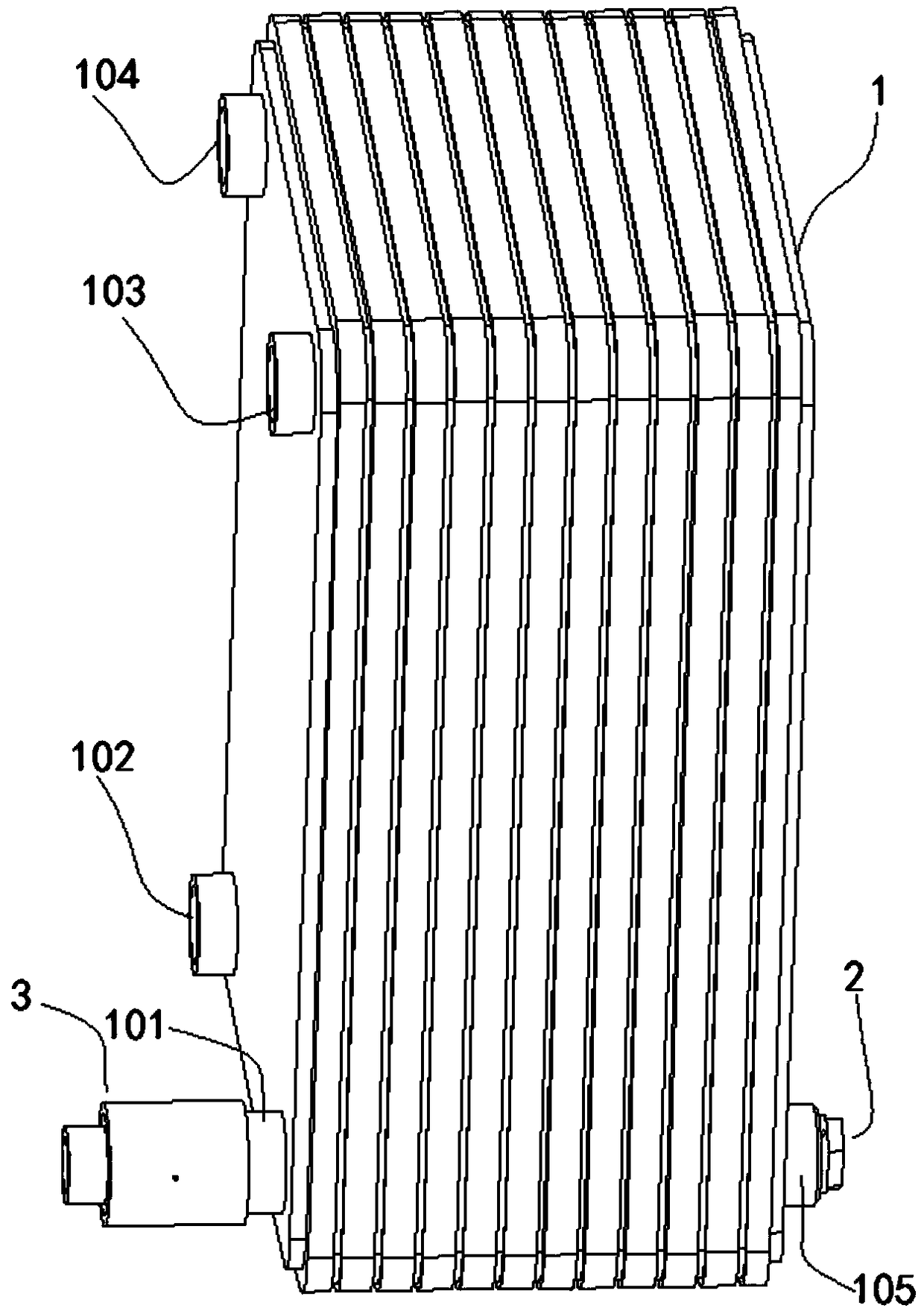

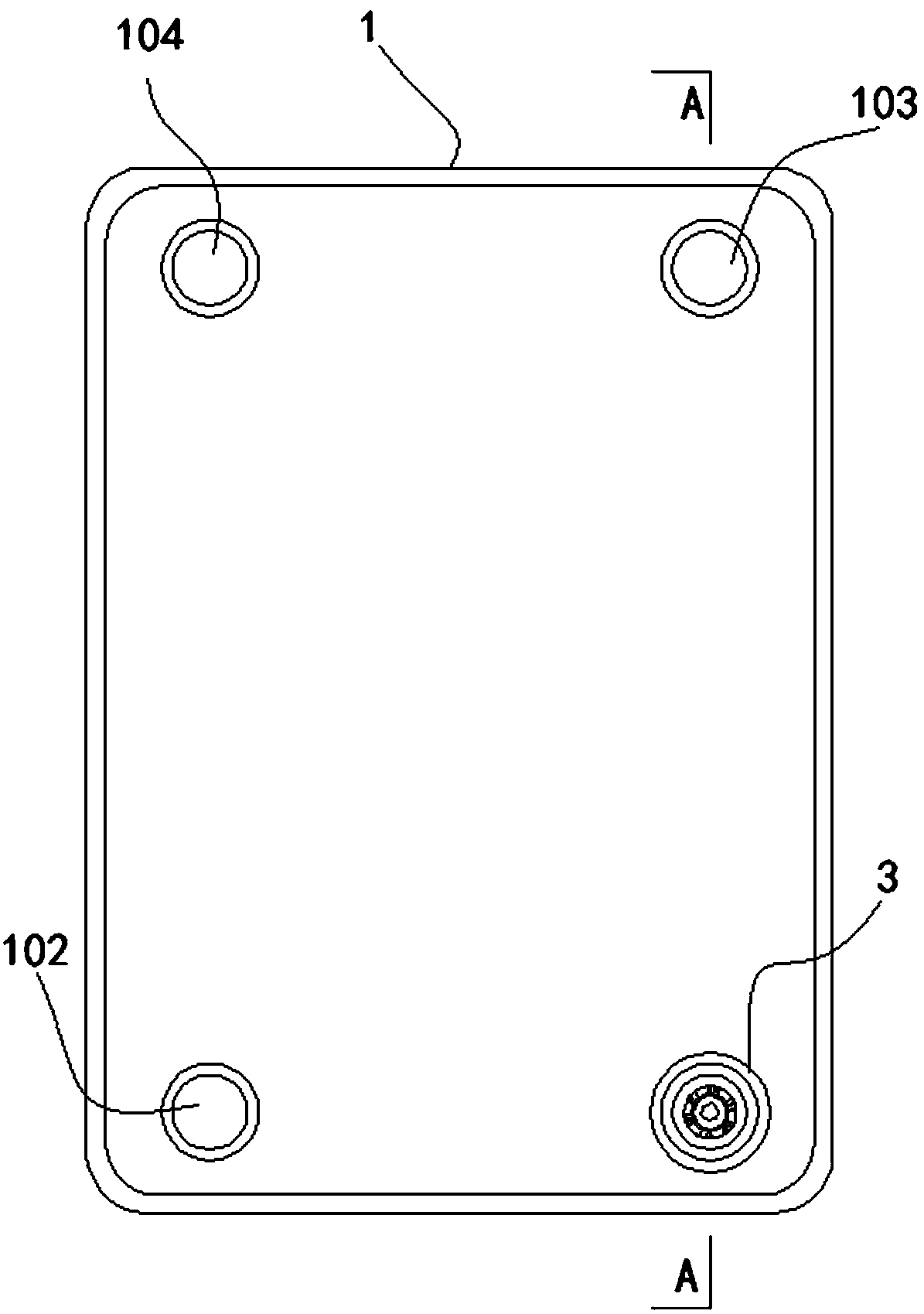

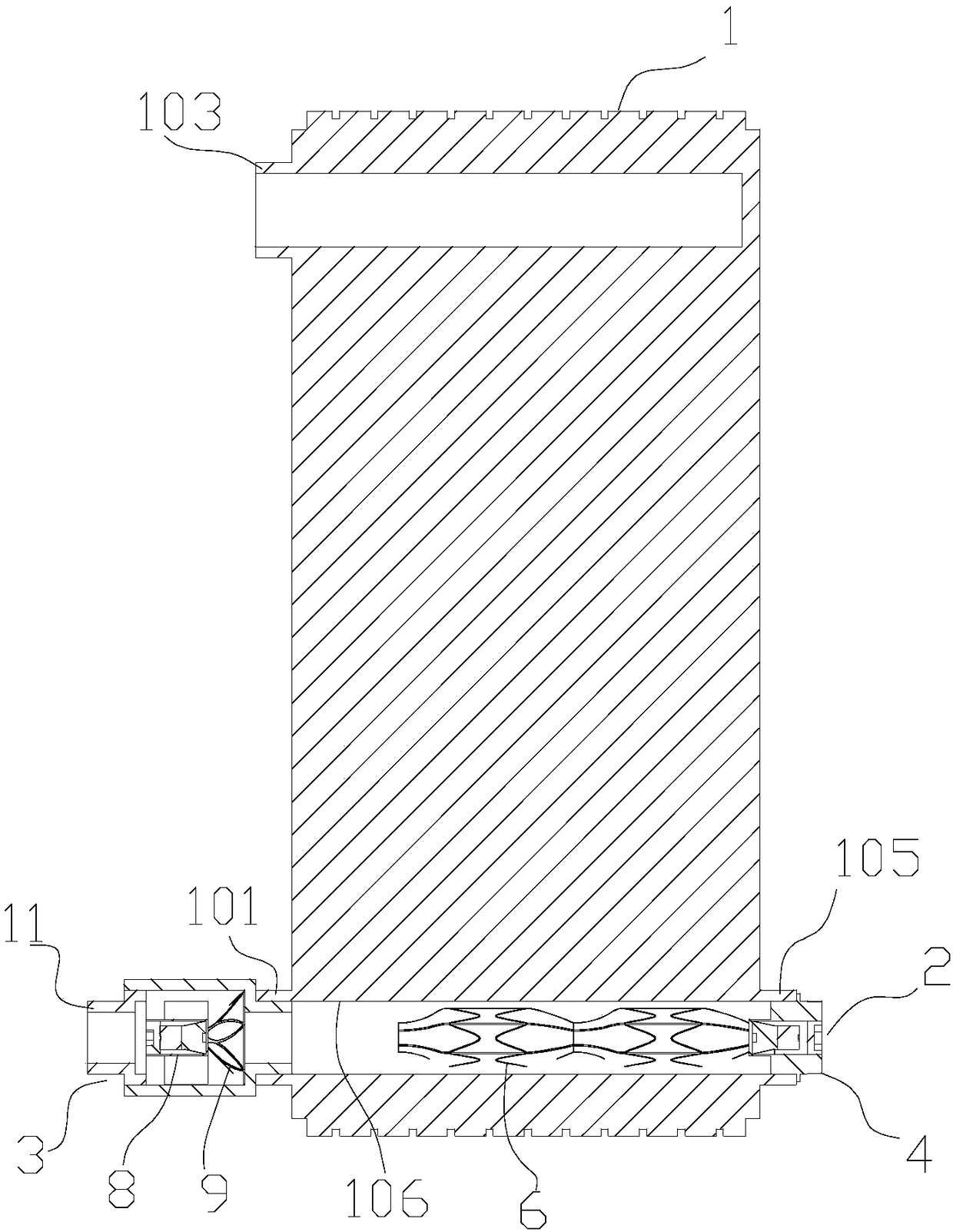

Anti-freezing plate heat exchanger

PendingCN108955320APrevent freezingContribute to radiationVehicle heating/cooling devicesIce removalInlet channelAnti freezing

The invention discloses an anti-freezing plate heat exchanger. The anti-freezing plate heat exchanger comprises a plate heat exchanger body (1). The plate heat exchanger body (1) is provided with a liquid inlet channel and a liquid outlet channel (106). A heat exchange medium gets into the plate heat exchanger body (1) to conduct heat exchange with a cooling medium to be cooled and then is discharged from the liquid outlet channel. The anti-freezing plate heat exchanger is characterized in that a fixed clamping plate is provided with a front-end port (105) communicating with the liquid outletchannel (106); and the front-end port (105) is in threaded connection with an oscillation assembly (2). The fixed clamping plate is provided with the front-end port for the liquid outlet channel of the plate heat exchanger. Meanwhile, a blocking assembly is mounted at the front-end port. Ultrasonic waves are radiated into the liquid outlet channel through an oscillation metal net frame. On one hand, frozen crystals nucleus are prevented from being formed in the liquid outlet channel; on the other hand, the crystal nucleus condensed on the plate heat exchanger around the liquid outlet channel are made to fall off. The two processes are conducted simultaneously, and occurrence of freezing is effectively avoided.

Owner:江苏远卓设备制造有限公司

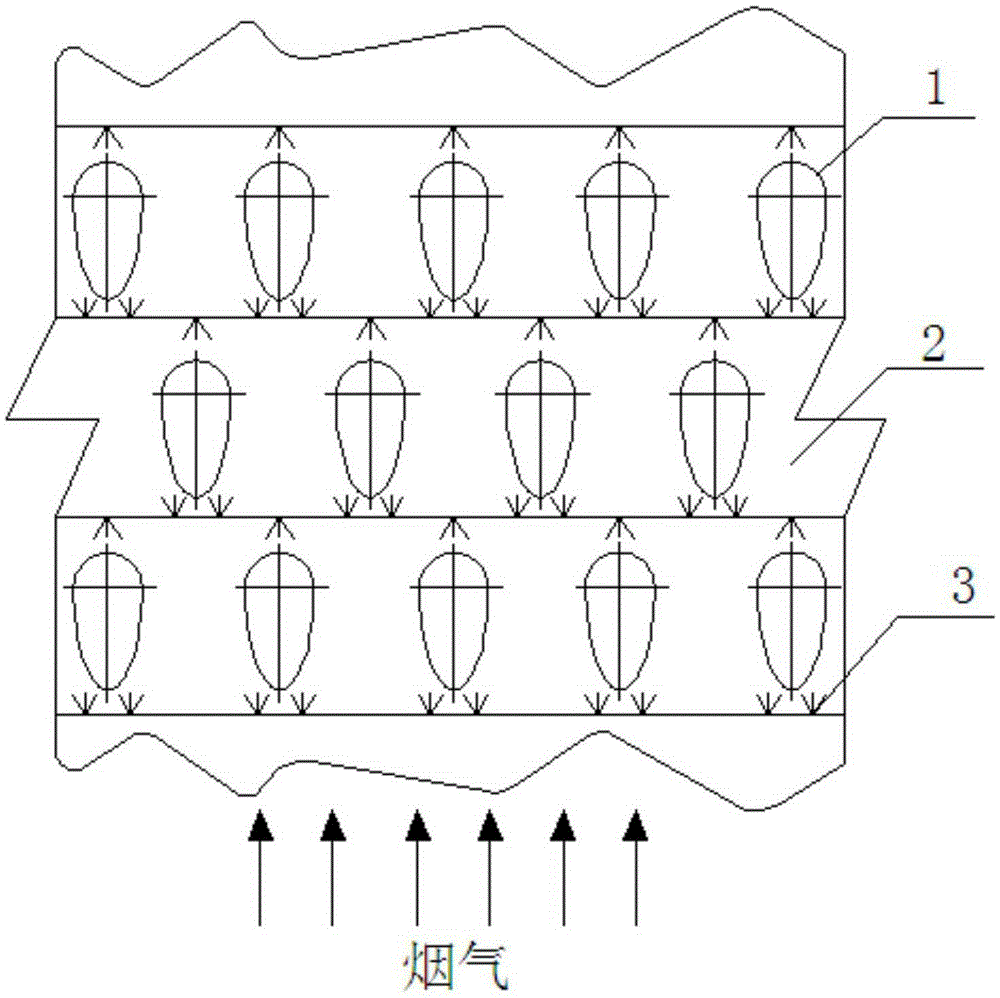

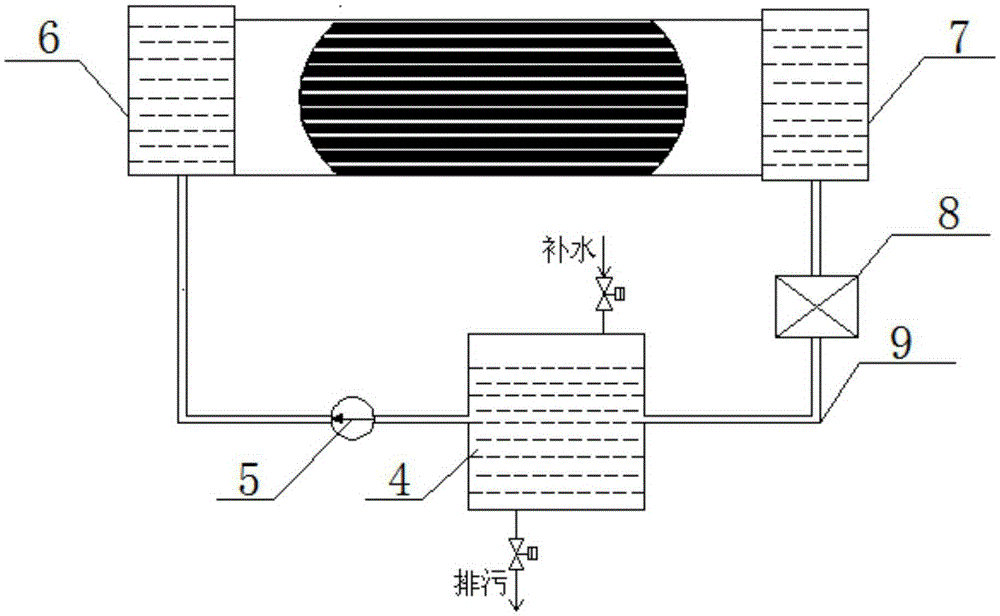

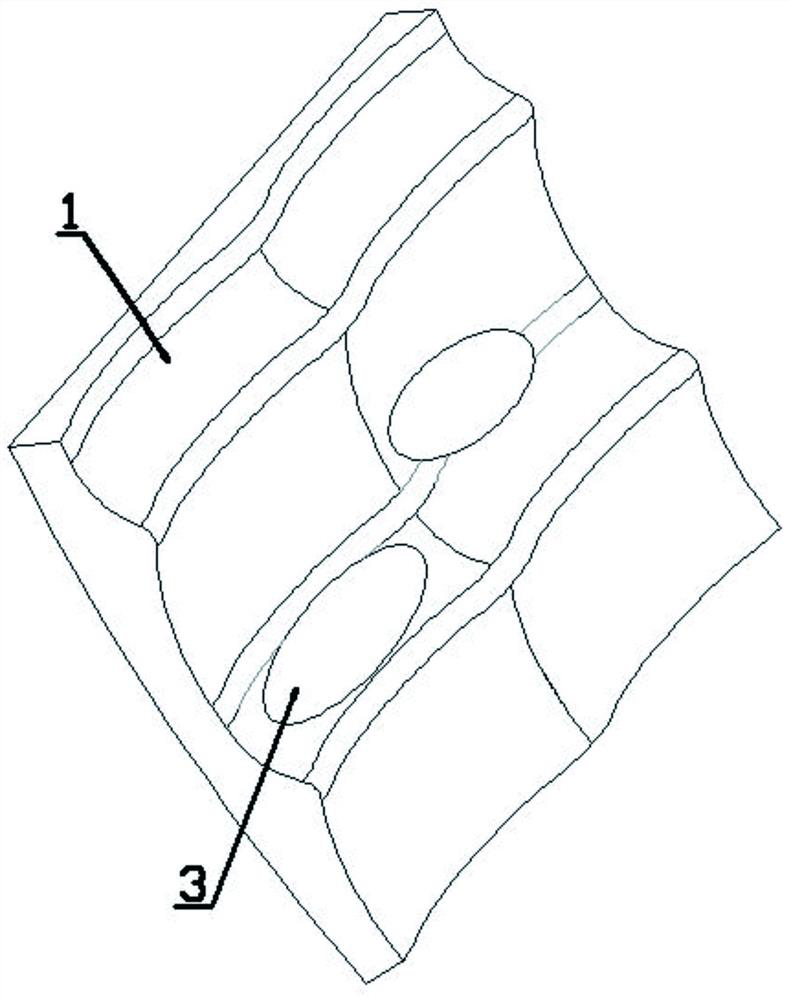

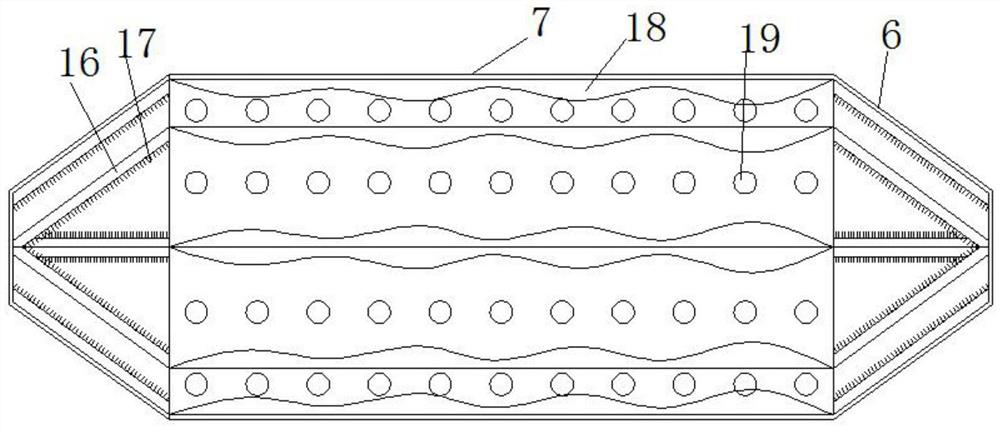

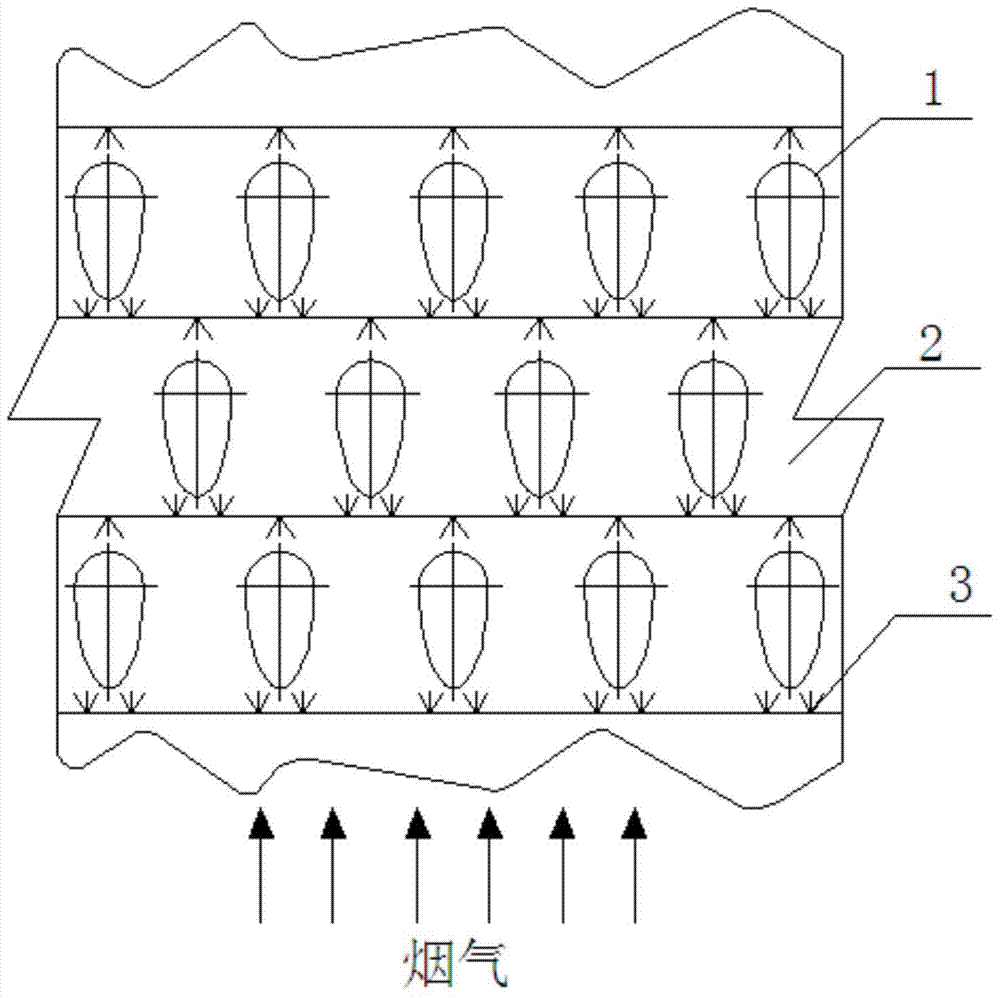

Low-resistance forced water cooling drip pipe type demister and demisting method

InactiveCN105289179AEfficient condensationIncrease contact areaCombination devicesVapor condensationEngineeringWater circulation

The invention discloses a low-resistance forced water cooling drip pipe type demister and demisting method. The demister comprises a drip pipe bundle demisting system arranged on the top of a desulfuration tower and a forced cooling water circulation system used for introducing cooling water into a pipe bundle. The drip pipe bundle demisting system comprises multiple layers of pipe row arrays with water-drop-shaped sections and multiple nozzles achieving upward and downward flushing, wherein the pipe row arrays are arranged in a pipe box in a lattice and staggered mode, and the nozzles are arranged between pipe bundles in a layered and array mode. The forced cooling water circulation system comprises a water storage box, a circulation pump, a water inlet box, a water outlet box and an air cooler. The water storage box is sequentially connected with the circulation pump, the water inlet box, the water outlet box and the air cooler through a circulation pipeline. The demister combines inertial separation with condensation separation, has the significant effect on removing fine particles, has the advantages of being high in demisting and dust removal efficiency, high in cooling efficiency and low in resistance, saving water and the like, and can effectively reduce gypsum rain produced after flue gas desulfurization.

Owner:SOUTH CHINA UNIV OF TECH

Underground garage polluted air decomposition and purification device

InactiveCN108144397AEasy to cleanLess harmful gasCombination devicesGas treatmentDecompositionEngineering

The invention discloses an underground garage polluted air decomposition and purification device. The underground garage polluted air decomposition and purification device comprises an air suction inlet (1), an air pipe (2) and a purification cavity (3), wherein the air suction inlet (1) is arranged at one end of the air pipe (2), and the other end of the air pipe (2) is communicated with the purification cavity (3); the lower end surface of the middle section of the air pipe (2) is provided with a dust collecting groove (4), one end of the dust collecting groove (4) which is away from the airsuction inlet (1) is provided with an internal separating sheet (5), and a gap is formed between the upper end edge of the internal separating sheet (5) and the inner wall of the air pipe (2). The underground garage polluted air decomposition and purification device has the advantages of being capable of overcoming the shortcomings in the prior art and meanwhile being reasonable and novel in structural design.

Owner:成都柒瑰科技有限公司

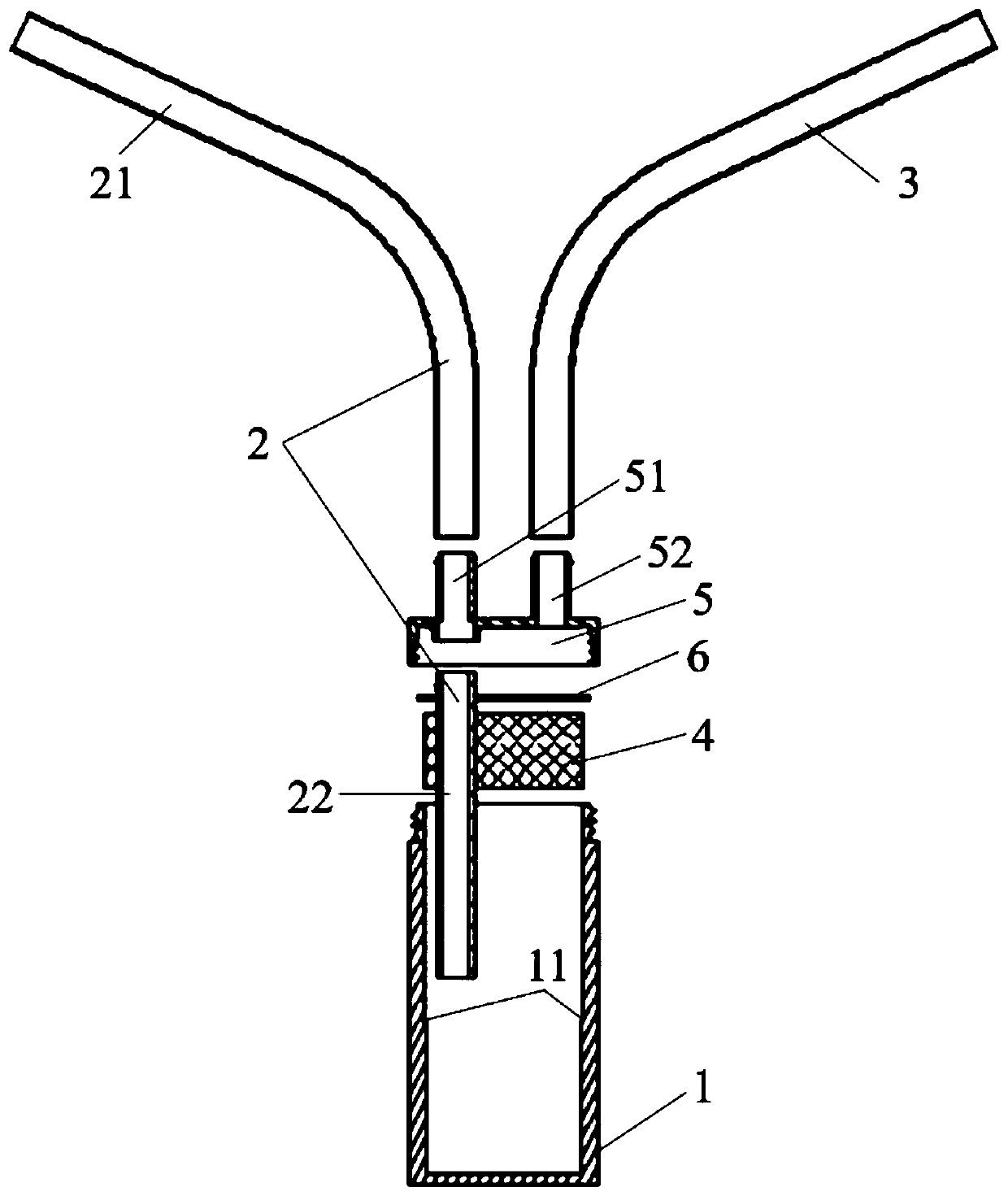

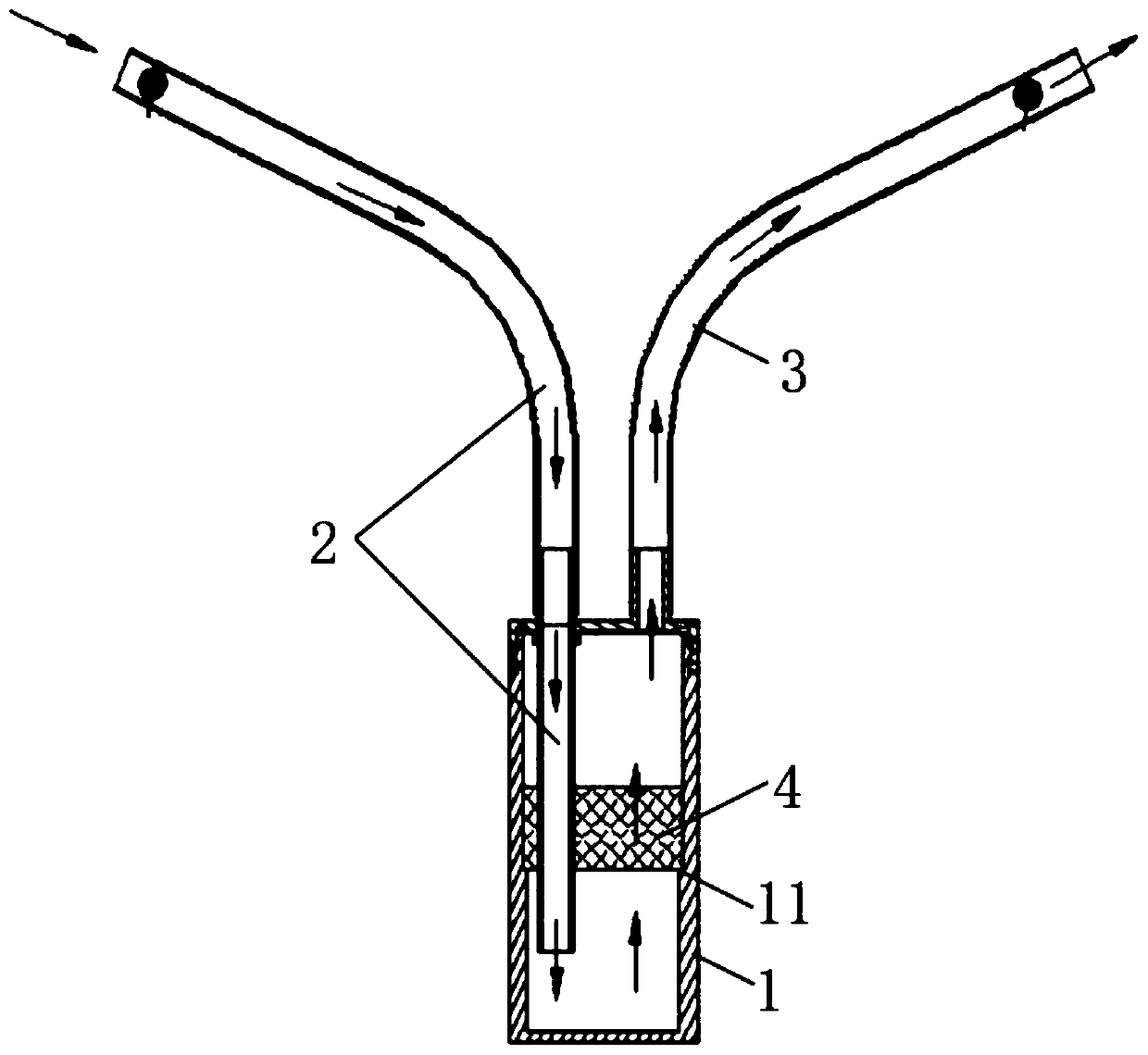

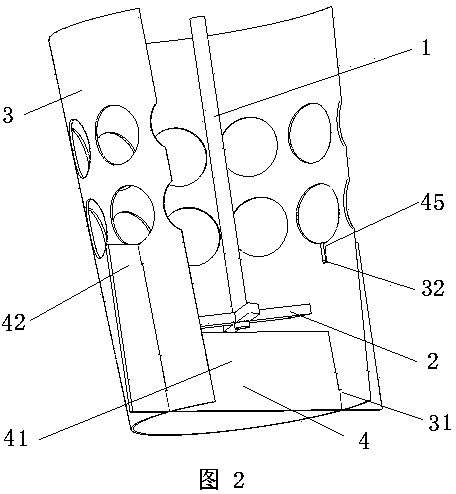

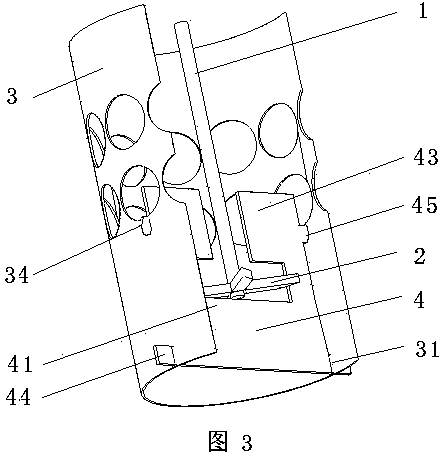

Oil-gas separation device for testing oil-gas separation efficiency of engine

InactiveCN109752189AIncreased chance of impactImprove accuracyInternal-combustion engine testingOil separationEngineering

The invention discloses an oil-gas separation device for testing the oil-gas separation efficiency of an engine. The device comprises an oil separation bottle, a gas inlet pipe, a gas outlet pipe andsponge; the sponge is arranged in the oil separation bottle; the gas inlet pipe is inserted into the oil separation bottle and penetrates through the sponge; and the gas outlet pipe is inserted into the oil separation bottle and is located above the sponge. A cavity of the oil separation bottle is divided into an upper layer and a lower layer through the sponge; the gas inlet pipe passes through the sponge to penetrate into the lower layer; gas introduced into the oil separation bottle through the gas inlet pipe directly enters the lower part of the sponge; a gas inlet of the gas outlet pipe is located at the upper layer, namely, above the sponge; and the gas introduced into the oil separation bottle needs to pass through the sponge and can be discharged through the gas outlet pipe. According to the oil-gas separation device, oil drops in the gas are adhered through the sponge, and the impact probability of the oil drops is greatly improved compared with a traditional oil separation bottle, so that the accuracy of testing the oil-gas separation efficiency of the engine is improved. The invention further provides a method for testing the oil-gas separation efficiency of the engine.

Owner:YIBIN COWIN AUTO CO LTD

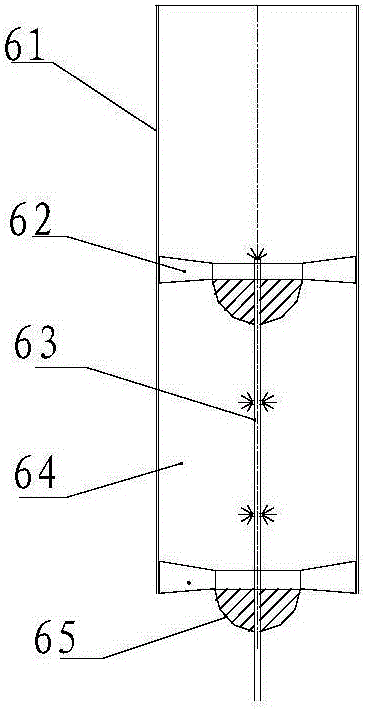

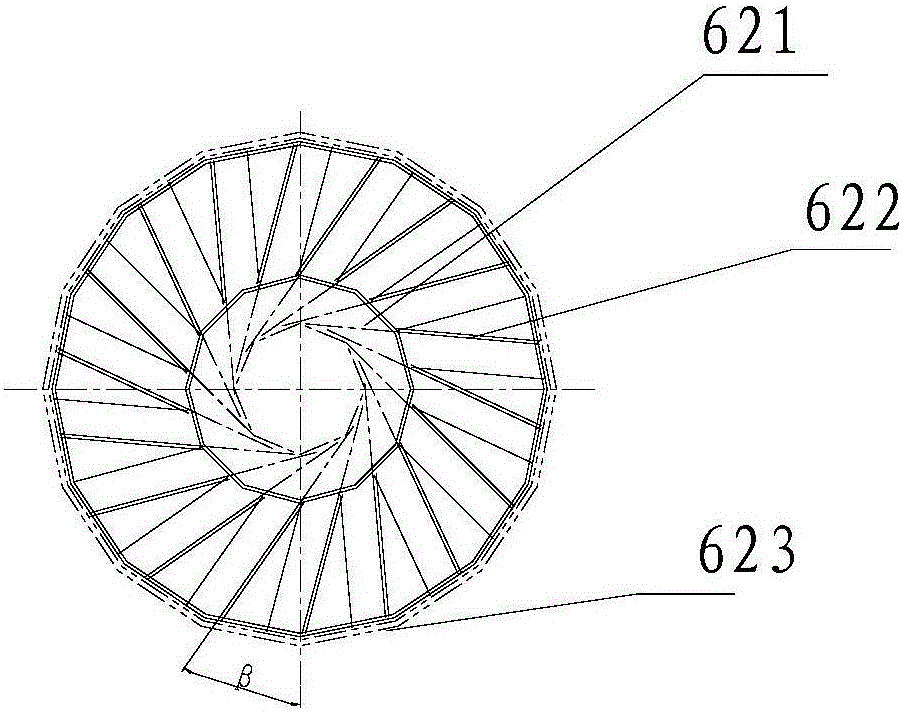

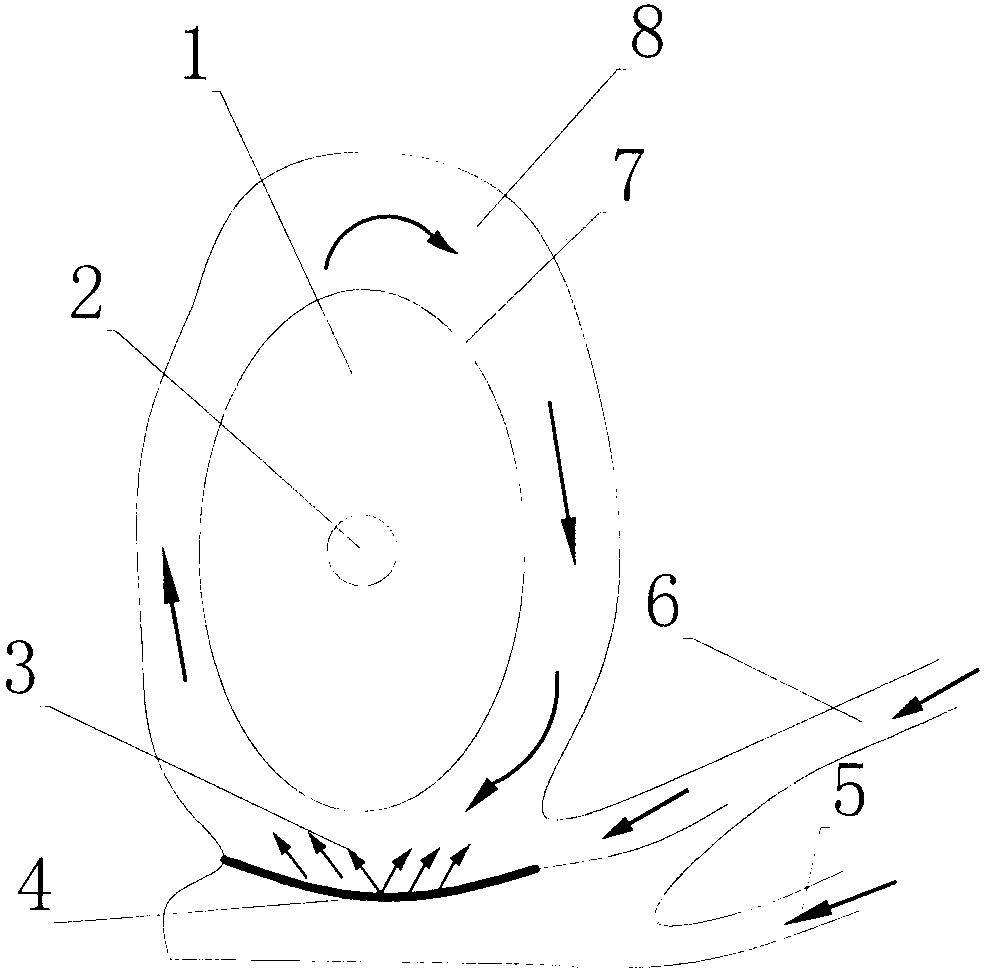

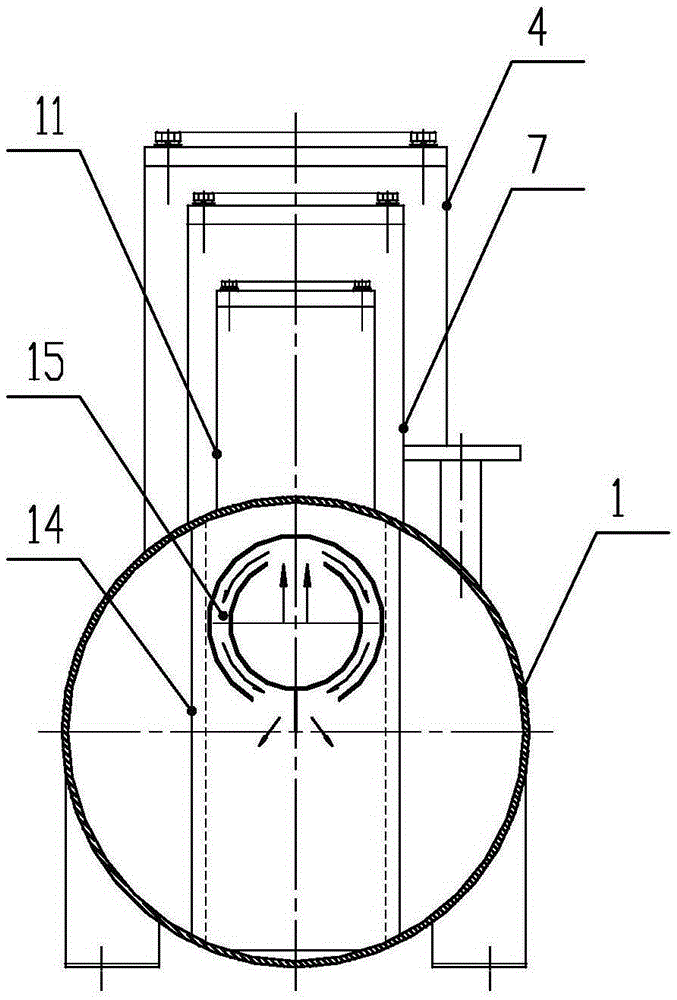

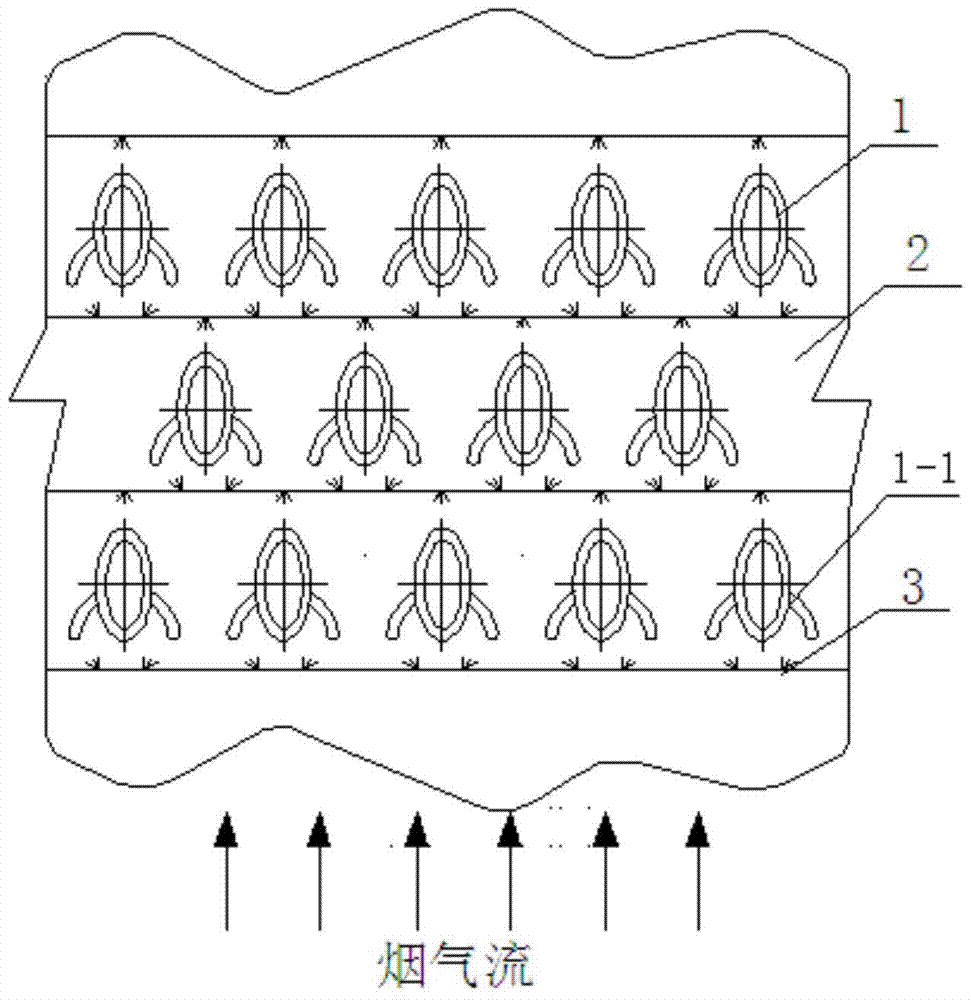

Demisting method and device based on rotary screen drum

ActiveCN112717614AIncreased disorderImprove the ability of dust removal and fog removalCombination devicesDispersed particle filtrationThermodynamicsSurface cleaning

The invention discloses a demisting method and a demisting device based on a rotary screen drum. The demisting device comprises a screen drum demisting system at the top of a desulfurizing tower and an automatic rotation control system for controlling the rotation speed of a screen drum demister. Flue gas flow is entrained and sucked into the screen drum demister by the rotating screen drum demister, and the demisting and dedusting efficiency of the flue gas is effectively improved under the dual effects of inertia separation and centrifugal separation. When the operation condition of the desulfurization system changes, the rotating speed of the worm gear mechanism is adjusted to adjust the rotating angle of the screen drum demister to adapt to different smoke flowing conditions. And the screen drum demister is flushed through the annular flushing water demisting system and the scraper. The device combines inertia separation, centrifugal separation and coagulation dust removal, adopts a worm gear mechanism to realize surface cleaning of the screen drum under all working conditions, has the characteristics of high demisting and dust removal efficiency, small flue gas flow resistance, small flushing water amount, no dead angle, low energy consumption, wide working condition adaptability and the like, and can effectively reduce the formation of gypsum rain.

Owner:SOUTH CHINA UNIV OF TECH +1

Soybean milk machine provided with turbulent flow tube

InactiveCN103371229AImprove crushing effectGood crushing effectBeverage vesselsMilk substitutesThin walledFlow sheet

The invention provides a soybean milk machine provided with a turbulent flow tube. The soybean milk machine comprises a cutter shaft mounted on a machine head, a rotary cutter fixed on the cutter shaft and the turbulent flow tube. The cutter is arranged in the turbulent flow tube; the cutter and the turbulent flow tube stretch into foods to be matched; channels for the foods to get in and out are formed at the two ends of the turbulent flow tube. The turbulent flow tube comprises a thin-wall pipe and a turbulent flow sheet which are detachably embedded and assembled. The crushing effect of the soybean milk machine can be improved.

Owner:陈曙东

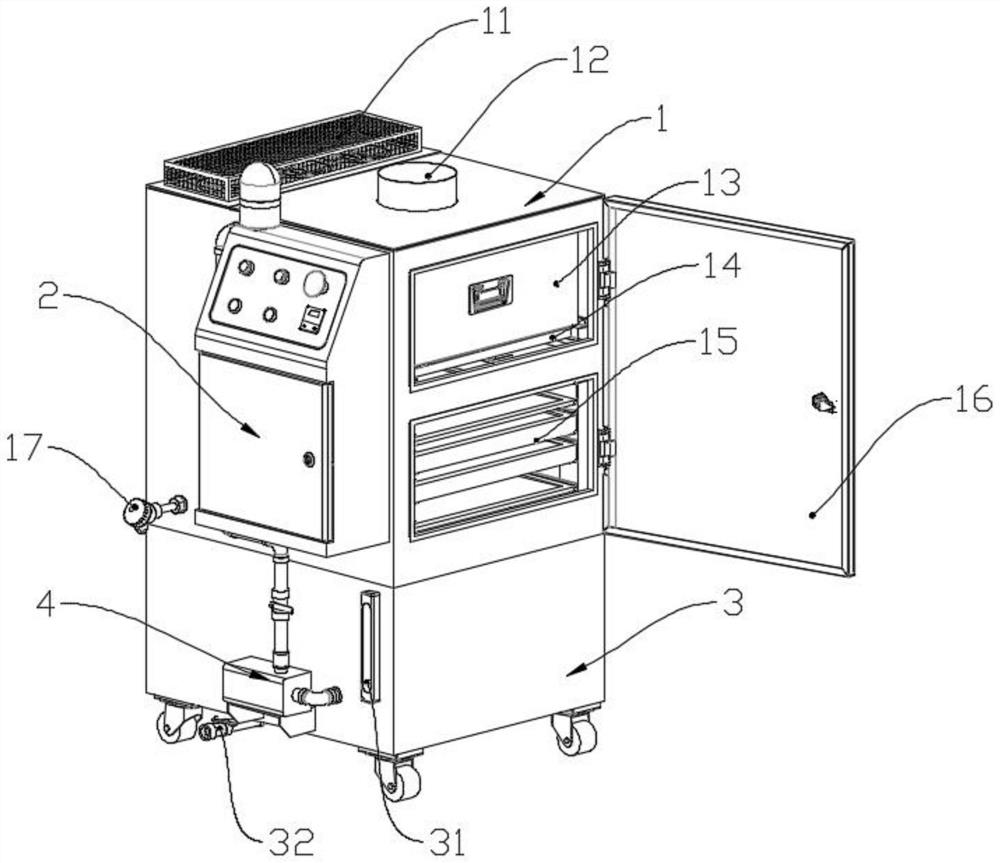

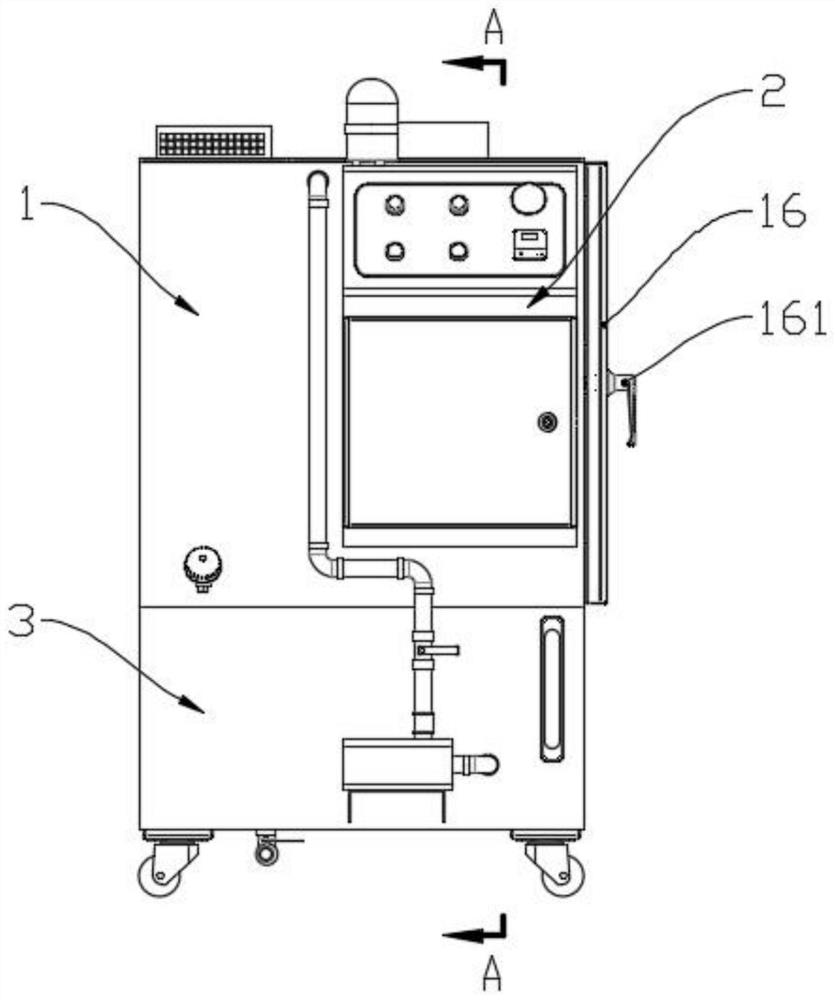

Welding working condition purification fan

PendingCN113738673AReduce the temperatureIncreased chance of impactDispersed particle filtrationPump componentsTemperature controlEngineering

A welding working condition purification fan comprises a machine box, a water tank, a spraying assembly and an electric cabinet. The electric cabinet is fixedly connected to one side of the machine box, an air inlet pipe is arranged at the top of the machine box, a fan body communicating with the interior of the machine box is fixedly connected to one side of the air inlet pipe, and a cooling box is fixedly connected to the upper layer of the interior of the machine box. A particle collecting box is arranged at the bottom of the cooling box, a filter plate set is arranged at the bottom of the particle collecting box, the water tank is fixedly connected to the bottom of the machine box, the spraying assembly is fixedly connected to one side of the machine box, and the water suction end of the spraying assembly extends into the water tank. The water outlet end of the spraying assembly extends into the machine box and is arranged above the cooling box, and a machine box water outlet valve is arranged at the bottom of one side of the machine box. The welding working condition purification fan is provided with the spraying assembly, when a temperature control display instrument detects that the temperature in the machine box is too high, the spraying assembly can be started to perform cooling and fire extinguishing on the inner part of the machine box, and fire disasters are prevented.

Owner:SUZHOU DONGSHAN PRECISION MANUFACTURING CO LTD

Grading method of ore ball mill

InactiveCN112934380AIncrease contact areaImprove crushing effectGrain treatmentsEngineeringBall mill

The invention relates to a grading method of an ore ball mill. The purposes of improving the collision probability of grinding balls and increasing the contact surface of the grinding balls and a lining plate are achieved. The proportion of the total convex surface area and concave surface area of the grinding balls and the lining plate is used as a grading basis, the proportion number of each grinding ball can be accurately calculated by solving an equation set, the total convex surface area and the total concave surface area of the lining plate and the grinding ball participating in ore grinding work are approximately equal, and the probability of convex-concave matching collision between the lining plate and the grinding balls is improved to the greatest extent, so that the comprehensive ore grinding efficiency of the ball mill is greatly improved. The grading method of the ore ball mill is suitable for grading of two-stage grinding balls, and is suitable for grading of multi-stage grinding balls. Besides, the crushing performance and the grinding performance of the ball mill are balanced, the ball mill does not need to be provided with a multi-bin structure, a through bin structure with a simple structure is adopted, so that the swelling caused by non-uniform capacity of each bin is avoided, the grading of the grinding balls is more reasonable, and the operation is easier.

Owner:栾川县金鼎矿业有限公司

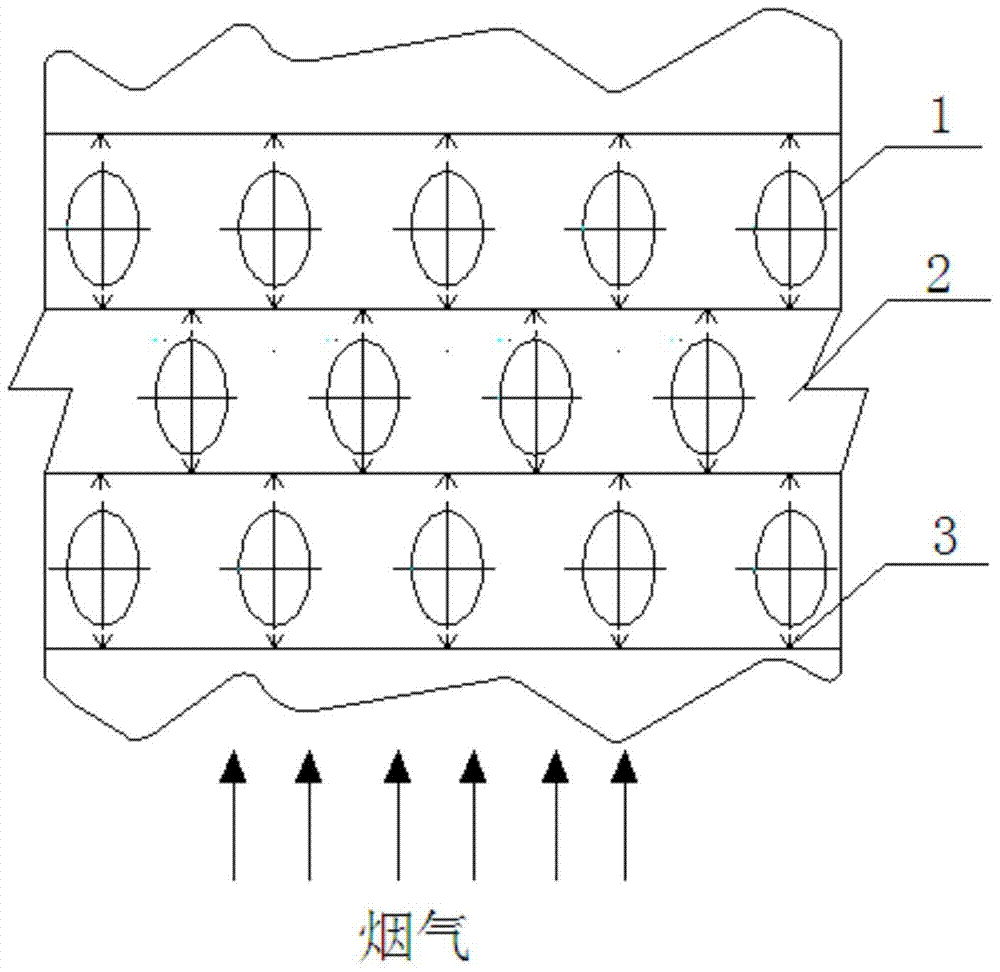

An integrated device and process for flue gas wet desulfurization and dust removal

ActiveCN106582248BLow air resistanceEffective diversionCombination devicesGas treatmentFlue gasEngineering

The invention discloses a flue gas wet desulfurization and dust removal integrated device and process. After the original flue gas enters the absorption tower, it passes through the tray layer, the spray layer, the ultra-fine atomization cooling area, and the swirl demisting layer, and then flows from the The outlet of the absorption tower is discharged. After the tray layer rectifies the flue gas entering the absorption tower, the flue gas rises at a uniform flow rate on the section of the absorption tower after being rectified by the tray layer. 2 After being absorbed and removed, the saturated flue gas with fine slurry droplets and dust after desulfurization is cooled by atomization and spraying. The flue gas carries the fine mist droplets and continues to rise through the swirling flow, impact enrichment and removal, and the clean flue gas is discharged. The present invention can not only improve SO 2 Removal efficiency, but also can significantly improve the dust removal efficiency of the absorption tower; realize ultra-low emission of flue gas.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

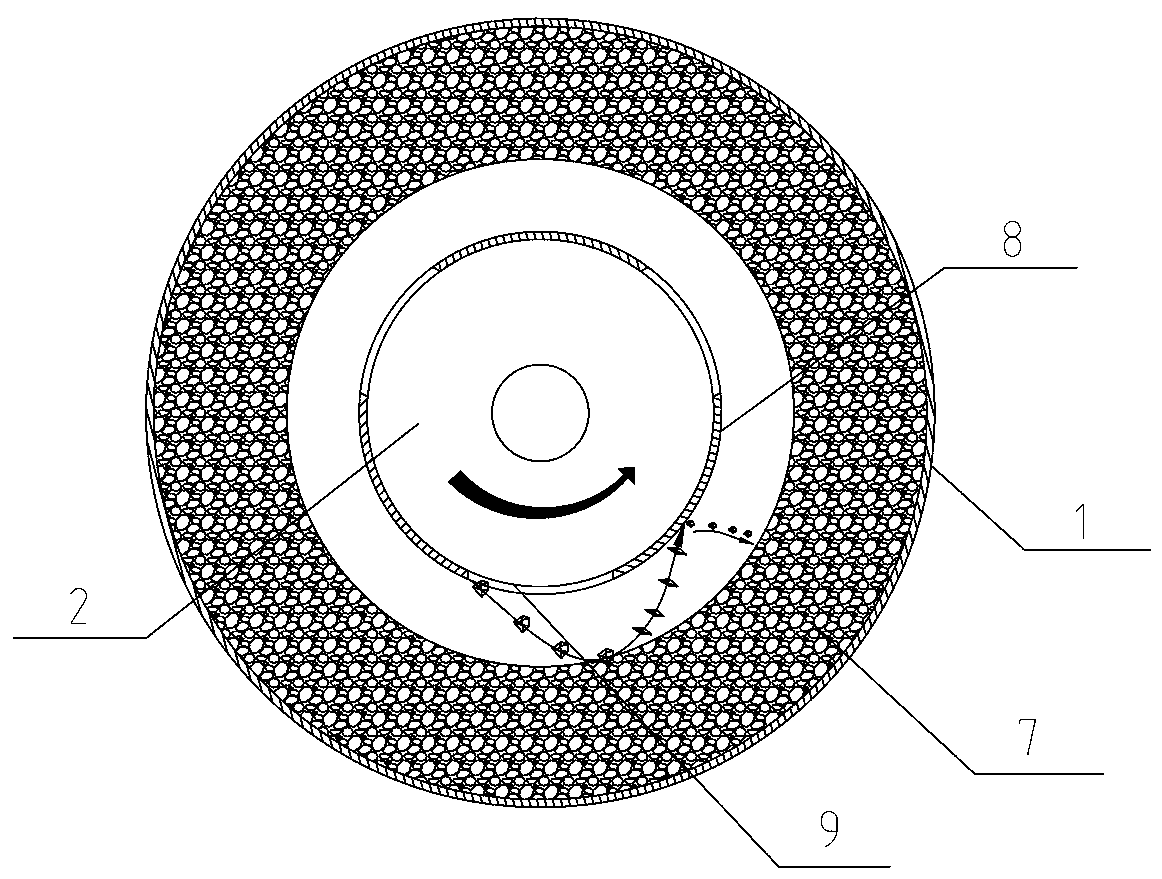

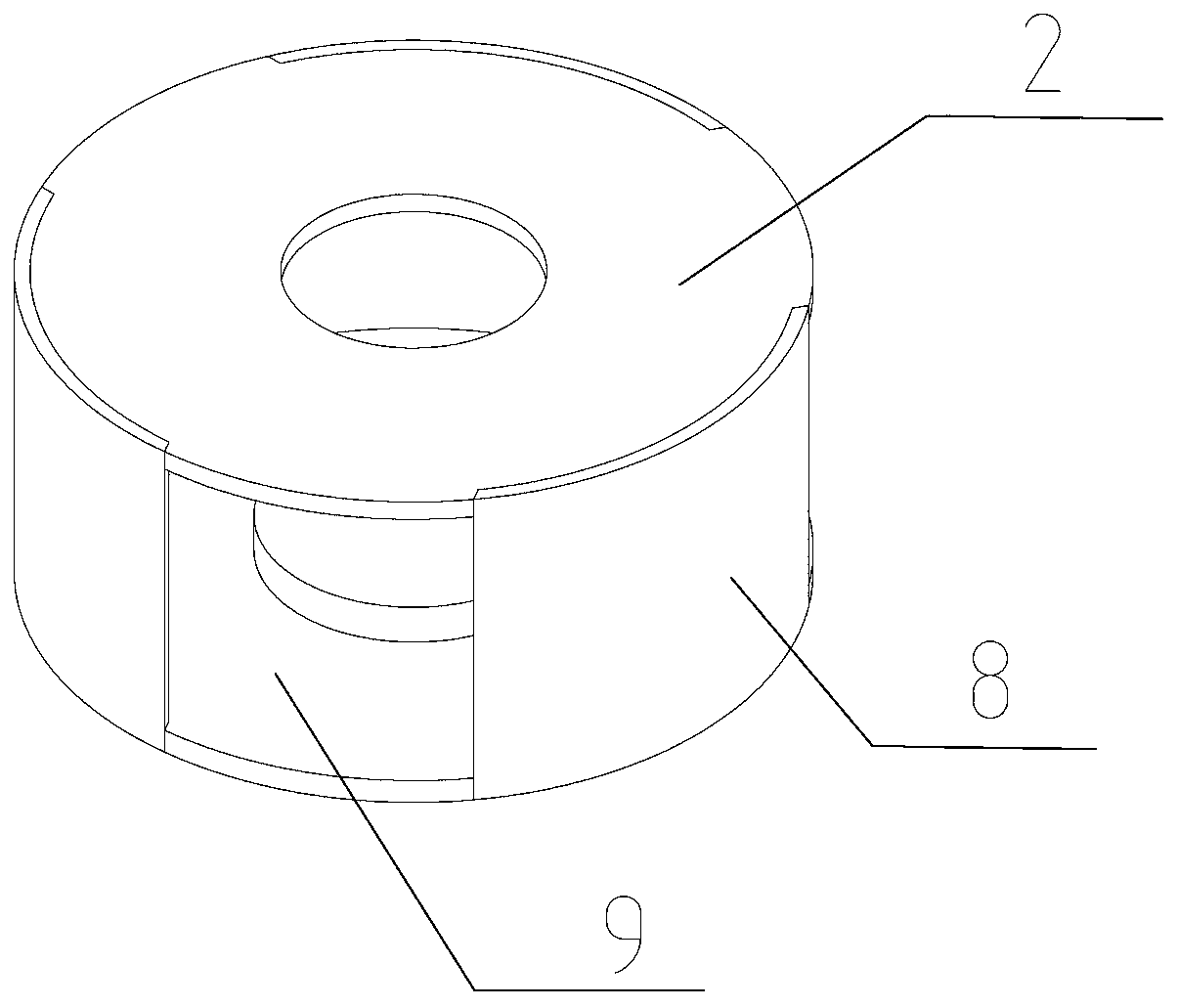

Centrifugal labyrinth type oil-gas separator with jet smashing function

InactiveCN108412579AEliminates non-condensing defectsGood flow rateMachines/enginesCrankcase ventillationParticle flowCentrifugation

The invention discloses a centrifugal labyrinth type oil-gas separator with a jet smashing function. Compressed air sprayed out of a nozzle accelerates mixed oil gas and enables the mixed oil gas intoa turbulence state, and oil particles collide and rub with one another to be smashed. The smashed oil particles ascend along the gas through an annular track, due to the centrifugation of the annulartrack, the rough oil particles move along the outer side of the track, the fine oil particles move along the inner side of the track, and the fine oil particles enter a centrifugal labyrinth to be separated again. The rough oil particles continue to keep away from an inner inlet along the outer side of the annular track to be sent back into a smashing chamber, and the rough oil particles and newly-input mixed oil gas are smashed again. The fine oil particles flow along the gas in the centrifugal labyrinth and are condensed when encountering a baffle to be collected. The finally separated gasis exhausted through an outlet. The oil-gas separator jets the high-pressure gas to smash the mixed oil gas, oil-gas separation is carried out through the centrifugal labyrinth, the oil particles areprone to be condensed into drops under the action of the centrifugation and the baffle, the oil-gas separation efficiency is high, and the separation quality is guaranteed.

Owner:JIYANG COLLEGE OF ZHEJIANG A & F UNIV

Stirring device for powder material mixing

InactiveCN110801762ASimple structureIncreased chance of impactShaking/oscillating/vibrating mixersTransportation and packagingElectric machineryDrive motor

The invention discloses a stirring device for powder material mixing and relates to the field of powder material processing equipment. The stirring device comprises a stirring bucket and a support rod, wherein a feeding hole is formed in the upper part of the stirring bucket; a discharge hole is formed in the lower part of the stirring bucket; a driving motor is mounted at the bottom of the stirring shaft; the stirring bucket is internally provided with a stirring shaft; the driving motor is used for providing power to the stirring shaft; the support rod is divided into two sections at the connecting part of the stirring shaft and the support rod; a flip plate is hinged with each section of the support rod; convex columns are arranged at lower ends of the flip plates and on sides close tothe stirring shaft; jack rods are hinged with the convex columns; sliding blocks are mounted at lower ends of the jack rods; the stirring bucket is internally provided with a sleeve; the sleeve is arranged outside the stirring shaft in a sleeving manner; the upper end of the stirring shaft extends outside the sleeve; chutes are formed in side surfaces of the sleeve along an axis direction; a column groove cam is fixedly mounted on the stirring shaft; and the sliding blocks penetrate through the chutes and are inserted into curved slots of the column groove cams. The collision rate of powder materials is increased, and the mixing effect of the powder material is improved.

Owner:安徽东阳矿业科技有限公司

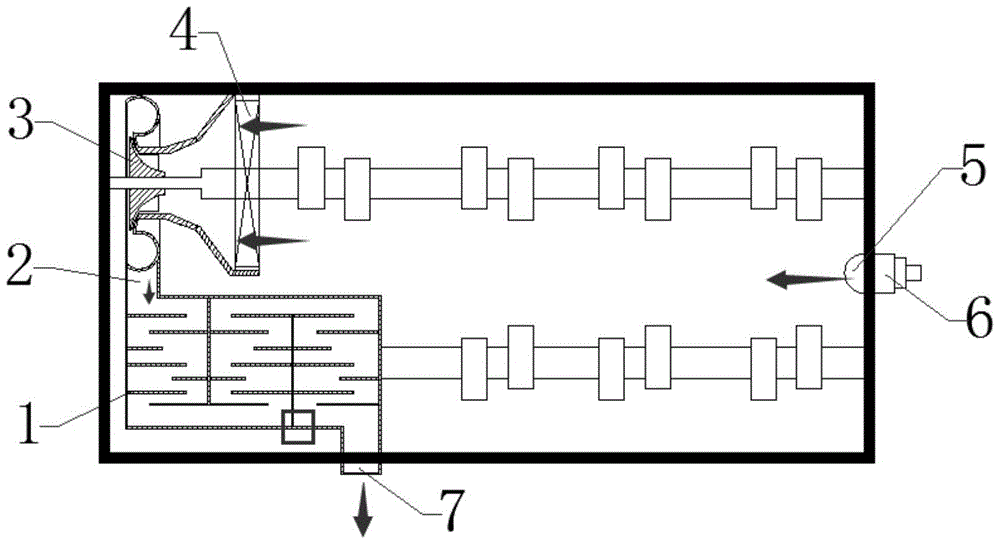

A wide-range horizontal high-efficiency oil-gas separator for a screw compressor test system

ActiveCN104019037BSimple structureGood degreasing effectRotary/oscillating piston pump componentsLiquid fuel engine componentsFiltrationCentrifugation

The invention relates to a wide range horizontal efficient oil-gas separator used for a screw compressor test system. The wide range horizontal efficient oil-gas separator used for the screw compressor test system comprises a cylindrical shell, a material inlet pipe used for conveying an oil-gas mixture, a cycle lubricating oil outlet pipe connected to an oil pump and an exhaust pipe system used for discharging an gaseous separating material are arranged on the cylindrical shell; a centrifugation oil removing unit, a labyrinth type oil removing unit and at least two arrays of the filtering oil removing units are arranged on the cylindrical shell from the material inlet pipe to the exhaust pipe system in order, and the outlets of the filtering oil removing unit are respectively connected to the exhaust pipe system. The horizontal efficient oil-gas separator integrates the effects of filtration, gravity and centrifugal force, through different combination modes of the parallel type controllable exhaust pipe system, the technology requirements with wide range, high efficiency and low cost to the test system can be solved, so that cycle utilization of a lubricating oil and performance test function of a multiple specification compressor can be reliably realized with high efficiency.

Owner:HEFEI GENERAL MACHINERY RES INST

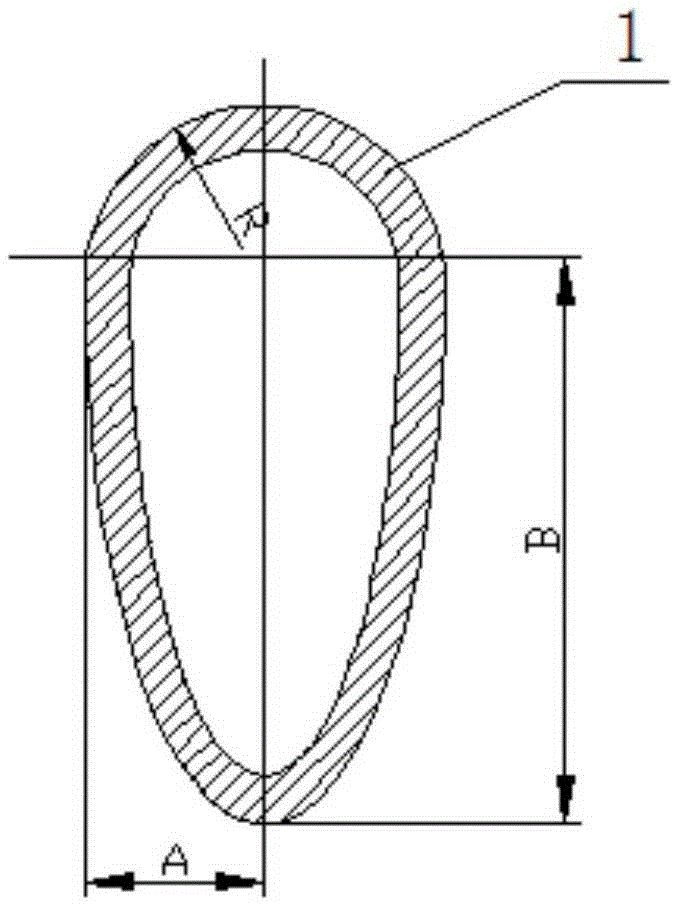

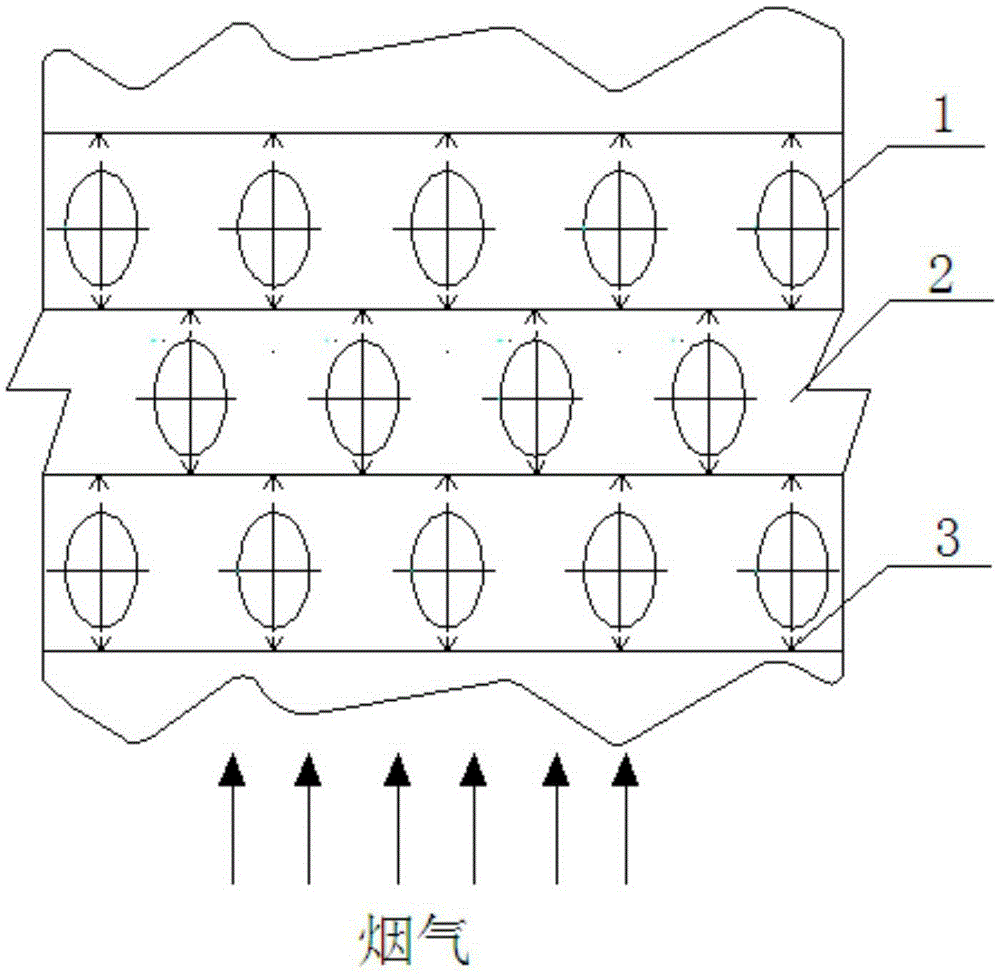

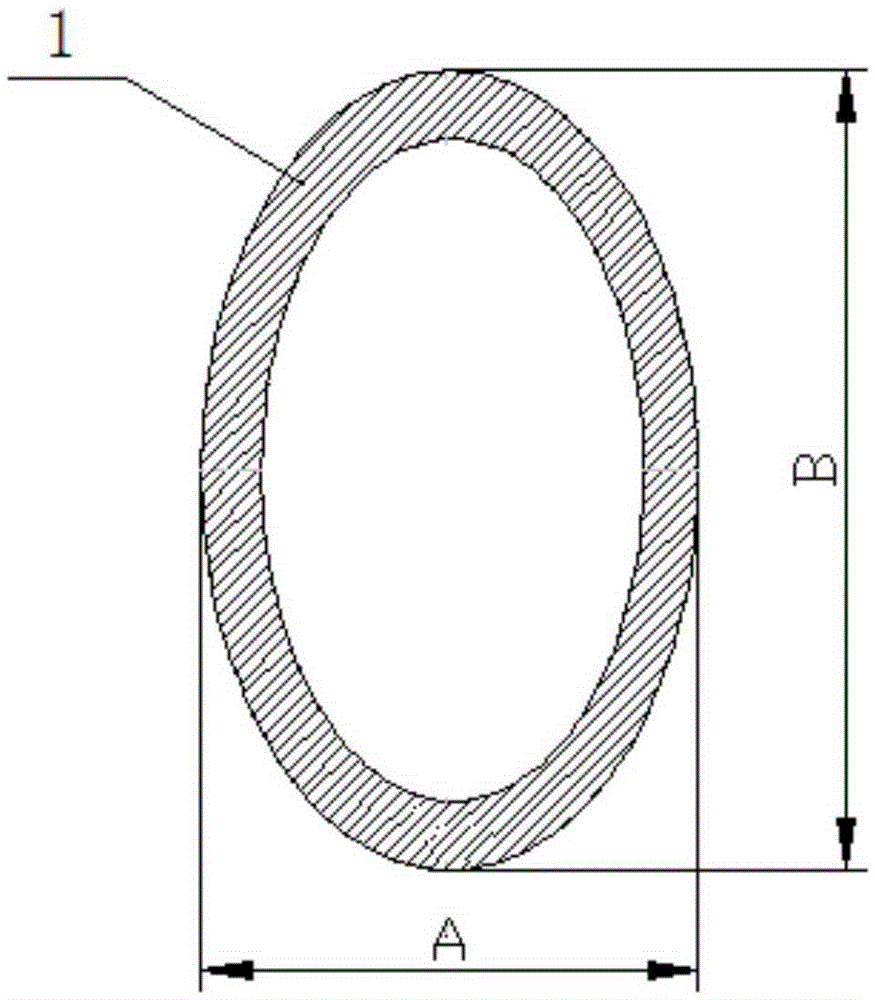

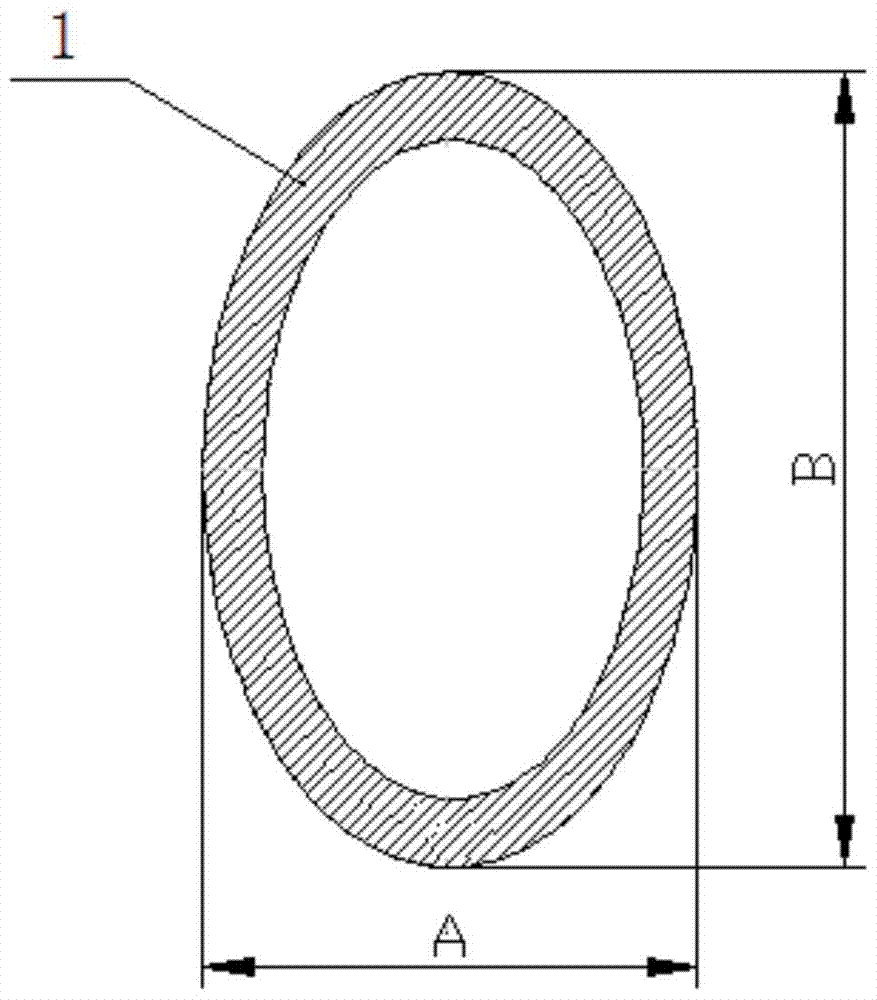

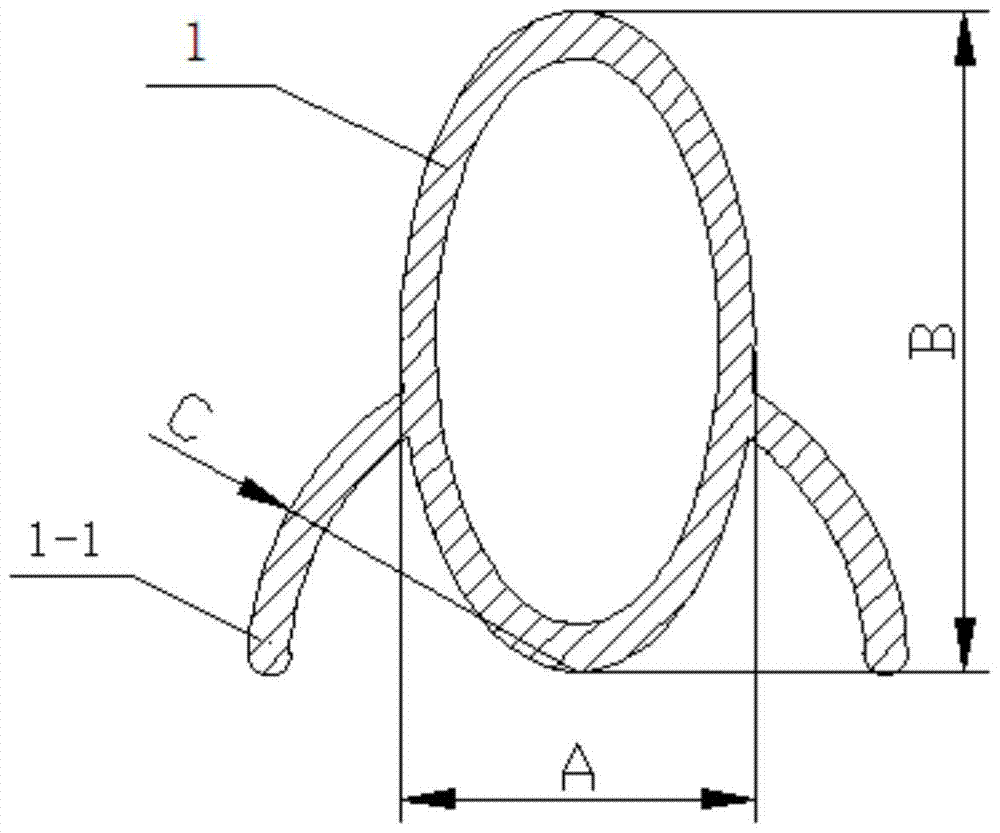

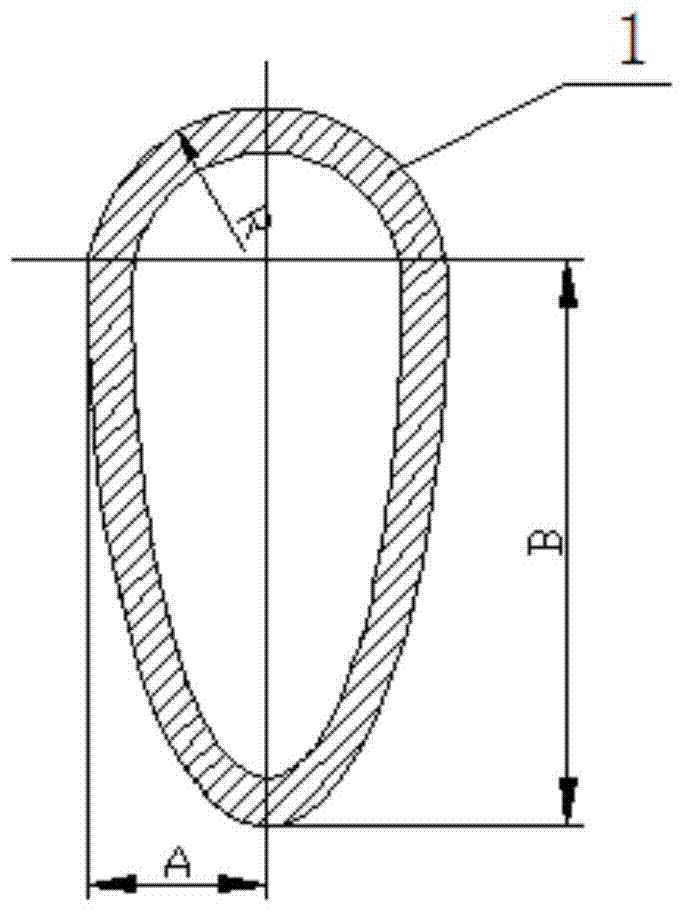

Low-resistance air-cooled elliptical tube-type demister and demisting method

ActiveCN105289182AHigh efficiency of fog and dust removalEfficient dust and fog removalCombination devicesVapor condensationEngineeringTubing types

The invention discloses a low-resistance air-cooled elliptical tube-type demister and a demisting method. The low-resistance air-cooled elliptical tube-type demister comprises an air-cooled elliptical tube-type demister system arranged on the top of a desulfurization tower and a cooling air automatic diversion system for introducing cold air into an elliptical tube bundle. The air-cooled elliptical tube-type demister system comprises a tube row array which comprises multiple layers of dot matrixes arranged staggerly and has the elliptical section. A grading directional washing water system comprises multiple nozzles spraying water upward and downward, and the multiple nozzles are arranged among the layered and arrayed elliptical tube bundles. The cooling air automatic diversion system comprises multiple wind direction fluid directors which are respectively arranged at windward ends and leeward ends of the tube row array along a perennial wind direction. The demister combines inertial separation and condensation separation, has the characteristics of high demisting and dedusting efficiency, small resistance, low energy consumption, scaling and obstruction difficulty and water saving and can effectively reduce gypsum rain produced by flue gas desulphurization.

Owner:SOUTH CHINA UNIV OF TECH

A low-resistance air-cooled elliptical tube demister and its demister method

ActiveCN105289182BHigh efficiency of fog and dust removalEfficient dust and fog removalCombination devicesVapor condensationFractionationEngineering

The invention discloses a low-resistance air-cooled elliptical tube type demister and a demisting method thereof, comprising an air-cooled elliptical tube bundle defogging system arranged on the top of a desulfurization tower, an automatic cooling air guide for introducing cold air into the elliptical tube bundle flow system. The air-cooled elliptical tube bundle defogging system includes a multi-layer dot matrix staggered arrangement of tube row arrays with an elliptical cross-section; The nozzles for jetting water flow; the automatic cooling wind guide system includes a plurality of wind deflectors respectively arranged in the windward end and the leeward end of the pipe row array in the perennial wind direction. This demister combines inertial separation and condensation separation. It has the characteristics of high fog and dust removal efficiency, low resistance, low energy consumption, not easy to scale and block, and water saving. It can effectively reduce the "gypsum rain" generated after flue gas desulfurization. ".

Owner:SOUTH CHINA UNIV OF TECH

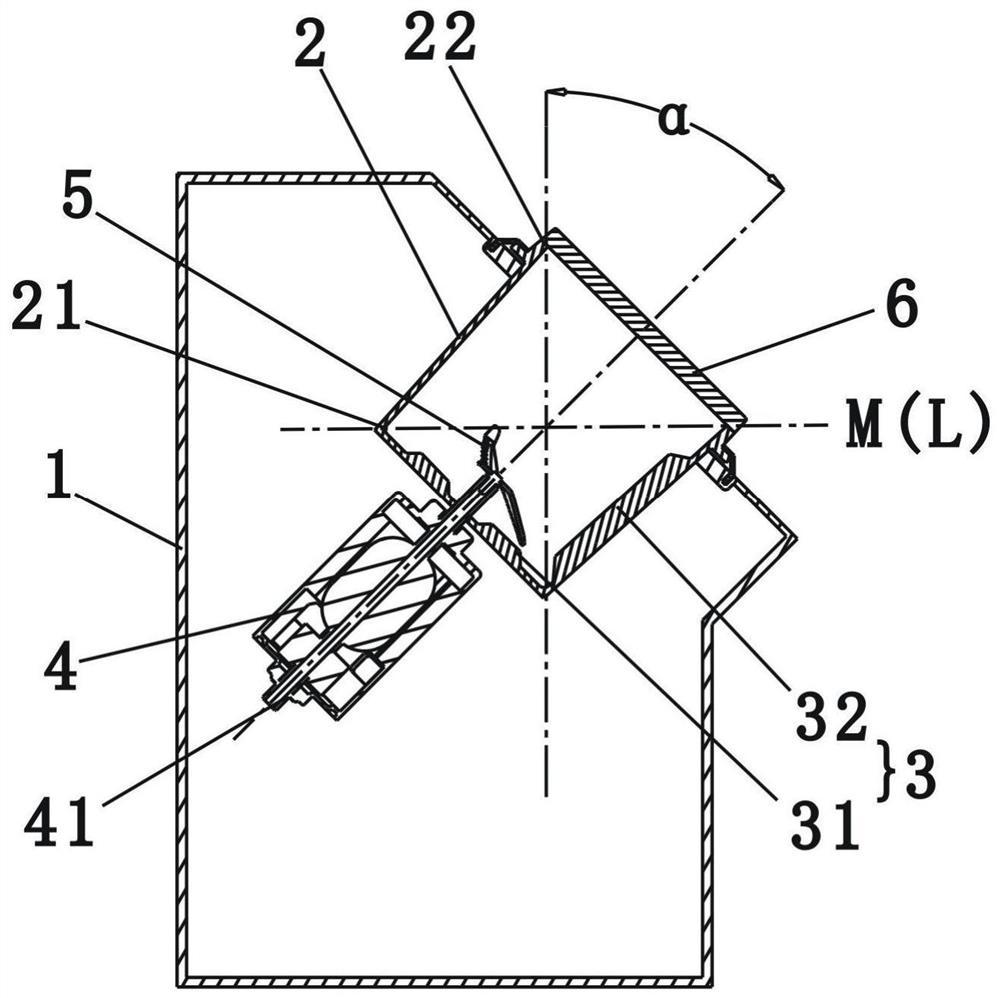

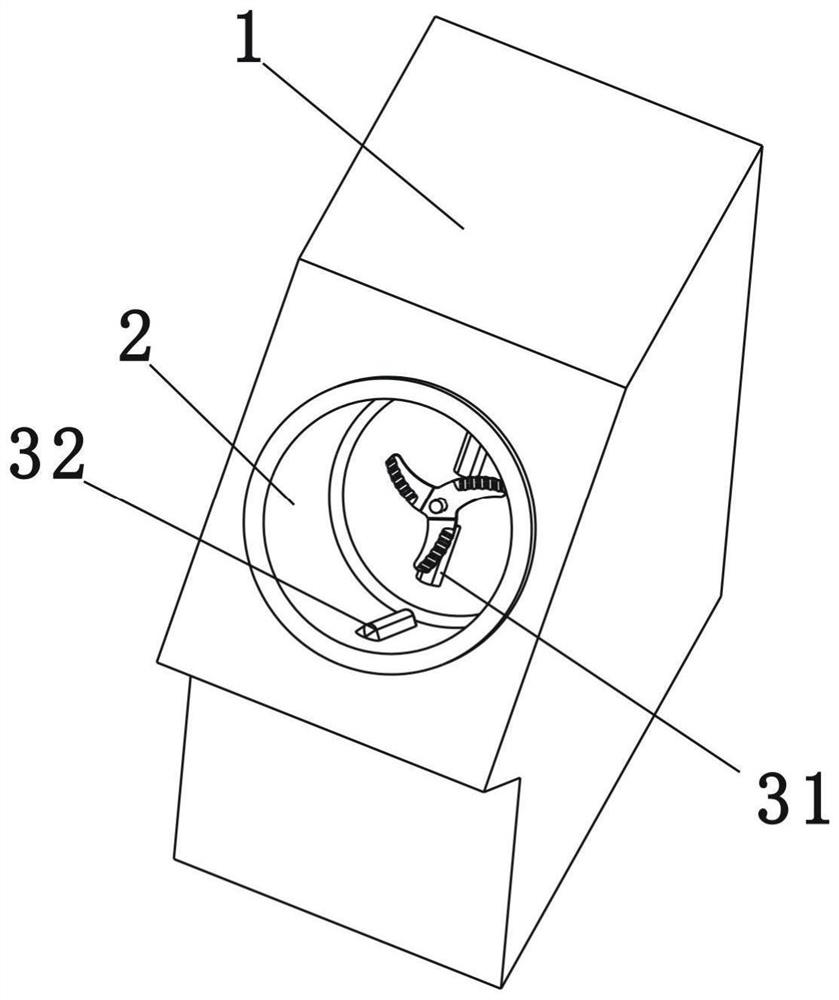

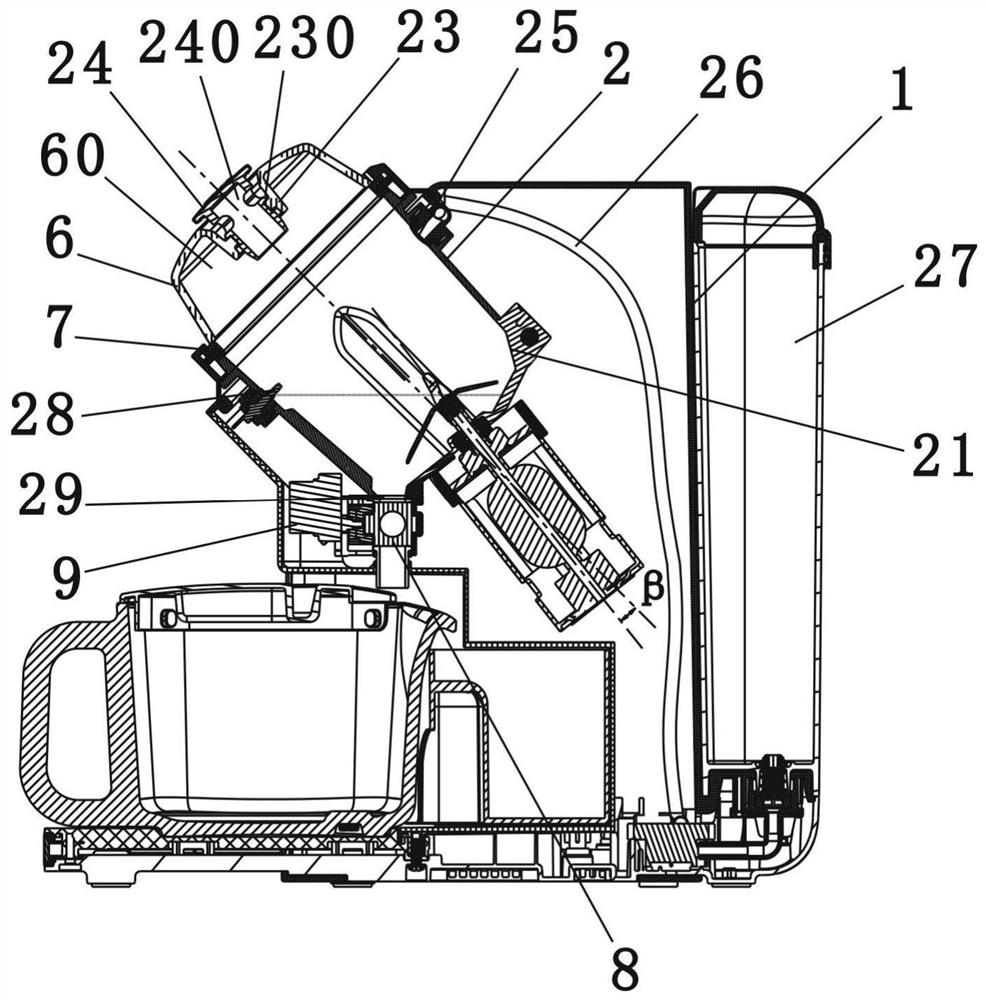

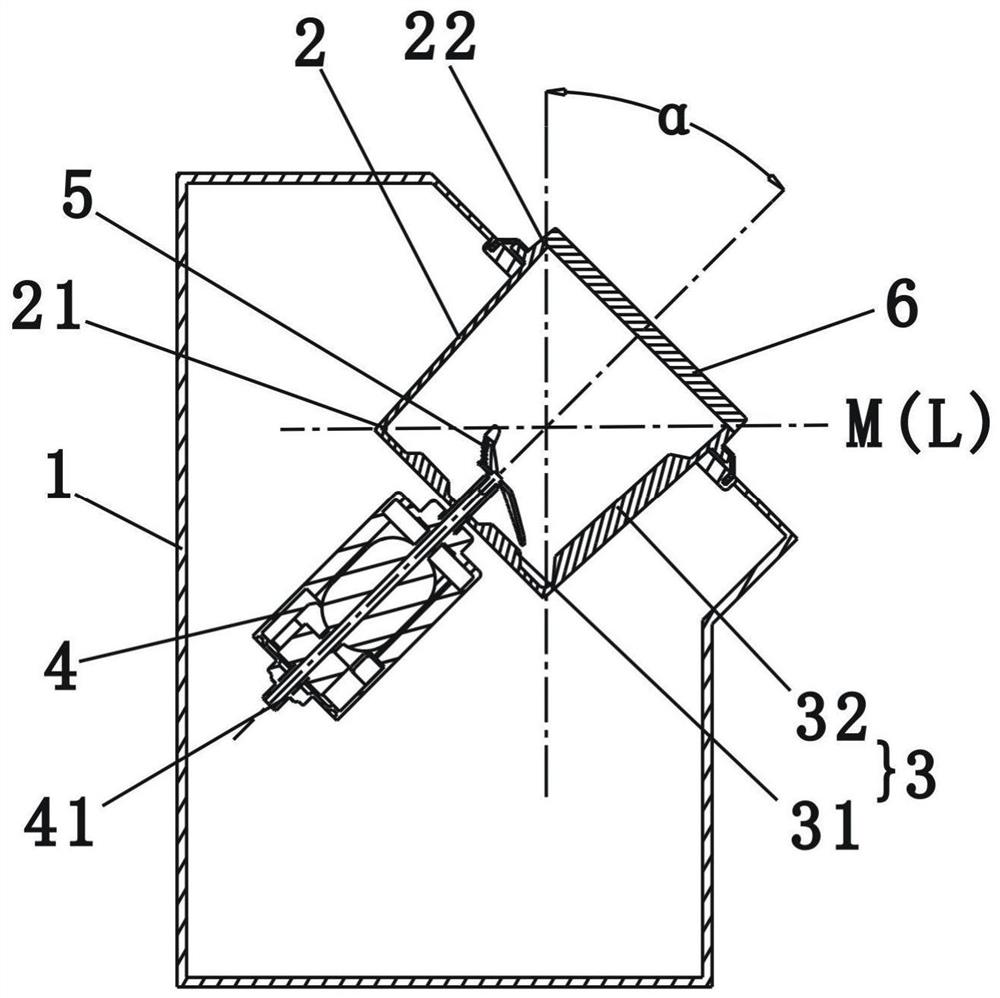

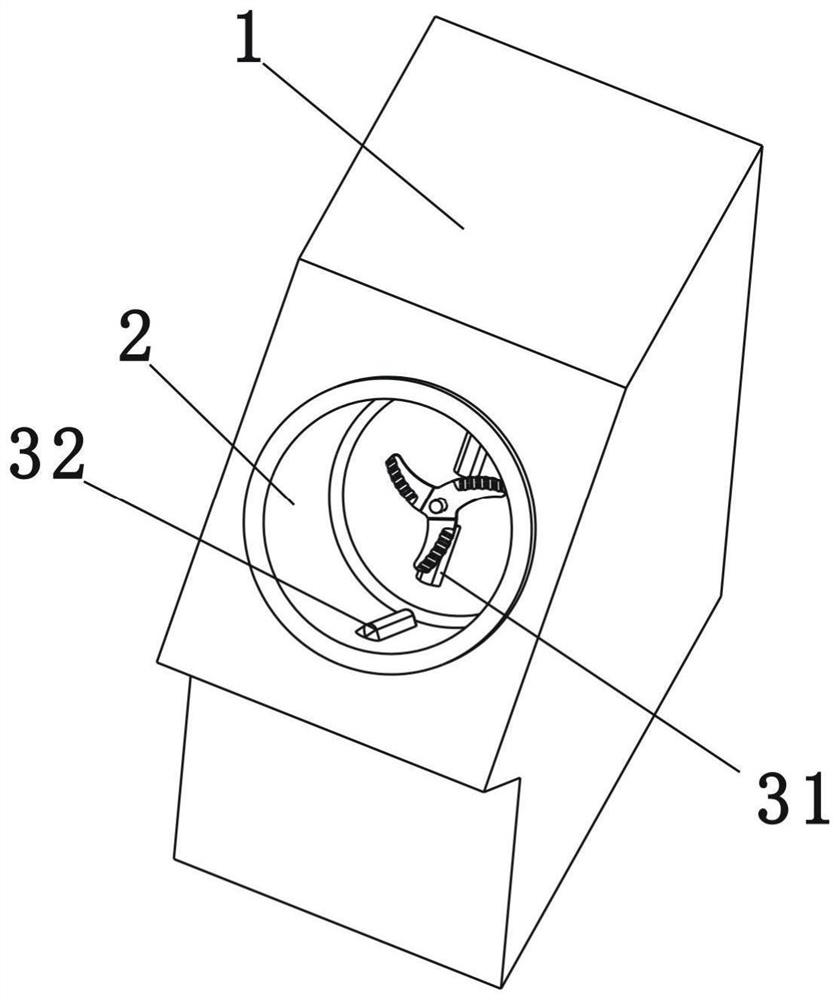

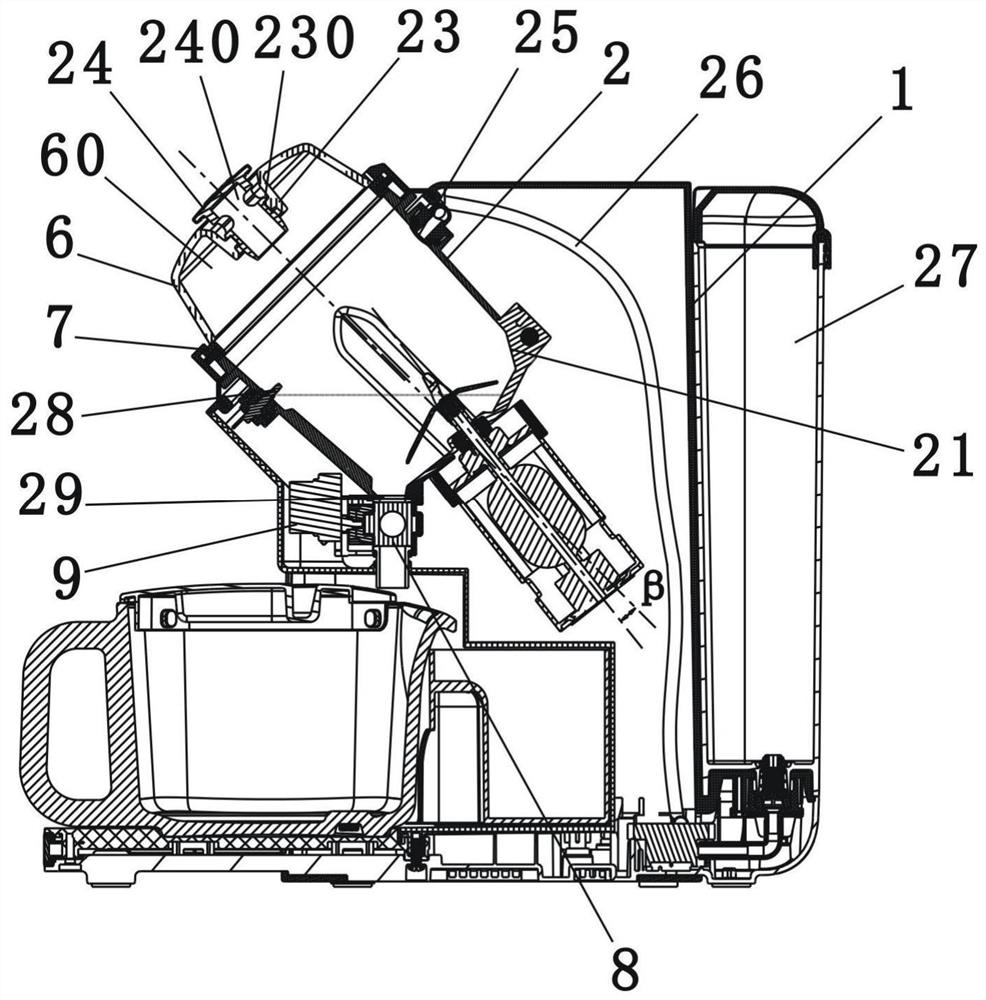

Automatic food processor

ActiveCN112043181AImprove crushing efficiencyImprove user experienceKitchen equipmentElectric machineryKnife blades

The invention relates to kitchen cooking electric appliances, in particular to an automatic food processor. The food processor is characterized by comprising a machine body, a crushing cup, a motor and a crushing blade, wherein the crushing cup is of a barrel-shaped structure, the crushing cup is obliquely installed in the machine body, and a turbulent flow rib protruding inwards is arranged on the inner wall of the crushing cup; the motor is located on the outer side of the crushing cup, and a rotating shaft driven by the motor penetrates the cup wall of the crushing cup and extends into thecrushing cup; and the crushing blade is positioned in the crushing cup and is mounted at the tail end of the rotating shaft, the peripheral wall and the bottom of the crushing cup are connected through a transition part, after the crushing cup is inclined, a connecting line from the highest point of the transition part to the lowest point of a cup opening is L, and a transverse plane where L is located is M, wherein the turbulent flow rib is at least arranged on the part, below the plane M, of the inner wall of the crushing cup. The food processor has no excessive requirements on a rotating speed of the motor, the crushing efficiency can be further improved to a filter-free level, and in addition, operations of automatic cleaning, automatic liquid discharging and the like can be performed.

Owner:JOYOUNG CO LTD

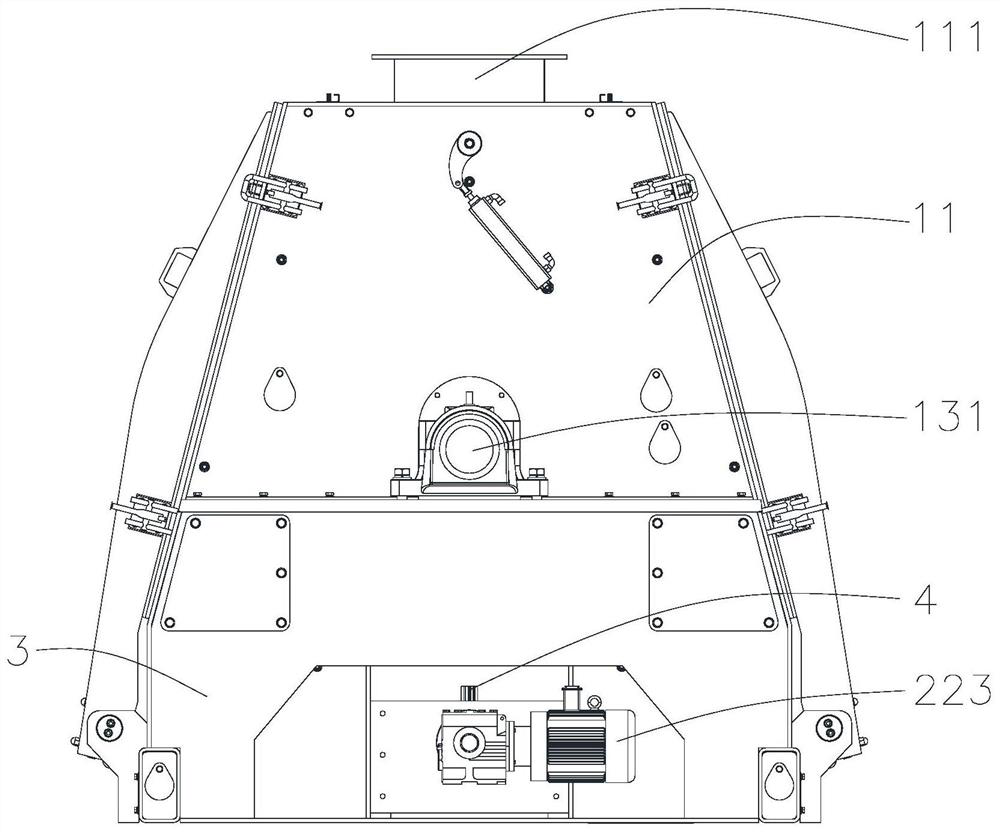

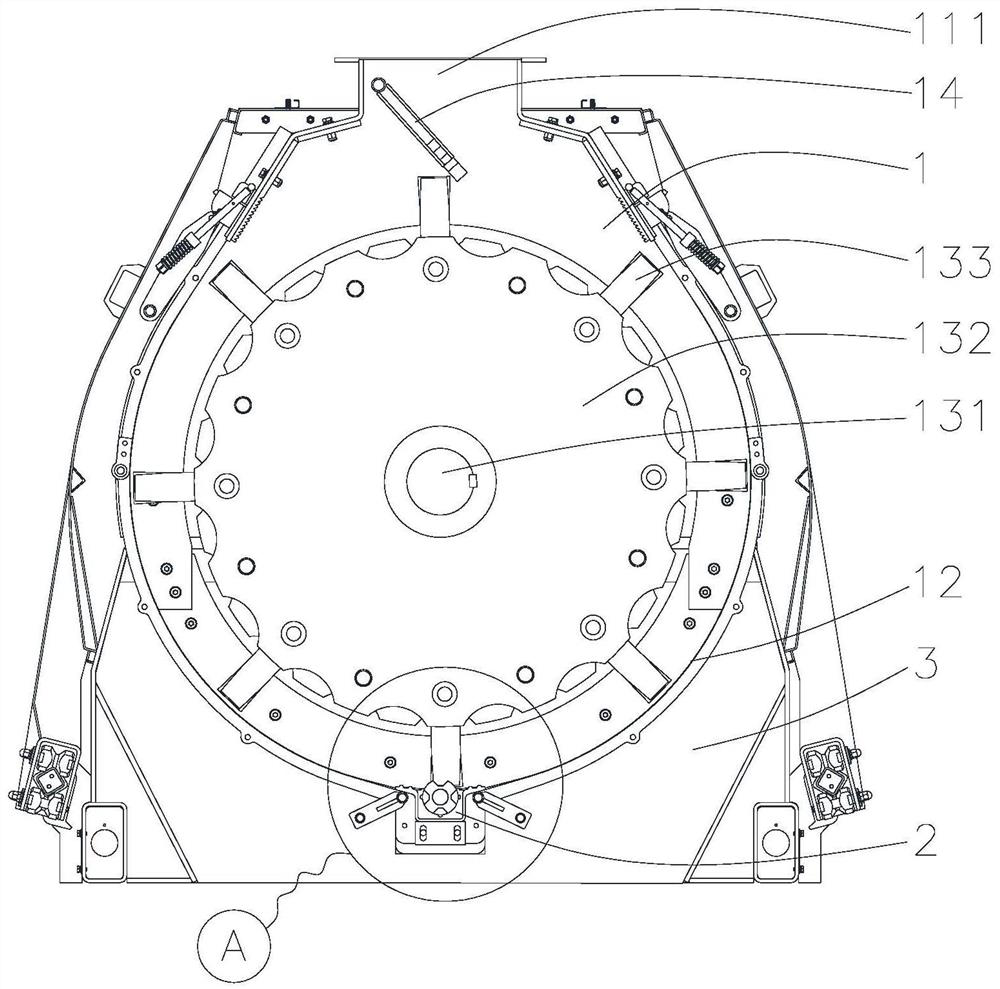

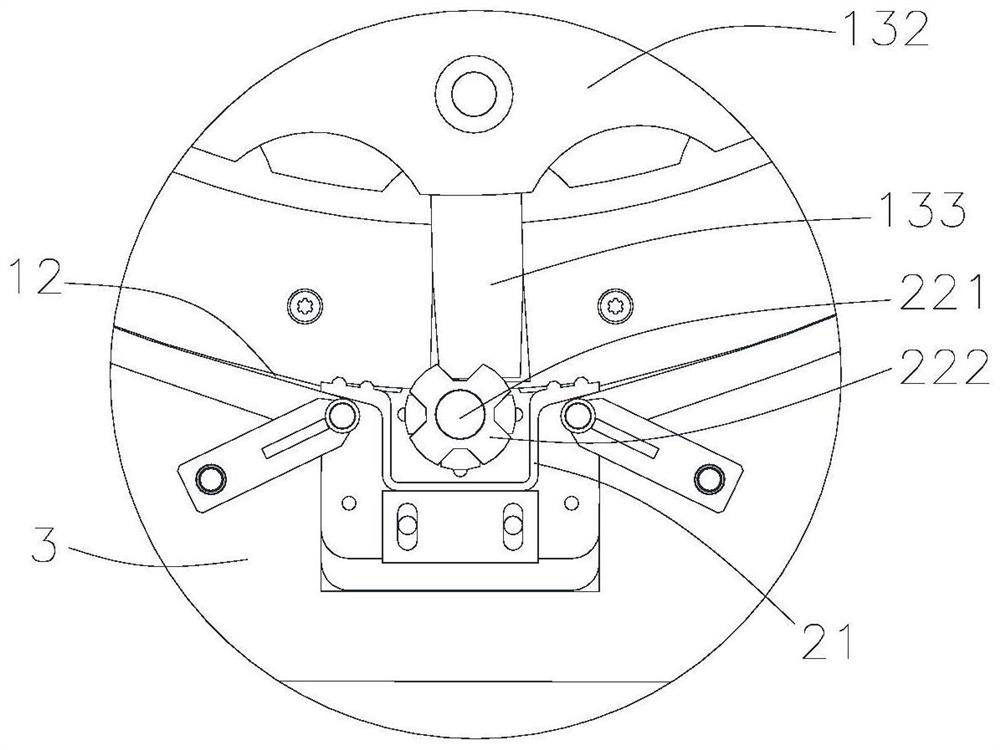

A drum type valve disc finishing machine

ActiveCN108890439BIncreased chance of impactIncrease frictionEdge grinding machinesPolishing machinesPolishingElectric machinery

The invention discloses a roller-type valve plate finishing machine comprising a support. The roller-type valve plate finishing machine is characterized in that support plates are disposed on both sides of the top of the support; a horizontal frame between the two support plates is provided with a polishing roller with a feeding port; the polishing roller comprises a multi-prism cylinder with twoopen ends; both ends of the cylinder are provided with a multi-pyramid sealing part integrally formed with the cylinder; an end shaft mounted on the support plates and integrally formed with the sealing part is arranged in the center of the sealing part; the end shaft is connected with an output shaft of a motor; a polishing body assembly mounted on an inner wall is arranged inside the polishing roller. The roller-type valve plate finishing machine has the advantages of increasing impact probability between valve plates and the polishing roller with the polishing roller comprising the multi-prism cylinder with two open ends and the multi-pyramid sealing part, increasing the friction between the valve plates and a polishing body with the polishing body assembly mounted on the inner wall ofthe polishing roller so as to strengthen polishing effect and improve polishing efficiency, being capable of removing burrs on the surfaces of the valve plates, and having good polishing effect and high polishing efficiency.

Owner:合肥安信通用阀片制造有限公司

An air-cooled airfoil type elliptical tube demister and its demister method

ActiveCN105289180BImprove the problem of inability to remove fine particlesHigh efficiency of fog and dust removalCombination devicesEllipseWater flow

The invention discloses an air-cooled airfoil type elliptical tube demister and its demisting method, comprising an airfoil elliptical tube bundle defogging system arranged on the top of a desulfurization tower, and a device for introducing cold wind into the airfoil elliptical tube bundle defogging system Cooling air automatic diversion system. The airfoil elliptical tube bundle defogging system is composed of a multi-layer dot matrix staggered arrangement of tube bundles with an elliptical cross-section, and arc-shaped wings are symmetrically arranged on both sides of each elliptical tube bundle; the directional circulation flushing water system includes multiple A layered, array arrangement of nozzles that spray water downwards between the airfoil elliptical tube bundles and nozzles that spray water upwards directed along the inner tangent of the arc-shaped wings; the cooling wind automatic diversion system includes respectively arranged at the windward end of the tube row array and multiple wind deflectors on the leeward end. The demister combines inertial separation, centrifugal separation and condensation separation. It has the characteristics of high fog and dust removal efficiency, low energy consumption, and no dead angle for flushing. It can effectively reduce the "gypsum rain" produced after flue gas desulfurization.

Owner:SOUTH CHINA UNIV OF TECH

A low-resistance air-cooled drop-type tube demister and its demister method

ActiveCN105289181BHigh efficiency of fog and dust removalEfficient dust and fog removalCombination devicesEngineeringDrop-shaped

The invention discloses a low-resistance air-cooled drop-type tube mist eliminator and a demisting method thereof, comprising a drop-shaped tube bundle defogging system arranged at the top of a desulfurization tower, a cooling air automatic Diversion system. The drop-shaped tube bundle defogging system includes a multi-layer lattice staggered arrangement of a water-drop-shaped tube row array; the graded directional flushing water system is composed of a plurality of upward and downward jetting water streams arranged in layers and arrays between the water-drop-shaped tube bundles. The nozzle is formed; the cooling air automatic guiding system includes a plurality of wind deflectors respectively arranged in the perennial wind direction of the windward end and the leeward end of the pipe row array. The mist eliminator combines inertial separation and condensation separation, and has the characteristics of high demisting and dust removal efficiency, low resistance, low energy consumption, not easy to scale and block, water saving, etc., and can effectively reduce the "gypsum rain" generated after flue gas desulfurization. ".

Owner:SOUTH CHINA UNIV OF TECH

An automatic food processor

ActiveCN112043181BPromote aggregationIncreased chance of impactKitchen equipmentElectric machineryStructural engineering

The invention relates to a kitchen cooking appliance, especially an automatic food processor, which is characterized in that it includes: a machine body; The inner wall is provided with inwardly protruding spoiler ribs; the motor is located on the outside of the crushing cup, and the rotating shaft driven by the motor penetrates the cup wall of the crushing cup and extends into the crushing cup; the crushing blade is located in the crushing cup and installed At the end of the rotating shaft; the peripheral wall of the crushing cup is connected to the bottom through a transition part. After the crushing cup is tilted, the line connecting the highest point of the transition part to the lowest point of the cup mouth is L, and the transverse plane where L is located is M , wherein, the spoiler ribs are at least arranged on the inner wall of the crushing cup below the plane M. The food processing machine of the present invention has no excessive requirements on the rotational speed of the motor, can further improve the crushing efficiency to the filter-free level, and can perform operations such as automatic cleaning and automatic liquid drainage.

Owner:JOYOUNG CO LTD

High-efficiency hammer mill

ActiveCN113751132AImprove impact efficiencyImprove uniformityGrain treatmentsRotational axisEngineering

The invention relates to a high-efficiency hammer mill. The high-efficiency hammer mill comprises a crushing chamber and a re-crushing chamber, wherein the crushing chamber comprises an upper body, a screen and a rotor assembly; the screen is arranged in the upper body, and the screen is wound outside the rotor assembly in the rotating direction of the rotor assembly; and the re-crushing chamber comprises a U-shaped groove and a rotary moving cutter, the U-shaped groove is formed in the bottom of the upper body, auxiliary wings extend from the two sides of the top of the U-shaped groove, the rotary moving cutter is rotationally arranged in the U-shaped groove, the rotation axis of the rotary moving cutter is parallel to the rotation axis of the rotor assembly, and the re-crushing chamber communicates with the crushing chamber. The high-efficiency hammer mill has the beneficial effects that when materials pass through the re-crushing chamber, the materials collide with rotary moving blades, so that on one hand, the collision efficiency of the materials is improved, on the other hand, a material circulation layer is further broken, the uniformity of material crushing particle size distribution is improved, and the materials meeting the particle size requirement are discharged through meshes of the screen in time.

Owner:TSZJANSU CHZHEHNCHAN SIRIEHL OIL EHND FID MASHINERI KO

Boiled egg peeling device

InactiveCN106580141BAvoid stickingImprove peeling efficiencyEgg-cookersAir compressorPower apparatus

The invention discloses a boiled egg shelling apparatus and relates to a food processing apparatus. The boiled egg shelling apparatus comprises a shell breaker; the shell breaker is a container and is cylindrical in shape; a central axis hole is formed in the bottom surface of the shell breaker and connected with a power apparatus; the power apparatus drives the shell breaker to rotate; a pair of shelling shafts are arranged in the shell breaker; a gap between the shelling shafts is smaller than the outer diameter of an egg; the pair of shelling shafts rotate in the opposite direction at the same speed; a water container is arranged below the shell breaker; the lower part of the water container clings to an electric heating plate; the motion directions of the close ends of the shelling shafts are both upward; cavities are formed in the shelling shafts; a plurality of air holes connected with each cavity are formed in the surface of the shelling shaft; an included angle of 30-90 degrees is formed between each air hole and the radial direction of each cavity; an air compressor is arranged and connected with the cavities; an air outlet is formed in the top of the shell breaker; and arc-shaped baffles are arranged at the lower parts of the shelling shafts. According to the apparatus, automatic shelling can be realized and the egg can be prevented from being scratched.

Owner:CHONGQING SHUNTAI FOOD

Electrostatic Controllable Abrasive Flow Machining Method Based on Charge Tip Aggregation Effect

ActiveCN109551374BControllable distributionReduce particle size unevennessAbrasive machine appurtenancesParticle flowEngineering

The invention discloses a static electricity controllable abrasive particle flow processing method based on a charge tip aggregation effect. An abrasive particle flow with non-electrolyte as a carrieris subjected to a high-voltage electrostatic field to be charged, so that the distribution of the abrasive particles in the flow field can be controlled, and negative influences produced by abrasiveparticle size unevenness and large-particle-size abrasive particles in the processing process are reduced; an electric field is applied to the flow field, the distribution characteristics of the abrasive particles with the negative charge on the collision area on the surface of a workpiece with the positive charge are changed through the electric charge tip aggregation effect, the possibility of collision of the abrasive particles to the microscopic surface crest of the workpiece is increased, workpiece surface crest removal is accelerated, the flow-in angle of the abrasive particles is periodically swung in a pulse mode, the optimal polishing alternating force acting on the workpiece is obtained by effectively adjusting and controlling the pulse frequency and the swing angle, and it is ensured that the high-quality surface is obtained on the premise of efficient removal.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com