High-efficiency hammer mill

A hammer mill, high-efficiency technology, applied in grain processing and other directions, can solve the problem that materials cannot be discharged in time, and achieve the effect of improving crushing efficiency, increasing impact probability, and improving impact efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

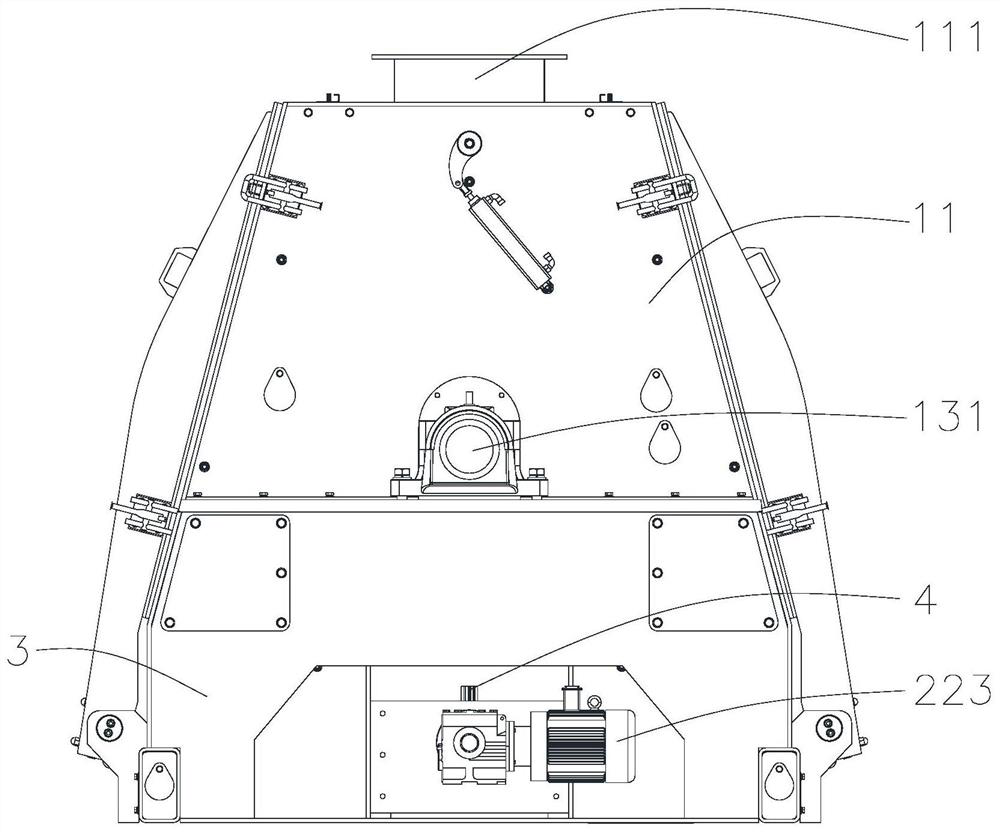

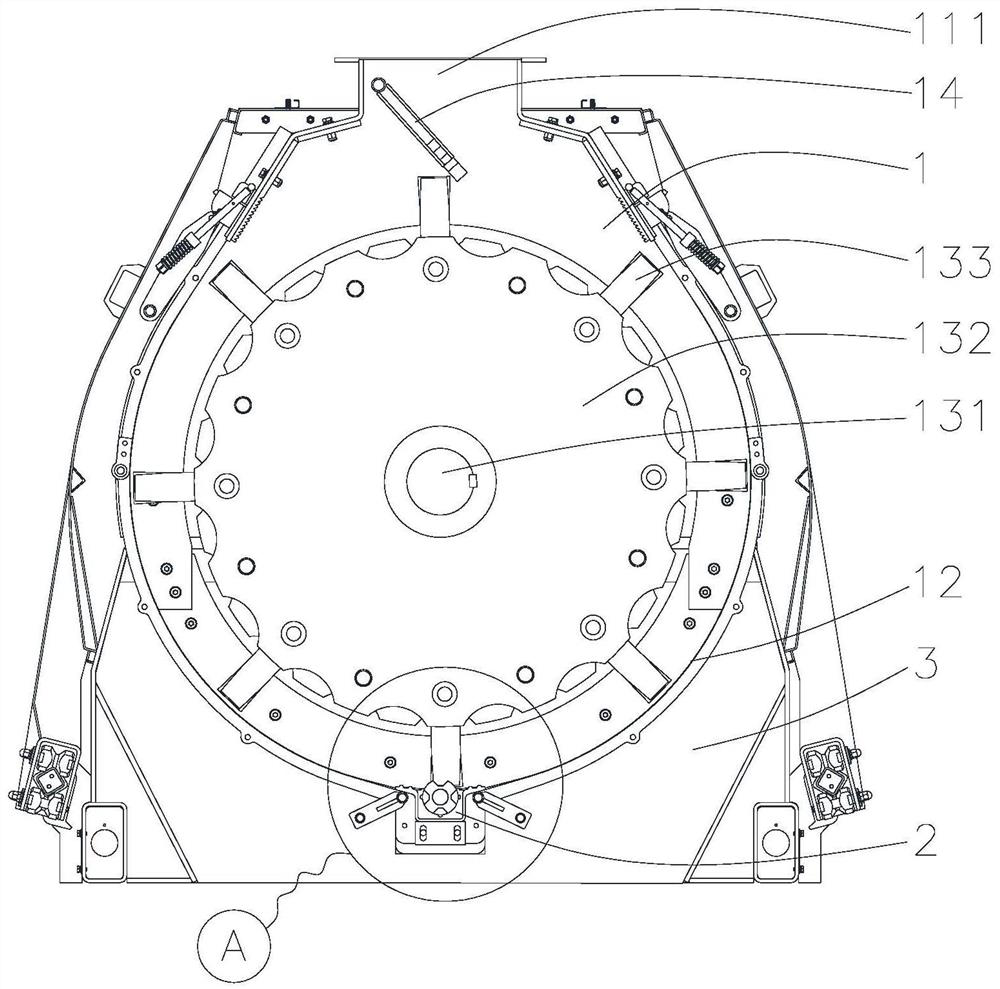

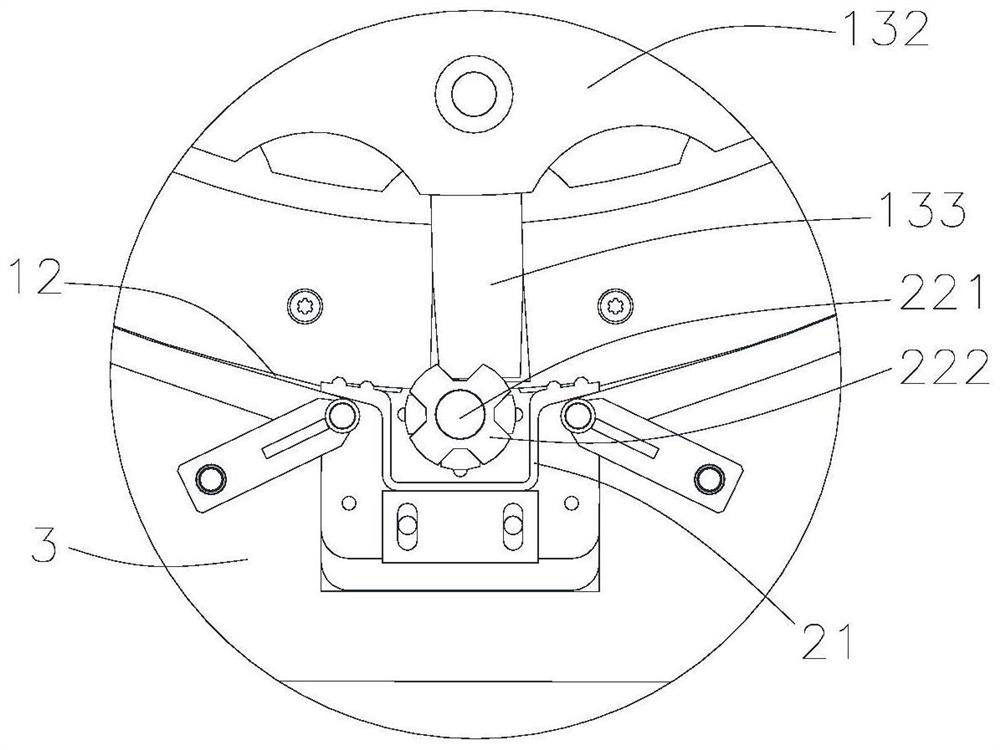

[0034] Such as Figure 1-9 As shown, a high-efficiency hammer mill includes a crushing chamber 1 and a re-grinding chamber 2, the crushing chamber 1 includes an upper body 11, a screen 12 and a rotor assembly 13, and the screen 12 is arranged on the upper body 11, the screen 12 is wound around the outside of the rotor assembly 13 along the rotation direction of the rotor assembly 13, and a feeding port 111 communicating with the crushing chamber 1 is provided above the upper body 11 of this embodiment, The feeding port 111 is provided with a material guide plate 14; the re-grinding chamber 2 includes a U-shaped groove 21 and a rotating movable knife 22, the U-shaped groove 21 is arranged on the bottom of the upper body 11, and the U-shaped groove Auxiliary wings 211 are extended on both sides of the top of 21. The rotating movable knife 22 is installed in the U-shaped groove 21. The rotating axis of the rotating movable knife 22 and the rotating axis of the rotor assembly 13 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com