Demisting method and device based on rotary screen drum

A technology of a demisting device and a rotary screen, applied in the field of mist eliminators, can solve the problems of poor demisting effect of fine droplets, difficulty in removing fine droplets, and great influence on the flow rate of flue gas, so as to reduce energy consumption and improve the effect , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

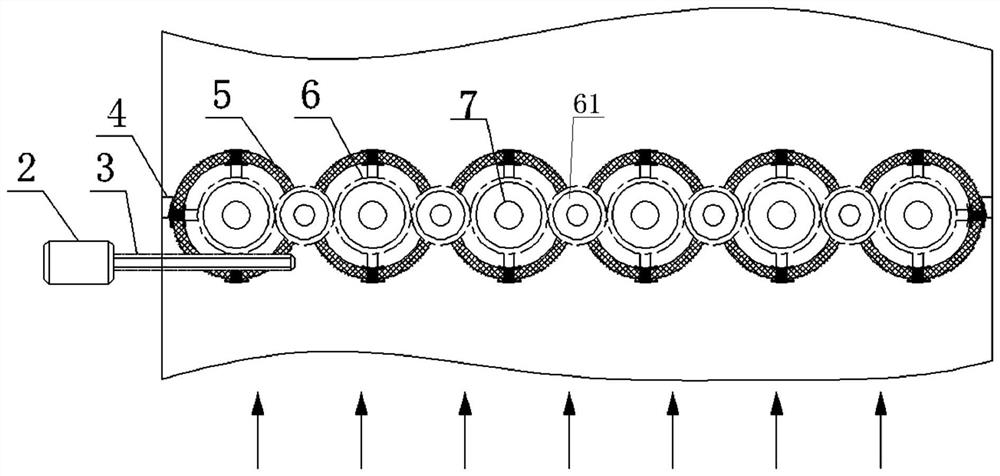

[0034] like Figure 1-2 shown. The invention discloses a demisting device based on a rotating screen cylinder, which includes a demisting system and its flushing water system arranged on the top of the desulfurization tower. On the top of the desulfurization tower or on the flue gas outlet flue.

[0035] The specific quantity and column number of screen cylinder demisters 5 are determined by the parameters of the desulfurization tower.

[0036] Each screen cylinder demister 5 is supported by a rotating shaft 7; a worm gear mechanism is installed at the shaft end of the rotating shaft 7; the worm gear mechanism drives the screen cylinder demister 5 to rotate;

[0037] When the desulfurized flue gas flow passes through the rotating screen drum demister 5, it is subjected to centrifugal or entrainment action, and eddy currents are generated when passing through the wires in the screen drum demister 5, which intensifies the gap between the fine particles entrained in the flue ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com