Low-resistance air-cooled elliptical tube-type demister and demisting method

A demister and elliptical technology, applied in low-resistance air-cooled elliptical tube demister and its field of demisting, can solve the problems of low dust removal efficiency, insufficient flushing, and large flow resistance of flue gas, so as to save operating costs , uniform flow, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

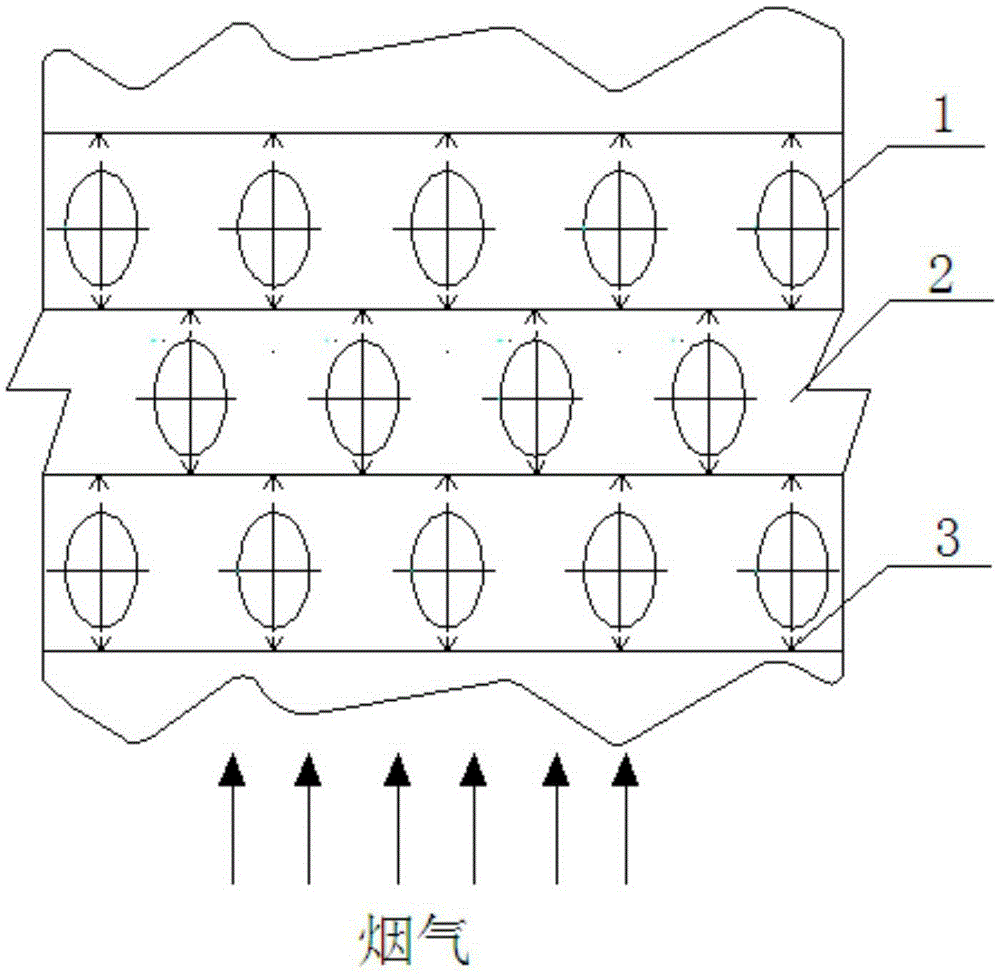

[0031] Such as Figures 1 to 4 shown. The invention discloses a low-resistance air-cooled elliptical tube demister, which comprises an air-cooled elliptical tube bundle defogging system arranged on the top of a desulfurization tower, and a (passive ) Cooling air automatic diversion system;

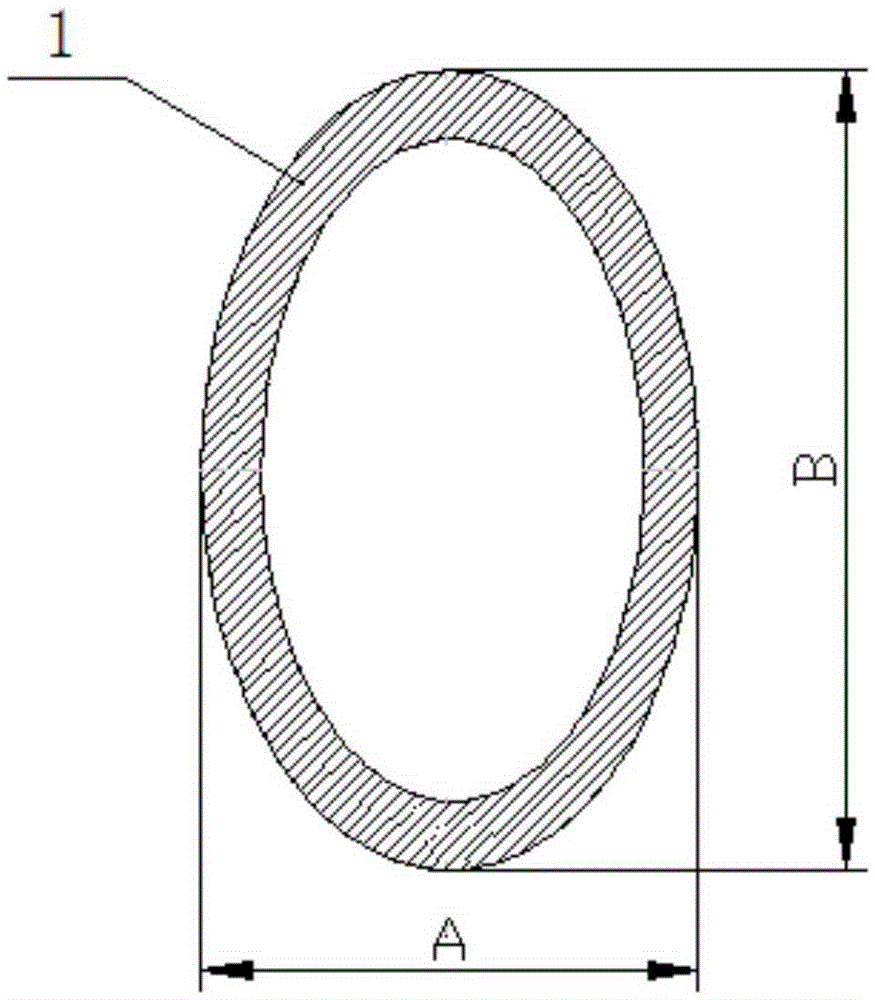

[0032] The air-cooled elliptical tube bundle defogging system consists of a tube row array composed of elliptical tube bundles 1 with multi-layer dot matrix staggered cross-section.

[0033] The major axis B of the cross-section of the elliptical tube bundle 1 is 1.5 to 2.5 times the minor axis A; the flue gas flow enters from the bottom of the tube row array, and then is discharged from the top of the tube row array.

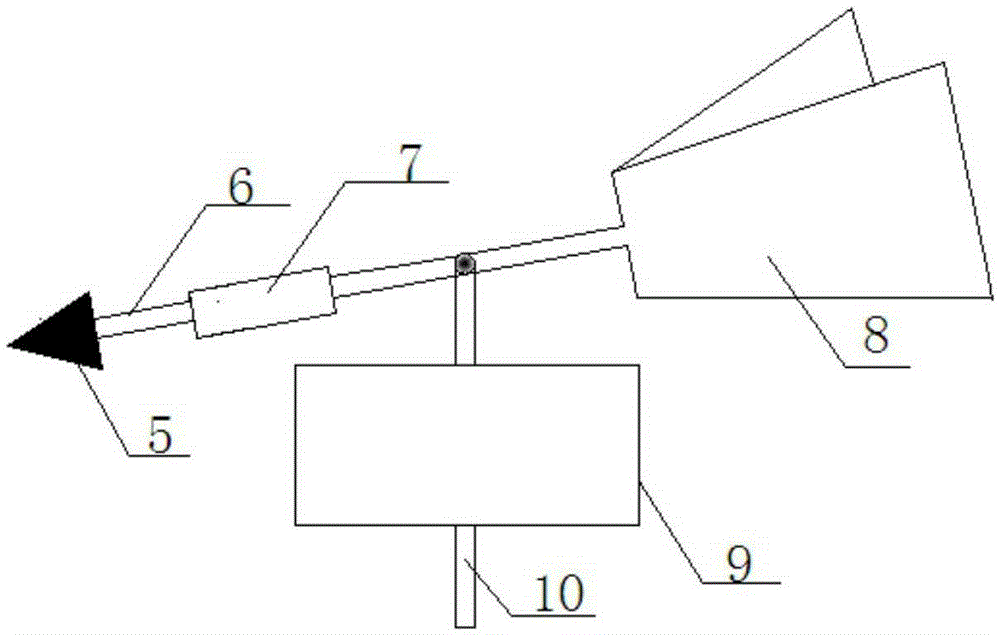

[0034] The cooling wind automatic deflector system is composed of a plurality of wind deflectors 4 respectively arranged at the windward end 11 and the leeward end 12 of the tube row array;

[0035] Each wind deflector 4 includes a support rod 10, a deflector 9 with a tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com