Stirring device for powder material mixing

A stirring device and mixing technology, applied in mixers, transportation and packaging, shaking/oscillating/vibrating mixers, etc., can solve the problems of reducing the impact force of dust, affecting the mixing effect of powder materials, etc., to increase the probability of impact, Simple structure, improve the effect of mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

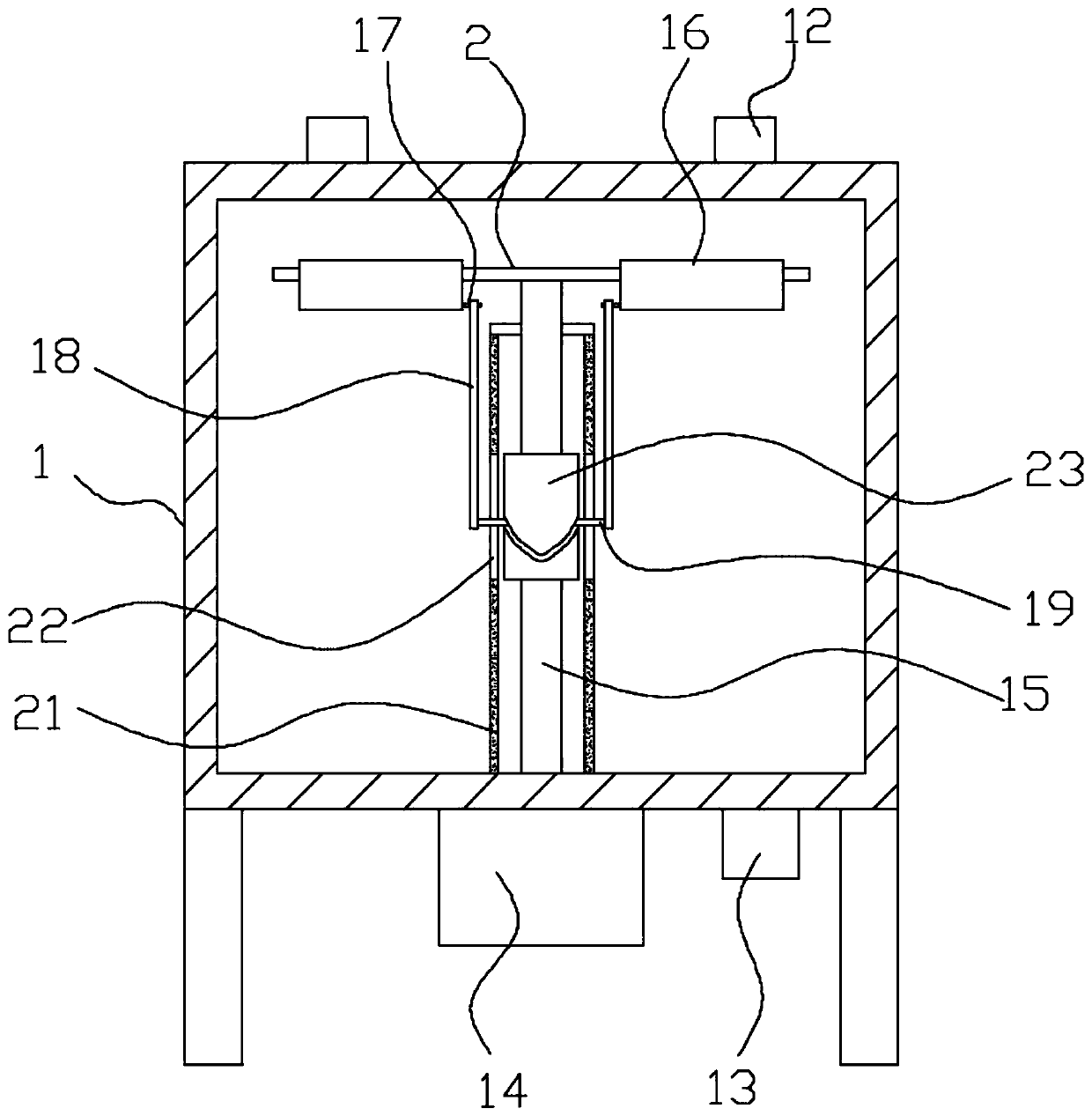

[0024] Such as figure 1 Shown; A stirring device for powder mixing, comprising:

[0025] Stirring barrel 1, the upper part of the stirring barrel 1 is provided with a material inlet 12, the lower part is provided with a discharge port 13, the bottom of the stirring barrel 1 is equipped with a driving motor 14, and the inside is provided with a stirring shaft 15, and the driving motor 14 is a stirring shaft 15 provide power;

[0026] The support rod 2 is vertically fixed on the upper part of the stirring shaft 15, and the connection between the stirring shaft 15 and the support rod 2 divides the support rod 2 into two sections, each section of the support rod is hinged with a flap 16, and the lower end of the flap 16 is close to the One side of the stirring shaft 15 is provided with a boss 17, the boss 17 is hinged with a push rod 18, and a slider 19 is installed at the lower end of the push rod 18;

[0027] A sleeve 21 is installed inside the mixing barrel body 1, and the sl...

Embodiment 2

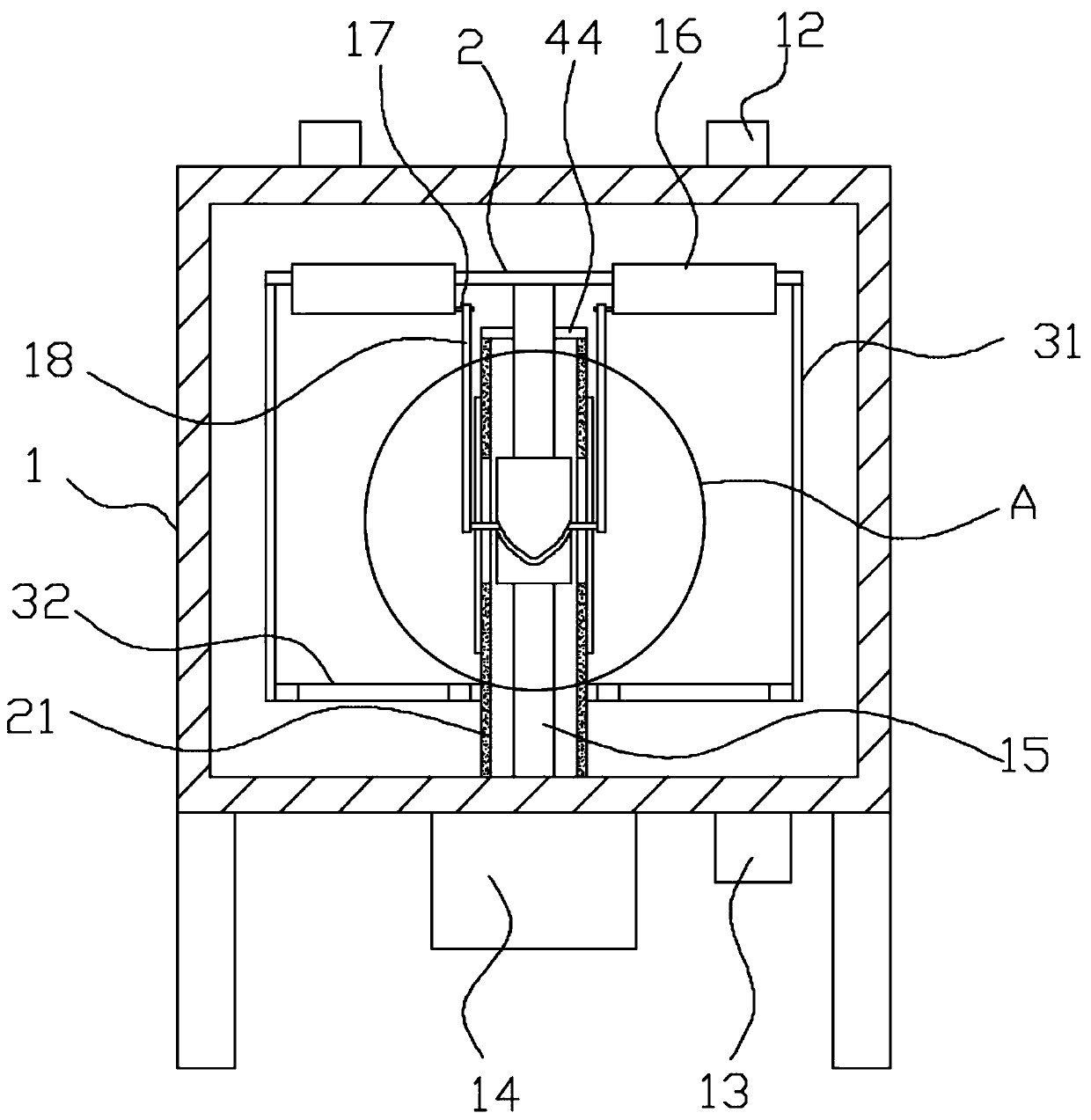

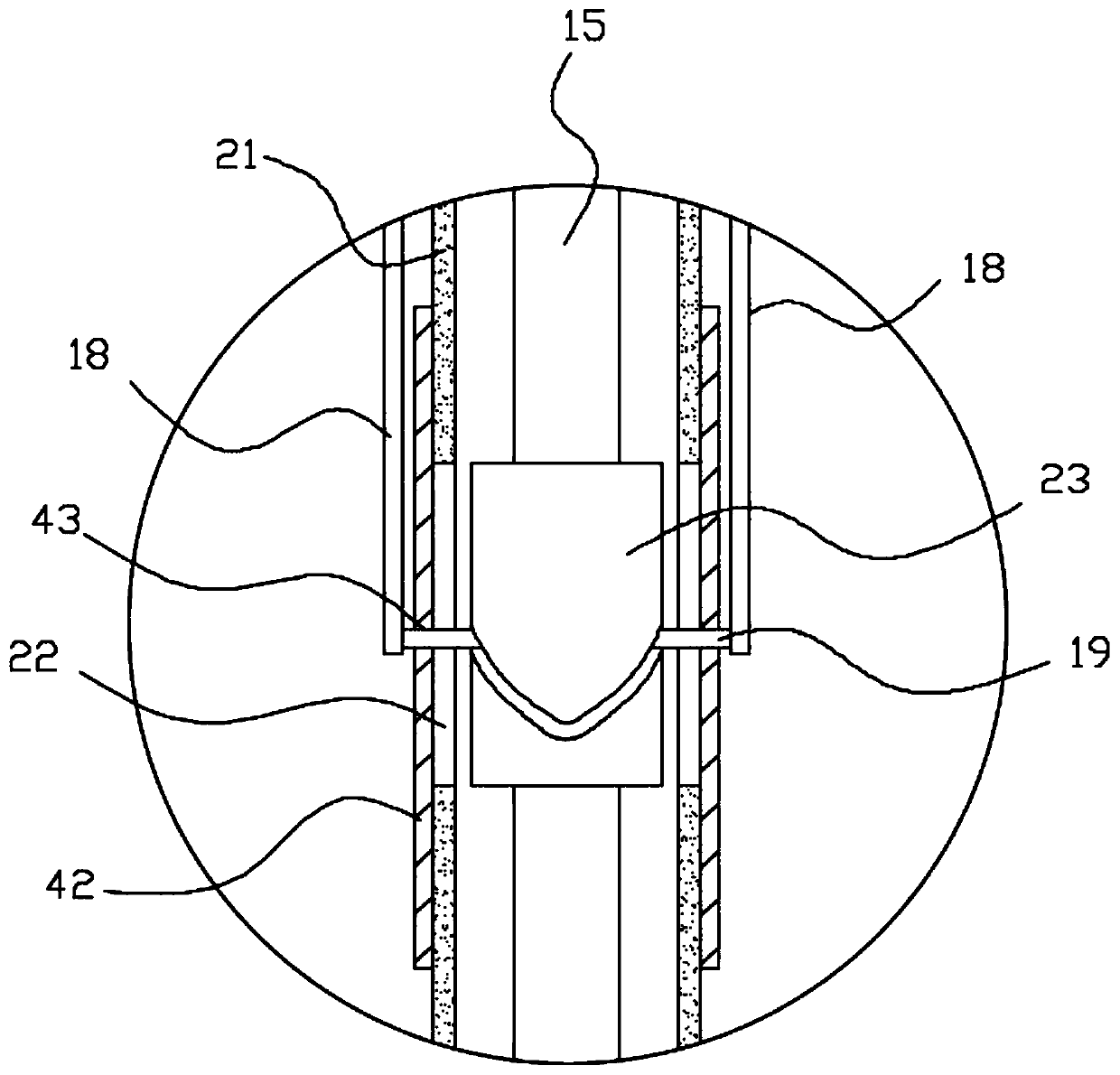

[0031] Such as figure 2 , image 3 , Figure 4 Shown; A stirring device for powder mixing, comprising:

[0032] Stirring barrel 1, the upper part of the stirring barrel 1 is provided with a material inlet 12, the lower part is provided with a discharge port 13, the bottom of the stirring barrel 1 is equipped with a driving motor 14, and the inside is provided with a stirring shaft 15, and the driving motor 14 is a stirring shaft 15 provide power;

[0033] The support rod 2 is vertically fixed on the upper part of the stirring shaft 15, and the connection between the stirring shaft 15 and the support rod 2 divides the support rod 2 into two sections, each section of the support rod is hinged with a flap 16, and the lower end of the flap 16 is close to the One side of the stirring shaft 15 is provided with a boss 17, the boss 17 is hinged with a push rod 18, and a slider 19 is installed at the lower end of the push rod 18;

[0034] A sleeve 21 is installed inside the mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com